How to Incorporate Colloidal Silica in Oil Recovery for Improved Sweep Efficiency

SEP 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Colloidal Silica in EOR: Background and Objectives

Colloidal silica has emerged as a promising agent in enhanced oil recovery (EOR) operations over the past three decades. The technology evolved from traditional silica applications in construction and manufacturing to specialized formulations designed specifically for petroleum engineering applications. Initially developed in the 1990s as potential mobility control agents, colloidal silica systems have undergone significant refinement to address the complex challenges of subsurface environments. The evolution of this technology has been marked by progressive improvements in particle stability, gelation control, and performance under varying reservoir conditions.

The fundamental principle behind colloidal silica in EOR lies in its ability to form in-situ gels that can effectively block high-permeability zones in heterogeneous reservoirs. This mechanism addresses one of the most persistent challenges in oil recovery: poor sweep efficiency due to preferential flow through thief zones. Historical data indicates that conventional waterflooding operations typically recover only 20-40% of original oil in place, leaving substantial resources untapped primarily due to reservoir heterogeneity and unfavorable mobility ratios.

Recent technological advancements have significantly expanded the potential applications of colloidal silica in EOR. Modern formulations incorporate surface-modified nanoparticles that demonstrate enhanced stability in high-salinity environments and improved temperature resistance, extending their applicability to a wider range of reservoir conditions. The integration of smart triggering mechanisms, such as pH-responsive or thermally-activated gelation, represents the cutting edge of this technology, allowing for more precise placement and timing of conformance control treatments.

Global research trends indicate growing interest in colloidal silica applications, with publication rates increasing by approximately 15% annually over the past five years. This surge in research activity correlates with the industry's broader shift toward more sustainable and environmentally friendly recovery methods, as colloidal silica offers a relatively benign alternative to many chemical EOR agents.

The primary technical objective for colloidal silica implementation in EOR is to develop robust, field-ready systems that can be effectively deployed in diverse reservoir environments to significantly improve sweep efficiency. Specific goals include: achieving controlled gelation timing that allows for deep reservoir penetration before solidification; ensuring long-term gel stability under reservoir conditions; developing cost-effective formulations that remain economically viable at scale; and creating environmentally compatible systems with minimal ecological impact.

Secondary objectives focus on optimizing deployment strategies, including injection protocols, well pattern configurations, and integration with existing recovery methods. The ultimate aim is to establish colloidal silica as a standard component in the EOR toolkit, capable of increasing recovery factors by 5-15% beyond conventional methods while maintaining operational feasibility and economic viability across various field conditions.

The fundamental principle behind colloidal silica in EOR lies in its ability to form in-situ gels that can effectively block high-permeability zones in heterogeneous reservoirs. This mechanism addresses one of the most persistent challenges in oil recovery: poor sweep efficiency due to preferential flow through thief zones. Historical data indicates that conventional waterflooding operations typically recover only 20-40% of original oil in place, leaving substantial resources untapped primarily due to reservoir heterogeneity and unfavorable mobility ratios.

Recent technological advancements have significantly expanded the potential applications of colloidal silica in EOR. Modern formulations incorporate surface-modified nanoparticles that demonstrate enhanced stability in high-salinity environments and improved temperature resistance, extending their applicability to a wider range of reservoir conditions. The integration of smart triggering mechanisms, such as pH-responsive or thermally-activated gelation, represents the cutting edge of this technology, allowing for more precise placement and timing of conformance control treatments.

Global research trends indicate growing interest in colloidal silica applications, with publication rates increasing by approximately 15% annually over the past five years. This surge in research activity correlates with the industry's broader shift toward more sustainable and environmentally friendly recovery methods, as colloidal silica offers a relatively benign alternative to many chemical EOR agents.

The primary technical objective for colloidal silica implementation in EOR is to develop robust, field-ready systems that can be effectively deployed in diverse reservoir environments to significantly improve sweep efficiency. Specific goals include: achieving controlled gelation timing that allows for deep reservoir penetration before solidification; ensuring long-term gel stability under reservoir conditions; developing cost-effective formulations that remain economically viable at scale; and creating environmentally compatible systems with minimal ecological impact.

Secondary objectives focus on optimizing deployment strategies, including injection protocols, well pattern configurations, and integration with existing recovery methods. The ultimate aim is to establish colloidal silica as a standard component in the EOR toolkit, capable of increasing recovery factors by 5-15% beyond conventional methods while maintaining operational feasibility and economic viability across various field conditions.

Market Analysis of Enhanced Oil Recovery Technologies

The Enhanced Oil Recovery (EOR) market has witnessed significant growth in recent years, driven by increasing global energy demands and declining production from conventional oil fields. As of 2023, the global EOR market is valued at approximately $58 billion, with projections indicating growth to reach $87 billion by 2028, representing a compound annual growth rate of 8.4%. This growth trajectory underscores the industry's recognition of EOR technologies as critical for maximizing recovery from existing reservoirs.

Chemical EOR methods, including polymer flooding, surfactant flooding, and alkaline flooding, currently hold the largest market share at 38%, followed by thermal methods at 32% and gas injection methods at 25%. Within the chemical EOR segment, colloidal silica applications are emerging as a promising technology, currently representing about 5% of the chemical EOR market but showing rapid growth potential due to their effectiveness in improving sweep efficiency.

North America dominates the EOR market with approximately 35% market share, followed by the Middle East (28%) and Asia-Pacific (20%). The United States, Saudi Arabia, and China are the leading countries implementing advanced EOR technologies. Notably, the adoption of colloidal silica-based solutions has seen particular traction in mature oilfields across North America and parts of the Middle East where water breakthrough and poor sweep efficiency are common challenges.

Key market drivers for colloidal silica in oil recovery include increasing recovery factors, extending the productive life of mature fields, and addressing environmental concerns associated with traditional recovery methods. The technology offers potential recovery improvements of 5-15% of original oil in place (OOIP) beyond conventional methods, making it economically attractive despite implementation costs.

Market challenges include high initial investment requirements, technical complexities in formulation and application, and competition from other emerging EOR technologies. The average implementation cost for colloidal silica-based EOR ranges from $8-15 per incremental barrel of oil recovered, which remains competitive when oil prices exceed $60 per barrel.

Industry analysts predict that as oil prices stabilize above $70 per barrel, investment in advanced EOR technologies including colloidal silica applications will accelerate. The market is also being shaped by increasing environmental regulations, with colloidal silica offering advantages due to its relatively lower environmental footprint compared to some chemical alternatives.

Chemical EOR methods, including polymer flooding, surfactant flooding, and alkaline flooding, currently hold the largest market share at 38%, followed by thermal methods at 32% and gas injection methods at 25%. Within the chemical EOR segment, colloidal silica applications are emerging as a promising technology, currently representing about 5% of the chemical EOR market but showing rapid growth potential due to their effectiveness in improving sweep efficiency.

North America dominates the EOR market with approximately 35% market share, followed by the Middle East (28%) and Asia-Pacific (20%). The United States, Saudi Arabia, and China are the leading countries implementing advanced EOR technologies. Notably, the adoption of colloidal silica-based solutions has seen particular traction in mature oilfields across North America and parts of the Middle East where water breakthrough and poor sweep efficiency are common challenges.

Key market drivers for colloidal silica in oil recovery include increasing recovery factors, extending the productive life of mature fields, and addressing environmental concerns associated with traditional recovery methods. The technology offers potential recovery improvements of 5-15% of original oil in place (OOIP) beyond conventional methods, making it economically attractive despite implementation costs.

Market challenges include high initial investment requirements, technical complexities in formulation and application, and competition from other emerging EOR technologies. The average implementation cost for colloidal silica-based EOR ranges from $8-15 per incremental barrel of oil recovered, which remains competitive when oil prices exceed $60 per barrel.

Industry analysts predict that as oil prices stabilize above $70 per barrel, investment in advanced EOR technologies including colloidal silica applications will accelerate. The market is also being shaped by increasing environmental regulations, with colloidal silica offering advantages due to its relatively lower environmental footprint compared to some chemical alternatives.

Technical Challenges in Colloidal Silica Implementation

Despite the promising potential of colloidal silica in enhanced oil recovery (EOR), several significant technical challenges impede its widespread implementation. The primary obstacle lies in the complex rheological behavior of colloidal silica suspensions under reservoir conditions. When exposed to high salinity environments typical of oil reservoirs, colloidal silica particles tend to aggregate and form gels at unpredictable rates, making controlled placement within target zones extremely difficult. This gelation kinetics variability creates substantial operational uncertainties during field applications.

Formation heterogeneity presents another major challenge, as preferential flow paths can lead to uneven distribution of colloidal silica throughout the reservoir. This results in inadequate coverage of high-permeability zones and insufficient diversion of injected fluids to lower-permeability regions containing residual oil. The effectiveness of sweep efficiency improvement is thus compromised by the inability to achieve uniform placement across the reservoir's varying permeability profile.

Temperature stability issues further complicate implementation, particularly in deeper reservoirs where temperatures exceed 80°C. At elevated temperatures, colloidal silica particles may undergo accelerated aggregation or structural changes that alter their mobility and plugging efficiency. The thermal degradation of stabilizing agents in colloidal suspensions can lead to premature gelation or, conversely, failure to form cohesive gels at the intended locations.

Compatibility with reservoir fluids represents another significant technical hurdle. When colloidal silica interacts with formation brines containing multivalent cations (particularly Ca²⁺ and Mg²⁺), rapid and often uncontrollable gelation can occur. Additionally, certain crude oil components may adsorb onto silica surfaces, potentially altering their surface properties and compromising their effectiveness as mobility control agents.

Scale-up challenges from laboratory to field implementation remain problematic. Laboratory experiments typically utilize homogeneous core samples under controlled conditions, whereas actual reservoirs feature complex fracture networks, varying mineralogy, and dynamic fluid flow patterns. The disparity between laboratory results and field performance creates uncertainty in predicting treatment outcomes and designing optimal injection strategies.

Long-term stability concerns also exist regarding the mechanical and chemical integrity of colloidal silica gels under continuous flow conditions. Over time, these gels may experience syneresis (expulsion of water), structural breakdown due to pressure gradients, or chemical degradation from exposure to reservoir fluids, potentially reducing their effectiveness in maintaining sweep efficiency improvements.

Formation heterogeneity presents another major challenge, as preferential flow paths can lead to uneven distribution of colloidal silica throughout the reservoir. This results in inadequate coverage of high-permeability zones and insufficient diversion of injected fluids to lower-permeability regions containing residual oil. The effectiveness of sweep efficiency improvement is thus compromised by the inability to achieve uniform placement across the reservoir's varying permeability profile.

Temperature stability issues further complicate implementation, particularly in deeper reservoirs where temperatures exceed 80°C. At elevated temperatures, colloidal silica particles may undergo accelerated aggregation or structural changes that alter their mobility and plugging efficiency. The thermal degradation of stabilizing agents in colloidal suspensions can lead to premature gelation or, conversely, failure to form cohesive gels at the intended locations.

Compatibility with reservoir fluids represents another significant technical hurdle. When colloidal silica interacts with formation brines containing multivalent cations (particularly Ca²⁺ and Mg²⁺), rapid and often uncontrollable gelation can occur. Additionally, certain crude oil components may adsorb onto silica surfaces, potentially altering their surface properties and compromising their effectiveness as mobility control agents.

Scale-up challenges from laboratory to field implementation remain problematic. Laboratory experiments typically utilize homogeneous core samples under controlled conditions, whereas actual reservoirs feature complex fracture networks, varying mineralogy, and dynamic fluid flow patterns. The disparity between laboratory results and field performance creates uncertainty in predicting treatment outcomes and designing optimal injection strategies.

Long-term stability concerns also exist regarding the mechanical and chemical integrity of colloidal silica gels under continuous flow conditions. Over time, these gels may experience syneresis (expulsion of water), structural breakdown due to pressure gradients, or chemical degradation from exposure to reservoir fluids, potentially reducing their effectiveness in maintaining sweep efficiency improvements.

Current Methodologies for Colloidal Silica Injection

01 Colloidal silica for enhanced oil recovery

Colloidal silica formulations are used in enhanced oil recovery operations to improve sweep efficiency in oil reservoirs. These formulations can modify the flow behavior of injection fluids, creating a more uniform displacement front that helps access bypassed oil. The small particle size of colloidal silica allows for deep penetration into reservoir formations, while its ability to form gels under certain conditions helps control fluid mobility and reduce channeling through high-permeability zones.- Enhanced oil recovery using colloidal silica: Colloidal silica can be used to improve sweep efficiency in enhanced oil recovery operations. When injected into oil reservoirs, colloidal silica forms a gel that blocks high-permeability zones, diverting subsequent fluid flow to unswept regions. This reduces fingering and channeling effects, leading to more uniform displacement of oil and improved recovery rates. The gelation time can be controlled by adjusting pH, salinity, and silica concentration to optimize performance in different reservoir conditions.

- Colloidal silica formulations for permeability modification: Specialized formulations of colloidal silica can be designed to modify the permeability of geological formations. These formulations typically include colloidal silica particles of specific size distributions combined with activators or cross-linking agents. When injected into reservoirs, they selectively reduce permeability in water-bearing zones while maintaining oil flow paths. This differential permeability modification improves sweep efficiency by reducing water production and redirecting injection fluids toward oil-rich regions.

- Measurement and monitoring of sweep efficiency: Various techniques have been developed to measure and monitor sweep efficiency when using colloidal silica treatments. These include tracer studies, pressure transient analysis, and advanced logging methods that can detect changes in fluid flow patterns. Real-time monitoring allows for optimization of injection parameters and evaluation of treatment effectiveness. These measurement techniques help in understanding the distribution of colloidal silica in the reservoir and its impact on fluid flow paths.

- Stabilization of colloidal silica for improved performance: Methods for stabilizing colloidal silica suspensions can significantly improve their performance in sweep efficiency applications. Stabilization techniques include surface modification, pH control, and addition of specific electrolytes or polymers. Stabilized colloidal silica exhibits improved transport through porous media, more uniform distribution in the reservoir, and better resistance to harsh reservoir conditions such as high temperature and salinity. This results in more effective permeability modification and enhanced sweep efficiency.

- Environmental and economic aspects of colloidal silica treatments: Colloidal silica offers environmental and economic advantages for sweep efficiency improvement compared to alternative technologies. It is generally non-toxic, environmentally friendly, and can be produced from abundant raw materials. The economic benefits include reduced water production, lower operating costs, and increased oil recovery. Additionally, colloidal silica treatments can extend the productive life of mature oil fields by accessing previously bypassed oil, improving the overall economics of field development.

02 Silica nanoparticles for conformance control

Silica nanoparticles are utilized for conformance control in heterogeneous reservoirs to improve sweep efficiency. These nanoparticles can be engineered to selectively block high-permeability zones, diverting subsequent injection fluids toward unswept regions containing residual oil. The surface properties of silica nanoparticles can be modified to enhance their stability in reservoir conditions and improve their interaction with rock surfaces, resulting in more effective permeability modification and improved volumetric sweep efficiency.Expand Specific Solutions03 Colloidal silica gel systems for fluid diversion

Colloidal silica gel systems are formulated to create in-situ gels that divert injection fluids from high-permeability streaks to low-permeability zones. These systems typically consist of colloidal silica particles that can be activated to form gels through pH adjustment, salinity changes, or temperature variations. The gelation time can be controlled to ensure proper placement within the reservoir before gel formation occurs. This approach significantly improves sweep efficiency by creating temporary or permanent barriers in thief zones, forcing injected fluids to contact previously unswept portions of the reservoir.Expand Specific Solutions04 Hybrid silica-polymer systems for mobility control

Hybrid systems combining colloidal silica with polymers are developed to enhance sweep efficiency through synergistic effects. These formulations benefit from the viscosifying properties of polymers and the stability and adsorption characteristics of silica particles. The polymer component provides initial mobility control while the silica particles offer long-term permeability modification. This combination results in improved displacement efficiency and better resistance to harsh reservoir conditions such as high temperature, salinity, and shear forces, leading to more effective oil recovery operations.Expand Specific Solutions05 Measurement and monitoring of sweep efficiency with colloidal silica

Methods for measuring and monitoring sweep efficiency when using colloidal silica treatments have been developed to optimize field applications. These techniques include tracer studies, pressure transient analysis, and advanced imaging methods to evaluate the distribution of injected fluids and the effectiveness of silica treatments. Real-time monitoring allows for adaptive injection strategies and better assessment of treatment performance. Laboratory testing protocols have also been established to predict field performance and design optimal colloidal silica formulations for specific reservoir conditions.Expand Specific Solutions

Key Industry Players and Research Institutions

The colloidal silica oil recovery market is currently in a growth phase, with increasing adoption as enhanced oil recovery (EOR) techniques gain prominence amid declining conventional reserves. The global market for this technology is estimated to reach $2-3 billion by 2025, driven by the need for improved sweep efficiency in mature oilfields. Technologically, the field is advancing from experimental to commercial implementation, with major players at different maturity levels. Companies like DuPont, Dow Global Technologies, and Nissan Chemical lead with established silica nanoparticle technologies, while national oil companies such as PetroChina, Sinopec, and Ecopetrol are actively implementing field trials. Academic-industry partnerships involving institutions like China Petroleum University and The University of Texas System are accelerating innovation in colloidal silica formulations optimized for diverse reservoir conditions.

Nissan Chemical Corp.

Technical Solution: Nissan Chemical Corporation has developed a specialized colloidal silica technology called "SNOWTEX-EOR" specifically engineered for enhanced oil recovery applications. Their approach utilizes precisely controlled silica nanoparticles (10-30 nm) with tailored surface properties that enable stable dispersion in injection brines while maintaining functionality under reservoir conditions. Nissan's technology incorporates proprietary surface modification techniques that allow the particles to penetrate deep into reservoir formations without filtration issues. The colloidal silica particles work through multiple mechanisms: they adsorb at pore surfaces to modify wettability toward more water-wet conditions, reduce interfacial tension at oil-water interfaces, and form weak network structures that improve mobility control. Field trials in Asian oilfields have demonstrated incremental oil recovery increases of 6-10% OOIP beyond conventional waterflooding, with significant improvements in sweep efficiency as evidenced by reduced water cut in production wells.

Strengths: Decades of expertise in colloidal silica manufacturing ensuring consistent quality; highly stable formulations even in challenging reservoir conditions; versatile application across different reservoir types. Weaknesses: Higher cost compared to some competing technologies; requires careful optimization for specific reservoir conditions; potential for reduced effectiveness in extremely high-temperature environments.

The Board of Regents of The University of Texas System

Technical Solution: The University of Texas System has developed a groundbreaking colloidal silica technology for enhanced oil recovery called "SiNanoPore." This approach utilizes functionalized silica nanoparticles (8-20 nm) with precisely engineered surface properties that enable them to penetrate deep into reservoir formations while maintaining colloidal stability. Their innovation lies in the development of silica particles with switchable surface properties that respond to reservoir conditions, transitioning from hydrophilic during injection to partially hydrophobic upon reaching target zones. This transformation allows the particles to adsorb at oil-water interfaces, reducing interfacial tension and altering rock wettability toward more water-wet conditions. Laboratory studies demonstrated incremental oil recovery increases of 15-25% beyond conventional waterflooding in carbonate core samples. The technology incorporates environmentally benign stabilizers and can be deployed using existing field infrastructure with minimal modifications.

Strengths: Cutting-edge research with novel surface modification techniques; excellent performance in laboratory tests with diverse rock types; environmentally friendly formulation with minimal chemical additives. Weaknesses: Limited large-scale field implementation data; potential scalability challenges for commercial deployment; may require specialized expertise for optimal implementation.

Critical Patents and Research on Silica-Based EOR

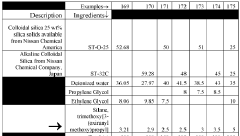

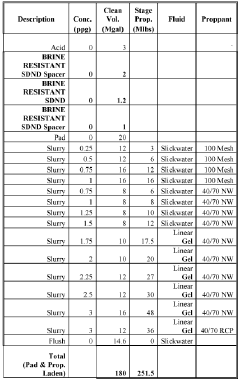

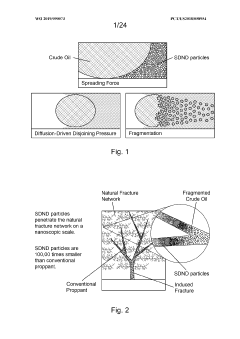

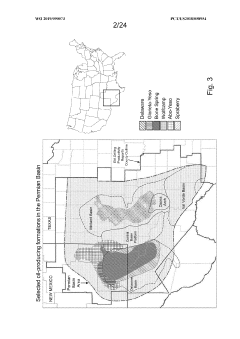

Using brine resistant silicon dioxide nanoparticle dispersions to improve oil recovery

PatentWO2019090073A1

Innovation

- The introduction of Brine Resistant Silicon Dioxide Nanoparticle Dispersion (BRINE RESISTANT SDND) technology, which involves adding a Brine Resistant Silicon Dioxide Nanoparticle Dispersion to conventional oil well treatment fluids, utilizing highly surface-modified, neutral wet colloidal silica nanoparticles to enhance reservoir flow dynamics through Brownian motion-driven diffusion and disjoining pressure, thereby improving hydrocarbon recovery.

Patent

Innovation

- Development of colloidal silica formulations with optimized particle size and surface chemistry for enhanced oil recovery, improving sweep efficiency by modifying flow patterns in heterogeneous reservoirs.

- Implementation of in-situ gelation mechanisms for colloidal silica that can be triggered at specific reservoir conditions (pH, temperature, salinity), allowing for targeted placement in high-permeability zones.

- Design of environmentally friendly colloidal silica systems with improved stability under harsh reservoir conditions (high temperature, high salinity) while maintaining cost-effectiveness for field-scale applications.

Environmental Impact Assessment of Silica-Based EOR

The environmental implications of silica-based Enhanced Oil Recovery (EOR) techniques require comprehensive assessment to ensure sustainable implementation. Colloidal silica, while offering promising sweep efficiency improvements, introduces various environmental considerations that must be evaluated across the entire operational lifecycle.

Water usage represents a primary environmental concern, as silica-based EOR typically requires substantial freshwater resources for injection fluid preparation. This demand can strain local water supplies, particularly in water-scarce regions where oil fields often operate. The water footprint extends beyond consumption to include potential contamination of groundwater systems if injection fluids migrate beyond target formations.

Chemical additives used in conjunction with colloidal silica formulations present additional environmental challenges. These compounds, necessary for stability and performance optimization, may contain surfactants, polymers, and other substances with varying biodegradability profiles. Their persistence in produced water and potential for bioaccumulation necessitates thorough toxicological evaluation before field implementation.

Waste management considerations emerge prominently in the environmental assessment framework. Produced water containing residual silica particles requires appropriate treatment before disposal or reuse. The solid waste generated from silica preparation and filtration processes must also be managed according to regulatory standards, with recycling opportunities explored where feasible.

Energy consumption and associated carbon emissions constitute another significant environmental dimension. The manufacturing, transportation, and injection of colloidal silica solutions involve substantial energy inputs, contributing to the overall carbon footprint of recovery operations. Life cycle assessment methodologies reveal that energy requirements for silica-based EOR may exceed conventional recovery methods in certain scenarios.

Ecosystem impacts warrant careful monitoring, particularly regarding potential changes to soil chemistry and microbial communities in the vicinity of injection sites. While silica is generally considered inert, the altered subsurface conditions following injection may influence local biogeochemical processes with cascading effects on ecosystem functioning.

Regulatory compliance frameworks vary significantly across jurisdictions, creating challenges for standardized environmental assessment. Operators must navigate complex permitting requirements, monitoring obligations, and reporting standards that govern silica-based EOR activities. The evolving nature of these regulations necessitates adaptive management approaches and ongoing engagement with regulatory authorities.

Mitigation strategies and best practices have emerged to address these environmental concerns, including closed-loop water systems, advanced treatment technologies for produced water, and energy efficiency improvements throughout the operational chain. These approaches, when properly implemented, can substantially reduce the environmental footprint of silica-based EOR technologies.

Water usage represents a primary environmental concern, as silica-based EOR typically requires substantial freshwater resources for injection fluid preparation. This demand can strain local water supplies, particularly in water-scarce regions where oil fields often operate. The water footprint extends beyond consumption to include potential contamination of groundwater systems if injection fluids migrate beyond target formations.

Chemical additives used in conjunction with colloidal silica formulations present additional environmental challenges. These compounds, necessary for stability and performance optimization, may contain surfactants, polymers, and other substances with varying biodegradability profiles. Their persistence in produced water and potential for bioaccumulation necessitates thorough toxicological evaluation before field implementation.

Waste management considerations emerge prominently in the environmental assessment framework. Produced water containing residual silica particles requires appropriate treatment before disposal or reuse. The solid waste generated from silica preparation and filtration processes must also be managed according to regulatory standards, with recycling opportunities explored where feasible.

Energy consumption and associated carbon emissions constitute another significant environmental dimension. The manufacturing, transportation, and injection of colloidal silica solutions involve substantial energy inputs, contributing to the overall carbon footprint of recovery operations. Life cycle assessment methodologies reveal that energy requirements for silica-based EOR may exceed conventional recovery methods in certain scenarios.

Ecosystem impacts warrant careful monitoring, particularly regarding potential changes to soil chemistry and microbial communities in the vicinity of injection sites. While silica is generally considered inert, the altered subsurface conditions following injection may influence local biogeochemical processes with cascading effects on ecosystem functioning.

Regulatory compliance frameworks vary significantly across jurisdictions, creating challenges for standardized environmental assessment. Operators must navigate complex permitting requirements, monitoring obligations, and reporting standards that govern silica-based EOR activities. The evolving nature of these regulations necessitates adaptive management approaches and ongoing engagement with regulatory authorities.

Mitigation strategies and best practices have emerged to address these environmental concerns, including closed-loop water systems, advanced treatment technologies for produced water, and energy efficiency improvements throughout the operational chain. These approaches, when properly implemented, can substantially reduce the environmental footprint of silica-based EOR technologies.

Economic Feasibility and ROI Analysis

The economic feasibility of incorporating colloidal silica in oil recovery operations hinges on several critical factors that influence return on investment. Initial implementation costs include specialized equipment for silica preparation, injection system modifications, and potential well reconfiguration expenses. These capital expenditures typically range from $500,000 to $2 million depending on field size and existing infrastructure. Additionally, operational costs encompass colloidal silica materials ($1,500-3,000 per ton), increased energy consumption for injection, and specialized workforce training.

When evaluating ROI, enhanced oil recovery rates provide the primary economic benefit. Field studies demonstrate that colloidal silica treatments can increase recovery factors by 5-15% of original oil in place (OOIP), translating to substantial revenue increases in mature fields. For a mid-sized reservoir with 10 million barrels of remaining oil, even a conservative 5% improvement yields 500,000 additional recoverable barrels, potentially generating $25-35 million at current oil prices.

Payback periods vary significantly based on reservoir characteristics and implementation scale. Most successful implementations achieve breakeven within 12-24 months, with some high-performance applications reporting payback periods as short as 8 months. The internal rate of return (IRR) typically ranges from 25% to 45%, making colloidal silica treatments financially attractive compared to alternative EOR methods.

Sensitivity analysis reveals that economic viability is most influenced by oil price fluctuations, reservoir heterogeneity, and silica material costs. At oil prices below $40 per barrel, the economic case weakens substantially unless implementation costs can be reduced. Conversely, fields with severe channeling problems often demonstrate the highest ROI due to dramatic improvements in sweep efficiency.

Long-term economic benefits extend beyond immediate production increases. Reduced water production decreases handling and disposal costs, which can represent 5-15% of operational expenses in mature fields. Additionally, the environmental benefits of reduced water usage and smaller surface footprint may translate to regulatory advantages and carbon credit opportunities in certain jurisdictions, further enhancing the economic case.

Risk mitigation strategies should include pilot testing to validate performance predictions before full-field implementation. Phased deployment approaches allow for optimization of injection parameters and more accurate economic forecasting, reducing financial exposure while maximizing potential returns.

When evaluating ROI, enhanced oil recovery rates provide the primary economic benefit. Field studies demonstrate that colloidal silica treatments can increase recovery factors by 5-15% of original oil in place (OOIP), translating to substantial revenue increases in mature fields. For a mid-sized reservoir with 10 million barrels of remaining oil, even a conservative 5% improvement yields 500,000 additional recoverable barrels, potentially generating $25-35 million at current oil prices.

Payback periods vary significantly based on reservoir characteristics and implementation scale. Most successful implementations achieve breakeven within 12-24 months, with some high-performance applications reporting payback periods as short as 8 months. The internal rate of return (IRR) typically ranges from 25% to 45%, making colloidal silica treatments financially attractive compared to alternative EOR methods.

Sensitivity analysis reveals that economic viability is most influenced by oil price fluctuations, reservoir heterogeneity, and silica material costs. At oil prices below $40 per barrel, the economic case weakens substantially unless implementation costs can be reduced. Conversely, fields with severe channeling problems often demonstrate the highest ROI due to dramatic improvements in sweep efficiency.

Long-term economic benefits extend beyond immediate production increases. Reduced water production decreases handling and disposal costs, which can represent 5-15% of operational expenses in mature fields. Additionally, the environmental benefits of reduced water usage and smaller surface footprint may translate to regulatory advantages and carbon credit opportunities in certain jurisdictions, further enhancing the economic case.

Risk mitigation strategies should include pilot testing to validate performance predictions before full-field implementation. Phased deployment approaches allow for optimization of injection parameters and more accurate economic forecasting, reducing financial exposure while maximizing potential returns.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!