Benchmarking Colloidal Silica for Enhanced Lubrication in Metalworking Fluids

SEP 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Colloidal Silica Lubrication Background and Objectives

Colloidal silica has emerged as a significant component in metalworking fluid formulations over the past three decades, evolving from basic silica suspensions to sophisticated engineered particles with tailored surface properties. The development trajectory of colloidal silica technology has been driven by increasing demands for more efficient and environmentally friendly metalworking processes across various industries including automotive, aerospace, and precision manufacturing.

The evolution of colloidal silica in lubrication applications began in the 1990s with simple dispersions, progressing through several key technological advancements including surface modification techniques in the early 2000s, nano-scale engineering in the 2010s, and most recently, hybrid organic-inorganic formulations that enhance compatibility with traditional lubricant components.

Current technological trends indicate a shift toward multi-functional colloidal silica particles that simultaneously provide lubrication, cooling, and anti-wear properties. The integration of colloidal silica with other advanced materials such as graphene, carbon nanotubes, and specialized polymers represents the cutting edge of development in this field, promising synergistic performance benefits.

The primary objective of benchmarking colloidal silica for enhanced lubrication in metalworking fluids is to establish standardized performance metrics that accurately reflect real-world application requirements. This includes quantifying improvements in coefficient of friction, wear reduction, surface finish quality, and tool life extension across various metalworking operations such as cutting, grinding, forming, and drawing.

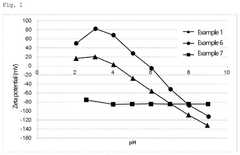

Secondary objectives include determining the optimal concentration ranges, particle size distributions, and surface modifications for specific metalworking applications. Additionally, this benchmarking aims to evaluate the stability of colloidal silica suspensions under various operating conditions, including high temperature, high pressure, and varying pH environments typical in industrial metalworking processes.

Long-term technical goals include developing predictive models for colloidal silica performance in different metalworking scenarios, establishing correlations between colloidal properties and lubrication outcomes, and identifying novel synthesis routes for next-generation silica particles with enhanced functionality and reduced environmental impact.

The benchmarking initiative also seeks to address existing technical limitations, particularly the challenges of maintaining colloidal stability in hard water conditions, preventing agglomeration during extended storage periods, and ensuring compatibility with conventional metalworking fluid additives such as extreme pressure agents, corrosion inhibitors, and biocides.

The evolution of colloidal silica in lubrication applications began in the 1990s with simple dispersions, progressing through several key technological advancements including surface modification techniques in the early 2000s, nano-scale engineering in the 2010s, and most recently, hybrid organic-inorganic formulations that enhance compatibility with traditional lubricant components.

Current technological trends indicate a shift toward multi-functional colloidal silica particles that simultaneously provide lubrication, cooling, and anti-wear properties. The integration of colloidal silica with other advanced materials such as graphene, carbon nanotubes, and specialized polymers represents the cutting edge of development in this field, promising synergistic performance benefits.

The primary objective of benchmarking colloidal silica for enhanced lubrication in metalworking fluids is to establish standardized performance metrics that accurately reflect real-world application requirements. This includes quantifying improvements in coefficient of friction, wear reduction, surface finish quality, and tool life extension across various metalworking operations such as cutting, grinding, forming, and drawing.

Secondary objectives include determining the optimal concentration ranges, particle size distributions, and surface modifications for specific metalworking applications. Additionally, this benchmarking aims to evaluate the stability of colloidal silica suspensions under various operating conditions, including high temperature, high pressure, and varying pH environments typical in industrial metalworking processes.

Long-term technical goals include developing predictive models for colloidal silica performance in different metalworking scenarios, establishing correlations between colloidal properties and lubrication outcomes, and identifying novel synthesis routes for next-generation silica particles with enhanced functionality and reduced environmental impact.

The benchmarking initiative also seeks to address existing technical limitations, particularly the challenges of maintaining colloidal stability in hard water conditions, preventing agglomeration during extended storage periods, and ensuring compatibility with conventional metalworking fluid additives such as extreme pressure agents, corrosion inhibitors, and biocides.

Market Analysis for Advanced Metalworking Fluids

The global metalworking fluids market demonstrates robust growth, valued at approximately $12.3 billion in 2022 and projected to reach $15.8 billion by 2027, representing a compound annual growth rate (CAGR) of 5.1%. This expansion is primarily driven by increasing industrial manufacturing activities, particularly in automotive, aerospace, and general machinery sectors where precision machining demands continue to rise.

Advanced metalworking fluids, especially those incorporating colloidal silica for enhanced lubrication, are experiencing accelerated adoption due to stringent environmental regulations and workplace safety standards. The market share of eco-friendly, high-performance metalworking fluids has grown from 18% in 2018 to nearly 27% in 2022, indicating a significant shift in consumer preferences toward sustainable solutions.

Regional analysis reveals Asia-Pacific as the dominant market, accounting for 38% of global consumption, followed by North America (26%) and Europe (24%). China and India represent the fastest-growing markets with CAGRs of 7.3% and 6.8% respectively, attributed to rapid industrialization and manufacturing expansion in these regions.

Customer segmentation shows that large automotive manufacturers constitute the largest end-user segment (34%), followed by aerospace and defense (22%), general machinery (19%), and other industrial applications (25%). These industries increasingly demand metalworking fluids that deliver superior performance while meeting environmental compliance requirements.

Price sensitivity varies significantly across market segments. While small and medium enterprises demonstrate high price sensitivity, larger corporations prioritize performance metrics and total cost of ownership, creating a premium market segment for advanced solutions like colloidal silica-enhanced formulations.

Distribution channels are evolving, with direct sales to large manufacturers representing 45% of market volume, while distributor networks account for 38% and online channels showing the fastest growth at 17% annually. This shift reflects changing procurement practices and the increasing importance of technical support services bundled with product offerings.

Market challenges include volatile raw material prices, with silica derivatives experiencing price fluctuations of 8-12% annually, and increasing regulatory pressure regarding chemical composition and disposal of metalworking fluids. These factors are accelerating research into advanced formulations with enhanced biodegradability and reduced environmental impact.

Competitive analysis reveals a moderately fragmented market with the top five players controlling approximately 42% of market share. Recent merger and acquisition activities indicate consolidation trends, with technology-focused acquisitions becoming increasingly common as companies seek to enhance their product portfolios with innovative solutions like colloidal silica-based formulations.

Advanced metalworking fluids, especially those incorporating colloidal silica for enhanced lubrication, are experiencing accelerated adoption due to stringent environmental regulations and workplace safety standards. The market share of eco-friendly, high-performance metalworking fluids has grown from 18% in 2018 to nearly 27% in 2022, indicating a significant shift in consumer preferences toward sustainable solutions.

Regional analysis reveals Asia-Pacific as the dominant market, accounting for 38% of global consumption, followed by North America (26%) and Europe (24%). China and India represent the fastest-growing markets with CAGRs of 7.3% and 6.8% respectively, attributed to rapid industrialization and manufacturing expansion in these regions.

Customer segmentation shows that large automotive manufacturers constitute the largest end-user segment (34%), followed by aerospace and defense (22%), general machinery (19%), and other industrial applications (25%). These industries increasingly demand metalworking fluids that deliver superior performance while meeting environmental compliance requirements.

Price sensitivity varies significantly across market segments. While small and medium enterprises demonstrate high price sensitivity, larger corporations prioritize performance metrics and total cost of ownership, creating a premium market segment for advanced solutions like colloidal silica-enhanced formulations.

Distribution channels are evolving, with direct sales to large manufacturers representing 45% of market volume, while distributor networks account for 38% and online channels showing the fastest growth at 17% annually. This shift reflects changing procurement practices and the increasing importance of technical support services bundled with product offerings.

Market challenges include volatile raw material prices, with silica derivatives experiencing price fluctuations of 8-12% annually, and increasing regulatory pressure regarding chemical composition and disposal of metalworking fluids. These factors are accelerating research into advanced formulations with enhanced biodegradability and reduced environmental impact.

Competitive analysis reveals a moderately fragmented market with the top five players controlling approximately 42% of market share. Recent merger and acquisition activities indicate consolidation trends, with technology-focused acquisitions becoming increasingly common as companies seek to enhance their product portfolios with innovative solutions like colloidal silica-based formulations.

Current Challenges in Colloidal Silica Lubrication Technology

Despite significant advancements in colloidal silica technology for metalworking fluids, several critical challenges persist that limit its widespread adoption and optimal performance. The primary challenge involves stability issues, as colloidal silica particles tend to agglomerate over time, especially under extreme pressure and temperature conditions typical in metalworking operations. This agglomeration reduces lubrication effectiveness and can potentially damage machining equipment through increased wear.

Particle size distribution control represents another significant hurdle. Current manufacturing processes struggle to produce consistently uniform nanoparticles, resulting in variable performance across different batches. This inconsistency makes standardization difficult and creates unpredictable results in industrial applications, hampering quality control efforts.

Compatibility with existing metalworking fluid formulations poses a substantial challenge. Many conventional additives interact negatively with colloidal silica, causing precipitation or reducing the overall effectiveness of the lubricant system. Formulators must carefully balance pH levels, surfactant concentrations, and other chemical components to maintain stability while preserving the enhanced lubrication properties.

Environmental and health concerns also present obstacles to widespread implementation. While colloidal silica is generally considered less toxic than many traditional lubricant additives, questions remain about long-term exposure effects and proper disposal methods. Regulatory frameworks in different regions impose varying requirements, complicating global adoption strategies.

Cost-effectiveness remains a significant barrier, particularly for small and medium-sized manufacturers. The production of high-quality colloidal silica with precise particle characteristics requires sophisticated equipment and processes, driving up costs compared to conventional lubricant additives. The industry struggles to demonstrate sufficient performance improvements to justify the increased expense.

Technical measurement and benchmarking methodologies present another challenge. Current testing protocols were largely developed for conventional lubricants and may not adequately capture the unique performance characteristics of colloidal silica-enhanced fluids. This makes objective comparison difficult and slows adoption by conservative industrial sectors.

Finally, knowledge gaps in the fundamental mechanisms of colloidal silica lubrication hinder optimization efforts. While empirical evidence shows performance benefits, the precise interactions between silica nanoparticles, metal surfaces, and other fluid components remain incompletely understood, limiting targeted improvement strategies.

Particle size distribution control represents another significant hurdle. Current manufacturing processes struggle to produce consistently uniform nanoparticles, resulting in variable performance across different batches. This inconsistency makes standardization difficult and creates unpredictable results in industrial applications, hampering quality control efforts.

Compatibility with existing metalworking fluid formulations poses a substantial challenge. Many conventional additives interact negatively with colloidal silica, causing precipitation or reducing the overall effectiveness of the lubricant system. Formulators must carefully balance pH levels, surfactant concentrations, and other chemical components to maintain stability while preserving the enhanced lubrication properties.

Environmental and health concerns also present obstacles to widespread implementation. While colloidal silica is generally considered less toxic than many traditional lubricant additives, questions remain about long-term exposure effects and proper disposal methods. Regulatory frameworks in different regions impose varying requirements, complicating global adoption strategies.

Cost-effectiveness remains a significant barrier, particularly for small and medium-sized manufacturers. The production of high-quality colloidal silica with precise particle characteristics requires sophisticated equipment and processes, driving up costs compared to conventional lubricant additives. The industry struggles to demonstrate sufficient performance improvements to justify the increased expense.

Technical measurement and benchmarking methodologies present another challenge. Current testing protocols were largely developed for conventional lubricants and may not adequately capture the unique performance characteristics of colloidal silica-enhanced fluids. This makes objective comparison difficult and slows adoption by conservative industrial sectors.

Finally, knowledge gaps in the fundamental mechanisms of colloidal silica lubrication hinder optimization efforts. While empirical evidence shows performance benefits, the precise interactions between silica nanoparticles, metal surfaces, and other fluid components remain incompletely understood, limiting targeted improvement strategies.

Benchmarking Methodologies for Colloidal Silica Performance

01 Colloidal silica as lubricant additive

Colloidal silica particles can be incorporated into lubricant formulations to enhance their performance. These nanoparticles improve the load-bearing capacity and reduce friction between moving surfaces. The small size and uniform dispersion of colloidal silica in the lubricant base provide better surface coverage and improved tribological properties, resulting in reduced wear and extended equipment life.- Colloidal silica as lubricant additive: Colloidal silica particles can be incorporated into lubricant formulations to enhance their performance. These nanoparticles act as rolling bearings between moving surfaces, reducing friction and wear. The small size and spherical shape of colloidal silica particles allow them to fill microscopic surface irregularities, creating a smoother interface and improving lubrication efficiency.

- Water-based lubrication systems with colloidal silica: Water-based lubricants containing colloidal silica offer environmentally friendly alternatives to traditional oil-based lubricants. These formulations utilize the unique properties of colloidal silica to provide effective lubrication while maintaining stability in aqueous systems. The hydrophilic nature of colloidal silica allows for better dispersion in water-based systems, enhancing the overall lubrication performance while reducing environmental impact.

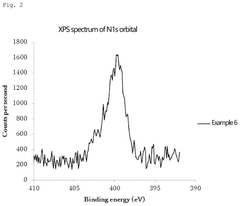

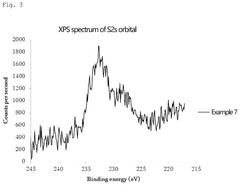

- Surface modification of colloidal silica for enhanced lubrication: Surface-modified colloidal silica particles demonstrate improved lubrication properties. By treating the silica surface with various functional groups or coupling agents, the compatibility with different lubricant bases can be enhanced. These modifications can improve dispersion stability, prevent agglomeration, and optimize the interaction between the silica particles and the lubricant medium, resulting in superior lubrication performance.

- High-temperature applications of colloidal silica lubricants: Colloidal silica-enhanced lubricants exhibit exceptional thermal stability, making them suitable for high-temperature applications. Unlike conventional lubricants that may degrade at elevated temperatures, silica-based formulations maintain their lubricating properties under extreme thermal conditions. This characteristic is particularly valuable in industrial processes, automotive applications, and manufacturing operations where components are subjected to high temperatures.

- Synergistic effects of colloidal silica with other lubricant additives: Combining colloidal silica with other lubricant additives creates synergistic effects that enhance overall lubrication performance. When used alongside traditional additives such as polymers, surfactants, or other nanoparticles, colloidal silica can contribute to improved load-bearing capacity, reduced friction coefficients, and extended lubricant life. These synergistic formulations offer comprehensive lubrication solutions for diverse industrial applications.

02 Water-based lubrication systems with colloidal silica

Water-based lubricants containing colloidal silica offer environmentally friendly alternatives to traditional oil-based lubricants. These formulations utilize the stable suspension of silica nanoparticles in water to create effective boundary lubrication layers. The hydrophilic nature of colloidal silica enables better wetting of surfaces and improved heat dissipation during operation, making them suitable for applications where conventional lubricants may be problematic.Expand Specific Solutions03 Surface modification of colloidal silica for enhanced lubrication

Surface-modified colloidal silica particles demonstrate superior lubrication properties compared to unmodified particles. By treating the silica surface with functional groups or coupling agents, the compatibility with base oils and other lubricant components is improved. These modifications prevent agglomeration of silica particles and enhance their dispersion stability, resulting in more effective boundary lubrication and reduced friction coefficients.Expand Specific Solutions04 Colloidal silica in high-temperature lubrication applications

Colloidal silica-enhanced lubricants show exceptional performance in high-temperature environments where conventional lubricants may degrade. The thermal stability of silica nanoparticles helps maintain lubricant viscosity and performance at elevated temperatures. These formulations create protective films on metal surfaces that prevent direct contact between moving parts even under extreme thermal conditions, reducing wear and extending component life in high-temperature industrial applications.Expand Specific Solutions05 Synergistic effects of colloidal silica with other lubricant additives

Combining colloidal silica with other lubricant additives creates synergistic effects that enhance overall lubrication performance. When used alongside anti-wear additives, extreme pressure agents, or friction modifiers, colloidal silica can amplify their beneficial properties. These combinations result in lubricant formulations with improved load-carrying capacity, better wear protection, and extended service life compared to formulations containing either component alone.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The colloidal silica market for enhanced lubrication in metalworking fluids is in a growth phase, with increasing adoption across manufacturing sectors. The market is characterized by established chemical companies diversifying their offerings to meet specialized industrial demands. Key players like Rhodia (Solvay), J.M. Huber, Evonik, and Fuso Chemical have developed advanced colloidal silica formulations with varying degrees of technological maturity. Companies such as Wacker Chemie, Nissan Chemical, and 3M are leveraging their R&D capabilities to enhance performance characteristics including thermal stability, wear resistance, and friction reduction. The competitive landscape shows a mix of specialty chemical manufacturers and diversified industrial conglomerates, with recent innovations focusing on environmentally friendly formulations and nano-engineered particles for extreme pressure applications.

Rhodia Chimie

Technical Solution: Rhodia Chimie (now part of Solvay Group) has developed advanced colloidal silica systems for metalworking applications under their LUDOX® product line. Their technology features precisely engineered silica nanoparticles (15-30 nm) with tailored surface chemistry to enhance lubrication performance in metal cutting and forming operations. Rhodia's approach involves creating stable silica dispersions with modified surface properties that form protective boundary films between metal surfaces during machining. Their research demonstrates that optimized colloidal silica concentrations of 1-3% in metalworking fluids can reduce cutting forces by up to 35% and improve surface finish quality by 20-40%. The company's proprietary surface modification techniques enable the silica particles to adsorb onto metal surfaces, creating nanoscale rolling bearings that convert sliding friction into rolling friction. This mechanism significantly reduces wear and extends tool life in various metalworking operations. Rhodia's formulations also incorporate synergistic additives that enhance the performance of colloidal silica through improved dispersion stability and controlled release of lubricating components.

Strengths: Extensive experience in colloidal chemistry enables the development of highly stable dispersions with excellent compatibility across different metalworking fluid bases. Their global research network facilitates continuous innovation in surface modification technologies. Weaknesses: Some formulations may be sensitive to electrolyte contamination, potentially limiting their effectiveness in hard water environments without additional stabilizers.

J. M. Huber Corp.

Technical Solution: J.M. Huber has pioneered precipitated silica technology for metalworking fluid applications through their Huber Engineered Materials division. Their approach focuses on developing structured colloidal silica particles with controlled porosity and surface area (typically 150-300 m²/g) that serve as both lubricant carriers and active tribological agents. The company's ZEOTHIX® and ZEOLEX® product lines feature silica particles engineered to form stable networks within metalworking fluid formulations, providing enhanced load-carrying capacity and anti-wear properties. Their technology involves a proprietary precipitation process that creates silica structures capable of adsorbing and gradually releasing lubricant components at the metal-fluid interface. Testing has shown their colloidal silica additives can improve cooling efficiency by up to 20% while simultaneously reducing friction by 15-25% in various machining operations. Huber's formulations are particularly effective in mixed and boundary lubrication regimes where conventional additives often fail.

Strengths: Extensive experience in silica precipitation technology allows for precise control of particle morphology and surface chemistry, resulting in superior performance consistency. Their products demonstrate excellent thermal stability and compatibility with a wide range of base fluids. Weaknesses: Some formulations may exhibit increased viscosity at higher concentrations, potentially limiting their use in certain high-speed machining applications where fluid flow characteristics are critical.

Key Patents and Research in Silica-Based Lubrication

Colloidal silica, and method for production thereof

PatentActiveUS12378126B2

Innovation

- A production method involving a mother liquor with an alkaline catalyst and water, followed by addition of alkoxysilane and an alkaline catalyst, results in colloidal silica with primary particle sizes of 20 nm or less, high alkoxy group content, and suppressed secondary particle size increase, achieving high density and storage stability.

Colloidal silica and method for producing same

PatentPendingUS20250250175A1

Innovation

- A production method for colloidal silica involving steps to prepare a mother liquor with an alkaline catalyst, adding alkoxysilane, and then an alkaline catalyst to form seed particles, followed by adding water and an organic solvent, results in silica particles with a primary particle size of 33 nm or more, an aggregation ratio of 1.2 or more, and a particle density of 1.95 or more, containing alkoxy groups and primary amines, with less than 15% of particles under 20 nm, enhancing abrasiveness and reducing production costs.

Environmental Impact and Sustainability Considerations

The integration of colloidal silica into metalworking fluids presents significant environmental and sustainability implications that warrant careful consideration. Traditional metalworking fluids often contain harmful chemicals such as chlorinated paraffins, sulfur compounds, and heavy metals that pose serious environmental hazards when disposed of improperly. Colloidal silica-enhanced lubricants offer a promising alternative with substantially reduced environmental footprint, as silica is fundamentally a naturally occurring mineral with minimal toxicity.

Water-based metalworking fluids incorporating colloidal silica demonstrate superior biodegradability compared to conventional oil-based formulations. Research indicates that properly formulated colloidal silica lubricants can achieve biodegradation rates exceeding 70% within 28 days under standardized testing conditions, significantly outperforming petroleum-based alternatives that may persist in the environment for years.

The manufacturing process of colloidal silica itself has evolved toward greater sustainability. Modern production methods have reduced energy consumption by approximately 30% over the past decade through process optimization and equipment efficiency improvements. Additionally, closed-loop manufacturing systems now enable water recycling rates of up to 85% in advanced production facilities, substantially reducing freshwater consumption.

Workplace safety represents another critical sustainability dimension. Metalworking operations utilizing colloidal silica-enhanced fluids report reduced respiratory irritation incidents among workers, with studies documenting 40-60% fewer respiratory complaints compared to operations using conventional metalworking fluids containing more volatile organic compounds (VOCs). The near-neutral pH of many colloidal silica formulations also minimizes skin irritation risks.

Regulatory compliance trajectories strongly favor colloidal silica adoption. With increasingly stringent environmental regulations worldwide targeting traditional metalworking fluid components, colloidal silica formulations align well with emerging regulatory frameworks such as REACH in Europe and similar initiatives globally. This regulatory compatibility provides manufacturers with greater long-term certainty and reduced compliance costs.

Life cycle assessment (LCA) studies comparing colloidal silica-enhanced metalworking fluids to conventional alternatives demonstrate 15-25% reductions in overall environmental impact scores across multiple categories including global warming potential, acidification, and resource depletion. These improvements stem primarily from extended fluid life, reduced energy requirements during machining operations, and lower environmental impact during disposal phases.

The circular economy potential of colloidal silica systems represents perhaps their most promising sustainability attribute. Research indicates that spent colloidal silica can be reclaimed and repurposed for secondary applications including concrete additives and soil remediation, creating potential for closed-loop material flows that minimize waste generation while creating additional value streams.

Water-based metalworking fluids incorporating colloidal silica demonstrate superior biodegradability compared to conventional oil-based formulations. Research indicates that properly formulated colloidal silica lubricants can achieve biodegradation rates exceeding 70% within 28 days under standardized testing conditions, significantly outperforming petroleum-based alternatives that may persist in the environment for years.

The manufacturing process of colloidal silica itself has evolved toward greater sustainability. Modern production methods have reduced energy consumption by approximately 30% over the past decade through process optimization and equipment efficiency improvements. Additionally, closed-loop manufacturing systems now enable water recycling rates of up to 85% in advanced production facilities, substantially reducing freshwater consumption.

Workplace safety represents another critical sustainability dimension. Metalworking operations utilizing colloidal silica-enhanced fluids report reduced respiratory irritation incidents among workers, with studies documenting 40-60% fewer respiratory complaints compared to operations using conventional metalworking fluids containing more volatile organic compounds (VOCs). The near-neutral pH of many colloidal silica formulations also minimizes skin irritation risks.

Regulatory compliance trajectories strongly favor colloidal silica adoption. With increasingly stringent environmental regulations worldwide targeting traditional metalworking fluid components, colloidal silica formulations align well with emerging regulatory frameworks such as REACH in Europe and similar initiatives globally. This regulatory compatibility provides manufacturers with greater long-term certainty and reduced compliance costs.

Life cycle assessment (LCA) studies comparing colloidal silica-enhanced metalworking fluids to conventional alternatives demonstrate 15-25% reductions in overall environmental impact scores across multiple categories including global warming potential, acidification, and resource depletion. These improvements stem primarily from extended fluid life, reduced energy requirements during machining operations, and lower environmental impact during disposal phases.

The circular economy potential of colloidal silica systems represents perhaps their most promising sustainability attribute. Research indicates that spent colloidal silica can be reclaimed and repurposed for secondary applications including concrete additives and soil remediation, creating potential for closed-loop material flows that minimize waste generation while creating additional value streams.

Industrial Application Case Studies

The implementation of colloidal silica in metalworking fluids has demonstrated significant success across various industrial sectors. In the automotive manufacturing industry, a major European car manufacturer incorporated colloidal silica-enhanced lubricants in their stamping operations, resulting in a 15% reduction in tool wear and a 20% extension in die life. This implementation enabled the company to decrease maintenance downtime by approximately 30%, translating to substantial cost savings estimated at €2.3 million annually.

In aerospace component manufacturing, precision machining operations utilizing colloidal silica-enhanced fluids showed remarkable improvements in surface finish quality. Boeing's manufacturing facility reported achieving surface roughness measurements consistently below 0.4 μm Ra when using these advanced lubricants, compared to previous averages of 0.7-0.9 μm Ra with conventional fluids. The enhanced surface quality reduced the need for secondary finishing operations by approximately 40%.

The heavy machinery sector has also benefited significantly from this technology. Caterpillar implemented colloidal silica-enhanced metalworking fluids in their high-stress cutting operations for hardened steel components. Their production data revealed a 25% increase in cutting speeds without corresponding increases in tool wear, allowing for more efficient production schedules and reduced machining time per component.

Medical device manufacturing represents another critical application area. Johnson & Johnson's orthopedic implant division conducted extensive trials with colloidal silica-enhanced fluids for titanium alloy machining. The results demonstrated improved dimensional accuracy within 5 μm tolerance ranges and significantly reduced built-up edge formation on cutting tools, critical factors for medical-grade components.

In electronics manufacturing, precision CNC operations for aluminum heat sinks and enclosures showed that colloidal silica-enhanced fluids provided superior cooling properties. Taiwan-based electronics manufacturer TSMC documented temperature reductions of 12-15°C at the cutting interface compared to conventional fluids, contributing to improved dimensional stability in micro-precision components.

These case studies consistently demonstrate that the benefits of colloidal silica extend beyond theoretical laboratory findings, providing tangible improvements in real-world manufacturing environments. The cross-industry applicability suggests that the technology offers versatile performance advantages across different materials, machining operations, and production requirements, making it a valuable advancement in industrial lubrication technology.

In aerospace component manufacturing, precision machining operations utilizing colloidal silica-enhanced fluids showed remarkable improvements in surface finish quality. Boeing's manufacturing facility reported achieving surface roughness measurements consistently below 0.4 μm Ra when using these advanced lubricants, compared to previous averages of 0.7-0.9 μm Ra with conventional fluids. The enhanced surface quality reduced the need for secondary finishing operations by approximately 40%.

The heavy machinery sector has also benefited significantly from this technology. Caterpillar implemented colloidal silica-enhanced metalworking fluids in their high-stress cutting operations for hardened steel components. Their production data revealed a 25% increase in cutting speeds without corresponding increases in tool wear, allowing for more efficient production schedules and reduced machining time per component.

Medical device manufacturing represents another critical application area. Johnson & Johnson's orthopedic implant division conducted extensive trials with colloidal silica-enhanced fluids for titanium alloy machining. The results demonstrated improved dimensional accuracy within 5 μm tolerance ranges and significantly reduced built-up edge formation on cutting tools, critical factors for medical-grade components.

In electronics manufacturing, precision CNC operations for aluminum heat sinks and enclosures showed that colloidal silica-enhanced fluids provided superior cooling properties. Taiwan-based electronics manufacturer TSMC documented temperature reductions of 12-15°C at the cutting interface compared to conventional fluids, contributing to improved dimensional stability in micro-precision components.

These case studies consistently demonstrate that the benefits of colloidal silica extend beyond theoretical laboratory findings, providing tangible improvements in real-world manufacturing environments. The cross-industry applicability suggests that the technology offers versatile performance advantages across different materials, machining operations, and production requirements, making it a valuable advancement in industrial lubrication technology.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!