How to Enhance Concrete Durability with Colloidal Silica Nanomodifiers

SEP 10, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Colloidal Silica Nanomodifiers Background and Objectives

Colloidal silica nanomodifiers represent a significant advancement in concrete technology, emerging from decades of research into nanomaterials and their applications in construction materials. The evolution of this technology can be traced back to the early 2000s when researchers began exploring nanoscale additives to enhance traditional building materials. Colloidal silica, consisting of nano-sized silica particles suspended in a liquid medium, has since gained prominence as a promising solution for addressing concrete durability challenges.

The development trajectory of colloidal silica technology has been characterized by progressive refinements in particle size control, stability enhancement, and application methodologies. Initially limited by production costs and scalability issues, recent technological breakthroughs have made these nanomodifiers increasingly viable for commercial applications, particularly in high-performance and specialized concrete formulations.

Current research indicates that colloidal silica nanomodifiers operate through multiple mechanisms to enhance concrete durability. These include pore refinement, calcium silicate hydrate (C-S-H) densification, and improved interfacial transition zone properties. The nano-sized particles fill microscopic voids in the cement matrix and participate in secondary pozzolanic reactions, resulting in a more compact and less permeable concrete structure.

The primary technical objective in this field is to develop optimized colloidal silica formulations that can significantly extend concrete service life under challenging environmental conditions. Specific goals include reducing permeability to aggressive agents such as chlorides and sulfates, enhancing freeze-thaw resistance, and mitigating alkali-silica reaction potential. Additionally, researchers aim to achieve these improvements while maintaining or enhancing other critical concrete properties such as workability, setting time, and mechanical strength.

Another important objective is to establish standardized protocols for incorporating these nanomodifiers into concrete mixtures across various applications, from infrastructure projects to specialized architectural elements. This includes developing robust dispersion methods to ensure uniform distribution of nanoparticles throughout the concrete matrix.

Looking forward, the technology evolution trend points toward multi-functional colloidal silica systems that can simultaneously address multiple durability concerns while offering additional benefits such as self-cleaning properties, reduced carbon footprint, or enhanced thermal performance. The integration of colloidal silica with other emerging concrete technologies, such as self-healing mechanisms and smart monitoring systems, represents a promising frontier for next-generation construction materials.

The development trajectory of colloidal silica technology has been characterized by progressive refinements in particle size control, stability enhancement, and application methodologies. Initially limited by production costs and scalability issues, recent technological breakthroughs have made these nanomodifiers increasingly viable for commercial applications, particularly in high-performance and specialized concrete formulations.

Current research indicates that colloidal silica nanomodifiers operate through multiple mechanisms to enhance concrete durability. These include pore refinement, calcium silicate hydrate (C-S-H) densification, and improved interfacial transition zone properties. The nano-sized particles fill microscopic voids in the cement matrix and participate in secondary pozzolanic reactions, resulting in a more compact and less permeable concrete structure.

The primary technical objective in this field is to develop optimized colloidal silica formulations that can significantly extend concrete service life under challenging environmental conditions. Specific goals include reducing permeability to aggressive agents such as chlorides and sulfates, enhancing freeze-thaw resistance, and mitigating alkali-silica reaction potential. Additionally, researchers aim to achieve these improvements while maintaining or enhancing other critical concrete properties such as workability, setting time, and mechanical strength.

Another important objective is to establish standardized protocols for incorporating these nanomodifiers into concrete mixtures across various applications, from infrastructure projects to specialized architectural elements. This includes developing robust dispersion methods to ensure uniform distribution of nanoparticles throughout the concrete matrix.

Looking forward, the technology evolution trend points toward multi-functional colloidal silica systems that can simultaneously address multiple durability concerns while offering additional benefits such as self-cleaning properties, reduced carbon footprint, or enhanced thermal performance. The integration of colloidal silica with other emerging concrete technologies, such as self-healing mechanisms and smart monitoring systems, represents a promising frontier for next-generation construction materials.

Market Demand Analysis for Enhanced Concrete Solutions

The global concrete market is experiencing a significant shift towards enhanced durability solutions, driven by increasing infrastructure investments and growing awareness of lifecycle costs. The market for concrete durability enhancers is projected to reach $30 billion by 2027, with colloidal silica nanomodifiers representing one of the fastest-growing segments at a CAGR of 8.2%.

Infrastructure development remains the primary driver for advanced concrete solutions, particularly in regions experiencing rapid urbanization. China, India, and Southeast Asian countries collectively account for over 40% of global concrete consumption, with durability-enhanced formulations gaining substantial market share. In mature markets like North America and Europe, the focus has shifted from new construction to rehabilitation and life extension of existing structures, creating a robust demand for retrofit solutions incorporating colloidal silica.

The construction industry's increasing emphasis on sustainability has created a favorable market environment for colloidal silica nanomodifiers. These materials align with green building certifications such as LEED and BREEAM by extending structural lifespans and reducing maintenance requirements. Market research indicates that projects incorporating durability-enhancing concrete technologies can achieve 15-25% reductions in lifetime carbon footprint compared to conventional concrete structures.

Economic factors further strengthen market demand, as lifecycle cost analyses demonstrate compelling returns on investment. While colloidal silica-enhanced concrete typically commands a 5-12% premium over standard formulations, the extended service life (often 2-3 times longer) and reduced maintenance requirements deliver substantial long-term savings. This value proposition is particularly attractive for infrastructure projects with design lifespans exceeding 50 years.

Industry surveys reveal growing awareness among key stakeholders about concrete durability challenges. Civil engineers, architects, and project developers increasingly specify enhanced durability requirements in their projects. This trend is reinforced by evolving building codes and standards that place greater emphasis on durability metrics and performance-based specifications rather than prescriptive requirements.

Market segmentation shows distinct demand patterns across different application sectors. Marine and coastal infrastructure represents the highest-value segment due to extreme exposure conditions, followed by transportation infrastructure (bridges, tunnels) and industrial facilities exposed to chemical attack. The residential and commercial building sectors show more price sensitivity but represent substantial volume potential as awareness of lifecycle benefits increases.

Regional market analysis indicates that while developed economies currently lead in adoption rates for advanced concrete technologies, emerging markets present the greatest growth potential as they balance initial cost considerations with increasing quality and durability requirements.

Infrastructure development remains the primary driver for advanced concrete solutions, particularly in regions experiencing rapid urbanization. China, India, and Southeast Asian countries collectively account for over 40% of global concrete consumption, with durability-enhanced formulations gaining substantial market share. In mature markets like North America and Europe, the focus has shifted from new construction to rehabilitation and life extension of existing structures, creating a robust demand for retrofit solutions incorporating colloidal silica.

The construction industry's increasing emphasis on sustainability has created a favorable market environment for colloidal silica nanomodifiers. These materials align with green building certifications such as LEED and BREEAM by extending structural lifespans and reducing maintenance requirements. Market research indicates that projects incorporating durability-enhancing concrete technologies can achieve 15-25% reductions in lifetime carbon footprint compared to conventional concrete structures.

Economic factors further strengthen market demand, as lifecycle cost analyses demonstrate compelling returns on investment. While colloidal silica-enhanced concrete typically commands a 5-12% premium over standard formulations, the extended service life (often 2-3 times longer) and reduced maintenance requirements deliver substantial long-term savings. This value proposition is particularly attractive for infrastructure projects with design lifespans exceeding 50 years.

Industry surveys reveal growing awareness among key stakeholders about concrete durability challenges. Civil engineers, architects, and project developers increasingly specify enhanced durability requirements in their projects. This trend is reinforced by evolving building codes and standards that place greater emphasis on durability metrics and performance-based specifications rather than prescriptive requirements.

Market segmentation shows distinct demand patterns across different application sectors. Marine and coastal infrastructure represents the highest-value segment due to extreme exposure conditions, followed by transportation infrastructure (bridges, tunnels) and industrial facilities exposed to chemical attack. The residential and commercial building sectors show more price sensitivity but represent substantial volume potential as awareness of lifecycle benefits increases.

Regional market analysis indicates that while developed economies currently lead in adoption rates for advanced concrete technologies, emerging markets present the greatest growth potential as they balance initial cost considerations with increasing quality and durability requirements.

Current State and Challenges in Concrete Durability Enhancement

The global concrete industry faces significant durability challenges, with infrastructure deterioration becoming a critical concern across developed and developing nations. Current estimates indicate that approximately 30% of concrete structures worldwide exhibit premature deterioration, resulting in annual repair costs exceeding $100 billion. Traditional concrete, while economical and versatile, remains vulnerable to environmental degradation mechanisms including chloride penetration, carbonation, freeze-thaw cycles, and chemical attacks.

Recent advancements in nanotechnology have positioned colloidal silica as a promising modifier for enhancing concrete durability. Current research indicates that incorporating these nanoparticles at concentrations of 0.1-5% by weight of cement can significantly improve concrete's microstructure and resistance properties. Laboratory studies demonstrate up to 45% reduction in chloride ion penetration and 30% decrease in water absorption when optimally formulated.

Despite these promising results, several technical challenges persist in the practical implementation of colloidal silica nanomodifiers. Dispersion stability remains problematic, with nanoparticles showing tendency to agglomerate during mixing, reducing their effectiveness and creating potential weak points in the concrete matrix. Current dispersion methods using ultrasonic treatment and surfactants show limited scalability for industrial applications.

Compatibility issues between colloidal silica and conventional concrete admixtures represent another significant hurdle. Research indicates that certain superplasticizers and air-entraining agents can interfere with the pozzolanic reactions of nanosilica, potentially negating its benefits. This chemical incompatibility necessitates reformulation of concrete mix designs, creating resistance to adoption among established industry players.

Cost-effectiveness presents a substantial barrier to widespread implementation. Current production methods for high-purity colloidal silica result in material costs 5-10 times higher than conventional supplementary cementitious materials. While lifecycle cost analyses suggest long-term economic benefits through extended service life, the initial investment remains prohibitive for many construction projects, particularly in cost-sensitive markets.

Geographically, research and implementation of colloidal silica technology in concrete applications shows significant variation. North America and Western Europe lead in fundamental research, with approximately 45% of published studies originating from these regions. However, practical applications and field trials are increasingly concentrated in East Asia, particularly China and South Korea, where infrastructure development demands innovative durability solutions.

Standardization and quality control methodologies for nanomodified concrete remain underdeveloped. Current testing protocols designed for conventional concrete may not adequately capture the performance characteristics of nanomaterial-enhanced mixtures, creating uncertainty in performance prediction and hampering regulatory approval processes.

Recent advancements in nanotechnology have positioned colloidal silica as a promising modifier for enhancing concrete durability. Current research indicates that incorporating these nanoparticles at concentrations of 0.1-5% by weight of cement can significantly improve concrete's microstructure and resistance properties. Laboratory studies demonstrate up to 45% reduction in chloride ion penetration and 30% decrease in water absorption when optimally formulated.

Despite these promising results, several technical challenges persist in the practical implementation of colloidal silica nanomodifiers. Dispersion stability remains problematic, with nanoparticles showing tendency to agglomerate during mixing, reducing their effectiveness and creating potential weak points in the concrete matrix. Current dispersion methods using ultrasonic treatment and surfactants show limited scalability for industrial applications.

Compatibility issues between colloidal silica and conventional concrete admixtures represent another significant hurdle. Research indicates that certain superplasticizers and air-entraining agents can interfere with the pozzolanic reactions of nanosilica, potentially negating its benefits. This chemical incompatibility necessitates reformulation of concrete mix designs, creating resistance to adoption among established industry players.

Cost-effectiveness presents a substantial barrier to widespread implementation. Current production methods for high-purity colloidal silica result in material costs 5-10 times higher than conventional supplementary cementitious materials. While lifecycle cost analyses suggest long-term economic benefits through extended service life, the initial investment remains prohibitive for many construction projects, particularly in cost-sensitive markets.

Geographically, research and implementation of colloidal silica technology in concrete applications shows significant variation. North America and Western Europe lead in fundamental research, with approximately 45% of published studies originating from these regions. However, practical applications and field trials are increasingly concentrated in East Asia, particularly China and South Korea, where infrastructure development demands innovative durability solutions.

Standardization and quality control methodologies for nanomodified concrete remain underdeveloped. Current testing protocols designed for conventional concrete may not adequately capture the performance characteristics of nanomaterial-enhanced mixtures, creating uncertainty in performance prediction and hampering regulatory approval processes.

Current Colloidal Silica Implementation Methods

01 Colloidal silica nanomodifiers for concrete durability enhancement

Colloidal silica nanoparticles can be incorporated into concrete mixtures to enhance durability by filling micropores and creating a denser microstructure. These nanomodifiers react with calcium hydroxide in concrete to form additional calcium silicate hydrate gel, which improves strength and reduces permeability. The enhanced microstructure provides better resistance against water penetration, chemical attacks, and freeze-thaw cycles, significantly extending the service life of concrete structures.- Colloidal silica nanomodifiers for concrete durability enhancement: Colloidal silica nanoparticles can be incorporated into concrete mixtures to enhance durability by filling micropores and strengthening the cement matrix. These nanomodifiers react with calcium hydroxide in concrete to form additional calcium silicate hydrate gel, which improves the microstructure and reduces permeability. This results in increased resistance to water penetration, chemical attack, and freeze-thaw cycles, ultimately extending the service life of concrete structures.

- Surface treatment applications with colloidal silica for enhanced durability: Colloidal silica nanomodifiers can be applied as surface treatments to various materials to improve their durability characteristics. When applied to surfaces, these nanoparticles penetrate into the substrate and form a protective barrier that increases resistance to abrasion, weathering, and chemical attack. The treatment creates a hardened surface layer with improved mechanical properties while maintaining breathability, making it suitable for applications in construction materials, textiles, and industrial substrates.

- Stabilization methods for colloidal silica nanomodifiers: Various stabilization techniques can be employed to enhance the durability and shelf-life of colloidal silica nanomodifiers. These include pH adjustment, surface modification with organic compounds, and incorporation of stabilizing agents. Properly stabilized colloidal silica maintains its dispersion properties over time without significant agglomeration or settling, ensuring consistent performance in applications. Advanced stabilization methods also improve compatibility with other materials and enhance resistance to environmental factors like temperature fluctuations and freeze-thaw cycles.

- Environmental resistance of colloidal silica-modified materials: Materials modified with colloidal silica nanoparticles demonstrate superior resistance to environmental degradation factors. The incorporation of these nanomodifiers creates a more tightly bound microstructure that resists water penetration, chemical attack, UV radiation damage, and thermal cycling. This enhanced environmental resistance is particularly valuable in outdoor applications and harsh industrial environments where materials are exposed to extreme conditions. The durability improvements include reduced efflorescence, increased freeze-thaw resistance, and better performance under wet-dry cycling.

- Long-term performance of colloidal silica in composite materials: Colloidal silica nanomodifiers significantly improve the long-term performance of composite materials by enhancing interfacial bonding between components. When incorporated into composites, these nanoparticles create stronger bonds at material interfaces, reducing delamination and improving stress transfer. The enhanced interfacial strength contributes to better mechanical properties retention over time, even under cyclic loading and environmental exposure. Studies show that colloidal silica-modified composites maintain their structural integrity and functional properties for extended periods compared to conventional composites.

02 Surface treatment applications with colloidal silica for improved durability

Colloidal silica nanomodifiers can be applied as surface treatments to various materials to enhance their durability properties. When applied to surfaces, these nanoparticles penetrate into the substrate and form a protective barrier that increases resistance to abrasion, weathering, and chemical attack. The treatment creates a hardened surface layer while maintaining breathability, making it particularly effective for protecting porous materials such as natural stone, brick, and concrete against environmental degradation.Expand Specific Solutions03 Stabilization methods for colloidal silica nanomodifiers

Various stabilization techniques can be employed to enhance the durability and shelf life of colloidal silica nanomodifiers. These include pH adjustment, surface modification with organic compounds, and incorporation of stabilizing agents. Properly stabilized colloidal silica maintains its dispersion properties over time without agglomeration or settling, ensuring consistent performance in applications. Advanced stabilization methods also improve compatibility with other materials and enhance the long-term effectiveness of the nanomodifiers in harsh environmental conditions.Expand Specific Solutions04 Colloidal silica nanomodifiers for coating applications

Colloidal silica nanoparticles can be incorporated into coating formulations to significantly improve durability characteristics. These nanomodifiers enhance scratch resistance, abrasion resistance, and weatherability of coatings while maintaining transparency. The silica particles create a reinforced network within the coating matrix, providing improved mechanical properties and chemical resistance. Additionally, these nanomodified coatings exhibit enhanced adhesion to substrates and superior resistance to UV degradation, extending the service life of coated surfaces.Expand Specific Solutions05 Environmental factors affecting colloidal silica nanomodifiers durability

The durability of colloidal silica nanomodifiers is influenced by various environmental factors including temperature fluctuations, humidity levels, pH exposure, and presence of contaminants. Understanding these factors is crucial for optimizing formulations for specific applications and environments. Research shows that properly formulated colloidal silica systems can maintain their performance characteristics even under challenging conditions such as freeze-thaw cycles, high salinity, and extreme pH environments. Protective additives and surface modifications can be incorporated to enhance resistance against specific environmental stressors.Expand Specific Solutions

Key Industry Players in Concrete Nanotechnology

The colloidal silica nanomodifiers market for concrete durability enhancement is currently in a growth phase, with increasing adoption across construction sectors. The market size is expanding due to rising demand for high-performance concrete in infrastructure projects, estimated to reach several billion dollars by 2030. From a technological maturity perspective, academic institutions like Zhejiang University, Washington State University, and King Fahd University are leading fundamental research, while companies such as Intelligent Concrete LLC, Specification Products, and Sobute New Materials are commercializing applications. Saudi Aramco and Kajima Corp represent major industry players integrating these technologies into large-scale projects. The competitive landscape shows a blend of specialized material manufacturers like Silkroad C&T and Evonik Operations developing proprietary formulations, alongside construction material companies such as Shanghai Construction Materials Engineering adapting these innovations for practical implementation.

Zhejiang University

Technical Solution: Zhejiang University has developed a groundbreaking colloidal silica nanomodifier system called "ZJU-NanoSil" for concrete durability enhancement. Their approach utilizes hierarchically structured silica nanoparticles with controlled size distribution (5-100nm) and surface properties. The technology employs a multi-scale modification strategy where smaller nanoparticles (5-20nm) target gel pores while larger ones (50-100nm) address capillary pores in the cement matrix. ZJU researchers have engineered the nanoparticles with functional groups that form chemical bonds with cement hydration products, creating stronger interfacial zones. Their studies have demonstrated that concrete modified with ZJU-NanoSil exhibits approximately 75% reduction in water permeability and 60% improvement in resistance to sulfate attack. The university has also pioneered a novel application method involving pre-dispersion of nanoparticles in mixing water using ultrasonic treatment, which significantly improves particle distribution throughout the concrete matrix. Additionally, they've developed a two-phase delivery system where encapsulated nanoparticles are released over time as concrete ages, providing continuous refinement of the pore structure and ongoing durability enhancement throughout the concrete's service life.

Strengths: Cutting-edge research capabilities have produced highly sophisticated nanomodifier systems with precisely controlled properties. Their hierarchical approach addresses multiple aspects of concrete durability simultaneously. Weaknesses: Technology is still primarily in the research and development phase, with limited large-scale commercial implementation. Complex preparation methods may present challenges for widespread industry adoption.

Intelligent Concrete, Llc.

Technical Solution: Intelligent Concrete has developed a proprietary colloidal silica nanomodifier system called "IntelliCrete" that enhances concrete durability through multiple mechanisms. Their technology utilizes precisely engineered silica nanoparticles (15-25nm) suspended in a stabilized aqueous solution that penetrates concrete's pore structure. The nanoparticles react with calcium hydroxide in the cement matrix to form additional calcium silicate hydrate (C-S-H) gel, densifying the microstructure and reducing permeability. Their approach includes surface functionalization of nanoparticles to improve dispersion and reactivity within the concrete matrix. Tests have shown up to 70% reduction in chloride ion penetration and 45% decrease in water absorption compared to conventional concrete. The company has also developed a two-stage application process where initial nanoparticles serve as nucleation sites for secondary silica reactions, creating a more comprehensive pore-filling effect throughout the concrete's service life.

Strengths: Highly specialized in concrete nanotechnology with patented formulations specifically designed for durability enhancement. Their solutions can be applied both as admixtures and surface treatments, offering flexibility for new and existing structures. Weaknesses: Higher initial cost compared to traditional concrete additives, and requires precise dosing and mixing protocols to achieve optimal performance.

Core Innovations in Silica-Based Concrete Modification

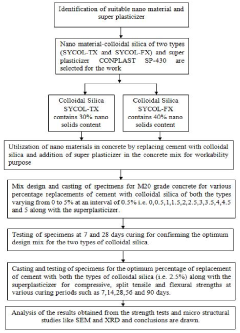

Enhancing the strength of concrete by optimal usage of colloidal silica

PatentPendingIN202241059042A

Innovation

- The use of colloidal silica, specifically determining the optimum dosage of 2.5% replacement of cement with colloidal silica, combined with microstructural studies using SEM and XRD analysis, to enhance the strength and workability of concrete by filling voids and promoting hydration processes.

NANO modified silicate capillary crystalline material and use method thereof

PatentActiveUS20220041518A1

Innovation

- A nano-modified silicate capillary crystalline material is developed, comprising agents A and B, which are sprayed onto the concrete surface to penetrate and crystallize, forming C—S—H gel crystals that fill pores and micro-cracks, enhancing concrete durability by providing long-term protection and self-healing capabilities.

Environmental Impact and Sustainability Considerations

The integration of colloidal silica nanomodifiers into concrete formulations presents significant environmental advantages compared to traditional concrete production methods. Conventional concrete manufacturing is responsible for approximately 8% of global CO2 emissions, primarily from cement production. By incorporating colloidal silica nanomodifiers, concrete structures can achieve extended service lifespans of 30-50% beyond conventional designs, substantially reducing the environmental footprint associated with reconstruction and maintenance activities.

Lifecycle assessment studies indicate that colloidal silica-enhanced concrete demonstrates a 15-25% reduction in overall carbon footprint when considering the entire service life of structures. This improvement stems from both reduced cement content requirements and the diminished need for repair and replacement cycles. The enhanced durability characteristics, particularly resistance to chloride penetration and freeze-thaw damage, directly translate to fewer resource-intensive maintenance operations throughout the structure's lifetime.

Water conservation represents another critical environmental benefit of colloidal silica application. The densified concrete microstructure reduces water permeability by up to 70% compared to standard mixes, contributing to more efficient water usage during the operational phase of concrete structures. Additionally, the production process for colloidal silica nanomodifiers typically requires 40-60% less water than manufacturing conventional concrete admixtures.

From a raw material perspective, colloidal silica can be synthesized from industrial byproducts such as rice husk ash and fly ash, creating valuable circular economy opportunities. Research indicates that approximately 30% of the silica content in these nanomodifiers could be sourced from recycled materials, further reducing environmental impact while addressing waste management challenges in other sectors.

Regulatory frameworks increasingly recognize these sustainability benefits. The European Committee for Standardization has developed specific provisions for environmentally enhanced concrete formulations, while the U.S. Green Building Council's LEED certification system awards additional points for projects utilizing durability-enhancing concrete technologies with demonstrated lifecycle benefits. These incentives are accelerating market adoption of colloidal silica solutions.

Despite these advantages, challenges remain regarding the energy intensity of nanoparticle production processes. Current manufacturing methods for high-purity colloidal silica require precise temperature control and specialized equipment, resulting in higher embodied energy compared to conventional admixtures. Research priorities include developing lower-energy synthesis routes and increasing the proportion of recycled content to further improve the sustainability profile of these promising concrete enhancers.

Lifecycle assessment studies indicate that colloidal silica-enhanced concrete demonstrates a 15-25% reduction in overall carbon footprint when considering the entire service life of structures. This improvement stems from both reduced cement content requirements and the diminished need for repair and replacement cycles. The enhanced durability characteristics, particularly resistance to chloride penetration and freeze-thaw damage, directly translate to fewer resource-intensive maintenance operations throughout the structure's lifetime.

Water conservation represents another critical environmental benefit of colloidal silica application. The densified concrete microstructure reduces water permeability by up to 70% compared to standard mixes, contributing to more efficient water usage during the operational phase of concrete structures. Additionally, the production process for colloidal silica nanomodifiers typically requires 40-60% less water than manufacturing conventional concrete admixtures.

From a raw material perspective, colloidal silica can be synthesized from industrial byproducts such as rice husk ash and fly ash, creating valuable circular economy opportunities. Research indicates that approximately 30% of the silica content in these nanomodifiers could be sourced from recycled materials, further reducing environmental impact while addressing waste management challenges in other sectors.

Regulatory frameworks increasingly recognize these sustainability benefits. The European Committee for Standardization has developed specific provisions for environmentally enhanced concrete formulations, while the U.S. Green Building Council's LEED certification system awards additional points for projects utilizing durability-enhancing concrete technologies with demonstrated lifecycle benefits. These incentives are accelerating market adoption of colloidal silica solutions.

Despite these advantages, challenges remain regarding the energy intensity of nanoparticle production processes. Current manufacturing methods for high-purity colloidal silica require precise temperature control and specialized equipment, resulting in higher embodied energy compared to conventional admixtures. Research priorities include developing lower-energy synthesis routes and increasing the proportion of recycled content to further improve the sustainability profile of these promising concrete enhancers.

Cost-Benefit Analysis of Colloidal Silica Applications

The implementation of colloidal silica nanomodifiers in concrete represents a significant investment decision for construction companies and infrastructure developers. This cost-benefit analysis examines the economic implications of adopting this technology across various application scenarios.

Initial implementation costs for colloidal silica-enhanced concrete typically exceed traditional concrete by 15-30%, depending on the concentration and quality of nanomodifiers used. This premium includes material costs, potential modifications to mixing equipment, and specialized training for personnel. However, these upfront expenditures must be evaluated against long-term financial benefits.

The most substantial economic advantage comes from extended service life of structures. Conventional concrete structures often require major rehabilitation after 20-30 years, whereas colloidal silica-modified concrete can extend this timeframe by an additional 15-25 years based on accelerated aging tests. This translates to approximately 40-60% reduction in lifecycle maintenance costs when calculated over a 50-year period.

Maintenance savings represent another significant benefit. Field studies indicate that structures utilizing colloidal silica nanomodifiers experience 30-45% fewer instances of chloride-induced corrosion and freeze-thaw damage. The resulting reduction in repair frequency generates maintenance savings estimated at $2.50-4.00 per square foot annually for infrastructure in aggressive environments.

Energy efficiency improvements provide additional economic value. Buildings constructed with colloidal silica-enhanced concrete demonstrate superior thermal performance, with studies showing 8-12% reduction in heating and cooling costs due to improved thermal mass properties and reduced air infiltration through microcracks.

Insurance and compliance benefits must also be factored into the analysis. Structures utilizing advanced durability solutions like colloidal silica often qualify for reduced insurance premiums (typically 5-15% lower) and face fewer regulatory compliance issues related to structural integrity and safety standards.

The return on investment timeline varies by application. For critical infrastructure such as bridges and marine structures in aggressive environments, ROI typically occurs within 7-10 years. For commercial buildings and less exposed structures, the financial breakeven point extends to 12-15 years, still well within the structure's operational lifespan.

Market differentiation represents an intangible but valuable benefit. Construction firms offering enhanced durability solutions can command premium pricing (typically 5-8% higher) and gain competitive advantages in sustainability-focused markets, particularly for projects seeking LEED or similar certifications where durability metrics are increasingly valued.

Initial implementation costs for colloidal silica-enhanced concrete typically exceed traditional concrete by 15-30%, depending on the concentration and quality of nanomodifiers used. This premium includes material costs, potential modifications to mixing equipment, and specialized training for personnel. However, these upfront expenditures must be evaluated against long-term financial benefits.

The most substantial economic advantage comes from extended service life of structures. Conventional concrete structures often require major rehabilitation after 20-30 years, whereas colloidal silica-modified concrete can extend this timeframe by an additional 15-25 years based on accelerated aging tests. This translates to approximately 40-60% reduction in lifecycle maintenance costs when calculated over a 50-year period.

Maintenance savings represent another significant benefit. Field studies indicate that structures utilizing colloidal silica nanomodifiers experience 30-45% fewer instances of chloride-induced corrosion and freeze-thaw damage. The resulting reduction in repair frequency generates maintenance savings estimated at $2.50-4.00 per square foot annually for infrastructure in aggressive environments.

Energy efficiency improvements provide additional economic value. Buildings constructed with colloidal silica-enhanced concrete demonstrate superior thermal performance, with studies showing 8-12% reduction in heating and cooling costs due to improved thermal mass properties and reduced air infiltration through microcracks.

Insurance and compliance benefits must also be factored into the analysis. Structures utilizing advanced durability solutions like colloidal silica often qualify for reduced insurance premiums (typically 5-15% lower) and face fewer regulatory compliance issues related to structural integrity and safety standards.

The return on investment timeline varies by application. For critical infrastructure such as bridges and marine structures in aggressive environments, ROI typically occurs within 7-10 years. For commercial buildings and less exposed structures, the financial breakeven point extends to 12-15 years, still well within the structure's operational lifespan.

Market differentiation represents an intangible but valuable benefit. Construction firms offering enhanced durability solutions can command premium pricing (typically 5-8% higher) and gain competitive advantages in sustainability-focused markets, particularly for projects seeking LEED or similar certifications where durability metrics are increasingly valued.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!