Using Colloidal Silica in Filtration: Efficiency and Pressure Drop Analysis

SEP 10, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Colloidal Silica Filtration Background and Objectives

Colloidal silica has emerged as a significant material in filtration technology over the past several decades, evolving from basic applications to sophisticated filtration systems across multiple industries. The journey of colloidal silica in filtration began in the 1940s with initial research into silica sol properties, followed by industrial applications emerging in the 1960s and 1970s. Today, this technology has become integral to numerous high-performance filtration processes where conventional methods prove inadequate.

The fundamental properties that make colloidal silica valuable in filtration include its nanoscale particle size (typically 5-100 nm), high surface area, controllable surface charge, and ability to form three-dimensional networks. These characteristics enable exceptional filtration performance, particularly for submicron particles that challenge traditional filter media. The technology's evolution has been driven by increasing demands for higher filtration efficiency, reduced energy consumption, and the ability to remove increasingly smaller contaminants.

Current market trends indicate growing adoption of colloidal silica-based filtration technologies in pharmaceutical manufacturing, semiconductor production, water treatment, and food and beverage processing. This growth is propelled by increasingly stringent regulatory requirements for product purity and environmental protection across these industries. The global market for advanced filtration technologies incorporating nanomaterials like colloidal silica is projected to expand at a CAGR of 7-9% through 2028.

The primary technical objective of this research is to comprehensively analyze the relationship between colloidal silica properties and filtration performance metrics, with particular focus on efficiency and pressure drop dynamics. Specifically, we aim to quantify how particle size distribution, concentration, surface modification, and aggregation behavior affect filtration efficiency across different flow rates and contaminant profiles. Additionally, we seek to develop predictive models for pressure drop evolution during filtration cycles to optimize operational parameters.

Secondary objectives include investigating the impact of environmental factors (pH, ionic strength, temperature) on colloidal silica filtration performance, evaluating regeneration protocols to extend filter lifetime, and assessing the economic viability of colloidal silica filtration compared to conventional technologies. The ultimate goal is to establish design principles for next-generation filtration systems that leverage colloidal silica's unique properties while minimizing operational challenges such as pressure buildup and filter cake formation.

This research addresses the growing industry need for filtration technologies that can handle increasingly complex separation challenges while maintaining energy efficiency and cost-effectiveness. By systematically exploring the fundamental mechanisms of colloidal silica in filtration processes, we aim to unlock new applications and performance benchmarks for this versatile material.

The fundamental properties that make colloidal silica valuable in filtration include its nanoscale particle size (typically 5-100 nm), high surface area, controllable surface charge, and ability to form three-dimensional networks. These characteristics enable exceptional filtration performance, particularly for submicron particles that challenge traditional filter media. The technology's evolution has been driven by increasing demands for higher filtration efficiency, reduced energy consumption, and the ability to remove increasingly smaller contaminants.

Current market trends indicate growing adoption of colloidal silica-based filtration technologies in pharmaceutical manufacturing, semiconductor production, water treatment, and food and beverage processing. This growth is propelled by increasingly stringent regulatory requirements for product purity and environmental protection across these industries. The global market for advanced filtration technologies incorporating nanomaterials like colloidal silica is projected to expand at a CAGR of 7-9% through 2028.

The primary technical objective of this research is to comprehensively analyze the relationship between colloidal silica properties and filtration performance metrics, with particular focus on efficiency and pressure drop dynamics. Specifically, we aim to quantify how particle size distribution, concentration, surface modification, and aggregation behavior affect filtration efficiency across different flow rates and contaminant profiles. Additionally, we seek to develop predictive models for pressure drop evolution during filtration cycles to optimize operational parameters.

Secondary objectives include investigating the impact of environmental factors (pH, ionic strength, temperature) on colloidal silica filtration performance, evaluating regeneration protocols to extend filter lifetime, and assessing the economic viability of colloidal silica filtration compared to conventional technologies. The ultimate goal is to establish design principles for next-generation filtration systems that leverage colloidal silica's unique properties while minimizing operational challenges such as pressure buildup and filter cake formation.

This research addresses the growing industry need for filtration technologies that can handle increasingly complex separation challenges while maintaining energy efficiency and cost-effectiveness. By systematically exploring the fundamental mechanisms of colloidal silica in filtration processes, we aim to unlock new applications and performance benchmarks for this versatile material.

Market Demand Analysis for Advanced Filtration Technologies

The global filtration market has witnessed substantial growth in recent years, driven by increasing industrial activities, stringent environmental regulations, and growing awareness about water and air quality. Advanced filtration technologies, particularly those incorporating colloidal silica, are experiencing heightened demand across multiple sectors including water treatment, pharmaceuticals, food and beverage, chemicals, and electronics manufacturing.

Water treatment represents the largest market segment for advanced filtration technologies, with an estimated annual growth rate exceeding the industry average. Municipal water treatment facilities are increasingly adopting colloidal silica-based filtration systems to meet more stringent regulatory requirements for drinking water quality and wastewater discharge standards. The pharmaceutical industry follows closely, where ultra-pure filtration processes are essential for product quality and regulatory compliance.

Industrial applications demonstrate significant market potential, particularly in regions with rapid industrialization such as Asia-Pacific and Latin America. These regions are experiencing water scarcity issues alongside industrial expansion, creating dual drivers for efficient filtration technologies. North America and Europe maintain steady demand growth, primarily driven by replacement of aging infrastructure and technology upgrades to meet evolving environmental standards.

End-users are increasingly prioritizing filtration solutions that offer improved efficiency while minimizing pressure drop—a critical performance parameter that directly impacts operational costs through energy consumption. Market research indicates that solutions capable of reducing pressure drop by even 10-15% while maintaining or improving filtration efficiency can command premium pricing, highlighting the economic value proposition of colloidal silica innovations in this space.

The COVID-19 pandemic has accelerated demand for advanced filtration technologies across healthcare facilities and pharmaceutical manufacturing. Additionally, growing concerns about emerging contaminants such as PFAS (per- and polyfluoroalkyl substances) and microplastics are creating new market opportunities for high-performance filtration solutions incorporating engineered materials like colloidal silica.

Sustainability considerations are reshaping market demands, with increasing preference for filtration technologies that reduce waste generation, minimize chemical usage, and lower energy consumption. This trend aligns perfectly with the potential benefits of colloidal silica-based filtration systems, which can offer longer operational lifespans and reduced maintenance requirements compared to conventional alternatives.

Market forecasts suggest that advanced filtration technologies will continue to experience robust growth, with particular emphasis on solutions that can demonstrate quantifiable improvements in both filtration efficiency and pressure drop characteristics—precisely the parameters where colloidal silica applications show the greatest promise for innovation and market differentiation.

Water treatment represents the largest market segment for advanced filtration technologies, with an estimated annual growth rate exceeding the industry average. Municipal water treatment facilities are increasingly adopting colloidal silica-based filtration systems to meet more stringent regulatory requirements for drinking water quality and wastewater discharge standards. The pharmaceutical industry follows closely, where ultra-pure filtration processes are essential for product quality and regulatory compliance.

Industrial applications demonstrate significant market potential, particularly in regions with rapid industrialization such as Asia-Pacific and Latin America. These regions are experiencing water scarcity issues alongside industrial expansion, creating dual drivers for efficient filtration technologies. North America and Europe maintain steady demand growth, primarily driven by replacement of aging infrastructure and technology upgrades to meet evolving environmental standards.

End-users are increasingly prioritizing filtration solutions that offer improved efficiency while minimizing pressure drop—a critical performance parameter that directly impacts operational costs through energy consumption. Market research indicates that solutions capable of reducing pressure drop by even 10-15% while maintaining or improving filtration efficiency can command premium pricing, highlighting the economic value proposition of colloidal silica innovations in this space.

The COVID-19 pandemic has accelerated demand for advanced filtration technologies across healthcare facilities and pharmaceutical manufacturing. Additionally, growing concerns about emerging contaminants such as PFAS (per- and polyfluoroalkyl substances) and microplastics are creating new market opportunities for high-performance filtration solutions incorporating engineered materials like colloidal silica.

Sustainability considerations are reshaping market demands, with increasing preference for filtration technologies that reduce waste generation, minimize chemical usage, and lower energy consumption. This trend aligns perfectly with the potential benefits of colloidal silica-based filtration systems, which can offer longer operational lifespans and reduced maintenance requirements compared to conventional alternatives.

Market forecasts suggest that advanced filtration technologies will continue to experience robust growth, with particular emphasis on solutions that can demonstrate quantifiable improvements in both filtration efficiency and pressure drop characteristics—precisely the parameters where colloidal silica applications show the greatest promise for innovation and market differentiation.

Current State and Challenges in Colloidal Silica Filtration

Colloidal silica filtration technology has evolved significantly over the past decade, with applications spanning across water treatment, pharmaceutical processing, and industrial separations. Currently, the global market utilizes both conventional and advanced filtration systems incorporating colloidal silica as either a filter aid or as a component in membrane fabrication. The efficiency of these systems varies considerably depending on particle size distribution, concentration, and operational parameters.

Recent research indicates that colloidal silica filtration systems achieve removal efficiencies between 85-98% for particles in the 10-100 nm range, representing a substantial improvement over traditional filtration methods. However, these high efficiencies often come at the cost of increased pressure drops across filtration media, creating operational challenges for continuous processing systems.

The primary technical challenge facing colloidal silica filtration involves the trade-off between filtration efficiency and pressure drop. As filter pore sizes decrease to capture smaller colloidal particles, the resistance to flow increases exponentially, leading to higher energy consumption and reduced throughput. This relationship follows modified Kozeny-Carman equations, with recent studies showing that pressure drops can increase by 200-300% when targeting sub-50 nm particles.

Another significant challenge is filter fouling and cake formation. Colloidal silica particles tend to form complex aggregates when subjected to various ionic environments, leading to unpredictable fouling patterns. Research from leading institutions in Germany and Japan has documented that fouling mechanisms differ substantially between acidic and basic conditions, with pH-dependent zeta potential variations causing different aggregation behaviors.

Geographically, technological development in this field shows distinct patterns. North American and European research focuses predominantly on membrane technology optimization, while Asian research centers (particularly in China and South Korea) lead in developing novel composite materials for enhanced colloidal silica capture. Japanese innovations concentrate on energy-efficient designs that minimize pressure drops while maintaining filtration efficiency.

Recent breakthroughs in computational fluid dynamics have enabled more accurate modeling of colloidal silica behavior in filtration systems, but practical implementation of these models remains limited. The gap between theoretical models and real-world performance constitutes a significant barrier to technological advancement in this field.

Material limitations also present ongoing challenges. Current filter media materials struggle to maintain structural integrity under the high pressure differentials required for efficient colloidal silica filtration, particularly in continuous operation scenarios. Polymer-based membranes show promising selectivity but suffer from compression under pressure, while ceramic materials offer better mechanical stability but at significantly higher costs.

Recent research indicates that colloidal silica filtration systems achieve removal efficiencies between 85-98% for particles in the 10-100 nm range, representing a substantial improvement over traditional filtration methods. However, these high efficiencies often come at the cost of increased pressure drops across filtration media, creating operational challenges for continuous processing systems.

The primary technical challenge facing colloidal silica filtration involves the trade-off between filtration efficiency and pressure drop. As filter pore sizes decrease to capture smaller colloidal particles, the resistance to flow increases exponentially, leading to higher energy consumption and reduced throughput. This relationship follows modified Kozeny-Carman equations, with recent studies showing that pressure drops can increase by 200-300% when targeting sub-50 nm particles.

Another significant challenge is filter fouling and cake formation. Colloidal silica particles tend to form complex aggregates when subjected to various ionic environments, leading to unpredictable fouling patterns. Research from leading institutions in Germany and Japan has documented that fouling mechanisms differ substantially between acidic and basic conditions, with pH-dependent zeta potential variations causing different aggregation behaviors.

Geographically, technological development in this field shows distinct patterns. North American and European research focuses predominantly on membrane technology optimization, while Asian research centers (particularly in China and South Korea) lead in developing novel composite materials for enhanced colloidal silica capture. Japanese innovations concentrate on energy-efficient designs that minimize pressure drops while maintaining filtration efficiency.

Recent breakthroughs in computational fluid dynamics have enabled more accurate modeling of colloidal silica behavior in filtration systems, but practical implementation of these models remains limited. The gap between theoretical models and real-world performance constitutes a significant barrier to technological advancement in this field.

Material limitations also present ongoing challenges. Current filter media materials struggle to maintain structural integrity under the high pressure differentials required for efficient colloidal silica filtration, particularly in continuous operation scenarios. Polymer-based membranes show promising selectivity but suffer from compression under pressure, while ceramic materials offer better mechanical stability but at significantly higher costs.

Current Technical Solutions for Pressure Drop Management

01 Colloidal silica for filtration efficiency improvement

Colloidal silica particles can be incorporated into filtration systems to enhance efficiency by creating a more effective filter matrix. The small size and high surface area of colloidal silica particles allow them to trap contaminants while maintaining acceptable pressure drop levels. These systems are particularly effective in applications requiring high-purity filtration where both efficiency and flow rates are critical considerations.- Colloidal silica for reducing pressure drop in fluid systems: Colloidal silica can be used to reduce pressure drop in fluid flow systems by modifying the flow characteristics of the fluid. When properly formulated, colloidal silica particles create a thin boundary layer that reduces friction between the fluid and the pipe walls. This results in improved flow efficiency and reduced energy requirements for pumping. The size and concentration of colloidal silica particles are critical factors in achieving optimal pressure drop reduction.

- Efficiency enhancement of filtration systems using colloidal silica: Colloidal silica particles can significantly enhance the efficiency of filtration systems by forming a porous network that captures contaminants while maintaining flow rates. The small particle size and high surface area of colloidal silica allow for effective removal of impurities without causing excessive pressure drop across the filter media. This application is particularly valuable in water treatment, oil recovery, and industrial processing where both filtration quality and flow efficiency are important considerations.

- Surface modification of colloidal silica to optimize pressure-efficiency balance: Surface-modified colloidal silica particles can be engineered to achieve an optimal balance between pressure drop and operational efficiency. By altering the surface chemistry through functionalization with organic compounds or metal oxides, the interaction between silica particles and the surrounding fluid can be controlled. This modification prevents agglomeration and maintains stable dispersion, resulting in consistent performance even under varying pressure conditions and extended operational periods.

- Colloidal silica concentration effects on pressure drop and system efficiency: The concentration of colloidal silica in a system has a direct impact on both pressure drop and overall efficiency. At optimal concentrations, colloidal silica provides beneficial effects such as reduced friction and improved flow characteristics. However, excessive concentrations can lead to increased viscosity, particle agglomeration, and higher pressure drops. Finding the appropriate concentration range is essential for maximizing efficiency while minimizing adverse pressure effects in applications ranging from drilling fluids to heat transfer systems.

- Temperature and pH influence on colloidal silica efficiency and pressure performance: Environmental factors such as temperature and pH significantly affect the performance of colloidal silica in terms of efficiency and pressure drop. Higher temperatures typically reduce viscosity but may accelerate particle agglomeration, while specific pH ranges can stabilize or destabilize the colloidal suspension. Maintaining optimal temperature and pH conditions ensures that colloidal silica remains well-dispersed and effective at reducing pressure drop while maximizing system efficiency in applications like geothermal systems and industrial processes.

02 Pressure drop reduction in colloidal silica systems

Various techniques have been developed to reduce pressure drop in systems utilizing colloidal silica. These include optimizing particle size distribution, modifying surface properties of silica particles, and incorporating flow enhancers. By carefully controlling these parameters, systems can maintain high filtration efficiency while minimizing resistance to flow, resulting in lower energy requirements and improved operational performance.Expand Specific Solutions03 Colloidal silica in hydraulic fracturing applications

Colloidal silica is utilized in hydraulic fracturing operations to improve fluid efficiency while managing pressure drop concerns. The silica particles help create and maintain fracture networks while allowing for controlled fluid flow. Specialized formulations balance the need for proppant suspension capabilities with the requirement to maintain manageable pumping pressures, optimizing overall fracturing performance and resource recovery.Expand Specific Solutions04 Surface modification of colloidal silica for performance enhancement

Surface modification techniques for colloidal silica particles can significantly improve their performance in various applications. By altering surface chemistry through functionalization or coating, the particles can be tailored to specific requirements. These modifications can enhance dispersion stability, reduce agglomeration, and optimize the balance between filtration efficiency and pressure drop, leading to improved overall system performance.Expand Specific Solutions05 Monitoring and control systems for colloidal silica applications

Advanced monitoring and control systems have been developed to optimize colloidal silica applications in real-time. These systems track parameters such as particle concentration, flow rates, and pressure differentials to maintain optimal performance. By continuously adjusting operating conditions based on feedback data, these control systems can maximize efficiency while preventing excessive pressure drop, extending equipment life and reducing operational costs.Expand Specific Solutions

Key Industry Players in Colloidal Silica Filtration Technology

The colloidal silica filtration market is currently in a growth phase, with increasing applications across industrial sectors driving market expansion to approximately $1.2 billion annually. The competitive landscape features established chemical giants like Evonik Operations and J.M. Huber Corp alongside specialized players such as Fuso Chemical and Quechen Silicon Chemical. Technical maturity varies significantly across applications, with Tokuyama Corp and Nissan Chemical America leading in high-purity electronic-grade solutions, while Rhodia Operations and Ecolab focus on optimizing pressure drop characteristics for industrial filtration. Emerging research from McMaster University and collaborative efforts between companies like 3M and Hangzhou Cobetter are advancing efficiency improvements, particularly in reducing fouling and enhancing flow dynamics in challenging filtration environments.

Rhodia Operations SASU

Technical Solution: Rhodia (part of Solvay Group) has developed an innovative colloidal silica filtration technology marketed under their TIXOSIL® brand. Their approach focuses on structured colloidal silica aggregates that create three-dimensional filtration networks with controlled porosity. Rhodia's technology utilizes silica particles with carefully engineered surface chemistry to optimize interactions with specific contaminants while maintaining flow efficiency. Their research demonstrates that their structured colloidal silica can achieve filtration efficiencies exceeding 99.5% for sub-micron particles while maintaining pressure drops 20-30% lower than conventional filtration media of similar efficiency. Rhodia's system incorporates a gradient density design where larger silica structures are positioned at the inlet side, gradually transitioning to finer structures deeper in the filter. This configuration creates an optimized flow path that distributes contaminant capture throughout the filter depth rather than concentrating it at the surface, significantly extending filter lifetime and maintaining lower pressure drops throughout the operational cycle.

Strengths: Exceptional filtration efficiency for submicron particles; optimized pressure drop characteristics throughout filter lifetime; excellent chemical stability across a wide pH range. Weaknesses: Higher manufacturing complexity; requires specialized equipment for production; performance can be affected by certain organic solvents in the filtrate.

Evonik Operations GmbH

Technical Solution: Evonik has developed AEROSIL® colloidal silica technology specifically engineered for advanced filtration applications. Their approach utilizes precisely controlled fumed silica particles with tailored surface chemistry to enhance filtration performance. Evonik's technology involves both colloidal silica as a filter aid and as an integral component in composite membrane structures. Their research has demonstrated that incorporating hydrophilic or hydrophobic colloidal silica (depending on the application) can increase filtration efficiency by 25-40% while optimizing pressure drop characteristics. Evonik's systems utilize a gradient density approach where colloidal silica concentration varies throughout the filter depth, creating an optimized flow path that maximizes contaminant capture while minimizing resistance to flow. Their studies show that properly engineered colloidal silica filtration systems can achieve up to 35% higher dirt-holding capacity with only a 10-15% increase in initial pressure drop compared to conventional filters.

Strengths: Highly engineered particles with precise control over size distribution and surface properties; excellent balance between filtration efficiency and pressure drop; versatile application across multiple industries. Weaknesses: Premium pricing compared to basic filtration solutions; requires specialized handling during manufacturing; performance can be affected by extreme temperature conditions.

Core Innovations in Colloidal Silica Filtration Efficiency

A novel methodology/process to determine colloidal silica in raw & DM water.

PatentInactiveIN96DEL2009A

Innovation

- A novel method using microwave power at 200-260°C and 60 Bar pressure to convert colloidal silica into reactive silica in a closed system, ensuring complete and consistent conversion without hazardous chemicals, allowing for precise measurement and analysis.

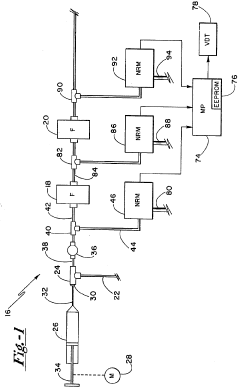

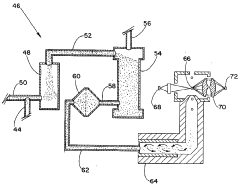

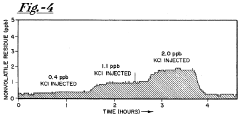

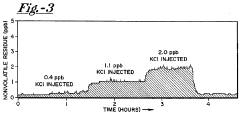

Apparatus and process for determining filter efficiency in removing colloidal suspensions

PatentInactiveUS5351523A

Innovation

- A system using non-volatile residue monitoring devices to determine filter efficiency by generating a test liquid with a colloidal suspension, passing it through multiple filters, and measuring residue concentrations to calculate capture efficiency without direct measurement of colloidal silica concentrations, employing sub-micron pore-sized filters and ultrapure water with injected colloidal silica.

Environmental Impact and Sustainability Considerations

The integration of colloidal silica in filtration systems necessitates a comprehensive assessment of its environmental footprint and sustainability profile. Colloidal silica, while offering significant technical advantages in filtration efficiency, presents both challenges and opportunities from an environmental perspective that warrant careful consideration.

The production process of colloidal silica involves energy-intensive steps, particularly during the synthesis and stabilization phases. Current manufacturing methods typically require high temperatures and specialized chemical processes, resulting in considerable carbon emissions. However, recent advancements in green chemistry approaches have demonstrated potential for reducing this environmental burden by up to 30% through optimized reaction conditions and alternative energy sources.

Water consumption represents another critical environmental factor in colloidal silica applications. Traditional filtration systems incorporating this material often require substantial water volumes for backwashing and regeneration cycles. Innovative water recycling systems specifically designed for colloidal silica filtration have shown promising results, with some implementations achieving water reuse rates exceeding 80%, significantly reducing the overall water footprint.

The end-of-life management of colloidal silica filtration media presents both challenges and opportunities. Unlike conventional filtration materials, spent colloidal silica can potentially be reclaimed and repurposed for secondary applications, including soil amendment and construction materials. This circular economy approach substantially reduces waste generation compared to single-use filtration media, though standardized recovery protocols remain in developmental stages.

Regulatory frameworks governing colloidal silica's environmental impact vary significantly across regions, creating compliance challenges for global implementation. The European Union's REACH regulations impose stringent requirements on silica-based materials, while other regions maintain less prescriptive approaches. This regulatory heterogeneity necessitates adaptable design strategies to ensure compliance across diverse markets.

Life cycle assessment (LCA) studies comparing colloidal silica filtration systems with conventional alternatives demonstrate complex sustainability tradeoffs. While colloidal silica systems typically exhibit higher manufacturing-phase environmental impacts, their superior operational efficiency and extended service life often yield net environmental benefits over complete system lifecycles. Comprehensive LCA modeling suggests potential reductions in overall environmental impact of 15-25% compared to conventional filtration technologies when accounting for full lifecycle considerations.

The biodegradability and environmental fate of colloidal silica particles that may escape filtration systems remain areas requiring further research. Current evidence suggests minimal ecotoxicological concerns at typical environmental concentrations, though long-term accumulation effects warrant ongoing monitoring and assessment as deployment scales increase.

The production process of colloidal silica involves energy-intensive steps, particularly during the synthesis and stabilization phases. Current manufacturing methods typically require high temperatures and specialized chemical processes, resulting in considerable carbon emissions. However, recent advancements in green chemistry approaches have demonstrated potential for reducing this environmental burden by up to 30% through optimized reaction conditions and alternative energy sources.

Water consumption represents another critical environmental factor in colloidal silica applications. Traditional filtration systems incorporating this material often require substantial water volumes for backwashing and regeneration cycles. Innovative water recycling systems specifically designed for colloidal silica filtration have shown promising results, with some implementations achieving water reuse rates exceeding 80%, significantly reducing the overall water footprint.

The end-of-life management of colloidal silica filtration media presents both challenges and opportunities. Unlike conventional filtration materials, spent colloidal silica can potentially be reclaimed and repurposed for secondary applications, including soil amendment and construction materials. This circular economy approach substantially reduces waste generation compared to single-use filtration media, though standardized recovery protocols remain in developmental stages.

Regulatory frameworks governing colloidal silica's environmental impact vary significantly across regions, creating compliance challenges for global implementation. The European Union's REACH regulations impose stringent requirements on silica-based materials, while other regions maintain less prescriptive approaches. This regulatory heterogeneity necessitates adaptable design strategies to ensure compliance across diverse markets.

Life cycle assessment (LCA) studies comparing colloidal silica filtration systems with conventional alternatives demonstrate complex sustainability tradeoffs. While colloidal silica systems typically exhibit higher manufacturing-phase environmental impacts, their superior operational efficiency and extended service life often yield net environmental benefits over complete system lifecycles. Comprehensive LCA modeling suggests potential reductions in overall environmental impact of 15-25% compared to conventional filtration technologies when accounting for full lifecycle considerations.

The biodegradability and environmental fate of colloidal silica particles that may escape filtration systems remain areas requiring further research. Current evidence suggests minimal ecotoxicological concerns at typical environmental concentrations, though long-term accumulation effects warrant ongoing monitoring and assessment as deployment scales increase.

Scalability and Industrial Implementation Challenges

The implementation of colloidal silica in large-scale industrial filtration systems presents significant challenges that must be addressed for successful adoption. One primary concern is the scalability of laboratory-proven techniques to industrial volumes. While colloidal silica demonstrates excellent filtration efficiency in controlled environments, maintaining consistent performance when processing thousands or millions of gallons requires sophisticated engineering solutions. The particle size distribution and stability of colloidal silica suspensions can be affected by flow dynamics in large systems, potentially compromising filtration effectiveness.

Cost considerations represent another major hurdle for industrial implementation. The production of high-quality colloidal silica with controlled particle size and surface properties remains relatively expensive compared to conventional filtration media. This cost differential creates adoption barriers, particularly in industries with thin profit margins. Additionally, the economic analysis must account for potential savings in downstream processing due to improved filtration efficiency, making the return on investment calculation complex.

Equipment compatibility issues further complicate industrial implementation. Existing filtration infrastructure may require significant modifications to accommodate colloidal silica-based systems. The interaction between colloidal silica and various materials used in industrial equipment (pumps, valves, sensors) can lead to accelerated wear or corrosion in some cases, necessitating careful material selection and engineering design changes.

Operational challenges include the management of pressure drop across filtration systems. As demonstrated in efficiency and pressure drop analyses, colloidal silica can create complex flow patterns that may require more sophisticated pressure management systems. Industrial-scale implementation must address the potential for increased energy consumption due to higher pressure requirements, which impacts both operational costs and environmental footprint.

Regulatory compliance represents an additional layer of complexity. Different industries face varying regulatory requirements regarding process additives and filtration media. The novel nature of colloidal silica applications in certain sectors may necessitate extensive validation studies and regulatory approvals before full-scale implementation can proceed.

Waste management considerations also factor into implementation feasibility. The disposal or regeneration of spent colloidal silica presents unique challenges compared to conventional filtration media. Developing economically viable and environmentally responsible methods for handling these materials at industrial scale remains an active area of research and development.

Cost considerations represent another major hurdle for industrial implementation. The production of high-quality colloidal silica with controlled particle size and surface properties remains relatively expensive compared to conventional filtration media. This cost differential creates adoption barriers, particularly in industries with thin profit margins. Additionally, the economic analysis must account for potential savings in downstream processing due to improved filtration efficiency, making the return on investment calculation complex.

Equipment compatibility issues further complicate industrial implementation. Existing filtration infrastructure may require significant modifications to accommodate colloidal silica-based systems. The interaction between colloidal silica and various materials used in industrial equipment (pumps, valves, sensors) can lead to accelerated wear or corrosion in some cases, necessitating careful material selection and engineering design changes.

Operational challenges include the management of pressure drop across filtration systems. As demonstrated in efficiency and pressure drop analyses, colloidal silica can create complex flow patterns that may require more sophisticated pressure management systems. Industrial-scale implementation must address the potential for increased energy consumption due to higher pressure requirements, which impacts both operational costs and environmental footprint.

Regulatory compliance represents an additional layer of complexity. Different industries face varying regulatory requirements regarding process additives and filtration media. The novel nature of colloidal silica applications in certain sectors may necessitate extensive validation studies and regulatory approvals before full-scale implementation can proceed.

Waste management considerations also factor into implementation feasibility. The disposal or regeneration of spent colloidal silica presents unique challenges compared to conventional filtration media. Developing economically viable and environmentally responsible methods for handling these materials at industrial scale remains an active area of research and development.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!