Colloidal Silica in 3D Printing: Enhancing Part Accuracy

SEP 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

3D Printing Evolution and Colloidal Silica Integration Goals

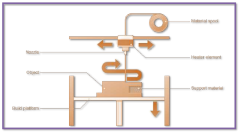

3D printing technology has evolved dramatically since its inception in the 1980s, transforming from a prototyping tool to a manufacturing methodology capable of producing functional end-use parts. The journey began with stereolithography (SLA), followed by fused deposition modeling (FDM), selective laser sintering (SLS), and more recently, digital light processing (DLP) and continuous liquid interface production (CLIP). Each iteration has brought improvements in speed, resolution, and material versatility, yet dimensional accuracy remains a persistent challenge across all platforms.

The industry has witnessed a compound annual growth rate of approximately 20% over the past decade, with the market expected to reach $40 billion by 2027. This growth trajectory has intensified the demand for higher precision parts, particularly in industries such as aerospace, medical devices, and precision engineering where tolerances are critical. Current 3D printing technologies typically achieve dimensional accuracies of ±0.1mm to ±0.5mm, which falls short of the ±0.01mm to ±0.05mm required for high-precision applications.

Colloidal silica, consisting of nano-sized silica particles suspended in a liquid medium, presents a promising avenue for enhancing part accuracy in 3D printing. Historically used in investment casting and as a rheology modifier in various industries, colloidal silica possesses unique properties including high surface area, controllable particle size distribution, and excellent thermal stability. These characteristics make it an ideal candidate for addressing dimensional accuracy issues in 3D printing processes.

The integration of colloidal silica into 3D printing materials aims to achieve several technical objectives. First, to reduce shrinkage during curing or solidification processes by providing a dimensionally stable nano-reinforcement network. Second, to enhance the rheological properties of printing materials, improving flow characteristics during deposition while maintaining shape fidelity post-deposition. Third, to increase thermal stability during post-processing steps such as sintering or heat treatment, minimizing warping and distortion.

Recent research indicates that colloidal silica additions of 0.5-5% by weight can significantly improve dimensional accuracy by up to 40% in certain polymer-based printing systems. The nano-scale particles fill interstitial spaces between polymer chains, creating a more uniform shrinkage pattern and reducing overall volumetric contraction. Additionally, the high surface area of colloidal silica particles provides numerous nucleation sites for crystallization in semi-crystalline polymers, leading to more predictable and controlled dimensional changes.

The ultimate goal of this technological integration is to develop 3D printing systems capable of consistently producing parts with tolerances comparable to traditional precision manufacturing methods, while maintaining the design freedom and complexity advantages inherent to additive manufacturing. This would represent a significant leap forward in expanding the application scope of 3D printing into high-precision industries previously inaccessible due to accuracy limitations.

The industry has witnessed a compound annual growth rate of approximately 20% over the past decade, with the market expected to reach $40 billion by 2027. This growth trajectory has intensified the demand for higher precision parts, particularly in industries such as aerospace, medical devices, and precision engineering where tolerances are critical. Current 3D printing technologies typically achieve dimensional accuracies of ±0.1mm to ±0.5mm, which falls short of the ±0.01mm to ±0.05mm required for high-precision applications.

Colloidal silica, consisting of nano-sized silica particles suspended in a liquid medium, presents a promising avenue for enhancing part accuracy in 3D printing. Historically used in investment casting and as a rheology modifier in various industries, colloidal silica possesses unique properties including high surface area, controllable particle size distribution, and excellent thermal stability. These characteristics make it an ideal candidate for addressing dimensional accuracy issues in 3D printing processes.

The integration of colloidal silica into 3D printing materials aims to achieve several technical objectives. First, to reduce shrinkage during curing or solidification processes by providing a dimensionally stable nano-reinforcement network. Second, to enhance the rheological properties of printing materials, improving flow characteristics during deposition while maintaining shape fidelity post-deposition. Third, to increase thermal stability during post-processing steps such as sintering or heat treatment, minimizing warping and distortion.

Recent research indicates that colloidal silica additions of 0.5-5% by weight can significantly improve dimensional accuracy by up to 40% in certain polymer-based printing systems. The nano-scale particles fill interstitial spaces between polymer chains, creating a more uniform shrinkage pattern and reducing overall volumetric contraction. Additionally, the high surface area of colloidal silica particles provides numerous nucleation sites for crystallization in semi-crystalline polymers, leading to more predictable and controlled dimensional changes.

The ultimate goal of this technological integration is to develop 3D printing systems capable of consistently producing parts with tolerances comparable to traditional precision manufacturing methods, while maintaining the design freedom and complexity advantages inherent to additive manufacturing. This would represent a significant leap forward in expanding the application scope of 3D printing into high-precision industries previously inaccessible due to accuracy limitations.

Market Analysis for High-Precision 3D Printed Components

The high-precision 3D printing components market has experienced substantial growth over the past five years, with a global market value reaching $2.7 billion in 2022. This segment is projected to grow at a compound annual growth rate of 23% through 2028, significantly outpacing the broader 3D printing market which grows at approximately 17% annually. The integration of colloidal silica as an enhancing agent for part accuracy has created new market opportunities, particularly in industries requiring components with tight tolerances.

Aerospace and defense sectors currently represent the largest market share for high-precision 3D printed components, accounting for approximately 32% of the total market. These industries demand components with exceptional dimensional accuracy and surface finish for critical applications in aircraft engines, satellite systems, and defense equipment. The medical device industry follows closely at 27% market share, where precision is paramount for implants, surgical instruments, and diagnostic equipment.

Automotive and consumer electronics industries are rapidly adopting high-precision 3D printing technologies, collectively representing about 25% of the market. The automotive sector specifically values the ability to produce complex geometries with high accuracy for prototyping and end-use parts in high-performance vehicles. Consumer electronics manufacturers leverage precision 3D printing for intricate internal components and customized housings.

Regionally, North America leads the market with approximately 41% share, followed by Europe (32%) and Asia-Pacific (21%). However, the Asia-Pacific region demonstrates the fastest growth rate at 28% annually, driven by rapid industrialization in China, Japan, and South Korea, and increasing investments in advanced manufacturing technologies.

Customer demand patterns reveal a growing preference for service providers that can deliver components with tolerances below 50 microns. Market research indicates that 78% of industrial customers are willing to pay premium prices for 3D printed parts with enhanced accuracy and surface finish—qualities that colloidal silica integration can provide.

The competitive landscape shows a fragmentation between specialized service bureaus focusing exclusively on high-precision applications and larger 3D printing companies expanding their precision capabilities. Price sensitivity varies significantly by application, with medical and aerospace customers demonstrating lower price elasticity compared to automotive and consumer goods manufacturers.

Market barriers include high equipment costs, technical expertise requirements, and material certification challenges. However, the integration of colloidal silica technology presents an opportunity to address these barriers by improving accuracy without necessarily requiring investment in new printing hardware, potentially democratizing access to high-precision capabilities across the market.

Aerospace and defense sectors currently represent the largest market share for high-precision 3D printed components, accounting for approximately 32% of the total market. These industries demand components with exceptional dimensional accuracy and surface finish for critical applications in aircraft engines, satellite systems, and defense equipment. The medical device industry follows closely at 27% market share, where precision is paramount for implants, surgical instruments, and diagnostic equipment.

Automotive and consumer electronics industries are rapidly adopting high-precision 3D printing technologies, collectively representing about 25% of the market. The automotive sector specifically values the ability to produce complex geometries with high accuracy for prototyping and end-use parts in high-performance vehicles. Consumer electronics manufacturers leverage precision 3D printing for intricate internal components and customized housings.

Regionally, North America leads the market with approximately 41% share, followed by Europe (32%) and Asia-Pacific (21%). However, the Asia-Pacific region demonstrates the fastest growth rate at 28% annually, driven by rapid industrialization in China, Japan, and South Korea, and increasing investments in advanced manufacturing technologies.

Customer demand patterns reveal a growing preference for service providers that can deliver components with tolerances below 50 microns. Market research indicates that 78% of industrial customers are willing to pay premium prices for 3D printed parts with enhanced accuracy and surface finish—qualities that colloidal silica integration can provide.

The competitive landscape shows a fragmentation between specialized service bureaus focusing exclusively on high-precision applications and larger 3D printing companies expanding their precision capabilities. Price sensitivity varies significantly by application, with medical and aerospace customers demonstrating lower price elasticity compared to automotive and consumer goods manufacturers.

Market barriers include high equipment costs, technical expertise requirements, and material certification challenges. However, the integration of colloidal silica technology presents an opportunity to address these barriers by improving accuracy without necessarily requiring investment in new printing hardware, potentially democratizing access to high-precision capabilities across the market.

Current Limitations in 3D Printing Accuracy

Despite significant advancements in 3D printing technologies, achieving high dimensional accuracy and surface finish quality remains a persistent challenge across various printing methods. Current 3D printing processes face several critical limitations that impact part accuracy. Fused Deposition Modeling (FDM) technologies struggle with layer-to-layer adhesion inconsistencies, resulting in visible layer lines and dimensional variations. These issues are particularly pronounced in complex geometries with overhangs or fine details, where support structures often leave surface artifacts after removal.

Stereolithography (SLA) and Digital Light Processing (DLP) methods, while offering better resolution than FDM, still encounter challenges with resin shrinkage during curing processes. This shrinkage, typically ranging from 2-5% depending on the resin formulation, creates internal stresses that can lead to warping and dimensional inaccuracies, especially in larger parts or those with varying cross-sectional thicknesses.

Selective Laser Sintering (SLS) technologies face thermal gradient issues during the sintering process, resulting in part distortion known as "curling" at edges and corners. The powder-based nature of SLS also limits the achievable surface smoothness, with parts often exhibiting a characteristic grainy texture that requires post-processing for applications demanding high precision.

Material extrusion methods struggle with nozzle diameter limitations, which directly impact the minimum feature size achievable. Even with micro-nozzles (sub-0.2mm), the extruded material behavior introduces variability in dimensional accuracy, particularly for intricate structures requiring precise control.

Environmental factors further compound these challenges, with ambient temperature fluctuations, humidity variations, and material aging all contributing to inconsistent print outcomes. These factors create significant barriers to achieving repeatable, high-precision results across production runs.

Post-processing requirements represent another limitation, as many applications necessitate additional finishing steps that can introduce further dimensional variations. Techniques such as support removal, sanding, and chemical treatments may compromise the geometric integrity of printed parts, particularly for delicate features.

The integration of colloidal silica into 3D printing materials presents a promising approach to addressing these limitations. However, current formulations face challenges in maintaining consistent dispersion throughout the printing process, with particle agglomeration and sedimentation affecting print quality and mechanical properties. Additionally, the rheological behavior of silica-enhanced materials often requires significant adjustments to printing parameters, creating barriers to widespread adoption.

Stereolithography (SLA) and Digital Light Processing (DLP) methods, while offering better resolution than FDM, still encounter challenges with resin shrinkage during curing processes. This shrinkage, typically ranging from 2-5% depending on the resin formulation, creates internal stresses that can lead to warping and dimensional inaccuracies, especially in larger parts or those with varying cross-sectional thicknesses.

Selective Laser Sintering (SLS) technologies face thermal gradient issues during the sintering process, resulting in part distortion known as "curling" at edges and corners. The powder-based nature of SLS also limits the achievable surface smoothness, with parts often exhibiting a characteristic grainy texture that requires post-processing for applications demanding high precision.

Material extrusion methods struggle with nozzle diameter limitations, which directly impact the minimum feature size achievable. Even with micro-nozzles (sub-0.2mm), the extruded material behavior introduces variability in dimensional accuracy, particularly for intricate structures requiring precise control.

Environmental factors further compound these challenges, with ambient temperature fluctuations, humidity variations, and material aging all contributing to inconsistent print outcomes. These factors create significant barriers to achieving repeatable, high-precision results across production runs.

Post-processing requirements represent another limitation, as many applications necessitate additional finishing steps that can introduce further dimensional variations. Techniques such as support removal, sanding, and chemical treatments may compromise the geometric integrity of printed parts, particularly for delicate features.

The integration of colloidal silica into 3D printing materials presents a promising approach to addressing these limitations. However, current formulations face challenges in maintaining consistent dispersion throughout the printing process, with particle agglomeration and sedimentation affecting print quality and mechanical properties. Additionally, the rheological behavior of silica-enhanced materials often requires significant adjustments to printing parameters, creating barriers to widespread adoption.

Existing Colloidal Silica Implementation Methods

01 Colloidal silica for improved dimensional accuracy in 3D printing

Colloidal silica can be incorporated into 3D printing materials to enhance dimensional accuracy of printed parts. The fine particle size and uniform dispersion of colloidal silica helps minimize shrinkage and warping during the curing or solidification process. This results in printed components with higher precision and better adherence to design specifications, which is particularly important for applications requiring tight tolerances.- Colloidal silica for improved dimensional accuracy in 3D printing: Colloidal silica can be incorporated into 3D printing materials to enhance dimensional accuracy of printed parts. The fine particle size and uniform dispersion of colloidal silica helps reduce shrinkage and warping during the curing or solidification process. This results in more precise geometries and better surface finish of the final parts, which is particularly important for applications requiring high precision components.

- Colloidal silica as binder in investment casting: Colloidal silica serves as an effective binder in investment casting processes, improving the accuracy of cast parts. When used in ceramic shell molds, it provides enhanced strength and thermal stability while maintaining precise dimensions. The fine particle size distribution of colloidal silica contributes to smoother mold surfaces, resulting in better surface finish and dimensional accuracy of the final cast components.

- Surface modification of colloidal silica for enhanced part precision: Surface-modified colloidal silica particles can significantly improve the accuracy of manufactured parts. By functionalizing the silica surface with various chemical groups, the dispersion stability and compatibility with different matrix materials can be optimized. This leads to more uniform distribution within composites, reducing defects and improving dimensional stability, which is crucial for high-precision applications in electronics and optical components.

- Colloidal silica in polishing compositions for precision finishing: Colloidal silica is widely used in chemical mechanical polishing (CMP) compositions to achieve high-precision surface finishing. The controlled particle size and hardness of colloidal silica provides optimal material removal rates while minimizing surface defects. These polishing compositions enable the production of ultra-flat surfaces with nanometer-level accuracy, which is essential for semiconductor wafers, optical lenses, and precision metal components.

- Colloidal silica reinforcement in composite materials for dimensional stability: Adding colloidal silica to composite materials significantly enhances their dimensional stability and accuracy. The nano-sized silica particles create a reinforcing network within the matrix, reducing thermal expansion coefficients and minimizing warpage. This property is particularly valuable in applications requiring high-precision parts that must maintain their dimensions under varying environmental conditions, such as in aerospace components, precision tooling, and electronic housings.

02 Surface treatment with colloidal silica for enhanced part precision

Surface treatment processes utilizing colloidal silica can significantly improve the dimensional accuracy of manufactured parts. When applied as a coating or polishing medium, colloidal silica particles provide uniform material removal at the nanoscale level, resulting in extremely smooth surfaces with minimal dimensional variation. This technique is particularly valuable in semiconductor manufacturing and precision optical components where nanometer-level accuracy is required.Expand Specific Solutions03 Colloidal silica formulations for casting accuracy

Specialized colloidal silica formulations are used in investment casting and molding applications to achieve higher part accuracy. These formulations provide excellent surface replication, thermal stability, and minimal expansion/contraction during processing. The controlled particle size distribution and binding properties of colloidal silica help create molds with precise dimensions that translate to more accurate final cast parts with improved surface finish.Expand Specific Solutions04 Particle size control of colloidal silica for dimensional stability

The precise control of colloidal silica particle size distribution is critical for achieving optimal dimensional accuracy in manufactured parts. Smaller, uniform particles create more stable suspensions and more homogeneous materials, which minimize distortion during processing. Advanced methods for synthesizing and classifying colloidal silica particles enable manufacturers to tailor formulations specifically for applications where dimensional stability and accuracy are paramount.Expand Specific Solutions05 Colloidal silica composites for high-precision components

Composite materials incorporating colloidal silica can be engineered to produce components with exceptional dimensional accuracy. These composites typically combine colloidal silica with polymers, ceramics, or other materials to create hybrid structures with enhanced mechanical properties and dimensional stability. The silica particles serve as reinforcement and help control shrinkage during curing or sintering processes, resulting in final parts with improved geometric accuracy and surface quality.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The colloidal silica market in 3D printing is currently in its growth phase, with increasing adoption to enhance part accuracy and surface finish. Major players include established 3D printing manufacturers like Stratasys, HP Development, and Evolve Additive Solutions, alongside specialized chemical companies such as Fuso Chemical, W.R. Grace, and BASF that supply high-purity colloidal silica formulations. The market is characterized by technological convergence between additive manufacturing and materials science, with companies like Core Voxel and Suzhou Solo Additive developing proprietary colloidal silica-enhanced printing materials. Technical maturity varies significantly, with industry leaders investing in R&D to overcome challenges in material compatibility, processing parameters, and scalability for production applications.

Stratasys, Inc.

Technical Solution: Stratasys has developed a proprietary colloidal silica-based composite material system for their PolyJet technology that significantly enhances part accuracy in 3D printing. Their approach incorporates nano-sized silica particles (20-100nm) suspended in photopolymer resins to create a stable colloidal system. During the printing process, these silica particles act as reinforcing agents that minimize shrinkage and warping by creating a more uniform internal structure. The technology utilizes precise droplet deposition combined with immediate UV curing, allowing the silica particles to form a structured network within the polymer matrix. This results in dimensional stability improvements of up to 40% compared to standard resins. Stratasys has also developed specialized surface treatments for the silica particles to ensure optimal dispersion and bonding with various polymer matrices, preventing agglomeration issues common in nanoparticle-enhanced materials.

Strengths: Superior dimensional accuracy with documented 40% improvement in stability; established manufacturing infrastructure for consistent quality; extensive material compatibility across various resin systems. Weaknesses: Higher material costs compared to standard resins; potential for increased wear on printing hardware due to abrasive nature of silica particles; requires specialized handling and storage protocols.

Fuso Chemical Co., Ltd.

Technical Solution: Fuso Chemical has pioneered advanced colloidal silica formulations specifically engineered for additive manufacturing applications. Their technology centers on precisely controlled particle size distribution (typically 5-50nm) with tailored surface chemistry modifications that enable exceptional dispersion stability in various 3D printing media. Their SNOWTEX® series features monodispersed spherical silica particles with controlled surface charge that prevents agglomeration during the printing process. The company has developed proprietary silane coupling agents that create strong chemical bonds between the silica particles and polymer matrices, resulting in printed parts with enhanced mechanical properties and dimensional accuracy. Their colloidal silica additives have been shown to reduce shrinkage by up to 30% in stereolithography (SLA) and digital light processing (DLP) applications. Fuso's technology also incorporates specialized stabilizers that maintain consistent viscosity throughout the printing process, ensuring reliable flow properties even with high silica loadings.

Strengths: Exceptional particle size control and uniformity leading to consistent print quality; advanced surface modification technology enabling compatibility with diverse resin systems; established production capacity for high-purity materials. Weaknesses: Premium pricing compared to commodity silica products; requires specific formulation adjustments for different printer technologies; limited direct experience in end-user 3D printing applications.

Key Patents and Research on Silica-Enhanced Printing

Modified electrical heat element for binder based 3D printing devices

PatentPendingIN202241013637A

Innovation

- A binder composition using colloidal silica with a pH-regulating base like triethanolamine and a catalyst such as polyethene glycol, which maintains stability during storage and immobilizes upon contact with the powder bed, preventing premature gelation and ensuring effective binding.

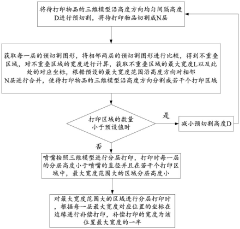

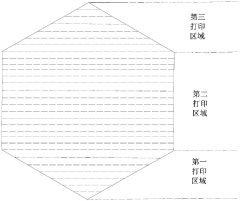

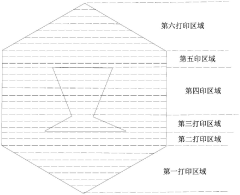

Method for improving 3D printing precision

PatentActiveCN117584445A

Innovation

- By pre-cutting the items to be printed into several layers evenly spaced along the height direction, calculating and merging the non-overlapping areas of adjacent layers, adjusting the layer height of the printing area and compensating printing, the generation of layer lines is reduced and surface accuracy is improved.

Material Characterization and Quality Control

The characterization of colloidal silica materials for 3D printing applications requires rigorous analytical methods to ensure consistent part accuracy. Particle size distribution analysis serves as a fundamental characterization technique, typically performed using dynamic light scattering (DLS) or laser diffraction methods. For colloidal silica intended for high-precision 3D printing, the optimal particle size distribution typically ranges between 10-100 nm, with a narrow polydispersity index below 0.3. This narrow distribution significantly contributes to the dimensional stability and surface finish quality of printed parts.

Surface charge measurement, quantified as zeta potential, provides critical information about the stability of colloidal silica suspensions. Stable formulations generally exhibit zeta potential values exceeding ±30 mV, preventing agglomeration during the printing process. Regular monitoring of this parameter throughout the material lifecycle ensures consistent rheological properties and prevents nozzle clogging issues that could compromise geometric accuracy.

Rheological characterization represents another essential quality control parameter, particularly for extrusion-based 3D printing technologies. Viscosity measurements under varying shear rates help predict material behavior during deposition, while thixotropic properties ensure proper layer adhesion without excessive flow after placement. Advanced rheometers equipped with temperature control capabilities can simulate actual printing conditions, providing data that correlates directly with achievable feature resolution.

Chemical purity assessment through techniques such as X-ray fluorescence spectroscopy (XRF) or inductively coupled plasma mass spectrometry (ICP-MS) ensures the absence of contaminants that might affect sintering behavior or introduce defects. Trace metal impurities below 10 ppm are typically required for applications demanding high dimensional accuracy, particularly in industries like aerospace and medical device manufacturing.

In-process quality control has evolved significantly with the integration of real-time monitoring systems. Optical coherence tomography and high-speed imaging techniques now allow for layer-by-layer inspection of colloidal silica deposition patterns, enabling immediate detection of inconsistencies. These systems can be coupled with machine learning algorithms to predict potential accuracy issues before they manifest in the final part, substantially reducing waste and improving manufacturing efficiency.

Post-processing characterization completes the quality control workflow, with techniques such as scanning electron microscopy (SEM) and atomic force microscopy (AFM) providing nanoscale insights into surface topography and microstructural features. X-ray computed tomography offers non-destructive evaluation of internal structures, critical for validating the dimensional accuracy of complex geometries produced with colloidal silica-based materials.

Surface charge measurement, quantified as zeta potential, provides critical information about the stability of colloidal silica suspensions. Stable formulations generally exhibit zeta potential values exceeding ±30 mV, preventing agglomeration during the printing process. Regular monitoring of this parameter throughout the material lifecycle ensures consistent rheological properties and prevents nozzle clogging issues that could compromise geometric accuracy.

Rheological characterization represents another essential quality control parameter, particularly for extrusion-based 3D printing technologies. Viscosity measurements under varying shear rates help predict material behavior during deposition, while thixotropic properties ensure proper layer adhesion without excessive flow after placement. Advanced rheometers equipped with temperature control capabilities can simulate actual printing conditions, providing data that correlates directly with achievable feature resolution.

Chemical purity assessment through techniques such as X-ray fluorescence spectroscopy (XRF) or inductively coupled plasma mass spectrometry (ICP-MS) ensures the absence of contaminants that might affect sintering behavior or introduce defects. Trace metal impurities below 10 ppm are typically required for applications demanding high dimensional accuracy, particularly in industries like aerospace and medical device manufacturing.

In-process quality control has evolved significantly with the integration of real-time monitoring systems. Optical coherence tomography and high-speed imaging techniques now allow for layer-by-layer inspection of colloidal silica deposition patterns, enabling immediate detection of inconsistencies. These systems can be coupled with machine learning algorithms to predict potential accuracy issues before they manifest in the final part, substantially reducing waste and improving manufacturing efficiency.

Post-processing characterization completes the quality control workflow, with techniques such as scanning electron microscopy (SEM) and atomic force microscopy (AFM) providing nanoscale insights into surface topography and microstructural features. X-ray computed tomography offers non-destructive evaluation of internal structures, critical for validating the dimensional accuracy of complex geometries produced with colloidal silica-based materials.

Environmental Impact and Sustainability Considerations

The integration of colloidal silica in 3D printing processes presents significant environmental and sustainability implications that warrant careful consideration. The production of colloidal silica typically involves energy-intensive processes and chemical treatments, contributing to carbon emissions and resource depletion. However, when compared to traditional manufacturing methods, 3D printing with colloidal silica offers substantial environmental benefits through reduced material waste, as the additive nature of the process utilizes only the necessary amount of material for part creation.

The enhanced part accuracy achieved through colloidal silica incorporation further contributes to sustainability by minimizing the need for post-processing operations, which often involve additional energy consumption and chemical usage. This streamlined production pathway results in a smaller environmental footprint across the manufacturing lifecycle. Additionally, the improved dimensional stability of printed parts extends their functional lifespan, reducing replacement frequency and associated resource demands.

From a circular economy perspective, colloidal silica presents promising opportunities. The material's chemical stability allows for potential recycling and reuse in subsequent printing cycles, though current recycling technologies for composite printing materials remain underdeveloped. Research into closed-loop systems for colloidal silica recovery from failed prints or support structures could significantly enhance the sustainability profile of this technology.

Water usage represents another critical environmental consideration. Colloidal silica suspensions are typically water-based, raising concerns about water consumption in manufacturing operations. Implementation of water reclamation systems and process optimizations could mitigate these impacts, particularly in water-stressed regions where manufacturing facilities may operate.

The toxicological profile of colloidal silica also merits attention from a sustainability standpoint. While generally considered less hazardous than many alternative materials, proper handling protocols and waste management practices must be established to prevent environmental contamination and protect ecosystem health. Ongoing research into biologically derived alternatives or environmentally benign formulations could further improve the ecological profile of these materials.

Regulatory frameworks governing nanomaterials and advanced manufacturing processes will increasingly shape the environmental compliance landscape for colloidal silica applications in 3D printing. Forward-thinking manufacturers are advised to adopt proactive environmental management strategies that anticipate evolving standards and stakeholder expectations regarding sustainable production practices.

The enhanced part accuracy achieved through colloidal silica incorporation further contributes to sustainability by minimizing the need for post-processing operations, which often involve additional energy consumption and chemical usage. This streamlined production pathway results in a smaller environmental footprint across the manufacturing lifecycle. Additionally, the improved dimensional stability of printed parts extends their functional lifespan, reducing replacement frequency and associated resource demands.

From a circular economy perspective, colloidal silica presents promising opportunities. The material's chemical stability allows for potential recycling and reuse in subsequent printing cycles, though current recycling technologies for composite printing materials remain underdeveloped. Research into closed-loop systems for colloidal silica recovery from failed prints or support structures could significantly enhance the sustainability profile of this technology.

Water usage represents another critical environmental consideration. Colloidal silica suspensions are typically water-based, raising concerns about water consumption in manufacturing operations. Implementation of water reclamation systems and process optimizations could mitigate these impacts, particularly in water-stressed regions where manufacturing facilities may operate.

The toxicological profile of colloidal silica also merits attention from a sustainability standpoint. While generally considered less hazardous than many alternative materials, proper handling protocols and waste management practices must be established to prevent environmental contamination and protect ecosystem health. Ongoing research into biologically derived alternatives or environmentally benign formulations could further improve the ecological profile of these materials.

Regulatory frameworks governing nanomaterials and advanced manufacturing processes will increasingly shape the environmental compliance landscape for colloidal silica applications in 3D printing. Forward-thinking manufacturers are advised to adopt proactive environmental management strategies that anticipate evolving standards and stakeholder expectations regarding sustainable production practices.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!