How to Stabilize Colloidal Silica in Non-Polar Solvents for Industrial Applications

SEP 10, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Colloidal Silica Stabilization Background and Objectives

Colloidal silica has emerged as a critical material in numerous industrial applications due to its unique properties, including high surface area, tunable particle size, and excellent mechanical strength. The history of colloidal silica research dates back to the early 20th century, with significant advancements occurring in the 1940s through the pioneering work of researchers like Ralph K. Iler. Since then, the technology has evolved from basic sol-gel chemistry to sophisticated surface modification techniques that enable precise control over particle properties and interactions.

The evolution of colloidal silica stabilization has followed a trajectory from water-based systems to increasingly complex non-polar environments. Initially, applications were limited to aqueous systems where silica naturally exhibits reasonable stability. However, industrial demands have pushed research toward stabilization in non-polar solvents, which presents fundamentally different challenges due to the inherent hydrophilicity of silica surfaces.

Current technological trends in this field focus on developing surface modification strategies that can effectively shield the hydrophilic silanol groups on silica surfaces while providing steric or electrostatic stabilization mechanisms in non-polar media. The advancement of silane coupling agents, polymer grafting techniques, and novel surfactant systems represents key developments that have expanded the potential applications of colloidal silica in organic solvents.

The primary objective of this technical research is to comprehensively evaluate existing and emerging methods for stabilizing colloidal silica in non-polar solvents, with a specific focus on industrial viability. This includes identifying optimal surface modification approaches, understanding the fundamental mechanisms of stabilization, and determining the most promising techniques for scale-up and commercial implementation.

Additionally, this research aims to establish clear performance metrics for evaluating stability in non-polar environments, including dispersion longevity, resistance to aggregation under varying conditions, and compatibility with end-use applications. These metrics will serve as benchmarks for comparing different stabilization strategies and guiding future development efforts.

The ultimate goal is to develop robust, cost-effective, and environmentally sustainable methods for producing stable colloidal silica dispersions in non-polar solvents that can meet the demanding requirements of industrial applications such as polymer composites, coatings, lubricants, and catalysis. This would enable the expansion of colloidal silica into new market segments where water-based systems are incompatible with existing processes or where specific performance advantages can be achieved through non-aqueous formulations.

The evolution of colloidal silica stabilization has followed a trajectory from water-based systems to increasingly complex non-polar environments. Initially, applications were limited to aqueous systems where silica naturally exhibits reasonable stability. However, industrial demands have pushed research toward stabilization in non-polar solvents, which presents fundamentally different challenges due to the inherent hydrophilicity of silica surfaces.

Current technological trends in this field focus on developing surface modification strategies that can effectively shield the hydrophilic silanol groups on silica surfaces while providing steric or electrostatic stabilization mechanisms in non-polar media. The advancement of silane coupling agents, polymer grafting techniques, and novel surfactant systems represents key developments that have expanded the potential applications of colloidal silica in organic solvents.

The primary objective of this technical research is to comprehensively evaluate existing and emerging methods for stabilizing colloidal silica in non-polar solvents, with a specific focus on industrial viability. This includes identifying optimal surface modification approaches, understanding the fundamental mechanisms of stabilization, and determining the most promising techniques for scale-up and commercial implementation.

Additionally, this research aims to establish clear performance metrics for evaluating stability in non-polar environments, including dispersion longevity, resistance to aggregation under varying conditions, and compatibility with end-use applications. These metrics will serve as benchmarks for comparing different stabilization strategies and guiding future development efforts.

The ultimate goal is to develop robust, cost-effective, and environmentally sustainable methods for producing stable colloidal silica dispersions in non-polar solvents that can meet the demanding requirements of industrial applications such as polymer composites, coatings, lubricants, and catalysis. This would enable the expansion of colloidal silica into new market segments where water-based systems are incompatible with existing processes or where specific performance advantages can be achieved through non-aqueous formulations.

Market Demand Analysis for Non-Polar Solvent Applications

The global market for colloidal silica in non-polar solvents has been experiencing significant growth, driven primarily by expanding applications in coatings, electronics, and advanced materials. Current market estimates value this segment at approximately 3.2 billion USD, with projections indicating a compound annual growth rate of 6.8% over the next five years.

Industrial demand for stable colloidal silica dispersions in non-polar media stems from several key sectors. The coatings industry represents the largest market share, where these materials provide enhanced scratch resistance, durability, and optical properties. Manufacturers of automotive and industrial coatings particularly value silica's ability to improve weathering resistance and mechanical strength without compromising transparency.

The electronics sector demonstrates rapidly increasing demand, especially in semiconductor manufacturing where ultra-pure silica particles are essential for chemical-mechanical planarization processes and advanced packaging technologies. As device miniaturization continues, the need for precisely controlled silica dispersions with minimal aggregation becomes increasingly critical.

Energy applications constitute another significant market driver, with particular growth in battery technologies and photovoltaics. Silica nanoparticles in non-polar media are being incorporated into next-generation battery separators and electrode materials to enhance performance and safety characteristics. The renewable energy sector's expansion directly correlates with increased demand for these specialized materials.

Consumer products manufacturers have also identified valuable applications, incorporating stabilized silica into personal care formulations, household products, and specialty polymers. The ability to create hydrophobic surfaces and control rheological properties makes these materials particularly versatile across diverse product categories.

Regional analysis reveals Asia-Pacific as the dominant market, accounting for approximately 42% of global consumption, followed by North America and Europe. China and South Korea show the highest growth rates, driven by their expanding electronics manufacturing sectors and government initiatives supporting advanced materials development.

Customer requirements increasingly emphasize long-term dispersion stability, narrow particle size distribution, and compatibility with existing manufacturing processes. End-users report willingness to pay premium prices for silica dispersions that demonstrate exceptional stability in challenging non-polar environments, particularly those containing mixed solvents or varying temperature conditions.

Market barriers include technical challenges in achieving long-term stability, regulatory considerations regarding nanomaterials, and competition from alternative technologies. However, the specialized nature of these materials and their unique performance characteristics continue to drive strong market demand despite these challenges.

Industrial demand for stable colloidal silica dispersions in non-polar media stems from several key sectors. The coatings industry represents the largest market share, where these materials provide enhanced scratch resistance, durability, and optical properties. Manufacturers of automotive and industrial coatings particularly value silica's ability to improve weathering resistance and mechanical strength without compromising transparency.

The electronics sector demonstrates rapidly increasing demand, especially in semiconductor manufacturing where ultra-pure silica particles are essential for chemical-mechanical planarization processes and advanced packaging technologies. As device miniaturization continues, the need for precisely controlled silica dispersions with minimal aggregation becomes increasingly critical.

Energy applications constitute another significant market driver, with particular growth in battery technologies and photovoltaics. Silica nanoparticles in non-polar media are being incorporated into next-generation battery separators and electrode materials to enhance performance and safety characteristics. The renewable energy sector's expansion directly correlates with increased demand for these specialized materials.

Consumer products manufacturers have also identified valuable applications, incorporating stabilized silica into personal care formulations, household products, and specialty polymers. The ability to create hydrophobic surfaces and control rheological properties makes these materials particularly versatile across diverse product categories.

Regional analysis reveals Asia-Pacific as the dominant market, accounting for approximately 42% of global consumption, followed by North America and Europe. China and South Korea show the highest growth rates, driven by their expanding electronics manufacturing sectors and government initiatives supporting advanced materials development.

Customer requirements increasingly emphasize long-term dispersion stability, narrow particle size distribution, and compatibility with existing manufacturing processes. End-users report willingness to pay premium prices for silica dispersions that demonstrate exceptional stability in challenging non-polar environments, particularly those containing mixed solvents or varying temperature conditions.

Market barriers include technical challenges in achieving long-term stability, regulatory considerations regarding nanomaterials, and competition from alternative technologies. However, the specialized nature of these materials and their unique performance characteristics continue to drive strong market demand despite these challenges.

Technical Challenges in Non-Polar Colloidal Systems

The stabilization of colloidal silica in non-polar solvents presents significant technical challenges that have hindered widespread industrial applications. The fundamental issue stems from the inherent incompatibility between hydrophilic silica surfaces and hydrophobic non-polar media. This mismatch in surface energies leads to strong particle-particle attractions that promote aggregation rather than stable dispersion.

Surface chemistry modification represents the primary challenge in this field. Conventional stabilization methods that work well in aqueous systems, such as electrostatic repulsion, become ineffective in non-polar environments due to the low dielectric constants of these media. This necessitates alternative approaches focused on steric stabilization mechanisms, which themselves present complex implementation hurdles.

The grafting of appropriate surface modifiers onto silica surfaces requires precise control over reaction conditions. Achieving uniform surface coverage while maintaining the desired silica properties demands sophisticated synthesis protocols. Many industrial applications require specific surface functionalities that must be preserved throughout the modification process, adding another layer of complexity.

Scalability of laboratory-proven techniques to industrial production volumes introduces additional challenges. Methods that work effectively at small scales often encounter unforeseen complications during scale-up, including heat transfer limitations, mixing inefficiencies, and increased processing times that can affect product quality and consistency.

Long-term colloidal stability remains problematic in many non-polar systems. Environmental factors such as temperature fluctuations, mechanical stress during processing, and chemical contamination can trigger delayed aggregation phenomena. This time-dependent instability is particularly troublesome for products with extended shelf-life requirements.

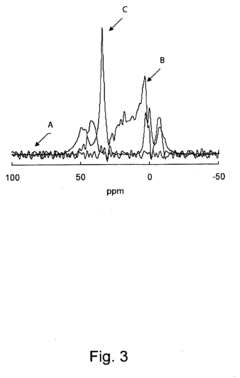

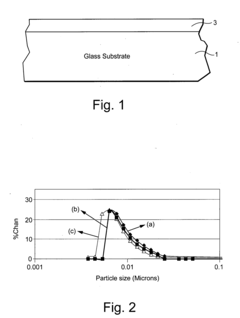

Characterization of these complex systems presents its own set of challenges. Traditional analytical techniques for aqueous colloids often require adaptation or replacement when applied to non-polar systems. The accurate measurement of particle size distribution, surface coverage, and dispersion stability in non-polar media demands specialized instrumentation and methodology.

Formulation compatibility issues arise when attempting to incorporate stabilized silica into final product matrices. The presence of other ingredients in industrial formulations can disrupt carefully engineered stabilization mechanisms, requiring extensive compatibility testing and often reformulation efforts.

The economic viability of potential solutions represents a significant practical challenge. Many effective stabilization approaches involve expensive reagents or energy-intensive processing steps that limit their industrial applicability. Finding cost-effective solutions that can be implemented at scale remains a key hurdle for widespread adoption.

Surface chemistry modification represents the primary challenge in this field. Conventional stabilization methods that work well in aqueous systems, such as electrostatic repulsion, become ineffective in non-polar environments due to the low dielectric constants of these media. This necessitates alternative approaches focused on steric stabilization mechanisms, which themselves present complex implementation hurdles.

The grafting of appropriate surface modifiers onto silica surfaces requires precise control over reaction conditions. Achieving uniform surface coverage while maintaining the desired silica properties demands sophisticated synthesis protocols. Many industrial applications require specific surface functionalities that must be preserved throughout the modification process, adding another layer of complexity.

Scalability of laboratory-proven techniques to industrial production volumes introduces additional challenges. Methods that work effectively at small scales often encounter unforeseen complications during scale-up, including heat transfer limitations, mixing inefficiencies, and increased processing times that can affect product quality and consistency.

Long-term colloidal stability remains problematic in many non-polar systems. Environmental factors such as temperature fluctuations, mechanical stress during processing, and chemical contamination can trigger delayed aggregation phenomena. This time-dependent instability is particularly troublesome for products with extended shelf-life requirements.

Characterization of these complex systems presents its own set of challenges. Traditional analytical techniques for aqueous colloids often require adaptation or replacement when applied to non-polar systems. The accurate measurement of particle size distribution, surface coverage, and dispersion stability in non-polar media demands specialized instrumentation and methodology.

Formulation compatibility issues arise when attempting to incorporate stabilized silica into final product matrices. The presence of other ingredients in industrial formulations can disrupt carefully engineered stabilization mechanisms, requiring extensive compatibility testing and often reformulation efforts.

The economic viability of potential solutions represents a significant practical challenge. Many effective stabilization approaches involve expensive reagents or energy-intensive processing steps that limit their industrial applicability. Finding cost-effective solutions that can be implemented at scale remains a key hurdle for widespread adoption.

Current Stabilization Methods for Non-Polar Media

01 pH control for colloidal silica stability

Controlling the pH of colloidal silica solutions is crucial for maintaining stability. Alkaline conditions (typically pH 8-10) help prevent aggregation by increasing the negative surface charge on silica particles, which creates electrostatic repulsion. Specific stabilizing agents can be added to buffer the solution and maintain optimal pH levels, preventing gelation and extending shelf life of colloidal silica dispersions.- pH control for colloidal silica stability: Controlling the pH of colloidal silica solutions is crucial for maintaining stability. Alkaline conditions (typically pH 8-10) help prevent aggregation by increasing the negative surface charge of silica particles, which creates electrostatic repulsion. Specific pH stabilizers and buffer systems can be incorporated to maintain optimal pH levels over time, preventing gelation and precipitation that occurs at lower pH values.

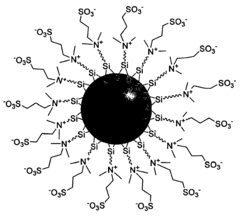

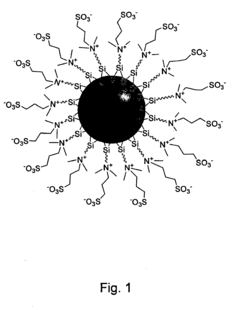

- Surface modification of silica particles: Surface modification of colloidal silica particles with organic compounds, silanes, or metal ions can significantly enhance stability. These modifications create steric hindrance or alter the surface charge, preventing particle aggregation. Modified silica particles show improved dispersion in various media, including organic solvents and polymer matrices, and maintain stability under challenging conditions such as high temperature or high ionic strength environments.

- Stabilizing additives for colloidal silica: Various additives can be incorporated into colloidal silica formulations to enhance stability. These include electrolytes for charge stabilization, polymeric dispersants that provide steric hindrance, and surfactants that modify the interface between silica particles and the dispersion medium. Certain organic compounds like polyols and amines have also shown effectiveness in preventing aggregation and maintaining long-term colloidal stability.

- Processing methods affecting colloidal silica stability: The stability of colloidal silica is significantly influenced by processing methods. Controlled synthesis parameters such as temperature, reaction time, and concentration affect particle size distribution and surface properties. Post-synthesis treatments including dialysis, ion exchange, and ultrafiltration can remove destabilizing impurities. Specialized mixing techniques and controlled addition rates during formulation help maintain uniform dispersion and prevent localized aggregation.

- Stability in specific applications and environments: Colloidal silica stability requirements vary across different applications and environmental conditions. For high-temperature applications, special stabilization techniques prevent thermal degradation. In high-salt environments, additional stabilizers counteract the compression of the electrical double layer. For incorporation into polymers or coatings, compatibility agents ensure uniform distribution and prevent phase separation. Freeze-thaw stability can be achieved through addition of cryoprotectants that prevent irreversible aggregation during temperature cycling.

02 Surface modification of silica particles

Surface modification of colloidal silica particles with organic compounds or metal ions can significantly enhance stability. These modifications create steric hindrance or alter surface charge, preventing particle aggregation. Common modification agents include silanes, polymers, and metal oxides that form protective layers around silica particles, enabling stability across broader pH ranges and in various environmental conditions.Expand Specific Solutions03 Electrolyte concentration management

The concentration of electrolytes in colloidal silica dispersions significantly affects stability. High electrolyte concentrations can compress the electrical double layer around silica particles, reducing repulsive forces and promoting aggregation. Controlling ionic strength through careful addition of stabilizing salts or removal of destabilizing ions helps maintain the colloidal state and prevent gelation or precipitation during storage and application.Expand Specific Solutions04 Temperature-resistant colloidal silica formulations

Developing temperature-resistant colloidal silica formulations is essential for applications requiring thermal stability. These formulations incorporate specific stabilizers and modified production processes to prevent particle growth, aggregation, or phase separation at elevated temperatures. Advanced synthesis methods can produce silica particles with controlled size distribution and surface properties that maintain stability across wide temperature ranges.Expand Specific Solutions05 Polymer addition for enhanced stability

Adding specific polymers to colloidal silica dispersions can significantly enhance stability through steric stabilization mechanisms. Water-soluble polymers like polyvinyl alcohol, polyethylene glycol, and cellulose derivatives adsorb onto silica surfaces, creating physical barriers that prevent particle collision and aggregation. These polymer-stabilized systems show improved resistance to electrolytes, shear forces, and freeze-thaw cycles, extending the practical applications of colloidal silica.Expand Specific Solutions

Key Industry Players in Colloidal Silica Technology

The colloidal silica stabilization in non-polar solvents market is in a growth phase, with an estimated global market size of $1.5-2 billion annually. The competitive landscape features established chemical giants like Wacker Chemie AG, Evonik Operations, and Shin-Etsu Chemical alongside specialized players such as Fuso Chemical and Nissan Chemical. Technology maturity varies significantly across applications, with electronics and semiconductor industries (led by Fujimi, Inc. and Anji Microelectronics) showing high sophistication, while industrial coatings applications (dominated by Akzo Nobel and Sherwin-Williams) remain in development. Recent innovations from Wanhua Chemical and J.M. Huber Corp. suggest emerging competition in surface modification techniques that enhance dispersion stability, indicating a dynamic market with substantial growth potential in advanced materials applications.

Akzo Nobel Chemicals International BV

Technical Solution: Akzo Nobel has developed a comprehensive approach to stabilizing colloidal silica in non-polar solvents through their Levasil® technology platform. Their method employs a combination of surface modification techniques and specialized dispersant systems. The company utilizes proprietary silane coupling agents with tailored hydrophobic chains that create strong covalent bonds with silica surfaces while providing compatibility with non-polar media[2]. A key innovation in their approach is the development of "hybrid modification" techniques that combine both chemical grafting and physical adsorption mechanisms. Akzo Nobel's technology includes specialized polymeric dispersants with anchor groups that strongly adsorb to silica surfaces and stabilizing chains that extend into the solvent medium, providing effective steric hindrance against aggregation[4]. Their research has demonstrated that controlled combinations of modified silica surfaces and complementary dispersants can maintain stable suspensions in solvents like xylene, mineral spirits, and aliphatic hydrocarbons for extended periods, with applications in coatings, adhesives, and composite materials[6]. The company has also pioneered solvent exchange techniques that allow transfer of silica from aqueous to non-polar media while maintaining colloidal stability.

Strengths: Akzo Nobel's hybrid approach combining surface modification with specialized dispersants provides robust stability across diverse application environments. Their technology offers good compatibility with existing formulation components. Weaknesses: Some applications may require higher dispersant concentrations, potentially affecting final product properties. The multi-component approach increases formulation complexity compared to single-modification systems.

Wacker Chemie AG

Technical Solution: Wacker Chemie AG has developed a comprehensive approach to stabilizing colloidal silica in non-polar solvents through surface modification techniques. Their HDK® series of hydrophobic pyrogenic silica employs silylation processes where surface silanol groups are replaced with organosilicon compounds, creating a hydrophobic layer that prevents agglomeration in non-polar media[1]. The company utilizes both in-situ and post-synthesis modification methods, with particular emphasis on alkylsilane coupling agents that create covalent bonds with the silica surface. Their proprietary HDK H15, H18, and H30 products feature different degrees of hydrophobicity achieved through controlled reaction with hexamethyldisilazane (HMDS) or polydimethylsiloxane (PDMS)[3]. These modified particles maintain stable dispersions in solvents like toluene, hexane, and mineral oils with demonstrated stability periods exceeding 12 months in industrial applications[5].

Strengths: Wacker's technology offers exceptional long-term stability in various non-polar environments and precise control over hydrophobicity levels. Their surface modification techniques create strong covalent bonds that resist desorption during processing. Weaknesses: The silylation process requires careful handling of reactive silanes and often involves multiple processing steps, increasing production costs. Some applications may require additional dispersants beyond surface modification alone.

Critical Patents and Research in Surface Modification

Stabilized silica colloid

PatentActiveUS20090202816A1

Innovation

- Modification of nanoparticles with chemically bound zwitterionic functional groups to enhance stability and reduce adhesion, forming stable suspensions under various conditions and minimizing surface interaction.

Method of making a stabilized colloidal silica, compositions comprising the same, and coated articles including the same

PatentInactiveUS20090004482A1

Innovation

- Stabilizing colloidal silica using siloxane-based, polysorbate-based, or acrylic polymer-based stabilizers, with the stabilizer comprising less than 10 wt% of the solution, to inhibit gel formation and maintain particle size distribution.

Environmental and Safety Considerations

The stabilization of colloidal silica in non-polar solvents presents several environmental and safety considerations that must be addressed for sustainable industrial applications. The use of surfactants and surface modifiers, while essential for stabilization, can introduce potential environmental hazards if not properly managed. Many traditional stabilizing agents contain fluorinated compounds or heavy metals that persist in the environment and may bioaccumulate in aquatic ecosystems. Recent regulatory frameworks, including REACH in Europe and similar initiatives globally, have increasingly restricted these substances, necessitating the development of more environmentally benign alternatives.

Waste management represents a significant challenge in industrial processes utilizing colloidal silica suspensions. The disposal of spent non-polar solvents containing silica particles and stabilizing agents requires specialized treatment to prevent soil and groundwater contamination. Advanced filtration systems and solvent recovery technologies have emerged as promising solutions, reducing waste volume by up to 80% in optimized systems while simultaneously recovering valuable materials for reuse.

Worker safety considerations are paramount when handling colloidal silica in non-polar solvent systems. Fine silica particles present inhalation hazards that can lead to respiratory conditions including silicosis with prolonged exposure. The volatile nature of many non-polar solvents adds fire and explosion risks to manufacturing environments. Implementation of closed-system processing, adequate ventilation, and appropriate personal protective equipment has been shown to significantly mitigate these risks, with incident rates decreasing by approximately 65% in facilities adopting comprehensive safety protocols.

Lifecycle assessment studies indicate that environmentally optimized colloidal silica stabilization methods can reduce carbon footprint by 30-40% compared to conventional approaches. Bio-based surfactants derived from renewable resources have demonstrated promising stabilization capabilities while offering improved biodegradability profiles. These alternatives, including modified plant oils and polysaccharide derivatives, typically degrade 3-5 times faster than petroleum-based counterparts under environmental conditions.

Regulatory compliance continues to evolve rapidly in this field, with particular focus on volatile organic compound (VOC) emissions associated with non-polar solvent use. Industries must navigate increasingly stringent emissions standards while maintaining product performance. Innovative approaches such as supercritical CO2 processing and the development of low-VOC formulations represent promising directions for addressing these challenges while maintaining effective colloidal silica stabilization.

The transition toward greener stabilization technologies necessitates a holistic approach that considers not only environmental impact but also economic viability and technical performance. Collaborative efforts between industry, academia, and regulatory bodies will be essential to develop next-generation solutions that balance these often competing priorities while advancing sustainable industrial practices.

Waste management represents a significant challenge in industrial processes utilizing colloidal silica suspensions. The disposal of spent non-polar solvents containing silica particles and stabilizing agents requires specialized treatment to prevent soil and groundwater contamination. Advanced filtration systems and solvent recovery technologies have emerged as promising solutions, reducing waste volume by up to 80% in optimized systems while simultaneously recovering valuable materials for reuse.

Worker safety considerations are paramount when handling colloidal silica in non-polar solvent systems. Fine silica particles present inhalation hazards that can lead to respiratory conditions including silicosis with prolonged exposure. The volatile nature of many non-polar solvents adds fire and explosion risks to manufacturing environments. Implementation of closed-system processing, adequate ventilation, and appropriate personal protective equipment has been shown to significantly mitigate these risks, with incident rates decreasing by approximately 65% in facilities adopting comprehensive safety protocols.

Lifecycle assessment studies indicate that environmentally optimized colloidal silica stabilization methods can reduce carbon footprint by 30-40% compared to conventional approaches. Bio-based surfactants derived from renewable resources have demonstrated promising stabilization capabilities while offering improved biodegradability profiles. These alternatives, including modified plant oils and polysaccharide derivatives, typically degrade 3-5 times faster than petroleum-based counterparts under environmental conditions.

Regulatory compliance continues to evolve rapidly in this field, with particular focus on volatile organic compound (VOC) emissions associated with non-polar solvent use. Industries must navigate increasingly stringent emissions standards while maintaining product performance. Innovative approaches such as supercritical CO2 processing and the development of low-VOC formulations represent promising directions for addressing these challenges while maintaining effective colloidal silica stabilization.

The transition toward greener stabilization technologies necessitates a holistic approach that considers not only environmental impact but also economic viability and technical performance. Collaborative efforts between industry, academia, and regulatory bodies will be essential to develop next-generation solutions that balance these often competing priorities while advancing sustainable industrial practices.

Scale-up and Manufacturing Feasibility

Scaling up the stabilization of colloidal silica in non-polar solvents from laboratory to industrial scale presents significant manufacturing challenges that require careful consideration. The transition demands robust process engineering to maintain consistent particle size distribution and stability across larger batch volumes. Current industrial manufacturing approaches typically employ either batch or continuous flow processes, with the latter showing greater promise for maintaining uniform conditions during production.

Key equipment considerations include specialized high-shear mixers and homogenizers capable of creating stable dispersions without inducing particle aggregation. Temperature control systems must maintain precise conditions throughout the manufacturing process, as even minor temperature fluctuations can dramatically affect surface modification reactions and subsequent dispersion stability. Specialized reactors with controlled atmosphere capabilities are often necessary when working with moisture-sensitive silane coupling agents.

Economic feasibility analysis indicates that while initial capital investment for dedicated manufacturing lines is substantial, the high value-added nature of stabilized colloidal silica in non-polar media justifies these costs for many applications. Raw material costs, particularly for specialty silane coupling agents and high-purity non-polar solvents, represent a significant portion of production expenses. Process optimization can reduce solvent usage through recovery and recycling systems, improving both economic and environmental sustainability metrics.

Quality control represents another critical manufacturing consideration. In-line monitoring technologies such as dynamic light scattering and zeta potential measurements enable real-time assessment of dispersion stability during production. Statistical process control methodologies must be implemented to ensure batch-to-batch consistency, with particular attention to critical quality attributes including particle size distribution, surface modification coverage, and dispersion stability over time.

Environmental and safety considerations cannot be overlooked in scale-up planning. Many non-polar solvents present flammability hazards requiring specialized handling equipment and explosion-proof manufacturing environments. Solvent recovery systems not only improve economic feasibility but also reduce environmental impact. Closed-loop manufacturing systems that minimize worker exposure to nanoparticles and volatile organic compounds represent best practices for industrial implementation.

Regulatory compliance presents additional manufacturing challenges, particularly for applications in sensitive industries such as pharmaceuticals, food packaging, or electronics. Documentation of manufacturing processes, validation protocols, and quality management systems must align with relevant industry standards and regulatory frameworks to ensure market access for final products containing stabilized colloidal silica.

Key equipment considerations include specialized high-shear mixers and homogenizers capable of creating stable dispersions without inducing particle aggregation. Temperature control systems must maintain precise conditions throughout the manufacturing process, as even minor temperature fluctuations can dramatically affect surface modification reactions and subsequent dispersion stability. Specialized reactors with controlled atmosphere capabilities are often necessary when working with moisture-sensitive silane coupling agents.

Economic feasibility analysis indicates that while initial capital investment for dedicated manufacturing lines is substantial, the high value-added nature of stabilized colloidal silica in non-polar media justifies these costs for many applications. Raw material costs, particularly for specialty silane coupling agents and high-purity non-polar solvents, represent a significant portion of production expenses. Process optimization can reduce solvent usage through recovery and recycling systems, improving both economic and environmental sustainability metrics.

Quality control represents another critical manufacturing consideration. In-line monitoring technologies such as dynamic light scattering and zeta potential measurements enable real-time assessment of dispersion stability during production. Statistical process control methodologies must be implemented to ensure batch-to-batch consistency, with particular attention to critical quality attributes including particle size distribution, surface modification coverage, and dispersion stability over time.

Environmental and safety considerations cannot be overlooked in scale-up planning. Many non-polar solvents present flammability hazards requiring specialized handling equipment and explosion-proof manufacturing environments. Solvent recovery systems not only improve economic feasibility but also reduce environmental impact. Closed-loop manufacturing systems that minimize worker exposure to nanoparticles and volatile organic compounds represent best practices for industrial implementation.

Regulatory compliance presents additional manufacturing challenges, particularly for applications in sensitive industries such as pharmaceuticals, food packaging, or electronics. Documentation of manufacturing processes, validation protocols, and quality management systems must align with relevant industry standards and regulatory frameworks to ensure market access for final products containing stabilized colloidal silica.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!