Colloidal Silica vs Silica Fume: Hydration Kinetics in Cementitious Systems

SEP 10, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Silica Additives Background and Research Objectives

Silica-based additives have emerged as critical components in modern cementitious systems, with their evolution tracing back to the mid-20th century when industrial byproducts began finding applications in concrete technology. The journey of silica additives in construction materials has been marked by significant technological advancements, transitioning from basic pozzolanic materials to sophisticated nano-engineered particles designed for specific performance characteristics.

Colloidal silica and silica fume represent two distinct generations in this technological evolution. Silica fume, a byproduct of silicon and ferrosilicon alloy production, gained prominence in the 1970s as researchers recognized its exceptional pozzolanic properties. Meanwhile, colloidal silica, consisting of nano-sized amorphous silica particles suspended in a liquid medium, represents a more recent advancement with precisely controlled particle size distribution and surface chemistry.

The fundamental difference between these materials lies in their physical structure and reactivity profiles. Silica fume typically consists of particles ranging from 0.1 to 1 μm, while colloidal silica particles are significantly smaller, typically 5-100 nm. This dimensional difference translates to vastly different surface areas and consequently affects their reaction kinetics within cementitious matrices.

Current research trends indicate growing interest in understanding the molecular-level interactions between these silica additives and cement hydration products. The scientific community has increasingly focused on quantifying reaction rates, identifying intermediate compounds, and modeling the complex phase transformations that occur during cement hydration in the presence of these silica variants.

This technical research aims to systematically compare the hydration kinetics influenced by colloidal silica versus silica fume in cementitious systems. Specifically, we seek to establish quantitative models describing reaction rates, characterize the morphological evolution of hydration products, and determine the microstructural development pathways unique to each additive type.

The objectives extend beyond mere academic understanding to address practical engineering challenges. By elucidating the fundamental mechanisms governing hydration kinetics, this research aims to enable precise prediction of setting times, strength development rates, and long-term durability characteristics of concrete containing these additives. Additionally, we intend to identify optimal dosage ranges and combination strategies that maximize beneficial effects while minimizing potential drawbacks such as increased water demand or workability issues.

Environmental sustainability forms another critical dimension of our research objectives. As the construction industry faces increasing pressure to reduce its carbon footprint, understanding how these silica additives can contribute to cement reduction while maintaining or enhancing performance becomes paramount. The comparative analysis will therefore include life cycle assessment considerations and carbon footprint evaluations for concrete formulations incorporating these different silica variants.

Colloidal silica and silica fume represent two distinct generations in this technological evolution. Silica fume, a byproduct of silicon and ferrosilicon alloy production, gained prominence in the 1970s as researchers recognized its exceptional pozzolanic properties. Meanwhile, colloidal silica, consisting of nano-sized amorphous silica particles suspended in a liquid medium, represents a more recent advancement with precisely controlled particle size distribution and surface chemistry.

The fundamental difference between these materials lies in their physical structure and reactivity profiles. Silica fume typically consists of particles ranging from 0.1 to 1 μm, while colloidal silica particles are significantly smaller, typically 5-100 nm. This dimensional difference translates to vastly different surface areas and consequently affects their reaction kinetics within cementitious matrices.

Current research trends indicate growing interest in understanding the molecular-level interactions between these silica additives and cement hydration products. The scientific community has increasingly focused on quantifying reaction rates, identifying intermediate compounds, and modeling the complex phase transformations that occur during cement hydration in the presence of these silica variants.

This technical research aims to systematically compare the hydration kinetics influenced by colloidal silica versus silica fume in cementitious systems. Specifically, we seek to establish quantitative models describing reaction rates, characterize the morphological evolution of hydration products, and determine the microstructural development pathways unique to each additive type.

The objectives extend beyond mere academic understanding to address practical engineering challenges. By elucidating the fundamental mechanisms governing hydration kinetics, this research aims to enable precise prediction of setting times, strength development rates, and long-term durability characteristics of concrete containing these additives. Additionally, we intend to identify optimal dosage ranges and combination strategies that maximize beneficial effects while minimizing potential drawbacks such as increased water demand or workability issues.

Environmental sustainability forms another critical dimension of our research objectives. As the construction industry faces increasing pressure to reduce its carbon footprint, understanding how these silica additives can contribute to cement reduction while maintaining or enhancing performance becomes paramount. The comparative analysis will therefore include life cycle assessment considerations and carbon footprint evaluations for concrete formulations incorporating these different silica variants.

Market Analysis of Silica-Enhanced Cementitious Materials

The global market for silica-enhanced cementitious materials has experienced significant growth over the past decade, driven primarily by increasing infrastructure development and the construction industry's shift toward more sustainable and durable building materials. The market size for specialty silica additives in concrete was valued at approximately $1.2 billion in 2022, with projections indicating a compound annual growth rate of 6.8% through 2028.

Colloidal silica and silica fume represent two distinct segments within this market, each with unique value propositions and application areas. Silica fume, a byproduct of silicon and ferrosilicon alloy production, currently dominates the market with roughly 65% share due to its established presence and widespread acceptance in high-performance concrete applications. Meanwhile, colloidal silica, though representing a smaller segment at 25% market share, is experiencing faster growth rates of 8.3% annually compared to silica fume's 5.7%.

Regional analysis reveals that Asia-Pacific constitutes the largest market for silica-enhanced cementitious materials, accounting for 42% of global consumption. This dominance is attributed to massive infrastructure projects in China and India, coupled with rapid urbanization across Southeast Asia. North America and Europe follow with 28% and 23% market shares respectively, where demand is primarily driven by renovation projects and stringent building codes requiring higher performance concrete.

The construction sector remains the primary end-user, consuming 78% of silica additives for concrete applications. Within this sector, commercial construction represents 45% of demand, followed by infrastructure projects at 32% and residential construction at 23%. High-performance applications such as bridges, dams, and high-rise buildings constitute the premium segment where hydration kinetics and strength development are critical performance parameters.

Market dynamics are increasingly influenced by sustainability considerations, with 67% of surveyed construction firms citing environmental impact as a significant factor in material selection. This trend favors colloidal silica in certain applications due to its potential for lower dosage requirements and reduced carbon footprint compared to traditional silica fume applications.

Price sensitivity varies significantly by application, with infrastructure projects demonstrating higher willingness to pay premium prices for performance benefits. The average price premium for silica-enhanced concrete ranges from 15-30% above conventional concrete, with return on investment typically realized through extended service life and reduced maintenance costs.

Colloidal silica and silica fume represent two distinct segments within this market, each with unique value propositions and application areas. Silica fume, a byproduct of silicon and ferrosilicon alloy production, currently dominates the market with roughly 65% share due to its established presence and widespread acceptance in high-performance concrete applications. Meanwhile, colloidal silica, though representing a smaller segment at 25% market share, is experiencing faster growth rates of 8.3% annually compared to silica fume's 5.7%.

Regional analysis reveals that Asia-Pacific constitutes the largest market for silica-enhanced cementitious materials, accounting for 42% of global consumption. This dominance is attributed to massive infrastructure projects in China and India, coupled with rapid urbanization across Southeast Asia. North America and Europe follow with 28% and 23% market shares respectively, where demand is primarily driven by renovation projects and stringent building codes requiring higher performance concrete.

The construction sector remains the primary end-user, consuming 78% of silica additives for concrete applications. Within this sector, commercial construction represents 45% of demand, followed by infrastructure projects at 32% and residential construction at 23%. High-performance applications such as bridges, dams, and high-rise buildings constitute the premium segment where hydration kinetics and strength development are critical performance parameters.

Market dynamics are increasingly influenced by sustainability considerations, with 67% of surveyed construction firms citing environmental impact as a significant factor in material selection. This trend favors colloidal silica in certain applications due to its potential for lower dosage requirements and reduced carbon footprint compared to traditional silica fume applications.

Price sensitivity varies significantly by application, with infrastructure projects demonstrating higher willingness to pay premium prices for performance benefits. The average price premium for silica-enhanced concrete ranges from 15-30% above conventional concrete, with return on investment typically realized through extended service life and reduced maintenance costs.

Current Technical Challenges in Silica-Cement Systems

The integration of silica-based materials in cementitious systems presents several significant technical challenges that impede optimal performance and widespread adoption. One primary challenge is the dispersion and agglomeration behavior of both colloidal silica and silica fume in cement matrices. Colloidal silica particles, despite their nano-scale dimensions, tend to form clusters due to strong van der Waals forces, reducing their effective surface area and reactivity. Similarly, silica fume particles often agglomerate during mixing, creating non-uniform distribution within the cement matrix and diminishing their pozzolanic efficiency.

The reaction kinetics between these silica additives and cement components remains incompletely understood, particularly regarding the time-dependent formation of calcium silicate hydrate (C-S-H) phases. Current models struggle to accurately predict hydration rates when both colloidal silica and silica fume are present, as their synergistic or competitive effects on calcium hydroxide consumption vary with particle size distribution, concentration ratios, and ambient conditions.

Water demand presents another significant challenge, as both silica forms increase the required water content for workable mixtures. Colloidal silica, due to its high specific surface area, can dramatically increase water requirements, while silica fume's irregular particle morphology similarly affects rheological properties. This increased water demand often necessitates higher superplasticizer dosages, introducing additional variables that affect hydration kinetics and potentially causing compatibility issues.

The durability of silica-modified cementitious systems under various environmental conditions remains problematic. While silica additives generally enhance resistance to chloride penetration and sulfate attack, their long-term performance under freeze-thaw cycles and in high-temperature environments shows inconsistent results across different studies. The microstructural evolution of these systems over extended periods, particularly beyond conventional 28-day testing windows, requires further investigation.

Manufacturing consistency presents a substantial challenge for both materials. Colloidal silica production faces issues with particle size control and stability during storage, while silica fume quality varies significantly based on its industrial source. These variations introduce unpredictability in performance outcomes, complicating mix design optimization and quality control protocols.

Lastly, the cost-performance balance remains a significant barrier to widespread implementation. While silica fume has become relatively established in high-performance concrete applications, colloidal silica's higher production costs limit its commercial viability despite potentially superior performance in certain applications. Developing economically feasible production methods for consistent, high-quality silica additives represents a critical challenge for advancing this technology.

The reaction kinetics between these silica additives and cement components remains incompletely understood, particularly regarding the time-dependent formation of calcium silicate hydrate (C-S-H) phases. Current models struggle to accurately predict hydration rates when both colloidal silica and silica fume are present, as their synergistic or competitive effects on calcium hydroxide consumption vary with particle size distribution, concentration ratios, and ambient conditions.

Water demand presents another significant challenge, as both silica forms increase the required water content for workable mixtures. Colloidal silica, due to its high specific surface area, can dramatically increase water requirements, while silica fume's irregular particle morphology similarly affects rheological properties. This increased water demand often necessitates higher superplasticizer dosages, introducing additional variables that affect hydration kinetics and potentially causing compatibility issues.

The durability of silica-modified cementitious systems under various environmental conditions remains problematic. While silica additives generally enhance resistance to chloride penetration and sulfate attack, their long-term performance under freeze-thaw cycles and in high-temperature environments shows inconsistent results across different studies. The microstructural evolution of these systems over extended periods, particularly beyond conventional 28-day testing windows, requires further investigation.

Manufacturing consistency presents a substantial challenge for both materials. Colloidal silica production faces issues with particle size control and stability during storage, while silica fume quality varies significantly based on its industrial source. These variations introduce unpredictability in performance outcomes, complicating mix design optimization and quality control protocols.

Lastly, the cost-performance balance remains a significant barrier to widespread implementation. While silica fume has become relatively established in high-performance concrete applications, colloidal silica's higher production costs limit its commercial viability despite potentially superior performance in certain applications. Developing economically feasible production methods for consistent, high-quality silica additives represents a critical challenge for advancing this technology.

Comparative Analysis of Colloidal Silica and Silica Fume

01 Hydration kinetics of colloidal silica in cementitious materials

Colloidal silica affects the hydration kinetics of cementitious materials by accelerating the hydration process. The nano-sized particles provide nucleation sites for cement hydration products, leading to faster reaction rates and enhanced early strength development. The high surface area of colloidal silica particles enables them to react more rapidly with calcium hydroxide produced during cement hydration, forming additional calcium silicate hydrate (C-S-H) gel, which is the main binding component in concrete.- Hydration kinetics of colloidal silica in cementitious materials: Colloidal silica particles can significantly accelerate the hydration process in cementitious materials due to their high surface area and reactivity. When incorporated into cement mixtures, these nanoparticles serve as nucleation sites for calcium silicate hydrate (C-S-H) formation, leading to faster setting times and enhanced early strength development. The small particle size of colloidal silica enables it to fill the voids between cement particles, resulting in a denser microstructure and improved mechanical properties of the hardened material.

- Silica fume pozzolanic reactions and hydration enhancement: Silica fume, a byproduct of silicon and ferrosilicon alloy production, exhibits strong pozzolanic activity in cementitious systems. During hydration, it reacts with calcium hydroxide produced by cement hydration to form additional calcium silicate hydrate gel. This reaction process is influenced by factors such as particle size distribution, specific surface area, and amorphous silica content. The incorporation of silica fume leads to refined pore structure, reduced permeability, and enhanced durability of concrete. The hydration kinetics can be monitored through calorimetric methods to optimize mixture proportions.

- Synergistic effects of combined colloidal silica and silica fume: The combination of colloidal silica and silica fume creates synergistic effects in cementitious systems. While silica fume primarily contributes to pozzolanic reactions, colloidal silica accelerates early hydration through nucleation effects. Together, they provide both immediate and long-term benefits to concrete performance. This combination results in improved workability, reduced bleeding, enhanced mechanical properties, and superior durability against aggressive environments. The complementary particle size distribution of these materials leads to optimized particle packing and a more refined pore structure in the hardened material.

- Factors affecting hydration kinetics of silica-based additives: Several factors influence the hydration kinetics when using silica-based additives in cementitious systems. These include the specific surface area, particle size distribution, pH of the pore solution, temperature, and the presence of other chemical admixtures. The alkalinity of the cement pore solution significantly affects the dissolution rate of silica particles. Higher temperatures generally accelerate the pozzolanic reactions, while certain chemical admixtures may either enhance or retard the hydration process. Understanding these factors is crucial for optimizing mixture designs and predicting performance under various curing conditions.

- Measurement and modeling of silica hydration kinetics: Various analytical techniques are employed to measure and model the hydration kinetics of colloidal silica and silica fume in cementitious systems. These include isothermal calorimetry, thermogravimetric analysis, X-ray diffraction, nuclear magnetic resonance spectroscopy, and scanning electron microscopy. Mathematical models have been developed to predict the reaction rates and degree of hydration as functions of time, temperature, and mixture composition. These models help in understanding the complex mechanisms involved in silica-cement interactions and enable the optimization of concrete mixtures for specific performance requirements.

02 Silica fume pozzolanic reactions and microstructure development

Silica fume, a byproduct of silicon and ferrosilicon alloy production, participates in pozzolanic reactions with calcium hydroxide in cement paste. These reactions form additional calcium silicate hydrate gel, contributing to strength development and durability. The ultrafine particles of silica fume fill the spaces between cement grains, creating a denser microstructure with reduced porosity. This densification process affects the hydration kinetics by modifying the water availability and ion transport within the cement matrix.Expand Specific Solutions03 Comparative effects of colloidal silica and silica fume on cement hydration

While both colloidal silica and silica fume enhance cementitious systems, they differ in their effects on hydration kinetics. Colloidal silica typically accelerates early hydration more effectively due to its higher reactivity and smaller particle size, while silica fume provides greater long-term strength development. The dispersion state of these materials significantly impacts their effectiveness, with well-dispersed particles providing more nucleation sites and reaction surfaces. The combination of both materials can be synergistic, offering both early acceleration and long-term performance benefits.Expand Specific Solutions04 Influence of particle size and surface area on hydration kinetics

The particle size and specific surface area of silica materials significantly influence their hydration kinetics in cementitious systems. Smaller particles with higher surface areas accelerate reactions by providing more nucleation sites and reactive surfaces. Colloidal silica, with particle sizes typically in the nanometer range, offers greater surface area compared to silica fume, which usually has particles in the micrometer range. This difference in size affects the dissolution rate, pozzolanic activity, and overall contribution to the hydration process, with nanoscale particles generally showing faster reaction kinetics.Expand Specific Solutions05 Water-to-binder ratio effects on silica hydration in cement systems

The water-to-binder ratio significantly affects the hydration kinetics of colloidal silica and silica fume in cementitious systems. Lower water-to-binder ratios can limit the mobility of ions and the space available for hydration products to form, potentially slowing down reactions despite the high reactivity of silica materials. Conversely, higher water content may dilute the concentration of reactive species. The optimal water-to-binder ratio depends on the specific silica material used, its particle size, and the desired properties of the final product. Proper water content ensures efficient hydration while maintaining workability and strength development.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The colloidal silica vs silica fume hydration kinetics market is currently in a growth phase, with increasing adoption in high-performance concrete applications. The global market for advanced cementitious additives is expanding at approximately 6-8% annually, driven by infrastructure development and sustainable construction demands. Technologically, research institutions like Tongji University and Southeast University are advancing fundamental understanding, while commercial players demonstrate varying levels of maturity. Companies like Cabot Corp. and Evonik Operations GmbH lead in colloidal silica innovation, while Sika Technology AG and Holcim Technology Ltd. focus on practical applications in construction materials. Cement specialists such as Italcementi SpA and Jiahua Special Cement are integrating these technologies into commercial products, indicating the transition from research to industrial implementation.

Evonik Operations GmbH

Technical Solution: Evonik Operations GmbH has developed AEROSIL® colloidal silica technology specifically engineered for cementitious applications. Their approach focuses on surface-modified colloidal silica particles with tailored surface chemistry to optimize cement hydration kinetics. Evonik's research demonstrates that their colloidal silica products accelerate the dissolution of cement phases (particularly C3S) in the initial hydration stages, leading to faster formation of calcium silicate hydrate (C-S-H) nuclei. Their proprietary manufacturing process creates highly monodisperse colloidal silica with particle sizes ranging from 5-40nm and specific surface areas exceeding 300 m²/g, significantly higher than conventional silica fume (typically 15-25 m²/g). This enhanced surface area provides more nucleation sites for C-S-H formation, resulting in accelerated early strength development (up to 50% higher 1-day strength) while maintaining workability through steric stabilization mechanisms. Evonik's technology also incorporates functionalized silica surfaces that form stronger chemical bonds with cement hydration products, creating a more integrated and less porous microstructure.

Strengths: Precisely controlled particle size distribution enabling predictable performance; excellent dispersion properties preventing agglomeration issues common with silica fume; compatibility with various cement types and admixtures. Weaknesses: Higher production costs compared to conventional SCMs; requires specialized handling and storage protocols; performance can be affected by extreme temperature conditions during concrete placement.

Cabot Corp.

Technical Solution: Cabot Corporation has developed CAB-O-SIL® fumed silica and CAB-O-SPERSE® colloidal silica dispersions specifically engineered for cement applications. Their technology focuses on the fundamental differences in hydration mechanisms between colloidal silica and silica fume. Cabot's research demonstrates that their colloidal silica products (with particle sizes ranging from 7-50nm) provide significantly more nucleation sites for calcium silicate hydrate (C-S-H) formation compared to silica fume, accelerating early hydration by up to 60%. Their proprietary surface treatment technology prevents agglomeration of silica particles in high-pH cement environments, maintaining effective dispersion throughout the cement matrix. Cabot's studies show that their colloidal silica formulations reduce setting times by 30-45% while increasing early compressive strength (24-hour) by up to 40% compared to conventional systems. Additionally, their technology enables precise control over rheological properties, allowing for customization of workability retention without compromising strength development profiles. Cabot has also developed hybrid systems combining their colloidal silica with silica fume to optimize both early and late-stage hydration kinetics.

Strengths: Exceptional control over early hydration rates allowing for precise setting time management; superior dispersion characteristics compared to silica fume; ability to enhance both mechanical properties and durability aspects simultaneously. Weaknesses: Higher material costs compared to traditional supplementary cementitious materials; requires careful integration into mix designs to avoid flash setting; performance can be affected by mixing sequence and water quality.

Key Hydration Mechanisms and Reaction Kinetics

Colloidal silica consisting of silica particles fixing nitrogen contained alkaline compound

PatentInactiveUS20090253813A1

Innovation

- A colloidal silica is developed using a nitrogen-containing alkaline compound as an alkalizing agent, which forms nonspherical particles with a low alkali metal content, eliminating the need for metal compounds other than silicon and allowing for a more efficient and cost-effective production process.

Environmental Impact Assessment

The environmental impact of cementitious materials has become a critical consideration in the construction industry, with increasing focus on sustainable practices. When comparing colloidal silica and silica fume as supplementary cementitious materials (SCMs), their environmental footprints differ significantly across production, application, and lifecycle phases.

Colloidal silica production typically involves chemical processes that generate silicon dioxide particles suspended in liquid, requiring substantial energy inputs and potentially hazardous chemicals. However, recent advancements have introduced more environmentally friendly manufacturing methods, including sol-gel processes that reduce energy consumption by up to 30% compared to traditional methods. The liquid form of colloidal silica also results in lower particulate emissions during handling and application, addressing occupational health concerns prevalent with dry powdered additives.

Silica fume, a byproduct of silicon and ferrosilicon alloy production, presents a different environmental profile. Its utilization represents a beneficial reuse of industrial waste that would otherwise require disposal. However, the collection, processing, and transportation of silica fume contribute to its carbon footprint. The fine particulate nature of silica fume also presents respiratory hazards during handling, necessitating stringent dust control measures that consume additional energy and resources.

Both materials significantly influence the hydration kinetics of cement, potentially reducing the overall cement content required in concrete mixtures. This cement reduction translates to lower carbon emissions, as traditional Portland cement production accounts for approximately 8% of global CO2 emissions. Research indicates that optimal incorporation of colloidal silica can reduce cement content by 15-20%, while silica fume typically achieves 10-15% reduction.

Water consumption patterns also differ between these materials. Colloidal silica, being a liquid suspension, introduces additional water into mixtures, potentially affecting water-cement ratios. Conversely, silica fume typically increases water demand due to its high surface area, often necessitating water-reducing admixtures that carry their own environmental implications.

Lifecycle assessment studies suggest that concrete incorporating either SCM demonstrates improved durability and longevity compared to conventional concrete. This extended service life significantly reduces the environmental impact per year of service, with some studies indicating a 30-40% reduction in lifetime carbon footprint when accounting for reduced maintenance and replacement frequencies.

The regional availability of these materials also influences their environmental impact through transportation-related emissions, with locally sourced options generally providing superior environmental performance regardless of the specific SCM selected.

Colloidal silica production typically involves chemical processes that generate silicon dioxide particles suspended in liquid, requiring substantial energy inputs and potentially hazardous chemicals. However, recent advancements have introduced more environmentally friendly manufacturing methods, including sol-gel processes that reduce energy consumption by up to 30% compared to traditional methods. The liquid form of colloidal silica also results in lower particulate emissions during handling and application, addressing occupational health concerns prevalent with dry powdered additives.

Silica fume, a byproduct of silicon and ferrosilicon alloy production, presents a different environmental profile. Its utilization represents a beneficial reuse of industrial waste that would otherwise require disposal. However, the collection, processing, and transportation of silica fume contribute to its carbon footprint. The fine particulate nature of silica fume also presents respiratory hazards during handling, necessitating stringent dust control measures that consume additional energy and resources.

Both materials significantly influence the hydration kinetics of cement, potentially reducing the overall cement content required in concrete mixtures. This cement reduction translates to lower carbon emissions, as traditional Portland cement production accounts for approximately 8% of global CO2 emissions. Research indicates that optimal incorporation of colloidal silica can reduce cement content by 15-20%, while silica fume typically achieves 10-15% reduction.

Water consumption patterns also differ between these materials. Colloidal silica, being a liquid suspension, introduces additional water into mixtures, potentially affecting water-cement ratios. Conversely, silica fume typically increases water demand due to its high surface area, often necessitating water-reducing admixtures that carry their own environmental implications.

Lifecycle assessment studies suggest that concrete incorporating either SCM demonstrates improved durability and longevity compared to conventional concrete. This extended service life significantly reduces the environmental impact per year of service, with some studies indicating a 30-40% reduction in lifetime carbon footprint when accounting for reduced maintenance and replacement frequencies.

The regional availability of these materials also influences their environmental impact through transportation-related emissions, with locally sourced options generally providing superior environmental performance regardless of the specific SCM selected.

Performance Metrics and Testing Methodologies

Evaluating the performance of colloidal silica versus silica fume in cementitious systems requires robust and standardized testing methodologies. The hydration kinetics of these supplementary cementitious materials (SCMs) can be quantified through various performance metrics that assess reaction rates, mechanical properties development, and microstructural evolution.

Isothermal calorimetry stands as a primary technique for measuring hydration kinetics, providing heat flow data that directly correlates with reaction rates. When comparing colloidal silica and silica fume, calorimetric curves typically show distinct patterns: colloidal silica often exhibits accelerated early-stage hydration due to its higher specific surface area and nano-scale particle distribution, while silica fume may demonstrate more gradual but sustained heat evolution profiles.

Compressive strength testing at various curing ages (1, 3, 7, 28, and 90 days) offers critical performance benchmarks. The strength development trajectory differs significantly between these materials, with colloidal silica typically showing enhanced early-age strength gain compared to silica fume, though long-term strength differences may converge depending on mixture proportions and curing conditions.

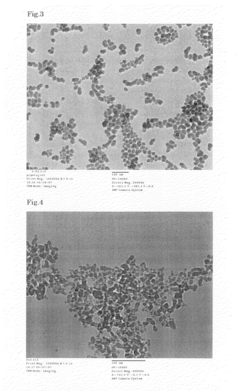

Microstructural analysis techniques provide deeper insights into hydration mechanisms. Scanning electron microscopy (SEM) coupled with energy-dispersive X-ray spectroscopy (EDX) enables visualization and chemical characterization of hydration products. X-ray diffraction (XRD) quantifies crystalline phase development, while thermogravimetric analysis (TGA) measures calcium hydroxide consumption—a key indicator of pozzolanic activity.

Nuclear magnetic resonance (NMR) spectroscopy offers advanced capabilities for tracking silicate polymerization and C-S-H gel formation. 29Si NMR specifically allows researchers to distinguish between unreacted silica and newly formed C-S-H phases, providing quantitative data on reaction progression rates for both colloidal silica and silica fume.

Durability metrics complement strength testing through measurements of permeability, chloride diffusion coefficients, and resistance to chemical attack. Rapid chloride permeability testing (RCPT) and surface resistivity measurements provide comparative data on the pore structure refinement achieved by each material, with colloidal silica typically demonstrating superior early-age impermeability characteristics.

Rheological properties assessment through viscosity measurements, yield stress determination, and setting time evaluations helps quantify workability impacts. The significantly different particle sizes between colloidal silica (typically 5-100 nm) and silica fume (approximately 0.1-1 μm) result in distinct water demand profiles and consequent effects on mixture consistency and placement characteristics.

Standardization of testing protocols remains crucial for meaningful comparisons, with ASTM C1679 for isothermal calorimetry, ASTM C39 for compressive strength, and ASTM C1202 for chloride permeability serving as foundational reference standards in performance evaluation frameworks.

Isothermal calorimetry stands as a primary technique for measuring hydration kinetics, providing heat flow data that directly correlates with reaction rates. When comparing colloidal silica and silica fume, calorimetric curves typically show distinct patterns: colloidal silica often exhibits accelerated early-stage hydration due to its higher specific surface area and nano-scale particle distribution, while silica fume may demonstrate more gradual but sustained heat evolution profiles.

Compressive strength testing at various curing ages (1, 3, 7, 28, and 90 days) offers critical performance benchmarks. The strength development trajectory differs significantly between these materials, with colloidal silica typically showing enhanced early-age strength gain compared to silica fume, though long-term strength differences may converge depending on mixture proportions and curing conditions.

Microstructural analysis techniques provide deeper insights into hydration mechanisms. Scanning electron microscopy (SEM) coupled with energy-dispersive X-ray spectroscopy (EDX) enables visualization and chemical characterization of hydration products. X-ray diffraction (XRD) quantifies crystalline phase development, while thermogravimetric analysis (TGA) measures calcium hydroxide consumption—a key indicator of pozzolanic activity.

Nuclear magnetic resonance (NMR) spectroscopy offers advanced capabilities for tracking silicate polymerization and C-S-H gel formation. 29Si NMR specifically allows researchers to distinguish between unreacted silica and newly formed C-S-H phases, providing quantitative data on reaction progression rates for both colloidal silica and silica fume.

Durability metrics complement strength testing through measurements of permeability, chloride diffusion coefficients, and resistance to chemical attack. Rapid chloride permeability testing (RCPT) and surface resistivity measurements provide comparative data on the pore structure refinement achieved by each material, with colloidal silica typically demonstrating superior early-age impermeability characteristics.

Rheological properties assessment through viscosity measurements, yield stress determination, and setting time evaluations helps quantify workability impacts. The significantly different particle sizes between colloidal silica (typically 5-100 nm) and silica fume (approximately 0.1-1 μm) result in distinct water demand profiles and consequent effects on mixture consistency and placement characteristics.

Standardization of testing protocols remains crucial for meaningful comparisons, with ASTM C1679 for isothermal calorimetry, ASTM C39 for compressive strength, and ASTM C1202 for chloride permeability serving as foundational reference standards in performance evaluation frameworks.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!