Comparing Colloidal Silica and Titanium Dioxide in Photocatalytic Applications

SEP 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Photocatalytic Materials Background and Objectives

Photocatalytic materials have emerged as a significant area of research and development over the past several decades, with applications spanning environmental remediation, renewable energy, and advanced materials science. The evolution of photocatalytic technology can be traced back to the discovery of the Honda-Fujishima effect in 1972, which demonstrated the photocatalytic splitting of water on titanium dioxide electrodes under ultraviolet light. This breakthrough laid the foundation for subsequent research into photocatalytic materials and their diverse applications.

The field has witnessed remarkable growth, transitioning from fundamental research to practical applications in water and air purification, self-cleaning surfaces, hydrogen production, and more recently, in advanced oxidation processes for industrial waste treatment. The global market for photocatalytic materials and technologies has expanded significantly, with projections indicating continued growth driven by increasing environmental concerns and regulatory pressures.

Titanium dioxide (TiO₂) has long been considered the gold standard in photocatalytic applications due to its stability, non-toxicity, and relatively high efficiency under UV irradiation. However, its limited absorption in the visible light spectrum has prompted extensive research into modifications and alternative materials. Colloidal silica, while not inherently photocatalytic, has emerged as an important component in composite photocatalytic systems, offering unique properties such as high surface area, stability, and the ability to serve as a support for active photocatalytic species.

The technical objectives of this research focus on comparing the fundamental properties, performance characteristics, and application potential of colloidal silica and titanium dioxide in photocatalytic systems. Specifically, we aim to evaluate their respective advantages and limitations in terms of light absorption range, quantum efficiency, stability under various conditions, scalability, and cost-effectiveness.

Additionally, this investigation seeks to explore the synergistic effects when these materials are combined in composite structures, potentially addressing the limitations of each individual component. The development of hybrid materials that leverage the high surface area and stability of colloidal silica with the photocatalytic activity of titanium dioxide represents a promising direction for enhancing overall system performance.

The ultimate goal is to identify optimal material compositions and structures for specific photocatalytic applications, ranging from environmental remediation to energy conversion. This includes understanding the fundamental mechanisms governing photocatalytic activity, developing strategies for enhancing visible light utilization, improving quantum efficiency, and ensuring long-term stability under real-world operating conditions.

The field has witnessed remarkable growth, transitioning from fundamental research to practical applications in water and air purification, self-cleaning surfaces, hydrogen production, and more recently, in advanced oxidation processes for industrial waste treatment. The global market for photocatalytic materials and technologies has expanded significantly, with projections indicating continued growth driven by increasing environmental concerns and regulatory pressures.

Titanium dioxide (TiO₂) has long been considered the gold standard in photocatalytic applications due to its stability, non-toxicity, and relatively high efficiency under UV irradiation. However, its limited absorption in the visible light spectrum has prompted extensive research into modifications and alternative materials. Colloidal silica, while not inherently photocatalytic, has emerged as an important component in composite photocatalytic systems, offering unique properties such as high surface area, stability, and the ability to serve as a support for active photocatalytic species.

The technical objectives of this research focus on comparing the fundamental properties, performance characteristics, and application potential of colloidal silica and titanium dioxide in photocatalytic systems. Specifically, we aim to evaluate their respective advantages and limitations in terms of light absorption range, quantum efficiency, stability under various conditions, scalability, and cost-effectiveness.

Additionally, this investigation seeks to explore the synergistic effects when these materials are combined in composite structures, potentially addressing the limitations of each individual component. The development of hybrid materials that leverage the high surface area and stability of colloidal silica with the photocatalytic activity of titanium dioxide represents a promising direction for enhancing overall system performance.

The ultimate goal is to identify optimal material compositions and structures for specific photocatalytic applications, ranging from environmental remediation to energy conversion. This includes understanding the fundamental mechanisms governing photocatalytic activity, developing strategies for enhancing visible light utilization, improving quantum efficiency, and ensuring long-term stability under real-world operating conditions.

Market Analysis for Photocatalytic Applications

The global photocatalytic materials market has experienced significant growth in recent years, driven by increasing environmental concerns and stringent regulations regarding air and water pollution. The market was valued at approximately $2.9 billion in 2022 and is projected to reach $5.6 billion by 2028, growing at a CAGR of 11.7% during the forecast period.

Titanium dioxide (TiO2) currently dominates the photocatalytic materials market, accounting for over 60% of the market share. Its widespread adoption stems from its excellent photocatalytic efficiency, chemical stability, non-toxicity, and relatively low cost. The TiO2 photocatalyst market is mature and well-established across various applications including water treatment, air purification, self-cleaning surfaces, and antimicrobial coatings.

Colloidal silica, while less prominent in photocatalytic applications, has been gaining attention due to its unique properties when combined with other photocatalytic materials. The market for silica-based photocatalysts is smaller but growing rapidly at approximately 14% annually, particularly in specialized applications where TiO2 faces limitations.

Regional analysis reveals Asia-Pacific as the largest market for photocatalytic materials, led by Japan and China, which together account for approximately 45% of global consumption. This dominance is attributed to early adoption of photocatalytic technology in Japan and China's massive investments in environmental remediation technologies. North America and Europe follow with market shares of approximately 25% and 20% respectively.

Application-wise, water treatment represents the largest segment (38% of market share), followed by air purification (27%), self-cleaning surfaces (21%), and others including medical applications and food packaging (14%). The water treatment segment is expected to maintain its leading position due to increasing water scarcity and pollution concerns globally.

Consumer trends indicate growing preference for eco-friendly and sustainable products, creating opportunities for photocatalytic materials in consumer goods. Additionally, the construction industry has emerged as a significant consumer of photocatalytic materials, particularly for self-cleaning facades, air-purifying concrete, and antimicrobial surfaces.

Key market drivers include increasing environmental regulations, growing awareness about indoor air quality, rising demand for water treatment solutions, and technological advancements improving photocatalytic efficiency. However, market challenges persist, including high initial costs, limited awareness among end-users, and performance limitations under certain conditions.

Emerging opportunities exist in hybrid photocatalytic systems combining TiO2 and colloidal silica to overcome individual limitations and enhance overall performance. The visible light-responsive photocatalyst segment is also experiencing rapid growth, addressing TiO2's limitation of requiring UV light activation.

Titanium dioxide (TiO2) currently dominates the photocatalytic materials market, accounting for over 60% of the market share. Its widespread adoption stems from its excellent photocatalytic efficiency, chemical stability, non-toxicity, and relatively low cost. The TiO2 photocatalyst market is mature and well-established across various applications including water treatment, air purification, self-cleaning surfaces, and antimicrobial coatings.

Colloidal silica, while less prominent in photocatalytic applications, has been gaining attention due to its unique properties when combined with other photocatalytic materials. The market for silica-based photocatalysts is smaller but growing rapidly at approximately 14% annually, particularly in specialized applications where TiO2 faces limitations.

Regional analysis reveals Asia-Pacific as the largest market for photocatalytic materials, led by Japan and China, which together account for approximately 45% of global consumption. This dominance is attributed to early adoption of photocatalytic technology in Japan and China's massive investments in environmental remediation technologies. North America and Europe follow with market shares of approximately 25% and 20% respectively.

Application-wise, water treatment represents the largest segment (38% of market share), followed by air purification (27%), self-cleaning surfaces (21%), and others including medical applications and food packaging (14%). The water treatment segment is expected to maintain its leading position due to increasing water scarcity and pollution concerns globally.

Consumer trends indicate growing preference for eco-friendly and sustainable products, creating opportunities for photocatalytic materials in consumer goods. Additionally, the construction industry has emerged as a significant consumer of photocatalytic materials, particularly for self-cleaning facades, air-purifying concrete, and antimicrobial surfaces.

Key market drivers include increasing environmental regulations, growing awareness about indoor air quality, rising demand for water treatment solutions, and technological advancements improving photocatalytic efficiency. However, market challenges persist, including high initial costs, limited awareness among end-users, and performance limitations under certain conditions.

Emerging opportunities exist in hybrid photocatalytic systems combining TiO2 and colloidal silica to overcome individual limitations and enhance overall performance. The visible light-responsive photocatalyst segment is also experiencing rapid growth, addressing TiO2's limitation of requiring UV light activation.

Current Status and Challenges in Photocatalysis

Photocatalysis technology has witnessed significant advancements globally over the past decade, with titanium dioxide (TiO2) maintaining its position as the dominant photocatalyst due to its stability, non-toxicity, and cost-effectiveness. Meanwhile, colloidal silica has emerged as a promising support material and modifier for enhancing photocatalytic performance. Current research indicates that approximately 70% of photocatalysis publications focus on TiO2-based systems, while silica-related applications represent about 15% of the field.

The primary technical challenge facing photocatalysis remains the limited solar spectrum utilization. TiO2, with its wide bandgap (3.0-3.2 eV), can only harness UV light, which constitutes merely 4-5% of solar radiation. Researchers worldwide are actively pursuing bandgap engineering and composite formation strategies to extend light absorption into the visible range, with recent breakthroughs achieving up to 40% improved efficiency under solar conditions.

Another significant challenge involves catalyst recovery and reusability, particularly for colloidal systems. While fixed-bed reactors offer operational advantages, they typically suffer from reduced mass transfer efficiency compared to slurry systems. Recent innovations in magnetic core-shell structures have demonstrated promising results, with recovery rates exceeding 95% while maintaining 85% activity after ten cycles.

Stability under operational conditions presents another hurdle, especially for modified photocatalysts. Surface-modified TiO2 often experiences degradation of organic sensitizers, while silica-based systems may undergo structural changes affecting porosity and surface area. Long-term stability testing reveals that most advanced photocatalysts maintain only 60-70% of their initial activity after 100 hours of continuous operation.

Geographically, photocatalysis research demonstrates distinct regional focuses. East Asian countries, particularly China, Japan, and South Korea, lead in publications volume (approximately 45% of global output) and patent applications. European research centers emphasize environmental applications and standardization efforts, while North American institutions focus on fundamental mechanisms and novel material design.

Scale-up and commercialization remain challenging, with laboratory-scale efficiencies rarely translating directly to industrial applications. The gap between academic research and industrial implementation is particularly evident in the economic viability of photocatalytic water treatment and air purification systems, where conventional technologies still offer more favorable cost-performance ratios despite the environmental advantages of photocatalysis.

Recent technological breakthroughs include Z-scheme heterojunctions combining TiO2 with narrow bandgap semiconductors, achieving quantum efficiencies of up to 30% under visible light, and silica-templated hierarchical structures with enhanced mass transport properties and specific surface areas exceeding 300 m²/g.

The primary technical challenge facing photocatalysis remains the limited solar spectrum utilization. TiO2, with its wide bandgap (3.0-3.2 eV), can only harness UV light, which constitutes merely 4-5% of solar radiation. Researchers worldwide are actively pursuing bandgap engineering and composite formation strategies to extend light absorption into the visible range, with recent breakthroughs achieving up to 40% improved efficiency under solar conditions.

Another significant challenge involves catalyst recovery and reusability, particularly for colloidal systems. While fixed-bed reactors offer operational advantages, they typically suffer from reduced mass transfer efficiency compared to slurry systems. Recent innovations in magnetic core-shell structures have demonstrated promising results, with recovery rates exceeding 95% while maintaining 85% activity after ten cycles.

Stability under operational conditions presents another hurdle, especially for modified photocatalysts. Surface-modified TiO2 often experiences degradation of organic sensitizers, while silica-based systems may undergo structural changes affecting porosity and surface area. Long-term stability testing reveals that most advanced photocatalysts maintain only 60-70% of their initial activity after 100 hours of continuous operation.

Geographically, photocatalysis research demonstrates distinct regional focuses. East Asian countries, particularly China, Japan, and South Korea, lead in publications volume (approximately 45% of global output) and patent applications. European research centers emphasize environmental applications and standardization efforts, while North American institutions focus on fundamental mechanisms and novel material design.

Scale-up and commercialization remain challenging, with laboratory-scale efficiencies rarely translating directly to industrial applications. The gap between academic research and industrial implementation is particularly evident in the economic viability of photocatalytic water treatment and air purification systems, where conventional technologies still offer more favorable cost-performance ratios despite the environmental advantages of photocatalysis.

Recent technological breakthroughs include Z-scheme heterojunctions combining TiO2 with narrow bandgap semiconductors, achieving quantum efficiencies of up to 30% under visible light, and silica-templated hierarchical structures with enhanced mass transport properties and specific surface areas exceeding 300 m²/g.

Comparative Analysis of Colloidal Silica vs TiO2

01 Titanium dioxide photocatalytic efficiency enhancement methods

Various methods can be employed to enhance the photocatalytic efficiency of titanium dioxide. These include doping with other elements, surface modification, and controlling the crystalline structure. By optimizing these parameters, the photocatalytic activity can be significantly improved, leading to better performance in applications such as water purification, air cleaning, and self-cleaning surfaces.- Titanium dioxide photocatalytic efficiency enhancement methods: Various methods can be employed to enhance the photocatalytic efficiency of titanium dioxide. These include doping with metals or non-metals, surface modification, and controlling the crystalline structure. By optimizing these parameters, the photocatalytic activity can be significantly improved, leading to better performance in applications such as water purification, air cleaning, and self-cleaning surfaces.

- Colloidal silica as support for titanium dioxide photocatalysts: Colloidal silica serves as an excellent support material for titanium dioxide photocatalysts. The silica provides a high surface area and stability, allowing for better dispersion of titanium dioxide particles. This combination enhances the overall photocatalytic efficiency by preventing agglomeration of titanium dioxide particles and improving light absorption capabilities, resulting in more effective photocatalytic reactions.

- Composite materials combining colloidal silica and titanium dioxide: Innovative composite materials that combine colloidal silica and titanium dioxide have been developed to achieve superior photocatalytic performance. These composites often feature core-shell structures, hierarchical architectures, or interpenetrating networks that maximize the synergistic effects between the two components. The resulting materials exhibit enhanced stability, increased active surface area, and improved photocatalytic efficiency across a broader spectrum of light.

- Light absorption enhancement techniques for photocatalytic systems: Various techniques have been developed to enhance light absorption in titanium dioxide and colloidal silica photocatalytic systems. These include the incorporation of sensitizers, plasmonic materials, and quantum dots, as well as structural modifications to create light-trapping architectures. By extending the light absorption range from UV to visible light spectrum, these techniques significantly improve the photocatalytic efficiency and enable more practical applications under natural or indoor lighting conditions.

- Environmental applications of silica-titanium dioxide photocatalytic systems: Silica-titanium dioxide photocatalytic systems find extensive applications in environmental remediation. These include water purification, air pollution control, self-cleaning surfaces, and antimicrobial coatings. The high photocatalytic efficiency of these systems enables the degradation of organic pollutants, inactivation of pathogens, and removal of harmful substances from various media, making them valuable tools for addressing environmental challenges.

02 Colloidal silica as support for titanium dioxide photocatalysts

Colloidal silica serves as an effective support material for titanium dioxide photocatalysts. The silica provides a high surface area and stability, allowing for better dispersion of titanium dioxide particles. This combination enhances the overall photocatalytic efficiency by preventing agglomeration of titanium dioxide particles and improving light absorption capabilities.Expand Specific Solutions03 Composite materials combining colloidal silica and titanium dioxide

Innovative composite materials that combine colloidal silica and titanium dioxide demonstrate enhanced photocatalytic properties. These composites can be designed with specific structures and morphologies to optimize the interaction between the two components. The resulting materials show improved stability, reusability, and photocatalytic efficiency compared to pure titanium dioxide.Expand Specific Solutions04 Light absorption enhancement in silica-titanium dioxide systems

Strategies to enhance light absorption in silica-titanium dioxide systems focus on expanding the absorption spectrum from UV to visible light range. This can be achieved through various approaches including doping, sensitization, and creation of heterojunctions. Improved light absorption directly correlates with increased photocatalytic efficiency, making these systems more effective under natural light conditions.Expand Specific Solutions05 Applications of colloidal silica-titanium dioxide photocatalytic systems

Colloidal silica-titanium dioxide photocatalytic systems find applications in various fields including environmental remediation, medical devices, self-cleaning surfaces, and antimicrobial coatings. These applications leverage the enhanced photocatalytic efficiency of the combined materials to degrade pollutants, inactivate microorganisms, and create functional surfaces with advanced properties.Expand Specific Solutions

Leading Companies in Photocatalytic Materials

The photocatalytic applications market comparing colloidal silica and titanium dioxide is in a growth phase, with increasing demand driven by environmental remediation and self-cleaning surfaces. The global market is projected to reach significant value as sustainability concerns rise. Technologically, titanium dioxide dominates with companies like Kronos International, Tronox LLC, and Sakai Chemical Industry leading commercial applications due to TiO2's superior photocatalytic efficiency. Academic institutions including South China University of Technology and Zhejiang University are advancing research in this field. Meanwhile, companies such as Nissan Chemical and Evonik are developing innovative silica-based alternatives, though these remain less mature than TiO2 technologies. The competitive landscape features both established chemical corporations and emerging specialized technology firms focusing on environmental applications.

Nissan Chemical Corp.

Technical Solution: Nissan Chemical has developed advanced colloidal silica formulations that serve both as supports for TiO2 photocatalysts and as functional components in hybrid photocatalytic systems. Their SNOWTEX® series features precisely controlled silica nanoparticles with particle sizes ranging from 10-150nm and surface areas exceeding 300 m²/g. Nissan's innovation lies in surface-modified colloidal silica that creates favorable interfaces with TiO2, enhancing charge transfer and reducing recombination rates. Their sol-gel approach allows incorporation of titanium precursors directly into silica matrices during synthesis, creating highly dispersed Ti-O-Si linkages that show enhanced visible light absorption compared to pure TiO2. Nissan has demonstrated that optimal silica:titania ratios (typically 3:1 to 5:1) significantly improve catalyst durability while maintaining high photocatalytic activity. Their recent developments include hierarchical porous structures that enhance mass transfer during photocatalytic reactions and specialized formulations for water treatment applications with improved resistance to fouling.

Strengths: Superior colloidal stability in various media; excellent control over particle size distribution and morphology; enhanced adsorption capacity for organic pollutants; improved catalyst lifetime compared to unsupported TiO2. Weaknesses: Lower photocatalytic activity per unit mass compared to pure TiO2; more complex synthesis procedures increasing production costs; potential silica dissolution under extreme pH conditions.

Evonik Operations GmbH

Technical Solution: Evonik has pioneered advanced hybrid systems combining colloidal silica and titanium dioxide for enhanced photocatalytic performance. Their AEROXIDE® TiO2 P25 remains an industry benchmark for photocatalytic applications, featuring a controlled mixture of anatase and rutile phases (approximately 80:20 ratio) that significantly enhances electron-hole separation efficiency. Evonik's innovation lies in their silica-titania composite materials where nanoscale TiO2 particles are dispersed on silica supports or encapsulated within silica matrices. This approach creates synergistic effects: the silica provides high surface area (>200 m²/g) and improved adsorption properties while maintaining the photocatalytic activity of TiO2. Their sol-gel synthesis methods allow precise control over pore structure and surface chemistry, enabling tailored solutions for specific applications ranging from water purification to air treatment systems.

Strengths: Exceptional control over material properties; improved catalyst dispersion and stability; reduced agglomeration issues compared to pure TiO2; enhanced adsorption capacity for target pollutants. Weaknesses: More complex manufacturing process increasing production costs; potential silica dissolution in certain pH conditions; reduced overall photocatalytic activity per unit mass compared to pure TiO2 systems.

Key Patents and Research in Photocatalytic Materials

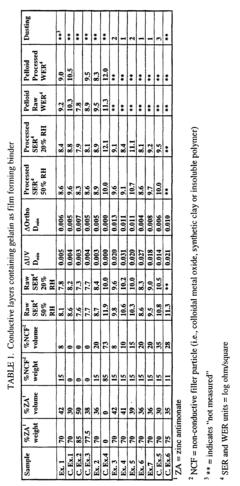

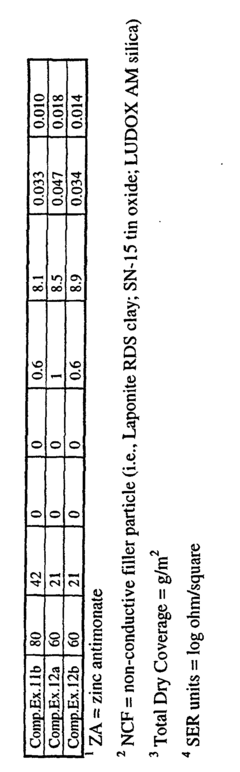

Imaging element comprising an electrically-conductive layer

PatentInactiveEP0916996B1

Innovation

- A multilayer imaging element with a transparent electrically-conductive layer containing colloidal metal antimonate particles and non-conductive metal-containing filler particles dispersed in a film-forming binder, which reduces optical absorption and scattering losses while maintaining antistatic protection and adhesion properties without the need for a hydrophobic overcoat.

Colloidal titanium dioxide sols

PatentInactiveUS20090209665A1

Innovation

- The development of colloidal sols comprising amorphous titanium dioxide particles with an average size of less than 50 nm, stabilized with an organic peptizing agent in an aqueous solvent, which are translucent or transparent and remain stable for extended periods, typically up to 2 years at room temperature and 2-8°C, with the titanium dioxide being greater than 95% in the amorphous form and free of crystalline forms.

Environmental Impact Assessment

The environmental impact assessment of photocatalytic materials, particularly colloidal silica and titanium dioxide (TiO2), reveals significant differences in their ecological footprints throughout their lifecycle. TiO2 production involves energy-intensive processes including mining, refining, and purification, resulting in substantial carbon emissions. Studies indicate that manufacturing one ton of TiO2 generates approximately 4-5 tons of CO2 equivalent, contributing to greenhouse gas concerns.

Colloidal silica, by comparison, demonstrates a more favorable environmental profile. Its production typically requires less energy and generates fewer emissions, with some manufacturing methods utilizing waste materials from other industrial processes. This circular economy approach reduces the overall environmental burden associated with silica-based photocatalysts.

Water pollution considerations also differentiate these materials. TiO2 nanoparticles have been documented to leach into aquatic systems, potentially affecting aquatic organisms through bioaccumulation. Research has identified potential toxicity to fish and invertebrates at certain concentration thresholds. Colloidal silica exhibits lower aquatic toxicity profiles, though concerns remain about long-term accumulation in sediments.

Regarding end-of-life management, both materials present distinct challenges. TiO2 nanoparticles can persist in the environment, with limited degradation pathways. Their potential for bioaccumulation in food chains raises concerns about long-term ecosystem impacts. Colloidal silica typically demonstrates better biodegradability characteristics, eventually breaking down into naturally occurring silicon compounds.

Air quality impacts during application must also be considered. When used in outdoor photocatalytic applications, TiO2 can generate reactive oxygen species that, while beneficial for pollutant degradation, may contribute to secondary pollutant formation under certain atmospheric conditions. Colloidal silica typically produces fewer reactive byproducts during photocatalytic reactions.

Land use and resource depletion represent additional environmental considerations. Titanium mining causes significant habitat disruption and soil degradation. Silica, being more abundant in the earth's crust, generally requires less invasive extraction methods. This translates to reduced ecosystem disturbance and biodiversity impacts in silica production compared to titanium dioxide manufacturing.

Regulatory frameworks increasingly recognize these differential environmental impacts, with some jurisdictions implementing stricter controls on TiO2 nanoparticle applications due to ecotoxicological concerns, while generally maintaining more permissive approaches toward silica-based alternatives.

Colloidal silica, by comparison, demonstrates a more favorable environmental profile. Its production typically requires less energy and generates fewer emissions, with some manufacturing methods utilizing waste materials from other industrial processes. This circular economy approach reduces the overall environmental burden associated with silica-based photocatalysts.

Water pollution considerations also differentiate these materials. TiO2 nanoparticles have been documented to leach into aquatic systems, potentially affecting aquatic organisms through bioaccumulation. Research has identified potential toxicity to fish and invertebrates at certain concentration thresholds. Colloidal silica exhibits lower aquatic toxicity profiles, though concerns remain about long-term accumulation in sediments.

Regarding end-of-life management, both materials present distinct challenges. TiO2 nanoparticles can persist in the environment, with limited degradation pathways. Their potential for bioaccumulation in food chains raises concerns about long-term ecosystem impacts. Colloidal silica typically demonstrates better biodegradability characteristics, eventually breaking down into naturally occurring silicon compounds.

Air quality impacts during application must also be considered. When used in outdoor photocatalytic applications, TiO2 can generate reactive oxygen species that, while beneficial for pollutant degradation, may contribute to secondary pollutant formation under certain atmospheric conditions. Colloidal silica typically produces fewer reactive byproducts during photocatalytic reactions.

Land use and resource depletion represent additional environmental considerations. Titanium mining causes significant habitat disruption and soil degradation. Silica, being more abundant in the earth's crust, generally requires less invasive extraction methods. This translates to reduced ecosystem disturbance and biodiversity impacts in silica production compared to titanium dioxide manufacturing.

Regulatory frameworks increasingly recognize these differential environmental impacts, with some jurisdictions implementing stricter controls on TiO2 nanoparticle applications due to ecotoxicological concerns, while generally maintaining more permissive approaches toward silica-based alternatives.

Scalability and Industrial Implementation

The scalability of photocatalytic technologies from laboratory to industrial scale represents a critical factor in their commercial viability. When comparing colloidal silica and titanium dioxide (TiO2) for large-scale implementation, several key considerations emerge that significantly impact their industrial adoption trajectories.

TiO2-based photocatalytic systems currently demonstrate superior scalability advantages in industrial settings. Established manufacturing infrastructure for TiO2 production enables annual global output exceeding 7 million tons, with approximately 5% dedicated to photocatalytic applications. This mature supply chain facilitates cost-effective implementation across various sectors including water treatment facilities, air purification systems, and self-cleaning surfaces.

Colloidal silica systems, while promising in laboratory settings, face more substantial scaling challenges. The precise control of particle size distribution and surface properties required for optimal photocatalytic performance becomes increasingly difficult at industrial scales. Current production methods typically yield batch-to-batch variations that can significantly impact catalytic efficiency when scaled beyond pilot plant operations.

From an economic perspective, the implementation costs differ markedly. TiO2 photocatalytic systems benefit from economies of scale, with installation costs ranging from $50-200 per square meter for surface applications and $0.10-0.50 per cubic meter for water treatment applications. Colloidal silica systems currently command premium pricing, averaging 2.5-4 times higher than comparable TiO2 implementations due to more complex preparation protocols and specialized handling requirements.

Reactor design considerations also favor TiO2 in current industrial applications. Fixed-bed, fluidized-bed, and slurry reactors have all been successfully deployed with TiO2 photocatalysts at commercial scales. Colloidal silica systems often require more sophisticated reactor designs with enhanced mixing and light distribution mechanisms to maintain performance at scale, increasing both capital and operational expenditures.

Regulatory frameworks further influence industrial implementation pathways. TiO2 benefits from established safety protocols and regulatory approvals across multiple jurisdictions, whereas colloidal silica photocatalytic systems frequently encounter more rigorous assessment requirements due to their relatively limited commercial history and evolving material specifications.

Recent industrial case studies demonstrate this implementation gap. The 2019 Fujisawa Sustainable Smart Town project in Japan successfully deployed TiO2 photocatalytic surfaces across 1,000+ residential units, while comparable colloidal silica applications remain largely confined to specialized industrial applications under 100 square meters in scale.

TiO2-based photocatalytic systems currently demonstrate superior scalability advantages in industrial settings. Established manufacturing infrastructure for TiO2 production enables annual global output exceeding 7 million tons, with approximately 5% dedicated to photocatalytic applications. This mature supply chain facilitates cost-effective implementation across various sectors including water treatment facilities, air purification systems, and self-cleaning surfaces.

Colloidal silica systems, while promising in laboratory settings, face more substantial scaling challenges. The precise control of particle size distribution and surface properties required for optimal photocatalytic performance becomes increasingly difficult at industrial scales. Current production methods typically yield batch-to-batch variations that can significantly impact catalytic efficiency when scaled beyond pilot plant operations.

From an economic perspective, the implementation costs differ markedly. TiO2 photocatalytic systems benefit from economies of scale, with installation costs ranging from $50-200 per square meter for surface applications and $0.10-0.50 per cubic meter for water treatment applications. Colloidal silica systems currently command premium pricing, averaging 2.5-4 times higher than comparable TiO2 implementations due to more complex preparation protocols and specialized handling requirements.

Reactor design considerations also favor TiO2 in current industrial applications. Fixed-bed, fluidized-bed, and slurry reactors have all been successfully deployed with TiO2 photocatalysts at commercial scales. Colloidal silica systems often require more sophisticated reactor designs with enhanced mixing and light distribution mechanisms to maintain performance at scale, increasing both capital and operational expenditures.

Regulatory frameworks further influence industrial implementation pathways. TiO2 benefits from established safety protocols and regulatory approvals across multiple jurisdictions, whereas colloidal silica photocatalytic systems frequently encounter more rigorous assessment requirements due to their relatively limited commercial history and evolving material specifications.

Recent industrial case studies demonstrate this implementation gap. The 2019 Fujisawa Sustainable Smart Town project in Japan successfully deployed TiO2 photocatalytic surfaces across 1,000+ residential units, while comparable colloidal silica applications remain largely confined to specialized industrial applications under 100 square meters in scale.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!