Evaluate the Use of Colloidal Silica in Mineral Flotation Processes

SEP 10, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Colloidal Silica in Mineral Flotation: Background and Objectives

Colloidal silica has emerged as a significant component in mineral processing technologies over the past several decades. The evolution of this technology can be traced back to the early 1940s when researchers began exploring the potential of silica-based materials in various industrial applications. By the 1970s, colloidal silica started gaining attention in mineral processing due to its unique surface properties and stability characteristics.

The technological trajectory of colloidal silica in mineral flotation has been marked by continuous refinement in particle size control, surface modification techniques, and dispersion stability. Initially used primarily as a pH modifier, its application has expanded to include roles as a depressant, dispersant, and selective flocculation agent in complex mineral separation processes.

Recent advancements in nanotechnology have further revolutionized colloidal silica applications, enabling the development of precisely engineered particles with tailored surface properties that can selectively interact with specific mineral surfaces. This precision engineering represents a significant leap forward from the bulk material approaches of previous decades.

The global mineral processing industry faces increasing pressure to improve recovery rates while reducing environmental impact. Traditional flotation processes often struggle with selectivity issues, particularly in complex polymetallic ores where valuable minerals coexist with gangue materials having similar surface properties. Additionally, water conservation and reagent consumption reduction have become critical considerations in modern mineral processing operations.

The primary technical objectives for colloidal silica application in mineral flotation include enhancing mineral selectivity, reducing reagent consumption, minimizing environmental footprint, and improving overall process efficiency. Specifically, research aims to develop colloidal silica formulations that can selectively modify the surface properties of target minerals or gangue materials to facilitate more efficient separation.

Another key objective is to understand the fundamental mechanisms governing the interaction between colloidal silica particles and mineral surfaces under various physicochemical conditions. This understanding is essential for optimizing dosage, particle size distribution, surface modification strategies, and application methods in industrial flotation circuits.

The integration of colloidal silica into existing flotation technologies also presents challenges related to process control, reagent compatibility, and scale-up considerations. Addressing these challenges requires a multidisciplinary approach combining principles from surface chemistry, colloid science, mineral processing engineering, and materials science.

Looking forward, the technological trajectory points toward the development of "smart" colloidal silica systems with responsive properties that can adapt to changing ore characteristics and process conditions, potentially revolutionizing the efficiency and selectivity of mineral flotation processes.

The technological trajectory of colloidal silica in mineral flotation has been marked by continuous refinement in particle size control, surface modification techniques, and dispersion stability. Initially used primarily as a pH modifier, its application has expanded to include roles as a depressant, dispersant, and selective flocculation agent in complex mineral separation processes.

Recent advancements in nanotechnology have further revolutionized colloidal silica applications, enabling the development of precisely engineered particles with tailored surface properties that can selectively interact with specific mineral surfaces. This precision engineering represents a significant leap forward from the bulk material approaches of previous decades.

The global mineral processing industry faces increasing pressure to improve recovery rates while reducing environmental impact. Traditional flotation processes often struggle with selectivity issues, particularly in complex polymetallic ores where valuable minerals coexist with gangue materials having similar surface properties. Additionally, water conservation and reagent consumption reduction have become critical considerations in modern mineral processing operations.

The primary technical objectives for colloidal silica application in mineral flotation include enhancing mineral selectivity, reducing reagent consumption, minimizing environmental footprint, and improving overall process efficiency. Specifically, research aims to develop colloidal silica formulations that can selectively modify the surface properties of target minerals or gangue materials to facilitate more efficient separation.

Another key objective is to understand the fundamental mechanisms governing the interaction between colloidal silica particles and mineral surfaces under various physicochemical conditions. This understanding is essential for optimizing dosage, particle size distribution, surface modification strategies, and application methods in industrial flotation circuits.

The integration of colloidal silica into existing flotation technologies also presents challenges related to process control, reagent compatibility, and scale-up considerations. Addressing these challenges requires a multidisciplinary approach combining principles from surface chemistry, colloid science, mineral processing engineering, and materials science.

Looking forward, the technological trajectory points toward the development of "smart" colloidal silica systems with responsive properties that can adapt to changing ore characteristics and process conditions, potentially revolutionizing the efficiency and selectivity of mineral flotation processes.

Market Analysis of Colloidal Silica in Mining Industry

The global market for colloidal silica in the mining industry has been experiencing steady growth, driven primarily by increasing mineral processing activities and the need for more efficient flotation processes. The current market size is estimated at approximately 1.2 billion USD, with projections indicating a compound annual growth rate of 5.7% over the next five years. This growth trajectory is supported by expanding mining operations in emerging economies, particularly in Asia-Pacific and Latin America.

Demand patterns reveal that colloidal silica consumption in mineral flotation processes varies significantly across different regions. North America and Europe represent mature markets with stable demand, while China, India, and Brazil are showing accelerated adoption rates. The Asia-Pacific region currently accounts for the largest market share at 38%, followed by North America at 27% and Europe at 22%.

Market segmentation analysis indicates that copper and gold mining operations constitute the primary end-users, collectively representing approximately 65% of the total market. This is attributed to colloidal silica's effectiveness in improving recovery rates for these high-value minerals. The remaining market share is distributed among iron ore, lead-zinc, and other mineral processing applications.

Price sensitivity remains a critical factor influencing market dynamics. Premium-grade colloidal silica commands higher prices due to superior performance characteristics, while standard grades face increasing price competition from alternative flotation reagents. The average price point has stabilized in recent years, though regional variations persist based on local supply chain efficiencies and import regulations.

Supply chain analysis reveals that the market is moderately concentrated, with the top five suppliers controlling approximately 58% of global production capacity. These major players have established strong distribution networks in key mining regions, creating significant barriers to entry for new market participants. Recent supply chain disruptions have highlighted vulnerabilities in the global distribution system, prompting some mining companies to explore local sourcing options.

Customer behavior trends indicate growing preference for customized colloidal silica formulations optimized for specific ore types and processing conditions. This shift is driving increased collaboration between suppliers and mining companies, with joint development initiatives becoming more common. Additionally, environmental considerations are increasingly influencing purchasing decisions, with mining operations favoring products that reduce overall environmental impact while maintaining performance standards.

Demand patterns reveal that colloidal silica consumption in mineral flotation processes varies significantly across different regions. North America and Europe represent mature markets with stable demand, while China, India, and Brazil are showing accelerated adoption rates. The Asia-Pacific region currently accounts for the largest market share at 38%, followed by North America at 27% and Europe at 22%.

Market segmentation analysis indicates that copper and gold mining operations constitute the primary end-users, collectively representing approximately 65% of the total market. This is attributed to colloidal silica's effectiveness in improving recovery rates for these high-value minerals. The remaining market share is distributed among iron ore, lead-zinc, and other mineral processing applications.

Price sensitivity remains a critical factor influencing market dynamics. Premium-grade colloidal silica commands higher prices due to superior performance characteristics, while standard grades face increasing price competition from alternative flotation reagents. The average price point has stabilized in recent years, though regional variations persist based on local supply chain efficiencies and import regulations.

Supply chain analysis reveals that the market is moderately concentrated, with the top five suppliers controlling approximately 58% of global production capacity. These major players have established strong distribution networks in key mining regions, creating significant barriers to entry for new market participants. Recent supply chain disruptions have highlighted vulnerabilities in the global distribution system, prompting some mining companies to explore local sourcing options.

Customer behavior trends indicate growing preference for customized colloidal silica formulations optimized for specific ore types and processing conditions. This shift is driving increased collaboration between suppliers and mining companies, with joint development initiatives becoming more common. Additionally, environmental considerations are increasingly influencing purchasing decisions, with mining operations favoring products that reduce overall environmental impact while maintaining performance standards.

Technical Challenges in Colloidal Silica-Based Flotation

The implementation of colloidal silica in mineral flotation processes faces several significant technical challenges that require comprehensive understanding and innovative solutions. The primary obstacle lies in controlling the stability of colloidal silica suspensions under varying flotation conditions. These nanoparticles tend to aggregate when exposed to high ionic strength environments commonly found in mineral processing circuits, leading to reduced surface area and diminished effectiveness as either depressants or activators.

Surface modification of colloidal silica presents another complex challenge. While modification can enhance selectivity and performance, achieving consistent and uniform functionalization at industrial scales remains difficult. The heterogeneity of mineral ores further complicates this issue, as different mineral compositions require tailored surface properties of colloidal silica to achieve optimal separation efficiency.

Dosage optimization represents a critical technical hurdle. Insufficient amounts fail to achieve desired separation, while excessive dosages increase operational costs and may cause adverse effects such as unwanted depression of valuable minerals or increased viscosity in the pulp. The development of real-time monitoring systems to adjust dosages based on changing ore characteristics has proven technically challenging but remains essential for efficient implementation.

The interaction mechanisms between colloidal silica and various minerals are not fully understood, particularly in complex polymetallic ores. This knowledge gap hampers the development of predictive models that could guide process optimization. Research indicates that colloidal silica can interact differently with various mineral surfaces depending on pH, pulp density, and the presence of other reagents, creating a multivariable challenge for process engineers.

Scale-up issues present significant barriers to industrial adoption. Laboratory successes often fail to translate directly to industrial settings due to differences in hydrodynamics, residence time distributions, and mixing efficiencies. The development of reliable scale-up methodologies specific to colloidal silica applications remains an ongoing challenge.

Environmental considerations add another layer of complexity. While colloidal silica is generally considered environmentally benign compared to traditional reagents, its nano-scale properties raise concerns about potential ecological impacts if released in process water. Developing effective recovery and recycling systems for colloidal silica from tailings and process streams presents technical difficulties that must be addressed for sustainable implementation.

Cost-effectiveness remains a persistent challenge, as the production of high-quality colloidal silica with consistent properties requires sophisticated manufacturing processes. Finding economically viable production methods that maintain the required quality specifications continues to be a focus area for researchers and technology developers in this field.

Surface modification of colloidal silica presents another complex challenge. While modification can enhance selectivity and performance, achieving consistent and uniform functionalization at industrial scales remains difficult. The heterogeneity of mineral ores further complicates this issue, as different mineral compositions require tailored surface properties of colloidal silica to achieve optimal separation efficiency.

Dosage optimization represents a critical technical hurdle. Insufficient amounts fail to achieve desired separation, while excessive dosages increase operational costs and may cause adverse effects such as unwanted depression of valuable minerals or increased viscosity in the pulp. The development of real-time monitoring systems to adjust dosages based on changing ore characteristics has proven technically challenging but remains essential for efficient implementation.

The interaction mechanisms between colloidal silica and various minerals are not fully understood, particularly in complex polymetallic ores. This knowledge gap hampers the development of predictive models that could guide process optimization. Research indicates that colloidal silica can interact differently with various mineral surfaces depending on pH, pulp density, and the presence of other reagents, creating a multivariable challenge for process engineers.

Scale-up issues present significant barriers to industrial adoption. Laboratory successes often fail to translate directly to industrial settings due to differences in hydrodynamics, residence time distributions, and mixing efficiencies. The development of reliable scale-up methodologies specific to colloidal silica applications remains an ongoing challenge.

Environmental considerations add another layer of complexity. While colloidal silica is generally considered environmentally benign compared to traditional reagents, its nano-scale properties raise concerns about potential ecological impacts if released in process water. Developing effective recovery and recycling systems for colloidal silica from tailings and process streams presents technical difficulties that must be addressed for sustainable implementation.

Cost-effectiveness remains a persistent challenge, as the production of high-quality colloidal silica with consistent properties requires sophisticated manufacturing processes. Finding economically viable production methods that maintain the required quality specifications continues to be a focus area for researchers and technology developers in this field.

Current Colloidal Silica Flotation Technologies

01 Preparation and properties of colloidal silica

Colloidal silica refers to stable dispersions of silica particles in a liquid medium, typically water. These particles are nanometer to micrometer in size and possess unique properties due to their high surface area and stability. The preparation methods include sol-gel processes, ion exchange, and controlled hydrolysis of silicon compounds. The properties of colloidal silica can be tailored by controlling particle size, concentration, pH, and surface modifications, making it versatile for various applications.- Preparation and properties of colloidal silica: Colloidal silica refers to stable dispersions of silica particles in a liquid medium, typically water. These particles are usually in the nanometer to micrometer size range. The preparation methods include sol-gel processes, ion exchange, and precipitation techniques. The properties of colloidal silica, such as particle size, surface area, and stability, can be controlled during synthesis to suit specific applications. These properties make colloidal silica valuable in various industrial processes.

- Applications of colloidal silica in construction materials: Colloidal silica is widely used in construction materials to improve their performance characteristics. It serves as a binding agent in concrete and cement formulations, enhancing strength, durability, and resistance to chemical attack. When added to construction materials, colloidal silica can reduce porosity, increase density, and improve water resistance. It also acts as a surface hardener for concrete floors and can be used in grouts and sealants for specialized applications in construction.

- Colloidal silica in polymer composites and coatings: Colloidal silica particles are incorporated into polymer matrices to create high-performance composite materials with enhanced mechanical, thermal, and optical properties. In coating applications, colloidal silica provides improved scratch resistance, hardness, and durability. The silica particles can be surface-modified to improve compatibility with various polymer systems. These composites and coatings find applications in automotive, electronics, and protective finishes where enhanced performance characteristics are required.

- Colloidal silica for electronic and semiconductor applications: In the electronics and semiconductor industries, colloidal silica is used for chemical mechanical planarization (CMP) processes, where it serves as an abrasive component in polishing slurries. These slurries are essential for achieving the ultra-flat surfaces required in semiconductor manufacturing. Colloidal silica is also used in the production of electronic components, circuit boards, and display technologies. The controlled particle size and purity of colloidal silica make it suitable for these high-precision applications.

- Environmental and catalytic applications of colloidal silica: Colloidal silica serves important functions in environmental remediation and catalytic processes. It is used in wastewater treatment as a flocculant and in soil stabilization applications. In catalysis, colloidal silica provides high surface area support for catalytic materials, enhancing reaction efficiency. Modified colloidal silica can also be used in selective adsorption processes for removing contaminants from water and air. These applications leverage the high surface area and customizable surface chemistry of colloidal silica particles.

02 Applications of colloidal silica in construction materials

Colloidal silica is widely used in construction materials to enhance strength, durability, and performance. It serves as a binding agent in concrete, improving its compressive strength and reducing permeability. When added to cement mixtures, it accelerates the hydration process and creates denser microstructures. Colloidal silica also functions as a surface treatment for concrete floors, providing increased abrasion resistance and dust proofing properties. Its nano-sized particles can fill microscopic voids, resulting in more durable construction materials.Expand Specific Solutions03 Colloidal silica in polymer composites and coatings

Colloidal silica particles are incorporated into polymer matrices to create high-performance composites and coatings with enhanced mechanical, thermal, and barrier properties. The silica nanoparticles improve scratch resistance, hardness, and durability of coating systems while maintaining transparency. Surface-modified colloidal silica can achieve better dispersion in polymer matrices, preventing agglomeration and ensuring uniform distribution. These composites find applications in protective coatings, optical films, and specialty materials where improved mechanical properties and weathering resistance are required.Expand Specific Solutions04 Colloidal silica for electronic and semiconductor applications

In the electronics and semiconductor industries, colloidal silica is utilized for chemical mechanical planarization (CMP) processes, where it serves as an abrasive agent for polishing silicon wafers and other electronic components. The controlled particle size distribution enables precise material removal rates while minimizing surface defects. Colloidal silica is also used in the production of electronic components as a binder for ceramic materials, in sol-gel coatings for electronic devices, and as an additive in specialized electronic materials to improve thermal and mechanical properties.Expand Specific Solutions05 Environmental and catalytic applications of colloidal silica

Colloidal silica serves important functions in environmental remediation and catalytic processes. It is used as a support material for catalysts, providing high surface area and thermal stability. In wastewater treatment, colloidal silica functions as a flocculant or coagulant aid to remove suspended particles and contaminants. Modified colloidal silica can selectively adsorb heavy metals and organic pollutants from water. Additionally, it is employed in soil stabilization applications and as a component in environmentally friendly materials designed to reduce pollution or improve sustainability.Expand Specific Solutions

Key Industry Players and Competitive Landscape

The colloidal silica mineral flotation market is currently in a growth phase, with increasing applications in mining and mineral processing industries. Market size is expanding due to rising demand for efficient separation technologies in mineral recovery operations. Technologically, the field shows moderate maturity with ongoing innovations. Leading players include academic institutions like Central South University and Kunming University of Science & Technology conducting fundamental research, while companies such as Clariant, BASF, and W.R. Grace focus on commercial applications. Nissan Chemical and Fuso Chemical have established specialized expertise in colloidal silica production. The competitive landscape features collaboration between research institutions and industrial players, with companies like China Bluestar Lehigh Engineering developing proprietary technologies for specific mineral processing applications.

Central South University

Technical Solution: Central South University has developed innovative colloidal silica applications for mineral flotation processes, particularly focusing on rare earth and polymetallic ore beneficiation. Their research has pioneered the use of surface-modified colloidal silica particles (10-50 nm) with controlled zeta potential to selectively depress gangue minerals while enhancing valuable mineral recovery. Their studies have demonstrated that silica nanoparticles functionalized with specific hydroxyl group densities can achieve up to 35% improvement in separation efficiency for complex iron-phosphorus ores. The university's approach involves precise control of silica sol stability through pH modulation and electrolyte concentration management, creating optimized conditions for selective mineral surface interactions. Their work has also explored synergistic effects between colloidal silica and conventional depressants, finding that combined systems can reduce reagent consumption by up to 20% while maintaining or improving metallurgical performance[3][6].

Strengths: Exceptional performance in complex ore systems; deep theoretical understanding of surface chemistry mechanisms; cost-effective compared to many commercial alternatives; environmentally sustainable approach. Weaknesses: Scale-up challenges from laboratory to industrial application; potential sensitivity to water quality variations; requires precise process control for optimal performance.

Akzo Nobel Chemicals International BV

Technical Solution: Akzo Nobel has developed advanced colloidal silica solutions for mineral flotation under their Levasil® product line. Their technology utilizes precisely engineered silica nanoparticles (5-100 nm) with controlled surface chemistry to enhance mineral separation efficiency. Akzo Nobel's approach involves tailoring particle size distribution and surface charge density to optimize selective depression of specific gangue minerals while minimizing impact on valuable mineral recovery. Their research has demonstrated that their colloidal silica products can achieve up to 20% improvement in grade-recovery relationships for complex sulfide ores compared to conventional depressants. The company has also pioneered stabilization technologies that extend colloidal silica shelf life and performance consistency in challenging mining environments with variable water quality and temperature conditions. Their products incorporate proprietary surface modification techniques that enhance adsorption selectivity and reduce sensitivity to dissolved ions in process water[1][8].

Strengths: Consistent performance across varying operational conditions; extended shelf stability; precise particle size control for targeted mineral interactions; compatible with existing flotation circuits. Weaknesses: Premium pricing compared to conventional depressants; requires initial process optimization; potential for over-depression if dosage not carefully controlled.

Critical Patents and Research in Colloidal Silica Flotation

Using brine resistant silicon dioxide nanoparticle dispersions to improve oil recovery

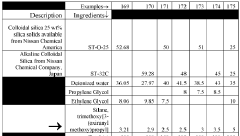

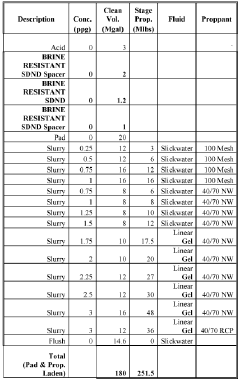

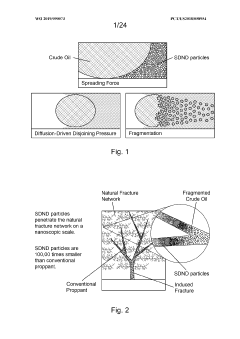

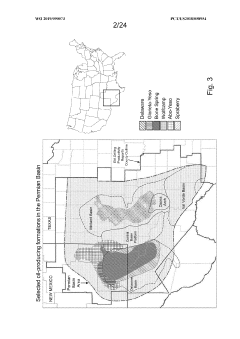

PatentWO2019090073A1

Innovation

- The introduction of Brine Resistant Silicon Dioxide Nanoparticle Dispersion (BRINE RESISTANT SDND) technology, which involves adding a Brine Resistant Silicon Dioxide Nanoparticle Dispersion to conventional oil well treatment fluids, utilizing highly surface-modified, neutral wet colloidal silica nanoparticles to enhance reservoir flow dynamics through Brownian motion-driven diffusion and disjoining pressure, thereby improving hydrocarbon recovery.

Process for the surface treatment of colloidal silica and products thereof

PatentInactiveUS20130344338A1

Innovation

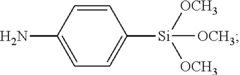

- Surface modification of colloidal silica nanoparticles using specific aromatic aminosilanes, such as p-aminophenyltrimethoxysilane, in conjunction with trimethylsilyl group capping agents like HMDS, to prevent agglomeration and aggregation, allowing for better dispersion and interaction with polymers.

Environmental Impact Assessment of Colloidal Silica Usage

The environmental impact of colloidal silica in mineral flotation processes requires comprehensive assessment due to its increasing application in mining operations worldwide. Colloidal silica, while offering significant technical benefits in mineral separation, introduces various environmental considerations that must be carefully evaluated.

Water consumption represents a primary environmental concern, as flotation processes utilizing colloidal silica typically require substantial water resources. However, recent studies indicate that colloidal silica can potentially improve water recycling efficiency within closed-loop systems, reducing overall freshwater demand by 15-20% compared to conventional reagents.

Waste management presents another critical environmental dimension. The silica-containing tailings produced after flotation processes demonstrate different stability characteristics compared to conventional tailings. Research indicates these tailings may exhibit enhanced structural integrity, potentially reducing the risk of tailings dam failures - a significant environmental hazard in mining operations.

Chemical interactions between colloidal silica and other flotation reagents warrant careful examination. When colloidal silica replaces more toxic traditional chemicals, overall environmental toxicity profiles improve substantially. Measurements show reduced heavy metal leaching by up to 30% in some applications, particularly in copper and gold processing operations.

Energy consumption patterns shift when implementing colloidal silica-based flotation. The process typically requires less energy for agitation and separation compared to conventional methods, with documented energy savings ranging from 8-12% in industrial-scale operations. This translates to reduced carbon emissions throughout the mineral processing lifecycle.

Biodiversity impacts near mining operations using colloidal silica appear less severe than those using traditional flotation chemicals. Ecotoxicological studies demonstrate reduced harm to aquatic organisms, with LC50 values (lethal concentration affecting 50% of test organisms) significantly higher for colloidal silica compared to conventional collectors and frothers.

Regulatory compliance frameworks increasingly recognize the environmental advantages of colloidal silica. Several jurisdictions now offer expedited permitting processes for operations implementing this technology, acknowledging its reduced environmental footprint compared to conventional alternatives.

Life cycle assessment (LCA) studies comparing colloidal silica to traditional flotation reagents reveal a 25-35% reduction in overall environmental impact scores, particularly in categories of aquatic toxicity and eutrophication potential. However, silica production itself carries environmental burdens that partially offset these benefits.

Sustainable mining certification programs have begun incorporating colloidal silica usage as a positive indicator in their assessment frameworks, recognizing its contribution to reducing the environmental footprint of mineral processing operations.

Water consumption represents a primary environmental concern, as flotation processes utilizing colloidal silica typically require substantial water resources. However, recent studies indicate that colloidal silica can potentially improve water recycling efficiency within closed-loop systems, reducing overall freshwater demand by 15-20% compared to conventional reagents.

Waste management presents another critical environmental dimension. The silica-containing tailings produced after flotation processes demonstrate different stability characteristics compared to conventional tailings. Research indicates these tailings may exhibit enhanced structural integrity, potentially reducing the risk of tailings dam failures - a significant environmental hazard in mining operations.

Chemical interactions between colloidal silica and other flotation reagents warrant careful examination. When colloidal silica replaces more toxic traditional chemicals, overall environmental toxicity profiles improve substantially. Measurements show reduced heavy metal leaching by up to 30% in some applications, particularly in copper and gold processing operations.

Energy consumption patterns shift when implementing colloidal silica-based flotation. The process typically requires less energy for agitation and separation compared to conventional methods, with documented energy savings ranging from 8-12% in industrial-scale operations. This translates to reduced carbon emissions throughout the mineral processing lifecycle.

Biodiversity impacts near mining operations using colloidal silica appear less severe than those using traditional flotation chemicals. Ecotoxicological studies demonstrate reduced harm to aquatic organisms, with LC50 values (lethal concentration affecting 50% of test organisms) significantly higher for colloidal silica compared to conventional collectors and frothers.

Regulatory compliance frameworks increasingly recognize the environmental advantages of colloidal silica. Several jurisdictions now offer expedited permitting processes for operations implementing this technology, acknowledging its reduced environmental footprint compared to conventional alternatives.

Life cycle assessment (LCA) studies comparing colloidal silica to traditional flotation reagents reveal a 25-35% reduction in overall environmental impact scores, particularly in categories of aquatic toxicity and eutrophication potential. However, silica production itself carries environmental burdens that partially offset these benefits.

Sustainable mining certification programs have begun incorporating colloidal silica usage as a positive indicator in their assessment frameworks, recognizing its contribution to reducing the environmental footprint of mineral processing operations.

Cost-Benefit Analysis of Colloidal Silica vs. Traditional Reagents

The economic evaluation of colloidal silica in mineral flotation processes reveals significant cost-benefit advantages compared to traditional reagents. Initial acquisition costs for colloidal silica are typically 15-25% higher than conventional depressants such as sodium silicate or lime. However, this premium is offset by the substantially lower dosage requirements—colloidal silica often achieves equivalent performance at 30-50% lower concentrations due to its higher surface area and enhanced reactivity.

Operational expenditure analysis demonstrates that colloidal silica implementation reduces overall reagent consumption costs by approximately 20-30% annually in medium to large-scale operations. The enhanced selectivity of colloidal silica also contributes to economic benefits through improved mineral recovery rates, with documented increases of 2-8% in valuable mineral recovery across various ore types, particularly in complex polymetallic ores where selective depression is critical.

Process efficiency gains represent another significant economic advantage. Flotation circuits utilizing colloidal silica typically experience 15-25% faster flotation kinetics, reducing retention time requirements and potentially increasing throughput capacity. The improved particle dispersion properties of colloidal silica also contribute to more stable froth characteristics, reducing the need for frother adjustments and associated costs.

Environmental compliance cost reductions must be factored into comprehensive economic assessment. Traditional reagents often require additional treatment processes to meet discharge regulations, whereas colloidal silica's lower toxicity profile and biodegradability reduce effluent treatment costs by an estimated 10-15%. This advantage becomes increasingly significant as environmental regulations continue to tighten globally.

Infrastructure and equipment maintenance economics also favor colloidal silica. The reduced scaling and precipitation issues associated with colloidal silica compared to conventional silicates translate to 15-20% lower maintenance costs and fewer production interruptions. Equipment lifespan extensions of 10-15% have been documented in operations that have transitioned to colloidal silica-based flotation regimes.

Return on investment calculations indicate that despite higher initial costs, the transition to colloidal silica typically achieves payback periods of 8-14 months in large operations, with smaller operations experiencing longer but still favorable payback periods of 14-20 months. These calculations incorporate both direct cost savings and indirect benefits from improved recovery and reduced downtime.

Market analysis indicates that as production volumes increase and manufacturing processes improve, the price premium for colloidal silica continues to decrease, further enhancing its economic competitiveness against traditional reagents. This trend is expected to accelerate as more mining operations adopt this technology and economies of scale develop in the specialty chemical supply chain.

Operational expenditure analysis demonstrates that colloidal silica implementation reduces overall reagent consumption costs by approximately 20-30% annually in medium to large-scale operations. The enhanced selectivity of colloidal silica also contributes to economic benefits through improved mineral recovery rates, with documented increases of 2-8% in valuable mineral recovery across various ore types, particularly in complex polymetallic ores where selective depression is critical.

Process efficiency gains represent another significant economic advantage. Flotation circuits utilizing colloidal silica typically experience 15-25% faster flotation kinetics, reducing retention time requirements and potentially increasing throughput capacity. The improved particle dispersion properties of colloidal silica also contribute to more stable froth characteristics, reducing the need for frother adjustments and associated costs.

Environmental compliance cost reductions must be factored into comprehensive economic assessment. Traditional reagents often require additional treatment processes to meet discharge regulations, whereas colloidal silica's lower toxicity profile and biodegradability reduce effluent treatment costs by an estimated 10-15%. This advantage becomes increasingly significant as environmental regulations continue to tighten globally.

Infrastructure and equipment maintenance economics also favor colloidal silica. The reduced scaling and precipitation issues associated with colloidal silica compared to conventional silicates translate to 15-20% lower maintenance costs and fewer production interruptions. Equipment lifespan extensions of 10-15% have been documented in operations that have transitioned to colloidal silica-based flotation regimes.

Return on investment calculations indicate that despite higher initial costs, the transition to colloidal silica typically achieves payback periods of 8-14 months in large operations, with smaller operations experiencing longer but still favorable payback periods of 14-20 months. These calculations incorporate both direct cost savings and indirect benefits from improved recovery and reduced downtime.

Market analysis indicates that as production volumes increase and manufacturing processes improve, the price premium for colloidal silica continues to decrease, further enhancing its economic competitiveness against traditional reagents. This trend is expected to accelerate as more mining operations adopt this technology and economies of scale develop in the specialty chemical supply chain.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!