Optimizing Colloidal Silica Dispersion in Polymer Composites for Strength

SEP 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Colloidal Silica-Polymer Composite Background and Objectives

Colloidal silica-polymer composites represent a significant advancement in materials science, emerging from decades of research into nanoparticle reinforcement technologies. Since the 1990s, researchers have recognized the potential of silica nanoparticles to dramatically enhance polymer mechanical properties. The evolution of this technology has progressed from simple mixing methods with limited dispersion quality to sophisticated surface modification techniques that enable unprecedented integration between organic polymers and inorganic silica particles.

The fundamental principle behind these composites lies in the exceptional surface area-to-volume ratio of colloidal silica particles, typically ranging from 5-100 nm in diameter. This characteristic enables extensive interfacial interactions with polymer matrices, creating materials with superior mechanical properties compared to conventional composites. Historical development shows a clear trajectory from early experimental applications toward increasingly controlled and predictable manufacturing processes.

Current technological trends indicate a shift toward precision engineering of the silica-polymer interface. This includes tailored surface functionalization of silica particles to optimize compatibility with specific polymer matrices, controlled aggregation strategies to create hierarchical structures, and in-situ polymerization techniques that enhance dispersion quality. These advancements address the persistent challenge of nanoparticle agglomeration that has historically limited performance gains.

The primary technical objective in this field is to develop systematic approaches for optimizing colloidal silica dispersion within polymer matrices to maximize mechanical strength enhancement while maintaining other desirable properties such as processability and optical clarity. This requires balancing competing factors including particle size distribution, surface chemistry, concentration thresholds, and processing parameters.

Secondary objectives include establishing quantitative models that can predict composite performance based on dispersion characteristics, developing scalable manufacturing protocols suitable for industrial implementation, and exploring multi-functional capabilities where mechanical reinforcement coexists with other properties such as thermal stability, barrier performance, or self-healing capabilities.

The significance of this technology extends beyond academic interest, as improved silica-polymer composites could revolutionize multiple industries. In automotive and aerospace sectors, stronger yet lighter materials translate directly to fuel efficiency gains. In construction, enhanced durability means longer-lasting infrastructure. Medical applications benefit from biocompatible materials with precisely engineered mechanical properties matching biological tissues.

As we look toward future developments, the convergence of nanotechnology, computational modeling, and advanced characterization techniques promises to accelerate innovation in this field, potentially enabling designer composites with previously unattainable property combinations.

The fundamental principle behind these composites lies in the exceptional surface area-to-volume ratio of colloidal silica particles, typically ranging from 5-100 nm in diameter. This characteristic enables extensive interfacial interactions with polymer matrices, creating materials with superior mechanical properties compared to conventional composites. Historical development shows a clear trajectory from early experimental applications toward increasingly controlled and predictable manufacturing processes.

Current technological trends indicate a shift toward precision engineering of the silica-polymer interface. This includes tailored surface functionalization of silica particles to optimize compatibility with specific polymer matrices, controlled aggregation strategies to create hierarchical structures, and in-situ polymerization techniques that enhance dispersion quality. These advancements address the persistent challenge of nanoparticle agglomeration that has historically limited performance gains.

The primary technical objective in this field is to develop systematic approaches for optimizing colloidal silica dispersion within polymer matrices to maximize mechanical strength enhancement while maintaining other desirable properties such as processability and optical clarity. This requires balancing competing factors including particle size distribution, surface chemistry, concentration thresholds, and processing parameters.

Secondary objectives include establishing quantitative models that can predict composite performance based on dispersion characteristics, developing scalable manufacturing protocols suitable for industrial implementation, and exploring multi-functional capabilities where mechanical reinforcement coexists with other properties such as thermal stability, barrier performance, or self-healing capabilities.

The significance of this technology extends beyond academic interest, as improved silica-polymer composites could revolutionize multiple industries. In automotive and aerospace sectors, stronger yet lighter materials translate directly to fuel efficiency gains. In construction, enhanced durability means longer-lasting infrastructure. Medical applications benefit from biocompatible materials with precisely engineered mechanical properties matching biological tissues.

As we look toward future developments, the convergence of nanotechnology, computational modeling, and advanced characterization techniques promises to accelerate innovation in this field, potentially enabling designer composites with previously unattainable property combinations.

Market Analysis for Reinforced Polymer Composites

The global market for reinforced polymer composites has been experiencing robust growth, driven by increasing demand across multiple industries including automotive, aerospace, construction, and consumer electronics. The market was valued at approximately 224 billion USD in 2022 and is projected to reach 295 billion USD by 2028, representing a compound annual growth rate (CAGR) of 4.7% during the forecast period.

Silica-reinforced polymer composites specifically constitute a significant segment within this market, with colloidal silica emerging as a premium reinforcement material due to its superior mechanical properties and versatility. The colloidal silica segment for polymer reinforcement was valued at 3.2 billion USD in 2022, with expectations to grow at a CAGR of 6.3% through 2028.

Automotive and transportation sectors remain the largest consumers of reinforced polymer composites, accounting for approximately 31% of the total market share. The push for lightweight materials to improve fuel efficiency and reduce emissions has accelerated the adoption of silica-reinforced composites in these industries. Additionally, stringent regulatory frameworks regarding vehicle emissions in major markets like Europe and North America are further propelling market growth.

The construction industry represents the second-largest application segment, utilizing reinforced polymer composites for structural components, insulation materials, and decorative elements. This sector accounts for roughly 24% of the market share, with silica-reinforced products gaining traction due to their enhanced durability and weather resistance properties.

Regionally, Asia-Pacific dominates the market with a 41% share, led by China, Japan, and South Korea. The region's manufacturing prowess, coupled with increasing industrialization and infrastructure development, continues to drive demand. North America and Europe follow with 28% and 23% market shares respectively, where advanced applications in aerospace and premium automotive segments are key growth drivers.

Market trends indicate a growing preference for nano-silica reinforced composites, which offer superior dispersion characteristics and enhanced mechanical properties compared to conventional micro-silica fillers. This segment is growing at nearly twice the rate of the overall market, highlighting the importance of optimizing colloidal silica dispersion technologies.

Customer demand is increasingly focused on composites that offer multifunctional properties beyond mere strength enhancement, including thermal stability, flame retardancy, and electrical conductivity. This trend is creating new market opportunities for advanced colloidal silica formulations that can deliver these additional performance attributes while maintaining optimal dispersion in polymer matrices.

Silica-reinforced polymer composites specifically constitute a significant segment within this market, with colloidal silica emerging as a premium reinforcement material due to its superior mechanical properties and versatility. The colloidal silica segment for polymer reinforcement was valued at 3.2 billion USD in 2022, with expectations to grow at a CAGR of 6.3% through 2028.

Automotive and transportation sectors remain the largest consumers of reinforced polymer composites, accounting for approximately 31% of the total market share. The push for lightweight materials to improve fuel efficiency and reduce emissions has accelerated the adoption of silica-reinforced composites in these industries. Additionally, stringent regulatory frameworks regarding vehicle emissions in major markets like Europe and North America are further propelling market growth.

The construction industry represents the second-largest application segment, utilizing reinforced polymer composites for structural components, insulation materials, and decorative elements. This sector accounts for roughly 24% of the market share, with silica-reinforced products gaining traction due to their enhanced durability and weather resistance properties.

Regionally, Asia-Pacific dominates the market with a 41% share, led by China, Japan, and South Korea. The region's manufacturing prowess, coupled with increasing industrialization and infrastructure development, continues to drive demand. North America and Europe follow with 28% and 23% market shares respectively, where advanced applications in aerospace and premium automotive segments are key growth drivers.

Market trends indicate a growing preference for nano-silica reinforced composites, which offer superior dispersion characteristics and enhanced mechanical properties compared to conventional micro-silica fillers. This segment is growing at nearly twice the rate of the overall market, highlighting the importance of optimizing colloidal silica dispersion technologies.

Customer demand is increasingly focused on composites that offer multifunctional properties beyond mere strength enhancement, including thermal stability, flame retardancy, and electrical conductivity. This trend is creating new market opportunities for advanced colloidal silica formulations that can deliver these additional performance attributes while maintaining optimal dispersion in polymer matrices.

Technical Challenges in Silica Dispersion

Despite significant advancements in polymer composite technology, achieving optimal dispersion of colloidal silica nanoparticles remains one of the most persistent technical challenges in the field. The fundamental issue stems from the inherent incompatibility between hydrophilic silica particles and hydrophobic polymer matrices. This physicochemical mismatch creates a natural tendency for silica particles to agglomerate rather than distribute evenly throughout the polymer matrix, significantly compromising the mechanical properties of the resulting composite.

Surface chemistry interactions present a major obstacle, as silica nanoparticles possess abundant silanol groups (Si-OH) on their surfaces that readily form hydrogen bonds with neighboring particles. This self-association behavior leads to the formation of hard agglomerates that are extremely difficult to break down during processing, even with high shear forces. These agglomerates act as stress concentration points in the final composite, initiating crack propagation and premature failure.

Processing limitations further compound the dispersion challenge. Conventional mixing methods often fail to provide sufficient energy to overcome the strong interparticle forces between silica nanoparticles. High-viscosity polymer melts restrict particle mobility, creating kinetic barriers to achieving homogeneous dispersion. Additionally, the processing window is often narrow, as extended high-shear mixing can lead to polymer degradation before adequate dispersion is achieved.

Scale-up issues represent another significant hurdle. Laboratory-scale dispersion techniques that work effectively for small batches often fail when translated to industrial production volumes. The heat transfer dynamics, mixing efficiency, and residence time distributions change dramatically at larger scales, necessitating complete reformulation of dispersion protocols.

Stability over time poses an ongoing challenge, as even well-dispersed silica particles can re-agglomerate during storage or subsequent processing steps. This phenomenon, known as secondary agglomeration, occurs due to thermodynamic driving forces that favor the lower energy state of agglomerated particles over the dispersed state.

Characterization difficulties further complicate progress in this field. Accurately quantifying dispersion quality across multiple length scales remains problematic. Current analytical techniques provide either excellent resolution at very small scales (e.g., electron microscopy) or broader statistical information (e.g., light scattering), but rarely both simultaneously. This creates blind spots in understanding the true dispersion state.

Environmental and processing conditions, including temperature, humidity, and shear history, significantly impact dispersion quality but are difficult to control precisely in industrial settings. These variables introduce inconsistency in product quality and performance, making it challenging to establish robust manufacturing protocols for silica-reinforced polymer composites.

Surface chemistry interactions present a major obstacle, as silica nanoparticles possess abundant silanol groups (Si-OH) on their surfaces that readily form hydrogen bonds with neighboring particles. This self-association behavior leads to the formation of hard agglomerates that are extremely difficult to break down during processing, even with high shear forces. These agglomerates act as stress concentration points in the final composite, initiating crack propagation and premature failure.

Processing limitations further compound the dispersion challenge. Conventional mixing methods often fail to provide sufficient energy to overcome the strong interparticle forces between silica nanoparticles. High-viscosity polymer melts restrict particle mobility, creating kinetic barriers to achieving homogeneous dispersion. Additionally, the processing window is often narrow, as extended high-shear mixing can lead to polymer degradation before adequate dispersion is achieved.

Scale-up issues represent another significant hurdle. Laboratory-scale dispersion techniques that work effectively for small batches often fail when translated to industrial production volumes. The heat transfer dynamics, mixing efficiency, and residence time distributions change dramatically at larger scales, necessitating complete reformulation of dispersion protocols.

Stability over time poses an ongoing challenge, as even well-dispersed silica particles can re-agglomerate during storage or subsequent processing steps. This phenomenon, known as secondary agglomeration, occurs due to thermodynamic driving forces that favor the lower energy state of agglomerated particles over the dispersed state.

Characterization difficulties further complicate progress in this field. Accurately quantifying dispersion quality across multiple length scales remains problematic. Current analytical techniques provide either excellent resolution at very small scales (e.g., electron microscopy) or broader statistical information (e.g., light scattering), but rarely both simultaneously. This creates blind spots in understanding the true dispersion state.

Environmental and processing conditions, including temperature, humidity, and shear history, significantly impact dispersion quality but are difficult to control precisely in industrial settings. These variables introduce inconsistency in product quality and performance, making it challenging to establish robust manufacturing protocols for silica-reinforced polymer composites.

Current Dispersion Methodologies

01 Colloidal silica dispersion methods for polymer reinforcement

Various methods for dispersing colloidal silica in polymer matrices to enhance mechanical strength. These techniques include surface modification of silica particles, use of coupling agents, and specialized mixing processes to ensure uniform distribution throughout the polymer matrix. Proper dispersion prevents agglomeration and maximizes the interfacial interaction between silica particles and polymer chains, resulting in significant improvements in tensile strength, modulus, and impact resistance.- Colloidal silica dispersion methods for polymer reinforcement: Various methods for dispersing colloidal silica in polymer matrices to enhance mechanical strength. These techniques include surface modification of silica particles, specialized mixing processes, and the use of coupling agents to improve compatibility between the inorganic silica and organic polymer phases. Proper dispersion prevents agglomeration and ensures uniform distribution throughout the composite, leading to significant improvements in tensile strength, modulus, and impact resistance.

- Silica particle size and concentration effects on composite properties: The size of colloidal silica particles and their concentration in polymer composites significantly impact mechanical properties. Nanoscale silica particles provide greater surface area for polymer interaction, while optimal loading levels balance reinforcement benefits against potential agglomeration issues. Research shows that controlled particle size distribution and precise concentration management can yield composites with enhanced tensile strength, flexural modulus, and abrasion resistance while maintaining processability.

- Surface functionalization of silica for polymer compatibility: Surface functionalization of colloidal silica particles improves their compatibility with polymer matrices. By modifying silica surfaces with silane coupling agents, organic functional groups, or polymer grafting, the interfacial adhesion between the inorganic filler and organic polymer is enhanced. This improved interface facilitates better stress transfer throughout the composite, resulting in superior mechanical properties including increased tensile strength, impact resistance, and dimensional stability.

- Processing techniques for silica-polymer composite formation: Advanced processing techniques for incorporating colloidal silica into polymer composites significantly affect final strength properties. Methods such as in-situ polymerization, sol-gel processing, melt compounding with specialized equipment, and solution blending followed by controlled solvent removal can improve silica dispersion. These techniques prevent agglomeration and ensure uniform distribution of silica particles throughout the polymer matrix, resulting in composites with enhanced mechanical performance and durability.

- Hybrid silica systems for multifunctional polymer composites: Hybrid colloidal silica systems combine silica with other reinforcing materials to create multifunctional polymer composites with synergistic strength improvements. These systems may incorporate organic-inorganic hybrids, core-shell structures, or hierarchical reinforcement architectures. By combining silica with complementary materials such as carbon nanotubes, clay, or other metal oxides, these hybrid systems can simultaneously enhance multiple properties including mechanical strength, thermal stability, barrier properties, and flame retardance.

02 Nanosilica particle size and concentration effects

The impact of colloidal silica particle size and concentration on polymer composite properties. Nanoscale silica particles (typically 5-100 nm) provide superior reinforcement compared to larger particles due to their higher surface area and better integration with polymer chains. Optimal concentration ranges have been identified for different polymer systems, with excessive loading potentially causing brittleness or agglomeration issues. Controlled particle size distribution contributes to enhanced mechanical properties including flexural strength and abrasion resistance.Expand Specific Solutions03 Surface functionalization of silica for polymer compatibility

Surface modification techniques for colloidal silica to improve compatibility with various polymer matrices. Functionalization with silane coupling agents, organic modifiers, or grafted polymer chains creates strong covalent or hydrogen bonding between the inorganic silica and organic polymer phases. These modified interfaces reduce stress concentration points and improve load transfer throughout the composite, resulting in enhanced tensile strength, thermal stability, and durability under mechanical stress.Expand Specific Solutions04 Processing techniques for silica-polymer composite formation

Advanced processing methods for incorporating colloidal silica into polymer composites. Techniques include sol-gel processing, in-situ polymerization in the presence of silica, melt compounding with specialized equipment, and solution blending followed by controlled solvent removal. These processing approaches control the microstructure development and prevent silica agglomeration, leading to composites with improved mechanical strength, dimensional stability, and resistance to environmental degradation.Expand Specific Solutions05 Hybrid silica-polymer systems for enhanced performance

Development of hybrid materials combining colloidal silica with multiple polymer types or additional reinforcing agents. These systems include interpenetrating networks, layered structures, and hierarchical composites that leverage synergistic effects between components. The resulting materials exhibit multifunctional properties including exceptional mechanical strength, thermal resistance, barrier properties, and specialized characteristics such as self-healing capabilities or stimuli-responsive behavior while maintaining processability.Expand Specific Solutions

Leading Companies in Silica-Polymer Composites

The colloidal silica dispersion optimization market in polymer composites is currently in a growth phase, with increasing demand driven by automotive, construction, and electronics industries seeking enhanced material performance. The global market is estimated at $1.2-1.5 billion annually with projected 6-8% CAGR through 2028. Technologically, the field shows moderate maturity with established players like Evonik Operations and Shin-Etsu Chemical leading with advanced dispersion technologies, while Rhodia Operations and Fuso Chemical focus on specialty formulations. Emerging competitors include Quechen Silicon Chemical and Suzhou Sunmun Technology, who are rapidly advancing cost-effective solutions. The competitive landscape features traditional chemical conglomerates (AkzoNobel, DIC Corp) alongside application specialists (Bridgestone, Michelin) developing proprietary dispersion methods for specific composite applications.

Bridgestone Corp.

Technical Solution: Bridgestone has developed a proprietary "Network Dispersion Technology" for incorporating colloidal silica into rubber compounds, particularly for high-performance tire applications. Their approach involves a multi-step process beginning with surface modification of silica particles using bifunctional silane coupling agents that create strong chemical bonds with both the silica surface and the polymer matrix. The company employs a controlled precipitation process that produces silica particles with high surface area (150-200 m²/g) and precisely controlled pore structure. Bridgestone's technology includes a specialized mixing sequence that introduces silica at specific temperatures and shear conditions to optimize dispersion while minimizing heat history. Their process incorporates proprietary processing aids that reduce viscosity during mixing while maintaining dispersion stability. Recent innovations include the development of hierarchical silica structures with both micro and nano features that enhance mechanical interlocking with the polymer matrix while maintaining good processability.

Strengths: Exceptional reinforcement properties while maintaining low rolling resistance in tire applications; proven technology with extensive commercial implementation; excellent balance of wet grip and wear resistance. Weaknesses: Highly specialized for elastomeric systems and may require significant modification for thermoplastic applications; energy-intensive mixing process; requires precise temperature control during processing.

Evonik Operations GmbH

Technical Solution: Evonik has developed AEROSIL® colloidal silica technology specifically for polymer composite reinforcement. Their approach involves surface modification of silica nanoparticles with silane coupling agents to create strong covalent bonds between the inorganic silica and organic polymer matrix. The company employs a proprietary precipitation process that produces highly uniform silica particles with controlled size distribution (typically 10-40 nm), which is critical for optimal dispersion. Evonik's AEROSIL® technology includes specialized dispersing additives that prevent agglomeration during processing by creating steric hindrance between particles. Their process also incorporates ultrasonic treatment during the mixing phase to break down silica clusters, followed by a controlled drying process that maintains the dispersed state. Recent innovations include functionalized silica particles with gradient surface properties that create an interfacial layer optimized for specific polymer systems.

Strengths: Superior particle size control and uniformity leading to excellent mechanical reinforcement; extensive surface modification capabilities allowing compatibility with diverse polymer systems; proven technology with established industrial scale production. Weaknesses: Higher cost compared to conventional fillers; requires specialized processing equipment for optimal dispersion; some formulations may increase composite viscosity, potentially complicating processing.

Key Patents in Colloidal Silica Dispersion

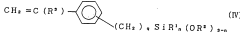

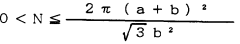

Composite and moldings produced therefrom

PatentWO1996034036A1

Innovation

- A composite is developed where negatively charged colloidal silica with an average particle size of 50 nm or less is dispersed in a negatively charged polymer, using surface-treated colloidal silica and specific alkoxysilane compounds to maintain primary particle state and improve dispersibility, allowing for melt-shaping and achieving high transparency and mechanical properties.

Methods for synthesizing precipitated silica and use thereof

PatentInactiveUS20050228106A1

Innovation

- The method involves reducing the ionic strength of the reaction solution by adding silicic acid and using surface modifying agents during the synthesis of precipitated silica, controlling the formation of 'hard' aggregates and 'soft' agglomerates, and modifying the silica surface to enhance hydrophobic characteristics and dispersion in polymer matrices.

Environmental Impact Assessment

The environmental impact of colloidal silica dispersion in polymer composites extends across the entire product lifecycle, from raw material extraction to end-of-life disposal. The production of colloidal silica typically involves energy-intensive processes that contribute to greenhouse gas emissions. However, when compared to traditional reinforcement materials like carbon fiber or glass fiber, colloidal silica generally has a lower carbon footprint due to its simpler manufacturing process and abundant raw material source (silicon dioxide).

Water usage represents a significant environmental concern in colloidal silica production. The synthesis process requires substantial amounts of water for particle formation and purification. Implementing closed-loop water systems and advanced filtration technologies can reduce freshwater consumption by up to 40%, according to recent industry studies. Additionally, wastewater from production facilities may contain trace amounts of silica and chemical modifiers that require proper treatment before discharge.

The dispersion process itself presents environmental challenges related to solvent usage. Traditional dispersion methods often employ volatile organic compounds (VOCs) that contribute to air pollution and pose health risks. Recent advancements in water-based dispersion techniques and the development of bio-derived dispersants offer promising alternatives with reduced environmental impact. These green chemistry approaches have demonstrated comparable dispersion efficiency while decreasing VOC emissions by 60-85%.

From a lifecycle perspective, polymer composites reinforced with optimally dispersed colloidal silica offer environmental benefits through extended product durability. Enhanced mechanical strength translates to longer service life and reduced material replacement frequency. Quantitative lifecycle assessments indicate that a 25% improvement in composite strength can extend product lifespan by 30-40%, significantly reducing waste generation and resource consumption over time.

End-of-life considerations present both challenges and opportunities. While polymer-silica composites can be difficult to separate for recycling, recent developments in solvolysis and selective dissolution techniques show promise for material recovery. Furthermore, the non-toxic nature of silica means these composites generally pose minimal leaching concerns in landfill environments compared to composites containing heavy metals or other hazardous fillers.

Regulatory frameworks worldwide are increasingly addressing nanomaterial environmental impacts, with particular attention to potential release during product use and disposal. Manufacturers optimizing colloidal silica dispersion must consider these evolving regulations and implement appropriate risk mitigation strategies throughout the product development process.

Water usage represents a significant environmental concern in colloidal silica production. The synthesis process requires substantial amounts of water for particle formation and purification. Implementing closed-loop water systems and advanced filtration technologies can reduce freshwater consumption by up to 40%, according to recent industry studies. Additionally, wastewater from production facilities may contain trace amounts of silica and chemical modifiers that require proper treatment before discharge.

The dispersion process itself presents environmental challenges related to solvent usage. Traditional dispersion methods often employ volatile organic compounds (VOCs) that contribute to air pollution and pose health risks. Recent advancements in water-based dispersion techniques and the development of bio-derived dispersants offer promising alternatives with reduced environmental impact. These green chemistry approaches have demonstrated comparable dispersion efficiency while decreasing VOC emissions by 60-85%.

From a lifecycle perspective, polymer composites reinforced with optimally dispersed colloidal silica offer environmental benefits through extended product durability. Enhanced mechanical strength translates to longer service life and reduced material replacement frequency. Quantitative lifecycle assessments indicate that a 25% improvement in composite strength can extend product lifespan by 30-40%, significantly reducing waste generation and resource consumption over time.

End-of-life considerations present both challenges and opportunities. While polymer-silica composites can be difficult to separate for recycling, recent developments in solvolysis and selective dissolution techniques show promise for material recovery. Furthermore, the non-toxic nature of silica means these composites generally pose minimal leaching concerns in landfill environments compared to composites containing heavy metals or other hazardous fillers.

Regulatory frameworks worldwide are increasingly addressing nanomaterial environmental impacts, with particular attention to potential release during product use and disposal. Manufacturers optimizing colloidal silica dispersion must consider these evolving regulations and implement appropriate risk mitigation strategies throughout the product development process.

Scale-up and Manufacturing Considerations

Scaling up colloidal silica dispersion in polymer composites from laboratory to industrial production presents significant challenges that require careful consideration of multiple manufacturing parameters. The transition demands precise control over processing conditions to maintain the homogeneous dispersion achieved in small-scale experiments. Industrial mixers and extruders operate under different shear conditions compared to laboratory equipment, potentially affecting the dispersion quality and requiring adjustment of processing parameters such as mixing time, temperature, and speed.

Material handling becomes increasingly complex at scale, particularly for nano-sized colloidal silica particles which may exhibit agglomeration tendencies during storage and transfer. Implementation of appropriate feeding systems and pre-dispersion techniques becomes essential to ensure consistent incorporation into the polymer matrix. Additionally, the rheological behavior of silica-polymer mixtures often changes with scale, necessitating modifications to processing equipment and conditions to maintain optimal flow characteristics.

Quality control protocols must be enhanced for large-scale production, incorporating in-line monitoring systems to assess dispersion quality throughout the manufacturing process. Techniques such as rheological measurements, optical methods, or specialized sensors can provide real-time feedback on dispersion status, allowing for immediate process adjustments. Batch-to-batch consistency becomes a critical concern, requiring robust standard operating procedures and potentially automated control systems.

Environmental and safety considerations gain prominence at industrial scale, particularly regarding the handling of nano-sized silica particles. Proper containment systems, filtration, and worker protection measures must be implemented to address potential inhalation hazards and environmental release. Energy efficiency also becomes a significant factor, with optimization of mixing and processing parameters to reduce energy consumption while maintaining dispersion quality.

Production economics introduces additional constraints, as the cost-effectiveness of various dispersion methods must be evaluated against performance benefits. Some high-performance dispersion techniques viable at laboratory scale may prove prohibitively expensive for mass production. The selection of equipment, processing aids, and manufacturing protocols must balance technical performance with economic feasibility, potentially leading to compromises or innovative solutions specific to industrial implementation.

Regulatory compliance represents another critical aspect of scale-up, particularly for applications in sensitive sectors such as food packaging or medical devices. Documentation of manufacturing processes, material traceability, and quality assurance become essential components of the production system, requiring integration into the overall manufacturing strategy from the earliest stages of scale-up planning.

Material handling becomes increasingly complex at scale, particularly for nano-sized colloidal silica particles which may exhibit agglomeration tendencies during storage and transfer. Implementation of appropriate feeding systems and pre-dispersion techniques becomes essential to ensure consistent incorporation into the polymer matrix. Additionally, the rheological behavior of silica-polymer mixtures often changes with scale, necessitating modifications to processing equipment and conditions to maintain optimal flow characteristics.

Quality control protocols must be enhanced for large-scale production, incorporating in-line monitoring systems to assess dispersion quality throughout the manufacturing process. Techniques such as rheological measurements, optical methods, or specialized sensors can provide real-time feedback on dispersion status, allowing for immediate process adjustments. Batch-to-batch consistency becomes a critical concern, requiring robust standard operating procedures and potentially automated control systems.

Environmental and safety considerations gain prominence at industrial scale, particularly regarding the handling of nano-sized silica particles. Proper containment systems, filtration, and worker protection measures must be implemented to address potential inhalation hazards and environmental release. Energy efficiency also becomes a significant factor, with optimization of mixing and processing parameters to reduce energy consumption while maintaining dispersion quality.

Production economics introduces additional constraints, as the cost-effectiveness of various dispersion methods must be evaluated against performance benefits. Some high-performance dispersion techniques viable at laboratory scale may prove prohibitively expensive for mass production. The selection of equipment, processing aids, and manufacturing protocols must balance technical performance with economic feasibility, potentially leading to compromises or innovative solutions specific to industrial implementation.

Regulatory compliance represents another critical aspect of scale-up, particularly for applications in sensitive sectors such as food packaging or medical devices. Documentation of manufacturing processes, material traceability, and quality assurance become essential components of the production system, requiring integration into the overall manufacturing strategy from the earliest stages of scale-up planning.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!