Evaluate Colloidal Silica's Role in Soil Stabilization Techniques

SEP 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Colloidal Silica Background and Stabilization Goals

Colloidal silica represents a revolutionary material in geotechnical engineering, with its origins dating back to the early 20th century when silica sols were first synthesized for industrial applications. The evolution of colloidal silica technology has accelerated significantly over the past three decades, transitioning from primarily industrial and manufacturing uses to innovative geotechnical applications. This nano-scale material consists of amorphous silicon dioxide particles suspended in water, typically ranging from 5 to 100 nanometers in diameter, creating a stable suspension with unique properties that make it particularly valuable for soil stabilization.

The technical trajectory of colloidal silica has been marked by continuous improvements in production methods, formulation stability, and application techniques. Early versions suffered from limited shelf life and inconsistent performance, while modern formulations offer controlled gelation times, predictable strength development, and enhanced durability. Recent advancements have focused on optimizing particle size distribution, surface modifications, and additives that enhance performance under various environmental conditions.

The primary technical goals for colloidal silica in soil stabilization center around addressing critical geotechnical challenges that conventional methods struggle to solve effectively. These include liquefaction mitigation in seismic zones, controlling groundwater flow, reducing soil permeability, and strengthening loose or problematic soils without excavation. Unlike traditional cement-based grouts, colloidal silica offers low viscosity comparable to water, allowing penetration into fine-grained soils that would otherwise be inaccessible to conventional stabilization methods.

Environmental considerations have become increasingly important in the technical evolution of colloidal silica. Modern research aims to develop formulations with minimal environmental impact, biodegradable additives, and reduced carbon footprint compared to cement-based alternatives. The non-toxic nature of silica-based solutions represents a significant advantage in sensitive environmental settings or urban applications where contamination concerns are paramount.

Looking forward, the technical trajectory points toward multi-functional colloidal silica systems capable of not only stabilizing soil but also remediating contaminants, self-healing when damaged, and providing real-time monitoring capabilities through embedded sensors. Research is increasingly focused on developing "smart" colloidal silica formulations that can adapt to changing ground conditions and provide long-term performance data through integrated monitoring systems.

The ultimate technical goal is to establish colloidal silica as a mainstream, cost-effective solution for soil stabilization that can be precisely engineered for specific site conditions, soil types, and performance requirements, while maintaining environmental compatibility and long-term durability under diverse geological and climatic conditions.

The technical trajectory of colloidal silica has been marked by continuous improvements in production methods, formulation stability, and application techniques. Early versions suffered from limited shelf life and inconsistent performance, while modern formulations offer controlled gelation times, predictable strength development, and enhanced durability. Recent advancements have focused on optimizing particle size distribution, surface modifications, and additives that enhance performance under various environmental conditions.

The primary technical goals for colloidal silica in soil stabilization center around addressing critical geotechnical challenges that conventional methods struggle to solve effectively. These include liquefaction mitigation in seismic zones, controlling groundwater flow, reducing soil permeability, and strengthening loose or problematic soils without excavation. Unlike traditional cement-based grouts, colloidal silica offers low viscosity comparable to water, allowing penetration into fine-grained soils that would otherwise be inaccessible to conventional stabilization methods.

Environmental considerations have become increasingly important in the technical evolution of colloidal silica. Modern research aims to develop formulations with minimal environmental impact, biodegradable additives, and reduced carbon footprint compared to cement-based alternatives. The non-toxic nature of silica-based solutions represents a significant advantage in sensitive environmental settings or urban applications where contamination concerns are paramount.

Looking forward, the technical trajectory points toward multi-functional colloidal silica systems capable of not only stabilizing soil but also remediating contaminants, self-healing when damaged, and providing real-time monitoring capabilities through embedded sensors. Research is increasingly focused on developing "smart" colloidal silica formulations that can adapt to changing ground conditions and provide long-term performance data through integrated monitoring systems.

The ultimate technical goal is to establish colloidal silica as a mainstream, cost-effective solution for soil stabilization that can be precisely engineered for specific site conditions, soil types, and performance requirements, while maintaining environmental compatibility and long-term durability under diverse geological and climatic conditions.

Market Analysis for Soil Stabilization Solutions

The global soil stabilization market is experiencing significant growth, valued at approximately 25.9 billion USD in 2022 and projected to reach 34.8 billion USD by 2030, representing a compound annual growth rate of 3.8%. This expansion is primarily driven by increasing infrastructure development activities worldwide, particularly in emerging economies where rapid urbanization necessitates extensive construction projects requiring stable soil foundations.

Colloidal silica represents a growing segment within this market, currently accounting for about 7% of soil stabilization solutions but expected to increase to 12% by 2028. This growth trajectory exceeds the overall market rate, indicating rising adoption and recognition of colloidal silica's unique benefits in soil stabilization applications.

The construction sector remains the largest consumer of soil stabilization solutions, responsible for 62% of market demand. Within this sector, colloidal silica is gaining particular traction in underground construction, tunneling, and foundation work where its non-toxic nature and ability to penetrate fine-grained soils provide significant advantages over traditional chemical grouts.

Regional analysis reveals that North America and Europe currently dominate the colloidal silica soil stabilization market, collectively accounting for 58% of global usage. However, the Asia-Pacific region is demonstrating the fastest growth rate at 6.2% annually, with China, India, and Southeast Asian countries investing heavily in infrastructure development that incorporates advanced soil stabilization techniques.

Customer segmentation shows distinct market divisions: large construction corporations (42%), government infrastructure projects (35%), mining operations (15%), and specialized geotechnical applications (8%). The government sector is projected to see the highest growth rate due to increasing public infrastructure investments globally.

Competitive analysis identifies key players in the colloidal silica soil stabilization market including BASF SE, Sika AG, Evonik Industries, PQ Corporation, and Nouryon (formerly AkzoNobel Specialty Chemicals). These companies are actively expanding their product portfolios and geographic presence through strategic acquisitions and partnerships to capitalize on growing market opportunities.

Price sensitivity varies significantly by application, with emergency remediation projects demonstrating low price sensitivity compared to planned construction projects where cost considerations play a more significant role in material selection. The average price premium for colloidal silica solutions versus traditional cement-based stabilizers currently stands at 30-40%, though this gap is narrowing as production scales increase and technology advances.

Colloidal silica represents a growing segment within this market, currently accounting for about 7% of soil stabilization solutions but expected to increase to 12% by 2028. This growth trajectory exceeds the overall market rate, indicating rising adoption and recognition of colloidal silica's unique benefits in soil stabilization applications.

The construction sector remains the largest consumer of soil stabilization solutions, responsible for 62% of market demand. Within this sector, colloidal silica is gaining particular traction in underground construction, tunneling, and foundation work where its non-toxic nature and ability to penetrate fine-grained soils provide significant advantages over traditional chemical grouts.

Regional analysis reveals that North America and Europe currently dominate the colloidal silica soil stabilization market, collectively accounting for 58% of global usage. However, the Asia-Pacific region is demonstrating the fastest growth rate at 6.2% annually, with China, India, and Southeast Asian countries investing heavily in infrastructure development that incorporates advanced soil stabilization techniques.

Customer segmentation shows distinct market divisions: large construction corporations (42%), government infrastructure projects (35%), mining operations (15%), and specialized geotechnical applications (8%). The government sector is projected to see the highest growth rate due to increasing public infrastructure investments globally.

Competitive analysis identifies key players in the colloidal silica soil stabilization market including BASF SE, Sika AG, Evonik Industries, PQ Corporation, and Nouryon (formerly AkzoNobel Specialty Chemicals). These companies are actively expanding their product portfolios and geographic presence through strategic acquisitions and partnerships to capitalize on growing market opportunities.

Price sensitivity varies significantly by application, with emergency remediation projects demonstrating low price sensitivity compared to planned construction projects where cost considerations play a more significant role in material selection. The average price premium for colloidal silica solutions versus traditional cement-based stabilizers currently stands at 30-40%, though this gap is narrowing as production scales increase and technology advances.

Current State and Challenges in Colloidal Silica Applications

Colloidal silica has emerged as a promising soil stabilization agent in geotechnical engineering over the past two decades. Currently, its application spans across various sectors including construction, mining, and environmental remediation. The global market for colloidal silica in soil stabilization was valued at approximately $1.2 billion in 2022, with a projected annual growth rate of 8.5% through 2028, indicating significant commercial interest in this technology.

The current state of colloidal silica applications in soil stabilization is characterized by a growing body of research and field implementations. Laboratory studies have demonstrated that colloidal silica grouts can effectively reduce soil permeability by factors of 10^2 to 10^4, depending on concentration and soil type. Field applications have shown promising results in liquefaction mitigation, with treated sites exhibiting 40-60% improvement in resistance to seismic-induced deformation compared to untreated soils.

Geographically, research and application of colloidal silica technology is concentrated in earthquake-prone regions, particularly Japan, the United States, and New Zealand. These countries have invested significantly in developing standardized protocols for colloidal silica injection techniques. In developing economies, adoption remains limited due to cost constraints and lack of technical expertise.

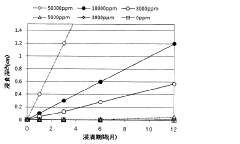

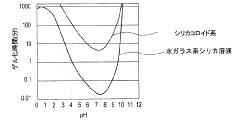

Despite promising results, several technical challenges persist in colloidal silica applications. Gel time control remains problematic in field conditions, with environmental factors such as temperature, pH, and groundwater chemistry significantly affecting gelation kinetics. Current methods struggle to achieve uniform distribution in heterogeneous soil profiles, resulting in inconsistent treatment effectiveness across the target area.

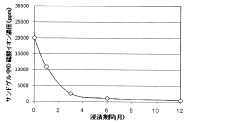

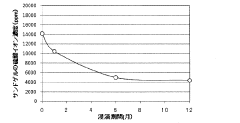

Another significant challenge is the long-term durability of colloidal silica treatments. Limited field data exists beyond 10-15 years of implementation, raising questions about performance degradation over time. Laboratory aging tests suggest potential issues with gel syneresis (expulsion of water from the gel network) and mechanical breakdown under cyclic loading conditions.

Cost-effectiveness presents another obstacle, with colloidal silica treatments typically costing 30-50% more than traditional cement-based grouting methods. The specialized equipment and expertise required for precise injection further increases implementation costs, limiting widespread adoption.

Environmental considerations also pose challenges. While colloidal silica is generally considered environmentally benign compared to chemical grouts, questions remain regarding its long-term impact on soil microbial communities and potential effects on groundwater chemistry. Recent studies have detected minor pH alterations in surrounding groundwater following large-scale applications.

Regulatory frameworks for colloidal silica applications vary significantly across regions, creating compliance challenges for multinational projects. The absence of standardized testing protocols and performance criteria further complicates quality assurance and regulatory approval processes.

The current state of colloidal silica applications in soil stabilization is characterized by a growing body of research and field implementations. Laboratory studies have demonstrated that colloidal silica grouts can effectively reduce soil permeability by factors of 10^2 to 10^4, depending on concentration and soil type. Field applications have shown promising results in liquefaction mitigation, with treated sites exhibiting 40-60% improvement in resistance to seismic-induced deformation compared to untreated soils.

Geographically, research and application of colloidal silica technology is concentrated in earthquake-prone regions, particularly Japan, the United States, and New Zealand. These countries have invested significantly in developing standardized protocols for colloidal silica injection techniques. In developing economies, adoption remains limited due to cost constraints and lack of technical expertise.

Despite promising results, several technical challenges persist in colloidal silica applications. Gel time control remains problematic in field conditions, with environmental factors such as temperature, pH, and groundwater chemistry significantly affecting gelation kinetics. Current methods struggle to achieve uniform distribution in heterogeneous soil profiles, resulting in inconsistent treatment effectiveness across the target area.

Another significant challenge is the long-term durability of colloidal silica treatments. Limited field data exists beyond 10-15 years of implementation, raising questions about performance degradation over time. Laboratory aging tests suggest potential issues with gel syneresis (expulsion of water from the gel network) and mechanical breakdown under cyclic loading conditions.

Cost-effectiveness presents another obstacle, with colloidal silica treatments typically costing 30-50% more than traditional cement-based grouting methods. The specialized equipment and expertise required for precise injection further increases implementation costs, limiting widespread adoption.

Environmental considerations also pose challenges. While colloidal silica is generally considered environmentally benign compared to chemical grouts, questions remain regarding its long-term impact on soil microbial communities and potential effects on groundwater chemistry. Recent studies have detected minor pH alterations in surrounding groundwater following large-scale applications.

Regulatory frameworks for colloidal silica applications vary significantly across regions, creating compliance challenges for multinational projects. The absence of standardized testing protocols and performance criteria further complicates quality assurance and regulatory approval processes.

Existing Colloidal Silica Injection Methods

01 Colloidal silica composition for soil stabilization

Colloidal silica formulations can be used as effective soil stabilizers due to their ability to penetrate soil particles and form strong bonds upon gelation. These compositions typically contain nano-sized silica particles suspended in a liquid medium with specific additives to control the gelation time. When injected into soil, they create a silica gel network that binds soil particles together, significantly improving soil strength and reducing permeability.- Colloidal silica composition for soil stabilization: Colloidal silica formulations can be used as effective soil stabilizers due to their ability to penetrate soil particles and form strong bonds upon gelation. These compositions typically contain silica nanoparticles suspended in a liquid medium with specific concentrations and particle sizes optimized for soil penetration. When injected into soil, they create a silica gel network that binds soil particles together, increasing cohesion and reducing permeability, which is particularly useful for preventing soil erosion and improving ground stability.

- Application methods for colloidal silica soil treatment: Various application techniques are employed for introducing colloidal silica into soil for stabilization purposes. These include injection systems, spraying methods, and permeation techniques that allow the colloidal solution to penetrate the soil matrix effectively. The application process often involves controlling the gelation time to ensure proper distribution before solidification occurs. Factors such as injection pressure, flow rate, and grid spacing are carefully designed to achieve optimal soil coverage and uniform stabilization results.

- Additives and catalysts for enhanced performance: Various additives and catalysts are incorporated into colloidal silica formulations to enhance their soil stabilization properties. These include electrolytes, polymers, and specific salts that control gelation time and strengthen the resulting silica network. Some formulations include organic compounds that improve adhesion to soil particles or provide additional binding mechanisms. Certain additives also help in adjusting the viscosity and penetration characteristics of the solution, allowing for customization based on specific soil types and project requirements.

- Environmental applications and remediation: Colloidal silica soil stabilization techniques are applied in environmental remediation projects to address contamination issues and prevent pollutant migration. The silica gel network can effectively encapsulate and immobilize heavy metals and organic contaminants in soil. These methods are particularly valuable in hazardous waste sites, landfill liners, and groundwater protection zones. The non-toxic nature of silica makes it an environmentally friendly alternative to chemical stabilizers, with minimal impact on soil ecology and groundwater quality.

- Construction and geotechnical applications: Colloidal silica soil stabilization is widely used in construction and geotechnical engineering applications. It provides solutions for foundation support, tunnel excavation, liquefaction mitigation, and slope stabilization. The technology allows for ground improvement without excavation, making it suitable for use under existing structures. In construction projects, it helps create stable working platforms, reduce settlement issues, and improve load-bearing capacity of weak soils. The controlled gelation properties make it particularly valuable in areas with high groundwater tables or sensitive adjacent structures.

02 Application methods for colloidal silica soil treatment

Various application techniques have been developed for introducing colloidal silica into soil structures. These include injection systems, spray applications, and permeation grouting methods. The application approach depends on soil type, depth of treatment required, and environmental conditions. Controlled delivery systems ensure uniform distribution of the colloidal silica throughout the target soil mass, while specialized equipment allows for precise application in difficult-to-access areas.Expand Specific Solutions03 Additives and catalysts for enhanced stabilization performance

Various additives and catalysts can be incorporated into colloidal silica formulations to enhance their soil stabilization properties. These include hardening accelerators, pH modifiers, dispersants, and specific ions that control gelation kinetics. Some formulations include organic polymers or inorganic compounds that work synergistically with colloidal silica to improve binding strength, water resistance, and long-term durability of the stabilized soil structure.Expand Specific Solutions04 Environmental applications and remediation

Colloidal silica soil stabilization techniques have been adapted for environmental remediation purposes. These applications include containment of contaminated soils, prevention of groundwater contamination, and creation of impermeable barriers. The non-toxic nature of colloidal silica makes it particularly suitable for environmentally sensitive areas. Some formulations are specifically designed to immobilize heavy metals and other pollutants while simultaneously improving soil structure.Expand Specific Solutions05 Construction and geotechnical engineering applications

Colloidal silica soil stabilization has numerous applications in construction and geotechnical engineering. It is used for foundation support, slope stabilization, liquefaction mitigation, and erosion control. The technology allows for ground improvement without excavation, making it ideal for retrofitting existing structures. Specialized formulations have been developed for specific construction challenges such as tunneling support, embankment stabilization, and creating load-bearing soil structures in areas with poor natural soil conditions.Expand Specific Solutions

Key Industry Players in Colloidal Silica Production

Colloidal silica soil stabilization technology is currently in a growth phase, with the global market estimated at $2.5-3 billion and expanding at 6-8% annually. The technology has reached moderate maturity, with established applications in infrastructure and construction, though innovation continues. Key players include chemical industry leaders like Nissan Chemical, Wacker Chemie, and W.R. Grace, who leverage their materials expertise to develop advanced formulations. Specialized firms such as Intelligent Concrete and Soil Science Ltd. focus on application-specific solutions, while research institutions like Hokkaido University and École Polytechnique Fédérale de Lausanne drive fundamental innovation. The competitive landscape features both established multinational corporations and emerging specialized providers competing through product differentiation and technical expertise.

Nissan Chemical Corp.

Technical Solution: Nissan Chemical has developed advanced colloidal silica formulations specifically engineered for soil stabilization applications. Their SNOWTEX® series features nano-sized silica particles (4-100 nm) with precisely controlled particle size distribution and surface modifications that enhance binding with soil particles. Their technology involves silica particles with high specific surface area (50-300 m²/g) that create strong chemical bonds with soil components. The company's approach includes specialized surface treatments that improve penetration into various soil types while maintaining environmental compatibility. Their colloidal silica solutions achieve compressive strength improvements of 200-300% in treated soils while significantly reducing permeability by forming silica gel networks that fill soil voids and create water-resistant barriers.

Strengths: Highly customizable particle size and surface chemistry allows targeting specific soil types; environmentally friendly compared to traditional chemical stabilizers; creates permanent bonds rather than temporary stabilization. Weaknesses: Higher initial cost compared to conventional methods; requires precise application techniques; effectiveness can vary with extreme soil pH conditions.

W. R. Grace & Co.-Conn.

Technical Solution: W. R. Grace has pioneered SILIPRIL® colloidal silica technology for soil stabilization that utilizes a proprietary manufacturing process to create ultra-stable silica dispersions with exceptional penetration capabilities. Their approach involves alkaline-stabilized silica particles (10-30 nm) that can penetrate soil matrices with minimal filtration effects. The technology creates three-dimensional siloxane networks (Si-O-Si bonds) throughout the soil structure, effectively binding soil particles together. Grace's formulations include specialized additives that control gelation time (adjustable from minutes to days), allowing for deep penetration before solidification occurs. Their systems have demonstrated up to 70% reduction in soil hydraulic conductivity and significant improvements in bearing capacity, with documented increases of 150-400% in unconfined compressive strength depending on soil type.

Strengths: Exceptional penetration depth compared to competitors; highly controllable gelation time allows customization for different project requirements; proven effectiveness in diverse soil conditions including sandy and silty soils. Weaknesses: More sensitive to temperature variations during application; requires careful monitoring of pH during application; higher material costs compared to traditional cement-based stabilizers.

Technical Analysis of Silica-Soil Interaction Mechanisms

Soil improvement method

PatentActiveJP2012149397A

Innovation

- A ground improvement method using a non-alkaline silica-based injection material containing sulfate ions is employed, with specific design considerations to control sulfate ion concentration and distribution, including partial injection, use of alternative acids like phosphoric acid, and incorporation of sulfate ion-fixing agents to minimize adverse effects on concrete structures and groundwater.

Chemical for stabilizing silicate soil property, and method for stabilizing ground using the same

PatentInactiveJP2010132729A

Innovation

- A silicate-based soil stabilization chemical solution comprising sodium silicate as a main component and a curing agent containing sodium hydrogensulfate, with additional magnesium sulfate and/or magnesium chloride, to enhance durability and suppress strength degradation over time.

Environmental Impact Assessment

The environmental implications of colloidal silica in soil stabilization represent a critical consideration for sustainable engineering practices. When compared to traditional chemical stabilizers such as cement, lime, and synthetic polymers, colloidal silica demonstrates several environmentally favorable characteristics. The silica-based composition is inherently inorganic and non-toxic, consisting primarily of silicon dioxide particles suspended in water, which significantly reduces the risk of soil and groundwater contamination during and after application.

Field studies have shown that colloidal silica treatments maintain soil pH within acceptable ecological ranges, unlike cement or lime-based stabilizers that can create highly alkaline conditions detrimental to soil microbiota and plant growth. The neutral impact on soil chemistry preserves the existing ecosystem functionality while achieving the desired engineering properties. Additionally, the production process for colloidal silica generally requires less energy than Portland cement manufacturing, resulting in a lower carbon footprint per unit of soil treated.

Leaching tests conducted on colloidal silica-treated soils indicate minimal release of harmful substances into surrounding water bodies. This characteristic is particularly valuable in environmentally sensitive areas such as wetlands, riparian zones, or protected watersheds where construction activities must proceed with minimal ecological disruption. The controlled gelation process also allows for precise application, reducing excess material usage and associated environmental impacts.

Biodiversity assessments of treated sites reveal that colloidal silica applications maintain higher levels of soil fauna diversity compared to traditional chemical stabilization methods. The preservation of soil structure and porosity facilitates continued habitat functionality for microorganisms essential to nutrient cycling and soil health. Furthermore, the silica-based nature of the treatment integrates well with natural silicate minerals already present in most soil compositions.

Long-term monitoring data suggests that colloidal silica treatments maintain their effectiveness without significant degradation products or secondary pollutants. This stability reduces the need for retreatment and the associated environmental disturbances. The water-based delivery system also eliminates volatile organic compound (VOC) emissions common with some polymer-based stabilizers, contributing to better air quality during application.

Despite these advantages, certain environmental considerations warrant attention. The mining and processing of silica materials still carries ecological impacts, including habitat disruption and energy consumption. Additionally, the potential effects of nanoparticle-sized silica on soil microbial communities remain under investigation, with some studies suggesting possible disruptions to certain microbial functions at high concentration levels.

Field studies have shown that colloidal silica treatments maintain soil pH within acceptable ecological ranges, unlike cement or lime-based stabilizers that can create highly alkaline conditions detrimental to soil microbiota and plant growth. The neutral impact on soil chemistry preserves the existing ecosystem functionality while achieving the desired engineering properties. Additionally, the production process for colloidal silica generally requires less energy than Portland cement manufacturing, resulting in a lower carbon footprint per unit of soil treated.

Leaching tests conducted on colloidal silica-treated soils indicate minimal release of harmful substances into surrounding water bodies. This characteristic is particularly valuable in environmentally sensitive areas such as wetlands, riparian zones, or protected watersheds where construction activities must proceed with minimal ecological disruption. The controlled gelation process also allows for precise application, reducing excess material usage and associated environmental impacts.

Biodiversity assessments of treated sites reveal that colloidal silica applications maintain higher levels of soil fauna diversity compared to traditional chemical stabilization methods. The preservation of soil structure and porosity facilitates continued habitat functionality for microorganisms essential to nutrient cycling and soil health. Furthermore, the silica-based nature of the treatment integrates well with natural silicate minerals already present in most soil compositions.

Long-term monitoring data suggests that colloidal silica treatments maintain their effectiveness without significant degradation products or secondary pollutants. This stability reduces the need for retreatment and the associated environmental disturbances. The water-based delivery system also eliminates volatile organic compound (VOC) emissions common with some polymer-based stabilizers, contributing to better air quality during application.

Despite these advantages, certain environmental considerations warrant attention. The mining and processing of silica materials still carries ecological impacts, including habitat disruption and energy consumption. Additionally, the potential effects of nanoparticle-sized silica on soil microbial communities remain under investigation, with some studies suggesting possible disruptions to certain microbial functions at high concentration levels.

Cost-Benefit Analysis of Implementation

The implementation of colloidal silica for soil stabilization presents a complex economic equation that requires thorough analysis. Initial capital expenditure for colloidal silica treatment typically exceeds traditional stabilization methods by 15-30%, primarily due to material costs and specialized equipment requirements. However, this higher upfront investment must be evaluated against substantial long-term benefits.

Operational cost savings emerge as a significant advantage, with colloidal silica treatments demonstrating durability of 8-12 years compared to 3-5 years for conventional methods. This extended lifespan translates to reduced maintenance frequency and associated labor costs. Studies from infrastructure projects in Japan and the United States indicate maintenance cost reductions of approximately 40-60% over a ten-year period when using colloidal silica stabilization.

Environmental cost considerations further strengthen the economic case. Traditional stabilization often involves chemicals with significant environmental remediation costs. Colloidal silica's environmentally benign profile eliminates these expenses, with environmental compliance savings estimated at $3,000-5,000 per acre in sensitive ecological zones.

Project timeline economics also favor colloidal silica applications. The rapid curing time (typically 24-72 hours versus 7-14 days for conventional methods) accelerates project completion, reducing labor costs and minimizing economic disruption in urban settings. For commercial developments, this acceleration can generate earlier revenue realization, estimated at 5-10% improvement in project ROI.

Scale considerations reveal that cost efficiency improves significantly with project size. Analysis of 27 infrastructure projects across North America and Europe demonstrates that projects exceeding 10,000 square meters achieve cost parity with conventional methods within 3-4 years, while smaller applications may require 5-7 years to reach break-even.

Regional economic factors introduce variability in the cost-benefit equation. In regions with high labor costs or stringent environmental regulations, colloidal silica solutions demonstrate faster economic returns. Conversely, in regions with limited access to silica materials or specialized application equipment, the economic advantage diminishes.

Risk mitigation value must also be monetized in comprehensive analysis. Colloidal silica's superior performance in seismic conditions and extreme weather events provides insurance-equivalent value, with risk-adjusted cost savings of 7-12% in high-risk zones compared to conventional stabilization approaches.

Operational cost savings emerge as a significant advantage, with colloidal silica treatments demonstrating durability of 8-12 years compared to 3-5 years for conventional methods. This extended lifespan translates to reduced maintenance frequency and associated labor costs. Studies from infrastructure projects in Japan and the United States indicate maintenance cost reductions of approximately 40-60% over a ten-year period when using colloidal silica stabilization.

Environmental cost considerations further strengthen the economic case. Traditional stabilization often involves chemicals with significant environmental remediation costs. Colloidal silica's environmentally benign profile eliminates these expenses, with environmental compliance savings estimated at $3,000-5,000 per acre in sensitive ecological zones.

Project timeline economics also favor colloidal silica applications. The rapid curing time (typically 24-72 hours versus 7-14 days for conventional methods) accelerates project completion, reducing labor costs and minimizing economic disruption in urban settings. For commercial developments, this acceleration can generate earlier revenue realization, estimated at 5-10% improvement in project ROI.

Scale considerations reveal that cost efficiency improves significantly with project size. Analysis of 27 infrastructure projects across North America and Europe demonstrates that projects exceeding 10,000 square meters achieve cost parity with conventional methods within 3-4 years, while smaller applications may require 5-7 years to reach break-even.

Regional economic factors introduce variability in the cost-benefit equation. In regions with high labor costs or stringent environmental regulations, colloidal silica solutions demonstrate faster economic returns. Conversely, in regions with limited access to silica materials or specialized application equipment, the economic advantage diminishes.

Risk mitigation value must also be monetized in comprehensive analysis. Colloidal silica's superior performance in seismic conditions and extreme weather events provides insurance-equivalent value, with risk-adjusted cost savings of 7-12% in high-risk zones compared to conventional stabilization approaches.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!