How to Optimize Colloidal Silica for Antimicrobial Coatings

SEP 10, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Colloidal Silica Antimicrobial Technology Background and Objectives

Colloidal silica has emerged as a promising material in antimicrobial applications over the past two decades, evolving from traditional industrial uses to advanced biomedical applications. This evolution represents a significant shift in materials science, where nanoscale silica particles suspended in liquid medium offer unique physicochemical properties that can be harnessed for antimicrobial purposes. The historical trajectory of colloidal silica development began with industrial applications in catalysis and surface treatments before researchers recognized its potential in biological interfaces.

The technological evolution of colloidal silica has been marked by several key advancements. Initially, research focused on basic silica nanoparticle synthesis methods such as sol-gel processes and Stöber synthesis. Subsequently, surface modification techniques emerged, allowing for functionalization with various antimicrobial agents including silver ions, quaternary ammonium compounds, and specific antimicrobial peptides. Recent innovations have centered on controlled release mechanisms and enhanced stability in diverse environmental conditions.

Current research trends indicate growing interest in hybrid colloidal silica systems that combine multiple antimicrobial mechanisms. These include photocatalytic properties, ion release capabilities, and physical bacterial membrane disruption. The integration of colloidal silica with other nanomaterials such as graphene oxide, metal oxides, and biodegradable polymers represents another significant trend, creating synergistic antimicrobial effects while addressing biocompatibility concerns.

The primary technical objective for optimizing colloidal silica in antimicrobial coatings is to develop formulations with enhanced antimicrobial efficacy against a broad spectrum of pathogens while maintaining long-term stability and minimal cytotoxicity. This includes engineering particles with precise size distribution (typically 10-100 nm) and controlled surface chemistry to maximize antimicrobial activity while ensuring uniform dispersion in coating matrices.

Secondary objectives include developing cost-effective and scalable production methods suitable for industrial implementation, as current advanced synthesis techniques often remain confined to laboratory settings. Additionally, there is a pressing need to design colloidal silica systems that maintain antimicrobial efficacy under challenging conditions such as varying pH levels, temperature fluctuations, and mechanical stress.

The environmental sustainability aspect represents another critical objective, with research increasingly focused on reducing the environmental footprint of colloidal silica production and ensuring end-of-life biodegradability. This aligns with global regulatory trends toward more sustainable nanomaterials and reduced reliance on traditional biocides with known environmental concerns.

Looking forward, the technological trajectory points toward smart responsive colloidal silica systems that can activate antimicrobial properties in response to specific environmental triggers, potentially revolutionizing applications in healthcare settings, food packaging, and public infrastructure where pathogen control remains a persistent challenge.

The technological evolution of colloidal silica has been marked by several key advancements. Initially, research focused on basic silica nanoparticle synthesis methods such as sol-gel processes and Stöber synthesis. Subsequently, surface modification techniques emerged, allowing for functionalization with various antimicrobial agents including silver ions, quaternary ammonium compounds, and specific antimicrobial peptides. Recent innovations have centered on controlled release mechanisms and enhanced stability in diverse environmental conditions.

Current research trends indicate growing interest in hybrid colloidal silica systems that combine multiple antimicrobial mechanisms. These include photocatalytic properties, ion release capabilities, and physical bacterial membrane disruption. The integration of colloidal silica with other nanomaterials such as graphene oxide, metal oxides, and biodegradable polymers represents another significant trend, creating synergistic antimicrobial effects while addressing biocompatibility concerns.

The primary technical objective for optimizing colloidal silica in antimicrobial coatings is to develop formulations with enhanced antimicrobial efficacy against a broad spectrum of pathogens while maintaining long-term stability and minimal cytotoxicity. This includes engineering particles with precise size distribution (typically 10-100 nm) and controlled surface chemistry to maximize antimicrobial activity while ensuring uniform dispersion in coating matrices.

Secondary objectives include developing cost-effective and scalable production methods suitable for industrial implementation, as current advanced synthesis techniques often remain confined to laboratory settings. Additionally, there is a pressing need to design colloidal silica systems that maintain antimicrobial efficacy under challenging conditions such as varying pH levels, temperature fluctuations, and mechanical stress.

The environmental sustainability aspect represents another critical objective, with research increasingly focused on reducing the environmental footprint of colloidal silica production and ensuring end-of-life biodegradability. This aligns with global regulatory trends toward more sustainable nanomaterials and reduced reliance on traditional biocides with known environmental concerns.

Looking forward, the technological trajectory points toward smart responsive colloidal silica systems that can activate antimicrobial properties in response to specific environmental triggers, potentially revolutionizing applications in healthcare settings, food packaging, and public infrastructure where pathogen control remains a persistent challenge.

Market Analysis for Antimicrobial Coating Applications

The global antimicrobial coatings market has experienced significant growth in recent years, driven by increasing awareness of infection control and hygiene across various sectors. As of 2023, the market is valued at approximately 4.2 billion USD and is projected to reach 7.5 billion USD by 2028, representing a compound annual growth rate (CAGR) of 12.3%. This growth trajectory is particularly relevant for colloidal silica-based antimicrobial coatings, which are gaining traction due to their versatility and effectiveness.

Healthcare remains the dominant application sector, accounting for nearly 35% of the total market share. Hospitals, clinics, and medical device manufacturers are increasingly adopting antimicrobial coatings to reduce healthcare-associated infections (HAIs). The COVID-19 pandemic has further accelerated this trend, with heightened focus on surface hygiene and pathogen control in medical environments.

The food and beverage industry represents the second-largest application segment, with growing implementation of antimicrobial coatings in processing equipment, packaging, and storage facilities. Regulatory pressures and consumer demand for safer food handling practices are key drivers in this sector, creating substantial opportunities for colloidal silica-based solutions.

Building and construction applications are emerging as a rapidly growing segment, particularly in high-traffic public spaces, educational institutions, and commercial buildings. The demand for antimicrobial surfaces in doorknobs, handrails, and other frequently touched surfaces has surged post-pandemic, with colloidal silica solutions offering durable protection without aesthetic compromise.

Regional analysis indicates North America currently leads the market with a 38% share, followed by Europe at 29% and Asia-Pacific at 24%. However, the Asia-Pacific region is expected to witness the fastest growth rate of 14.5% annually through 2028, driven by rapid industrialization, healthcare infrastructure development, and increasing awareness of hygiene standards in countries like China, India, and South Korea.

Consumer preferences are shifting toward environmentally friendly and non-toxic antimicrobial solutions, creating a significant opportunity for colloidal silica-based coatings that can offer effective protection without relying on traditional biocides. Market research indicates that 67% of industrial buyers now prioritize sustainability credentials when selecting antimicrobial coating technologies.

The competitive landscape features both established chemical companies and innovative startups focusing on advanced antimicrobial technologies. Strategic partnerships between colloidal silica manufacturers and coating formulators are becoming increasingly common, aiming to develop specialized solutions for specific industry applications and compliance with evolving regulatory standards.

Healthcare remains the dominant application sector, accounting for nearly 35% of the total market share. Hospitals, clinics, and medical device manufacturers are increasingly adopting antimicrobial coatings to reduce healthcare-associated infections (HAIs). The COVID-19 pandemic has further accelerated this trend, with heightened focus on surface hygiene and pathogen control in medical environments.

The food and beverage industry represents the second-largest application segment, with growing implementation of antimicrobial coatings in processing equipment, packaging, and storage facilities. Regulatory pressures and consumer demand for safer food handling practices are key drivers in this sector, creating substantial opportunities for colloidal silica-based solutions.

Building and construction applications are emerging as a rapidly growing segment, particularly in high-traffic public spaces, educational institutions, and commercial buildings. The demand for antimicrobial surfaces in doorknobs, handrails, and other frequently touched surfaces has surged post-pandemic, with colloidal silica solutions offering durable protection without aesthetic compromise.

Regional analysis indicates North America currently leads the market with a 38% share, followed by Europe at 29% and Asia-Pacific at 24%. However, the Asia-Pacific region is expected to witness the fastest growth rate of 14.5% annually through 2028, driven by rapid industrialization, healthcare infrastructure development, and increasing awareness of hygiene standards in countries like China, India, and South Korea.

Consumer preferences are shifting toward environmentally friendly and non-toxic antimicrobial solutions, creating a significant opportunity for colloidal silica-based coatings that can offer effective protection without relying on traditional biocides. Market research indicates that 67% of industrial buyers now prioritize sustainability credentials when selecting antimicrobial coating technologies.

The competitive landscape features both established chemical companies and innovative startups focusing on advanced antimicrobial technologies. Strategic partnerships between colloidal silica manufacturers and coating formulators are becoming increasingly common, aiming to develop specialized solutions for specific industry applications and compliance with evolving regulatory standards.

Current State and Challenges in Colloidal Silica Antimicrobial Technology

The global landscape of colloidal silica antimicrobial technology presents a complex picture of advancement and limitation. Currently, research institutions across North America, Europe, and Asia have demonstrated significant progress in developing colloidal silica-based antimicrobial coatings with enhanced efficacy against a broad spectrum of pathogens. These developments have been particularly accelerated in response to the COVID-19 pandemic, which highlighted the critical need for effective antimicrobial surfaces in healthcare settings.

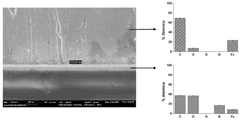

The current technological state shows promising results in laboratory settings, with colloidal silica nanoparticles exhibiting strong antimicrobial properties when properly functionalized. Recent studies have achieved log reductions of 3-5 against common pathogens such as E. coli, S. aureus, and several enveloped viruses. However, translation from laboratory success to commercial application remains challenging.

A significant technical hurdle involves the stability of colloidal silica in antimicrobial formulations. Current solutions often suffer from aggregation during storage, reducing shelf life and diminishing antimicrobial efficacy over time. This instability is particularly pronounced when attempting to incorporate higher concentrations of active antimicrobial agents into the silica matrix.

Another major challenge is achieving uniform dispersion of colloidal silica particles within coating formulations. Uneven distribution leads to inconsistent antimicrobial performance across treated surfaces and potential weak points where pathogen colonization can occur. This issue becomes more pronounced when scaling up production from laboratory to industrial volumes.

Durability presents another substantial obstacle. Many current colloidal silica antimicrobial coatings demonstrate reduced efficacy after repeated cleaning cycles or exposure to environmental stressors. Studies indicate that most commercial formulations lose significant antimicrobial activity after 50-100 cleaning cycles, falling short of the durability requirements for high-touch surfaces in healthcare or public settings.

Geographically, research leadership in this field shows distinct patterns. North American institutions lead in fundamental research and novel functionalization approaches, while Asian manufacturers, particularly in Japan and South Korea, dominate in scaled production technologies. European research centers excel in environmental impact assessment and regulatory compliance frameworks for these materials.

Regulatory hurdles further complicate advancement, with varying standards across regions creating a fragmented approval landscape. The EPA in the United States, for instance, requires specific efficacy testing protocols that differ from those mandated by European authorities, creating barriers to global commercialization.

Cost-effectiveness remains a significant constraint, with current manufacturing methods for high-performance colloidal silica antimicrobial coatings being prohibitively expensive for widespread adoption outside of specialized healthcare applications. The production process typically requires multiple steps of functionalization and quality control, driving costs significantly higher than conventional antimicrobial solutions.

The current technological state shows promising results in laboratory settings, with colloidal silica nanoparticles exhibiting strong antimicrobial properties when properly functionalized. Recent studies have achieved log reductions of 3-5 against common pathogens such as E. coli, S. aureus, and several enveloped viruses. However, translation from laboratory success to commercial application remains challenging.

A significant technical hurdle involves the stability of colloidal silica in antimicrobial formulations. Current solutions often suffer from aggregation during storage, reducing shelf life and diminishing antimicrobial efficacy over time. This instability is particularly pronounced when attempting to incorporate higher concentrations of active antimicrobial agents into the silica matrix.

Another major challenge is achieving uniform dispersion of colloidal silica particles within coating formulations. Uneven distribution leads to inconsistent antimicrobial performance across treated surfaces and potential weak points where pathogen colonization can occur. This issue becomes more pronounced when scaling up production from laboratory to industrial volumes.

Durability presents another substantial obstacle. Many current colloidal silica antimicrobial coatings demonstrate reduced efficacy after repeated cleaning cycles or exposure to environmental stressors. Studies indicate that most commercial formulations lose significant antimicrobial activity after 50-100 cleaning cycles, falling short of the durability requirements for high-touch surfaces in healthcare or public settings.

Geographically, research leadership in this field shows distinct patterns. North American institutions lead in fundamental research and novel functionalization approaches, while Asian manufacturers, particularly in Japan and South Korea, dominate in scaled production technologies. European research centers excel in environmental impact assessment and regulatory compliance frameworks for these materials.

Regulatory hurdles further complicate advancement, with varying standards across regions creating a fragmented approval landscape. The EPA in the United States, for instance, requires specific efficacy testing protocols that differ from those mandated by European authorities, creating barriers to global commercialization.

Cost-effectiveness remains a significant constraint, with current manufacturing methods for high-performance colloidal silica antimicrobial coatings being prohibitively expensive for widespread adoption outside of specialized healthcare applications. The production process typically requires multiple steps of functionalization and quality control, driving costs significantly higher than conventional antimicrobial solutions.

Current Optimization Methods for Colloidal Silica Antimicrobial Properties

01 Particle size control and distribution optimization

Controlling the particle size and optimizing the distribution of colloidal silica particles is crucial for enhancing performance in various applications. Methods include precise synthesis conditions, temperature control, and pH adjustment to achieve desired particle sizes ranging from nanometers to micrometers. Optimized particle size distribution contributes to improved mechanical properties, stability, and application-specific performance.- Particle size and distribution optimization: Optimizing the particle size and distribution of colloidal silica is crucial for enhancing its performance in various applications. Controlling the size of silica particles within specific ranges (typically from nanometers to micrometers) can significantly impact properties such as surface area, reactivity, and stability of the colloid. Methods for achieving optimal particle size distribution include controlled nucleation, growth conditions manipulation, and post-synthesis classification techniques. These optimizations result in improved mechanical strength, optical clarity, and uniform coating performance.

- Surface modification and functionalization: Surface modification of colloidal silica particles enhances their compatibility with various matrices and expands their application range. Functionalization techniques include silane coupling agent treatments, polymer grafting, and metal ion incorporation to create specialized surface properties. These modifications can improve dispersion stability, prevent agglomeration, and create specific interactions with surrounding media. Modified colloidal silica demonstrates enhanced performance in applications requiring hydrophobicity, adhesion promotion, or specific chemical reactivity.

- Stability enhancement methods: Improving the colloidal stability of silica dispersions is essential for maintaining performance during storage and application. Stability enhancement methods include pH adjustment, electrolyte control, addition of stabilizing agents, and surface charge modification. These techniques prevent aggregation, sedimentation, and gelation by optimizing the balance between attractive and repulsive forces between particles. Stable colloidal silica systems maintain their intended properties over extended periods and under varying environmental conditions, resulting in consistent performance in end applications.

- Production process optimization: Optimizing the production process of colloidal silica involves refining synthesis parameters such as temperature, pressure, reaction time, and precursor concentrations. Advanced production methods include sol-gel processes, flame hydrolysis, ion exchange techniques, and continuous flow reactors. These optimizations aim to increase yield, reduce energy consumption, improve batch consistency, and enhance purity. Process innovations also focus on environmentally friendly approaches that minimize waste generation and reduce the use of hazardous chemicals while maintaining or improving product quality.

- Application-specific formulations: Developing specialized colloidal silica formulations for specific applications requires tailoring properties such as solid content, viscosity, pH, and additives. These customized formulations are designed to meet the requirements of industries including paper manufacturing, metal casting, electronics, catalysis, and construction. Optimization involves balancing multiple parameters to achieve desired performance characteristics such as binding strength, abrasion resistance, or thermal stability. Application-specific formulations may incorporate synergistic components that enhance the functionality of colloidal silica in particular use cases.

02 Surface modification and functionalization techniques

Surface modification of colloidal silica involves treating particles with various functional groups to enhance compatibility with different matrices. Techniques include silanization, polymer grafting, and organic coating to improve dispersion stability and interfacial interactions. These modifications can tailor colloidal silica for specific applications by controlling hydrophobicity/hydrophilicity balance and surface charge characteristics.Expand Specific Solutions03 Stabilization methods for colloidal silica suspensions

Various stabilization methods are employed to prevent aggregation and sedimentation of colloidal silica in suspensions. These include electrostatic stabilization through pH control, steric stabilization using polymeric additives, and electrosteric stabilization combining both approaches. Optimized stabilization techniques extend shelf life, maintain consistent performance, and prevent gelation during storage and application.Expand Specific Solutions04 Process optimization for colloidal silica production

Manufacturing processes for colloidal silica can be optimized through various parameters including reaction temperature, time, pH, and precursor concentration. Advanced techniques such as continuous flow reactors, sol-gel methods, and hydrothermal synthesis allow for precise control over particle characteristics. Process optimization focuses on increasing yield, reducing energy consumption, and ensuring batch-to-batch consistency.Expand Specific Solutions05 Application-specific formulation development

Colloidal silica formulations can be tailored for specific applications such as paper coatings, catalysts, polishing agents, and concrete additives. Optimization involves adjusting silica concentration, incorporating synergistic additives, and modifying rheological properties. Application-specific formulations focus on enhancing key performance attributes while maintaining stability and compatibility with other system components.Expand Specific Solutions

Key Industry Players in Antimicrobial Coating Development

The antimicrobial coatings market utilizing colloidal silica is currently in a growth phase, with increasing applications across healthcare, construction, and consumer goods sectors. The global market size is estimated to reach $6.3 billion by 2026, growing at a CAGR of 12.5%. Technologically, the field is in mid-maturity, with established players like W.R. Grace & Co. and Shin-Etsu Chemical leading commercial applications, while companies such as Nissan Chemical America and Fuso Chemical are advancing specialized formulations. Emerging players like Viraschutz Europe and Resonac Holdings are introducing innovations in nanoparticle dispersion and surface modification techniques. Research institutions including Northeastern University and The Australian National University are collaborating with industry to overcome challenges in durability and controlled release mechanisms, positioning colloidal silica antimicrobial coatings at the intersection of established technology and emerging innovation.

W. R. Grace & Co.-Conn.

Technical Solution: W. R. Grace has developed sophisticated colloidal silica systems for antimicrobial applications through their LUDOX® technology platform. Their approach centers on precisely controlled silica nanoparticles (4-22 nm) with tailored surface properties that enhance compatibility with various antimicrobial agents. The company employs a proprietary manufacturing process that produces highly monodisperse silica particles with narrow size distributions, ensuring consistent antimicrobial performance across applications. Their technology incorporates silver and copper ions through ion-exchange mechanisms on modified silica surfaces, creating stable metal-silica complexes that provide controlled release of antimicrobial agents[5]. Grace's formulations achieve extended antimicrobial activity through specialized surface treatments that modulate the release kinetics of active ions in response to environmental conditions. Their research has demonstrated that optimized formulations maintain efficacy in high-humidity environments where traditional antimicrobial coatings often fail, with testing showing sustained activity after exposure to 95% relative humidity for over 30 days. The company has successfully applied this technology in healthcare settings, where their coatings have shown significant reduction in surface contamination levels.

Strengths: Exceptional particle size uniformity leading to consistent performance; excellent stability in various pH conditions; effective in high-humidity environments where many antimicrobial systems fail. Weaknesses: Higher cost compared to conventional antimicrobial additives; potential for reduced efficacy on porous substrates; requires specialized application equipment for optimal performance in some coating systems.

Shin-Etsu Chemical Co., Ltd.

Technical Solution: Shin-Etsu Chemical has developed innovative colloidal silica systems for antimicrobial applications through their silicone-silica hybrid technology. Their approach combines the advantages of silicone chemistry with precisely engineered colloidal silica particles to create durable antimicrobial surfaces. The company's proprietary process involves surface modification of silica nanoparticles (20-60 nm) with organosilicon compounds that enhance dispersion in silicone matrices while providing anchoring sites for antimicrobial agents. Their technology incorporates zinc oxide and silver nanoparticles into the silica matrix, creating a synergistic antimicrobial effect that targets both gram-positive and gram-negative bacteria[3]. Shin-Etsu's formulations achieve extended antimicrobial activity through controlled ion release mechanisms, where the silica particles act as reservoirs for the active agents. Their research has demonstrated that these hybrid systems maintain antimicrobial efficacy even after repeated washing cycles, with testing showing >99% reduction in bacterial populations after 100 abrasion cycles, addressing a key limitation in conventional antimicrobial coatings.

Strengths: Exceptional durability and abrasion resistance; excellent adhesion to various substrates; synergistic antimicrobial effects through multiple active mechanisms. Weaknesses: Higher production complexity requiring specialized manufacturing processes; potential for reduced transparency in certain formulations; limited effectiveness in highly acidic environments.

Critical Patents and Research in Colloidal Silica Antimicrobial Technology

Building board

PatentActiveUS20080233160A1

Innovation

- A building board with a coat containing colloidal silica as a main component and an antimicrobial composite material, where the antimicrobial composite material is fixed to the surface via hydrogen bonding with colloidal silica, providing long-lasting control over algae and fungi growth and incorporating a synergistic blend of organic and inorganic agents for enhanced efficacy.

Antimicrobial coatings

PatentWO2025017233A1

Innovation

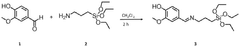

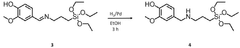

- A silica-based antimicrobial coating with covalently immobilized bioactive molecules using a linker molecule, such as 3-aminopropyl triethoxysilane, forming stable Si-O-Si bonds, which enhances the coating's durability and antimicrobial effectiveness against bacteria, viruses, and fungi.

Environmental Impact and Sustainability Considerations

The optimization of colloidal silica for antimicrobial coatings presents significant environmental implications that warrant careful consideration. Traditional antimicrobial agents often contain heavy metals or synthetic chemicals that pose ecological risks through bioaccumulation and persistence in the environment. Colloidal silica-based antimicrobial coatings offer a potentially more sustainable alternative, particularly when formulated with environmentally benign components.

Life cycle assessment (LCA) studies indicate that colloidal silica production has a lower environmental footprint compared to conventional antimicrobial compounds such as silver nanoparticles or quaternary ammonium compounds. The primary raw material, silicon dioxide, is abundant in nature, reducing resource depletion concerns. However, the energy-intensive processes required for colloidal silica synthesis, particularly high-temperature treatments, contribute significantly to its carbon footprint.

Water consumption represents another critical environmental factor in colloidal silica production. The synthesis process typically requires substantial quantities of purified water, raising concerns about water resource management. Implementing closed-loop water recycling systems and optimizing reaction conditions can substantially reduce this environmental burden while maintaining product quality.

Biodegradability and end-of-life considerations must be integrated into colloidal silica antimicrobial coating development. Unlike persistent organic pollutants, properly formulated silica-based coatings can degrade into non-toxic components over time. Research indicates that silica ultimately reverts to silicon dioxide, a naturally occurring compound, minimizing long-term environmental accumulation risks.

Regulatory frameworks increasingly emphasize reduced environmental impact for antimicrobial products. The European Union's Biocidal Products Regulation and similar legislation worldwide are progressively restricting environmentally harmful antimicrobial agents. Colloidal silica formulations that meet antimicrobial efficacy requirements while demonstrating minimal ecotoxicity will likely gain regulatory advantage in coming years.

Green chemistry principles offer valuable guidance for optimizing colloidal silica antimicrobial coatings. Approaches such as ambient temperature synthesis routes, solvent-free processing, and renewable precursors can significantly enhance sustainability profiles. Recent innovations in sol-gel chemistry have demonstrated feasible pathways for reducing environmental impact without compromising antimicrobial performance.

Balancing antimicrobial efficacy with environmental considerations remains challenging. Optimization strategies must consider the entire product lifecycle, from raw material sourcing through disposal. Emerging research suggests that hybrid systems combining colloidal silica with naturally-derived antimicrobial compounds may offer the most promising path toward environmentally responsible yet effective antimicrobial protection.

Life cycle assessment (LCA) studies indicate that colloidal silica production has a lower environmental footprint compared to conventional antimicrobial compounds such as silver nanoparticles or quaternary ammonium compounds. The primary raw material, silicon dioxide, is abundant in nature, reducing resource depletion concerns. However, the energy-intensive processes required for colloidal silica synthesis, particularly high-temperature treatments, contribute significantly to its carbon footprint.

Water consumption represents another critical environmental factor in colloidal silica production. The synthesis process typically requires substantial quantities of purified water, raising concerns about water resource management. Implementing closed-loop water recycling systems and optimizing reaction conditions can substantially reduce this environmental burden while maintaining product quality.

Biodegradability and end-of-life considerations must be integrated into colloidal silica antimicrobial coating development. Unlike persistent organic pollutants, properly formulated silica-based coatings can degrade into non-toxic components over time. Research indicates that silica ultimately reverts to silicon dioxide, a naturally occurring compound, minimizing long-term environmental accumulation risks.

Regulatory frameworks increasingly emphasize reduced environmental impact for antimicrobial products. The European Union's Biocidal Products Regulation and similar legislation worldwide are progressively restricting environmentally harmful antimicrobial agents. Colloidal silica formulations that meet antimicrobial efficacy requirements while demonstrating minimal ecotoxicity will likely gain regulatory advantage in coming years.

Green chemistry principles offer valuable guidance for optimizing colloidal silica antimicrobial coatings. Approaches such as ambient temperature synthesis routes, solvent-free processing, and renewable precursors can significantly enhance sustainability profiles. Recent innovations in sol-gel chemistry have demonstrated feasible pathways for reducing environmental impact without compromising antimicrobial performance.

Balancing antimicrobial efficacy with environmental considerations remains challenging. Optimization strategies must consider the entire product lifecycle, from raw material sourcing through disposal. Emerging research suggests that hybrid systems combining colloidal silica with naturally-derived antimicrobial compounds may offer the most promising path toward environmentally responsible yet effective antimicrobial protection.

Regulatory Framework for Antimicrobial Coating Applications

The regulatory landscape for antimicrobial coatings incorporating colloidal silica presents a complex framework that manufacturers must navigate to ensure compliance and market access. In the United States, the Environmental Protection Agency (EPA) regulates antimicrobial products under the Federal Insecticide, Fungicide, and Rodenticide Act (FIFRA), requiring registration of active ingredients and efficacy data submission. Products containing colloidal silica with antimicrobial claims must undergo rigorous testing protocols to demonstrate both safety and effectiveness against specified microorganisms.

The Food and Drug Administration (FDA) maintains oversight when these coatings are used in food contact surfaces or medical devices, with additional requirements under the Food, Drug, and Cosmetic Act. For medical applications, antimicrobial coatings may require premarket approval or notification depending on their intended use and claims.

In the European Union, the Biocidal Products Regulation (BPR) governs antimicrobial substances, requiring authorization of active substances before market placement. Colloidal silica formulations must comply with REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) regulations, with particular attention to nanomaterial provisions if particle sizes fall within the nanoscale range.

International standards organizations, including ISO and ASTM, have developed specific testing methodologies for evaluating antimicrobial efficacy. ISO 22196 and JIS Z 2801 are commonly referenced standards for measuring antibacterial activity on surfaces, while ASTM E2180 addresses antimicrobial activity of polymeric materials.

Environmental considerations have gained prominence in regulatory frameworks globally. Many jurisdictions now require environmental impact assessments for antimicrobial products, examining potential effects on non-target organisms and ecosystems. The leaching potential of antimicrobial agents from colloidal silica coatings must be thoroughly characterized to meet increasingly stringent environmental protection standards.

Labeling requirements represent another critical regulatory aspect. Claims regarding antimicrobial performance must be substantiated through approved testing protocols, with specific language restrictions varying by jurisdiction. Misleading claims about health benefits or protection against specific pathogens without sufficient evidence can result in regulatory enforcement actions.

Recent regulatory trends indicate movement toward harmonization of international standards, though significant regional differences persist. Manufacturers developing colloidal silica antimicrobial coatings must implement comprehensive regulatory strategies that address the specific requirements of target markets while monitoring evolving regulations, particularly regarding nanomaterials and novel antimicrobial mechanisms.

The Food and Drug Administration (FDA) maintains oversight when these coatings are used in food contact surfaces or medical devices, with additional requirements under the Food, Drug, and Cosmetic Act. For medical applications, antimicrobial coatings may require premarket approval or notification depending on their intended use and claims.

In the European Union, the Biocidal Products Regulation (BPR) governs antimicrobial substances, requiring authorization of active substances before market placement. Colloidal silica formulations must comply with REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) regulations, with particular attention to nanomaterial provisions if particle sizes fall within the nanoscale range.

International standards organizations, including ISO and ASTM, have developed specific testing methodologies for evaluating antimicrobial efficacy. ISO 22196 and JIS Z 2801 are commonly referenced standards for measuring antibacterial activity on surfaces, while ASTM E2180 addresses antimicrobial activity of polymeric materials.

Environmental considerations have gained prominence in regulatory frameworks globally. Many jurisdictions now require environmental impact assessments for antimicrobial products, examining potential effects on non-target organisms and ecosystems. The leaching potential of antimicrobial agents from colloidal silica coatings must be thoroughly characterized to meet increasingly stringent environmental protection standards.

Labeling requirements represent another critical regulatory aspect. Claims regarding antimicrobial performance must be substantiated through approved testing protocols, with specific language restrictions varying by jurisdiction. Misleading claims about health benefits or protection against specific pathogens without sufficient evidence can result in regulatory enforcement actions.

Recent regulatory trends indicate movement toward harmonization of international standards, though significant regional differences persist. Manufacturers developing colloidal silica antimicrobial coatings must implement comprehensive regulatory strategies that address the specific requirements of target markets while monitoring evolving regulations, particularly regarding nanomaterials and novel antimicrobial mechanisms.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!