How to Tailor Colloidal Silica Properties for Optical Clarity in Films

SEP 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Colloidal Silica Technology Evolution and Objectives

Colloidal silica technology has evolved significantly over the past century, with its origins dating back to the early 1900s when scientists first began to understand and manipulate particles at the colloidal scale. The fundamental breakthrough came in the 1940s with the development of stable silica sols by researchers at DuPont and other institutions, establishing the foundation for modern colloidal silica applications.

The 1960s and 1970s witnessed substantial advancements in synthesis methods, particularly the Stöber process, which enabled precise control over particle size and morphology. This period marked the transition from basic scientific understanding to engineered applications, especially in industrial coatings and polishing compounds where optical properties were becoming increasingly important.

By the 1990s, colloidal silica technology had expanded into high-tech applications, including semiconductor manufacturing and optical films. The ability to produce monodisperse particles with controlled surface chemistry became crucial for achieving specific optical properties in thin films. This era also saw the development of modified silica particles with organic functional groups, expanding the range of possible applications.

The early 2000s brought nanotechnology approaches to colloidal silica, with researchers developing methods to create hierarchical structures and composite materials with enhanced optical clarity. The focus shifted toward understanding and controlling the interaction between colloidal silica particles and polymer matrices in films, which directly impacts light scattering and transmission properties.

Current technological objectives center on tailoring colloidal silica properties specifically for optical clarity in films through several approaches. These include precise control of particle size distribution to minimize Rayleigh scattering, surface modification to enhance compatibility with various polymer matrices, and development of core-shell architectures to manipulate refractive index matching.

Another key objective is the development of scalable, environmentally friendly synthesis methods that maintain precise control over particle characteristics while reducing energy consumption and hazardous waste. This aligns with broader industry trends toward sustainable manufacturing processes.

Looking forward, the field is moving toward smart colloidal silica systems with stimuli-responsive optical properties, enabling films that can dynamically adjust their transparency, anti-reflective properties, or light diffusion characteristics. Integration with other nanomaterials such as quantum dots or plasmonic nanoparticles represents another frontier, potentially enabling films with unprecedented optical functionality.

The ultimate technological goal remains the ability to design and synthesize colloidal silica particles with precisely tailored properties that can be predictably translated into specific optical behaviors when incorporated into films, allowing for application-specific optimization across industries ranging from electronics to architecture.

The 1960s and 1970s witnessed substantial advancements in synthesis methods, particularly the Stöber process, which enabled precise control over particle size and morphology. This period marked the transition from basic scientific understanding to engineered applications, especially in industrial coatings and polishing compounds where optical properties were becoming increasingly important.

By the 1990s, colloidal silica technology had expanded into high-tech applications, including semiconductor manufacturing and optical films. The ability to produce monodisperse particles with controlled surface chemistry became crucial for achieving specific optical properties in thin films. This era also saw the development of modified silica particles with organic functional groups, expanding the range of possible applications.

The early 2000s brought nanotechnology approaches to colloidal silica, with researchers developing methods to create hierarchical structures and composite materials with enhanced optical clarity. The focus shifted toward understanding and controlling the interaction between colloidal silica particles and polymer matrices in films, which directly impacts light scattering and transmission properties.

Current technological objectives center on tailoring colloidal silica properties specifically for optical clarity in films through several approaches. These include precise control of particle size distribution to minimize Rayleigh scattering, surface modification to enhance compatibility with various polymer matrices, and development of core-shell architectures to manipulate refractive index matching.

Another key objective is the development of scalable, environmentally friendly synthesis methods that maintain precise control over particle characteristics while reducing energy consumption and hazardous waste. This aligns with broader industry trends toward sustainable manufacturing processes.

Looking forward, the field is moving toward smart colloidal silica systems with stimuli-responsive optical properties, enabling films that can dynamically adjust their transparency, anti-reflective properties, or light diffusion characteristics. Integration with other nanomaterials such as quantum dots or plasmonic nanoparticles represents another frontier, potentially enabling films with unprecedented optical functionality.

The ultimate technological goal remains the ability to design and synthesize colloidal silica particles with precisely tailored properties that can be predictably translated into specific optical behaviors when incorporated into films, allowing for application-specific optimization across industries ranging from electronics to architecture.

Market Analysis for Optically Clear Film Applications

The global market for optically clear films has experienced significant growth in recent years, primarily driven by the expanding electronics industry and increasing demand for high-quality display technologies. The market value for optically clear films reached approximately $6.2 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 7.8% through 2028, potentially reaching $9.7 billion by the end of the forecast period.

The demand for colloidal silica-enhanced optically clear films is particularly strong in consumer electronics, where manufacturers seek materials that can deliver superior clarity, scratch resistance, and durability. Smartphones represent the largest application segment, accounting for roughly 38% of the total market share, followed by tablets and laptops at 24% and 19% respectively.

Automotive displays constitute a rapidly growing segment, with a projected CAGR of 9.3% through 2028, as advanced driver-assistance systems (ADAS) and infotainment systems become standard features in modern vehicles. The integration of colloidal silica in these applications helps address challenges related to glare reduction and durability under varying temperature conditions.

Regional analysis indicates that Asia-Pacific dominates the market with approximately 52% share, attributed to the concentration of electronics manufacturing in countries like China, South Korea, and Taiwan. North America and Europe follow with 24% and 19% market shares respectively, with growth primarily driven by automotive and medical device applications.

Customer requirements are increasingly focused on films that offer not only optical clarity but also additional functionalities such as anti-fingerprint properties, enhanced touch sensitivity, and improved impact resistance. This trend has created a premium segment within the market, where advanced colloidal silica formulations command price premiums of 15-25% over standard offerings.

The competitive landscape features both established chemical companies and specialized materials science firms. Key market players have been investing heavily in R&D to develop proprietary colloidal silica formulations that can deliver specific optical properties while maintaining compatibility with existing manufacturing processes.

Market challenges include price sensitivity in consumer electronics applications, where manufacturers face pressure to reduce component costs while maintaining performance. Additionally, environmental regulations regarding chemical processing and disposal are becoming more stringent, creating demand for more sustainable colloidal silica production methods and formulations.

The demand for colloidal silica-enhanced optically clear films is particularly strong in consumer electronics, where manufacturers seek materials that can deliver superior clarity, scratch resistance, and durability. Smartphones represent the largest application segment, accounting for roughly 38% of the total market share, followed by tablets and laptops at 24% and 19% respectively.

Automotive displays constitute a rapidly growing segment, with a projected CAGR of 9.3% through 2028, as advanced driver-assistance systems (ADAS) and infotainment systems become standard features in modern vehicles. The integration of colloidal silica in these applications helps address challenges related to glare reduction and durability under varying temperature conditions.

Regional analysis indicates that Asia-Pacific dominates the market with approximately 52% share, attributed to the concentration of electronics manufacturing in countries like China, South Korea, and Taiwan. North America and Europe follow with 24% and 19% market shares respectively, with growth primarily driven by automotive and medical device applications.

Customer requirements are increasingly focused on films that offer not only optical clarity but also additional functionalities such as anti-fingerprint properties, enhanced touch sensitivity, and improved impact resistance. This trend has created a premium segment within the market, where advanced colloidal silica formulations command price premiums of 15-25% over standard offerings.

The competitive landscape features both established chemical companies and specialized materials science firms. Key market players have been investing heavily in R&D to develop proprietary colloidal silica formulations that can deliver specific optical properties while maintaining compatibility with existing manufacturing processes.

Market challenges include price sensitivity in consumer electronics applications, where manufacturers face pressure to reduce component costs while maintaining performance. Additionally, environmental regulations regarding chemical processing and disposal are becoming more stringent, creating demand for more sustainable colloidal silica production methods and formulations.

Current Challenges in Colloidal Silica Synthesis

Despite significant advancements in colloidal silica synthesis, several persistent challenges continue to impede the development of optically clear films. The primary obstacle remains achieving precise control over particle size distribution. Current synthesis methods often produce particles with varying diameters, leading to light scattering and reduced transparency in the resulting films. Even minor variations in particle size can significantly impact optical clarity, particularly when targeting applications requiring high transparency in the visible light spectrum.

Surface modification of silica particles presents another substantial challenge. The hydroxyl groups naturally present on silica surfaces tend to form hydrogen bonds, causing particle aggregation during film formation. While various silane coupling agents can modify these surfaces, achieving uniform and complete surface coverage without introducing new optical defects remains difficult. The balance between hydrophobicity and hydrophilicity critically affects film formation properties but is challenging to optimize consistently.

Colloidal stability during the transition from sol to film represents a significant hurdle. As solvents evaporate during film formation, the increasing concentration of particles often leads to uncontrolled aggregation, creating optical inhomogeneities. Current stabilization methods using electrostatic or steric mechanisms frequently fail to maintain particle dispersion throughout the entire drying process, particularly at the final stages when interparticle distances decrease dramatically.

The scalability of laboratory synthesis methods to industrial production introduces additional complications. Batch-to-batch variations in particle characteristics become more pronounced at larger scales, affecting optical quality consistency. Reactor design, mixing efficiency, and temperature control all become more challenging to manage precisely in industrial settings, leading to compromises in optical clarity.

Environmental and regulatory constraints further complicate synthesis approaches. Traditional methods often rely on hazardous chemicals like ammonia or organic solvents that face increasing restrictions. Alternative green synthesis routes typically yield particles with less controlled properties, creating a difficult trade-off between environmental sustainability and optical performance.

Integration challenges with matrix materials constitute another significant barrier. When incorporating silica particles into polymer matrices for film applications, incompatibilities between the inorganic silica and organic polymers frequently lead to phase separation or interfacial defects that scatter light. Current compatibilization strategies often introduce their own optical issues or compromise other film properties like mechanical strength or adhesion.

The characterization of silica particles and their distribution within films also presents methodological limitations. Existing analytical techniques struggle to provide comprehensive, real-time information about particle behavior during film formation, making process optimization largely empirical rather than systematically driven by fundamental understanding.

Surface modification of silica particles presents another substantial challenge. The hydroxyl groups naturally present on silica surfaces tend to form hydrogen bonds, causing particle aggregation during film formation. While various silane coupling agents can modify these surfaces, achieving uniform and complete surface coverage without introducing new optical defects remains difficult. The balance between hydrophobicity and hydrophilicity critically affects film formation properties but is challenging to optimize consistently.

Colloidal stability during the transition from sol to film represents a significant hurdle. As solvents evaporate during film formation, the increasing concentration of particles often leads to uncontrolled aggregation, creating optical inhomogeneities. Current stabilization methods using electrostatic or steric mechanisms frequently fail to maintain particle dispersion throughout the entire drying process, particularly at the final stages when interparticle distances decrease dramatically.

The scalability of laboratory synthesis methods to industrial production introduces additional complications. Batch-to-batch variations in particle characteristics become more pronounced at larger scales, affecting optical quality consistency. Reactor design, mixing efficiency, and temperature control all become more challenging to manage precisely in industrial settings, leading to compromises in optical clarity.

Environmental and regulatory constraints further complicate synthesis approaches. Traditional methods often rely on hazardous chemicals like ammonia or organic solvents that face increasing restrictions. Alternative green synthesis routes typically yield particles with less controlled properties, creating a difficult trade-off between environmental sustainability and optical performance.

Integration challenges with matrix materials constitute another significant barrier. When incorporating silica particles into polymer matrices for film applications, incompatibilities between the inorganic silica and organic polymers frequently lead to phase separation or interfacial defects that scatter light. Current compatibilization strategies often introduce their own optical issues or compromise other film properties like mechanical strength or adhesion.

The characterization of silica particles and their distribution within films also presents methodological limitations. Existing analytical techniques struggle to provide comprehensive, real-time information about particle behavior during film formation, making process optimization largely empirical rather than systematically driven by fundamental understanding.

Existing Methods for Enhancing Optical Clarity

01 Colloidal silica formulations for optical clarity enhancement

Specific formulations of colloidal silica can be used to enhance optical clarity in various applications. These formulations typically involve controlling the particle size, concentration, and dispersion stability of the silica particles. By optimizing these parameters, the light scattering properties can be minimized, resulting in improved transparency and optical clarity in the final product.- Colloidal silica composition for optical clarity: Colloidal silica compositions are formulated with specific particle sizes and distributions to enhance optical clarity in various applications. These formulations typically contain silica particles in the nanometer range, which minimize light scattering and improve transparency. The stability of these colloidal dispersions is critical for maintaining optical clarity over time, often achieved through pH control and surface modification of the silica particles.

- Surface treatment of colloidal silica for improved clarity: Surface modification of colloidal silica particles can significantly enhance optical clarity. Treatments include functionalization with organic groups, silane coupling agents, or polymer coatings that prevent aggregation and improve dispersion stability. These surface treatments reduce light scattering by maintaining proper particle separation and compatibility with the surrounding medium, resulting in higher transparency in the final application.

- Colloidal silica in transparent films and coatings: Colloidal silica is incorporated into films and coatings to enhance optical clarity while providing additional functional properties such as scratch resistance, UV protection, and anti-reflective characteristics. The silica particles are typically dispersed in polymer matrices at controlled concentrations to maintain transparency. Processing techniques such as controlled drying and curing are essential to prevent haze formation and ensure uniform distribution of silica particles throughout the coating.

- Size-controlled colloidal silica for transparency applications: The size and size distribution of colloidal silica particles are critical factors affecting optical clarity. Precisely controlled synthesis methods produce uniform particles with dimensions significantly smaller than the wavelength of visible light, minimizing light scattering. Monodisperse colloidal silica systems with particles typically in the 5-50 nm range offer superior optical clarity compared to polydisperse systems, as they provide more predictable optical properties and better transparency.

- Stabilization methods for optically clear colloidal silica dispersions: Various stabilization techniques are employed to maintain the optical clarity of colloidal silica dispersions over time. These include electrostatic stabilization through pH adjustment, steric stabilization using polymeric additives, and electrosteric stabilization combining both approaches. Additives such as surfactants, polyelectrolytes, and organic solvents help prevent aggregation and sedimentation that would otherwise compromise optical clarity. Proper stabilization ensures long-term transparency and consistent performance in applications requiring high optical clarity.

02 Surface modification of colloidal silica for clarity improvement

Surface modification techniques can be applied to colloidal silica particles to improve their optical clarity. This involves treating the silica surface with various functional groups or coating agents that prevent aggregation and improve compatibility with the surrounding medium. Modified colloidal silica demonstrates reduced light scattering, enhanced transparency, and better stability in different environments.Expand Specific Solutions03 Colloidal silica in transparent films and coatings

Colloidal silica is incorporated into films and coatings to create optically clear materials with enhanced properties. The silica particles provide mechanical strength and durability while maintaining transparency when properly dispersed. These films and coatings find applications in electronics, displays, optical devices, and protective layers where both clarity and performance are essential.Expand Specific Solutions04 Size-controlled colloidal silica for optical applications

The particle size of colloidal silica significantly impacts optical clarity. Precisely controlled nano-sized silica particles below certain critical dimensions minimize light scattering according to Rayleigh scattering principles. Manufacturing processes that produce uniform, monodisperse colloidal silica with controlled size distribution are essential for applications requiring high optical clarity such as optical coatings, display technologies, and transparent composites.Expand Specific Solutions05 Stabilization methods for optically clear colloidal silica dispersions

Various stabilization methods are employed to maintain the optical clarity of colloidal silica dispersions over time. These include pH adjustment, addition of stabilizing agents, surface charge modification, and prevention of gelation or aggregation. Stable colloidal silica dispersions retain their optical clarity during storage and application, which is crucial for consistent performance in optical materials, coatings, and other transparency-dependent applications.Expand Specific Solutions

Industry Leaders in Colloidal Silica Production

The colloidal silica market for optical film applications is in a growth phase, with increasing demand driven by expanding display technologies and optical coatings industries. Market size is projected to grow significantly as consumer electronics and advanced optical applications proliferate. Technologically, the field is moderately mature but continues to evolve, with leading companies developing proprietary solutions. FUJIFILM, JSR, and Nissan Chemical lead with advanced particle size control technologies, while Momentive and W.R. Grace focus on surface modification approaches. Asahi Kasei and Mitsubishi Kasei contribute innovations in silica dispersion stability, while academic institutions like South China University of Technology and Southeast University advance fundamental research in colloidal behavior for next-generation optical applications.

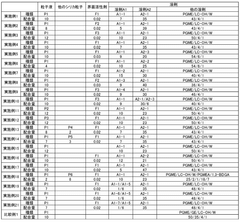

FUJIFILM Corp.

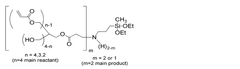

Technical Solution: FUJIFILM has developed advanced colloidal silica technologies specifically tailored for optical film applications. Their approach involves precise control of particle size distribution in the 10-20nm range, which minimizes light scattering while maintaining mechanical strength. The company employs a proprietary surface modification technique that functionalizes silica nanoparticles with organosilane compounds, creating stable dispersions in various organic solvents used in film formation processes. This surface treatment prevents particle aggregation during film drying, resulting in highly transparent films with refractive indices that can be fine-tuned between 1.38-1.50 depending on application requirements. FUJIFILM's process also incorporates controlled hydrolysis and condensation reactions to produce monodisperse silica particles with narrow size distributions, essential for maintaining optical clarity in thin films used in display technologies and optical components.

Strengths: Superior particle size control resulting in excellent optical clarity; proprietary surface modification technology enabling stable dispersions in various solvents; ability to fine-tune refractive indices for specific applications. Weaknesses: Higher production costs compared to conventional silica; complex manufacturing process requiring specialized equipment; potential challenges in scaling production for high-volume applications.

Nissan Chemical Corp.

Technical Solution: Nissan Chemical has pioneered the development of specialized colloidal silica products under their SNOWTEX® brand specifically engineered for optical film applications. Their technology focuses on controlling silica particle morphology through a unique sol-gel process that produces uniform spherical particles with diameters precisely controlled between 10-150nm. The company has developed proprietary stabilization methods using both steric and electrostatic mechanisms to prevent aggregation in various solvent systems. Their most advanced products feature core-shell architectures where silica particles are encapsulated with organic polymers that enhance compatibility with film matrices while maintaining transparency. Nissan Chemical's process includes post-synthesis surface modification with functional silanes containing epoxy, amino, or methacrylate groups that can form covalent bonds with the polymer matrix, improving adhesion and mechanical properties without compromising optical clarity. Their colloidal silica dispersions achieve transmittance values exceeding 99% in the visible spectrum for films under 100μm thickness.

Strengths: Exceptional particle uniformity leading to superior optical clarity; versatile surface modification options for compatibility with various polymer systems; established manufacturing infrastructure allowing consistent quality at commercial scale. Weaknesses: Higher cost compared to conventional silica fillers; some formulations have limited shelf stability in certain environmental conditions; potential for yellowing in UV-exposed applications over extended periods.

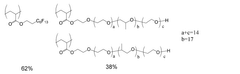

Key Patents in Colloidal Silica Modification

Composition and membrane manufacturing method

PatentWO2020116300A1

Innovation

- A composition comprising colloidal silica particles and a solvent with specific properties, including a solvent with a boiling point between 190°C and 280°C and a viscosity of 4 mPa·s or less, which suppresses particle aggregation and enhances film formation, resulting in a low refractive index film with improved porosity and surface quality.

Composition, method for producing film, and method for producing photosensor

PatentWO2019017280A1

Innovation

- A composition comprising colloidal silica particles with specific size and shape characteristics, combined with solvents having high boiling points and solubility parameters, is used to prevent aggregation and enhance film uniformity, comprising colloidal silica particles with average diameters between 25 nm and 1000 nm, connected in planar or beaded shapes, and solvents like polyethylene glycol monomethyl ether, which suppress aggregation and improve film porosity.

Environmental Impact Assessment of Silica Production

The production of colloidal silica for optical film applications carries significant environmental implications that warrant comprehensive assessment. Traditional silica manufacturing processes, particularly those utilizing chemical precipitation methods, consume substantial energy and generate considerable greenhouse gas emissions. The energy-intensive nature of high-temperature processes required for silica synthesis contributes approximately 0.8-1.2 tons of CO2 equivalent per ton of silica produced, positioning it as a moderate carbon footprint material within specialty chemicals.

Water usage represents another critical environmental concern, with conventional silica production methods requiring 15-20 cubic meters of water per ton of product. This consumption becomes particularly problematic in water-stressed regions where manufacturing facilities operate. Additionally, the acidification potential from sulfur dioxide and nitrogen oxide emissions during thermal processing stages presents localized environmental challenges that must be mitigated through appropriate control technologies.

Waste management issues arise primarily from the generation of byproducts during silica purification. These include metal salts and unreacted precursors that require proper treatment before disposal. Advanced manufacturing techniques for optical-grade colloidal silica have demonstrated potential for reducing waste generation by 30-40% compared to conventional methods, though implementation costs remain a barrier to widespread adoption.

Recent life cycle assessments reveal that sol-gel processing routes for specialized colloidal silica production offer reduced environmental impacts compared to thermal methods. These alternative approaches typically reduce energy consumption by 25-35% and decrease associated greenhouse gas emissions proportionally. However, they often introduce different environmental challenges through increased solvent usage and specialized chemical inputs.

Regulatory frameworks governing silica production vary significantly across regions, with the European Union implementing the most stringent environmental standards through REACH regulations and emissions trading schemes. Manufacturers seeking to optimize colloidal silica for optical clarity must navigate these regulatory landscapes while implementing best available techniques for pollution prevention and control.

Sustainable innovation pathways for environmentally responsible silica production include biomimetic synthesis routes, closed-loop water recycling systems, and renewable energy integration. These approaches collectively offer potential environmental impact reductions of 40-60% across key indicators, though they remain at various technology readiness levels. Industry leaders have begun implementing these measures, with several major producers committing to carbon neutrality targets for specialty silica production by 2030-2035.

Water usage represents another critical environmental concern, with conventional silica production methods requiring 15-20 cubic meters of water per ton of product. This consumption becomes particularly problematic in water-stressed regions where manufacturing facilities operate. Additionally, the acidification potential from sulfur dioxide and nitrogen oxide emissions during thermal processing stages presents localized environmental challenges that must be mitigated through appropriate control technologies.

Waste management issues arise primarily from the generation of byproducts during silica purification. These include metal salts and unreacted precursors that require proper treatment before disposal. Advanced manufacturing techniques for optical-grade colloidal silica have demonstrated potential for reducing waste generation by 30-40% compared to conventional methods, though implementation costs remain a barrier to widespread adoption.

Recent life cycle assessments reveal that sol-gel processing routes for specialized colloidal silica production offer reduced environmental impacts compared to thermal methods. These alternative approaches typically reduce energy consumption by 25-35% and decrease associated greenhouse gas emissions proportionally. However, they often introduce different environmental challenges through increased solvent usage and specialized chemical inputs.

Regulatory frameworks governing silica production vary significantly across regions, with the European Union implementing the most stringent environmental standards through REACH regulations and emissions trading schemes. Manufacturers seeking to optimize colloidal silica for optical clarity must navigate these regulatory landscapes while implementing best available techniques for pollution prevention and control.

Sustainable innovation pathways for environmentally responsible silica production include biomimetic synthesis routes, closed-loop water recycling systems, and renewable energy integration. These approaches collectively offer potential environmental impact reductions of 40-60% across key indicators, though they remain at various technology readiness levels. Industry leaders have begun implementing these measures, with several major producers committing to carbon neutrality targets for specialty silica production by 2030-2035.

Quality Control Standards for Optical Films

Establishing robust quality control standards is essential for ensuring consistent optical clarity in films utilizing colloidal silica. These standards must address multiple parameters that directly impact the optical performance of the final product. The primary metrics include haze value, light transmission rate, refractive index uniformity, and surface roughness measurements, all of which must be precisely controlled to achieve optimal optical clarity.

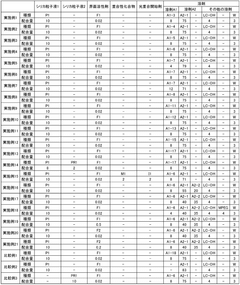

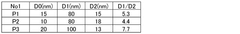

Particle size distribution represents a critical quality control parameter, as it significantly influences light scattering properties. Industry standards typically require that 90% of colloidal silica particles fall within ±5% of the target size range, with advanced applications demanding even tighter tolerances of ±2%. Regular monitoring using dynamic light scattering (DLS) or nanoparticle tracking analysis (NTA) should be implemented at multiple production stages.

Chemical purity standards must be rigorously maintained, with specifications typically allowing no more than 10 ppm of metallic impurities such as iron, sodium, and calcium, which can introduce color shifts or localized refractive index variations. Silica concentration consistency must be maintained within ±0.5% of target values to ensure uniform film formation and optical properties across production batches.

Film thickness uniformity represents another crucial quality parameter, with variations typically restricted to less than ±2% across the entire film surface. This requires precise application methods and environmental controls during the coating and drying processes. Automated optical inspection systems utilizing interferometry can provide real-time thickness mapping to identify deviations before downstream processing.

Surface defect analysis must be conducted using high-resolution imaging techniques, with standards typically specifying maximum allowable defect densities (e.g., <5 defects per cm² for particles >1μm). Additionally, accelerated aging tests should be performed to verify long-term optical stability, with standards requiring less than 2% change in optical properties after exposure to defined temperature, humidity, and UV radiation conditions for specified durations.

Statistical process control methodologies should be implemented throughout the production process, with control charts maintained for critical parameters and capability indices (Cpk) exceeding 1.33 for key optical characteristics. Regular calibration of measurement equipment against certified reference materials ensures the reliability of quality data, with traceability to international standards such as those from NIST or equivalent organizations.

Particle size distribution represents a critical quality control parameter, as it significantly influences light scattering properties. Industry standards typically require that 90% of colloidal silica particles fall within ±5% of the target size range, with advanced applications demanding even tighter tolerances of ±2%. Regular monitoring using dynamic light scattering (DLS) or nanoparticle tracking analysis (NTA) should be implemented at multiple production stages.

Chemical purity standards must be rigorously maintained, with specifications typically allowing no more than 10 ppm of metallic impurities such as iron, sodium, and calcium, which can introduce color shifts or localized refractive index variations. Silica concentration consistency must be maintained within ±0.5% of target values to ensure uniform film formation and optical properties across production batches.

Film thickness uniformity represents another crucial quality parameter, with variations typically restricted to less than ±2% across the entire film surface. This requires precise application methods and environmental controls during the coating and drying processes. Automated optical inspection systems utilizing interferometry can provide real-time thickness mapping to identify deviations before downstream processing.

Surface defect analysis must be conducted using high-resolution imaging techniques, with standards typically specifying maximum allowable defect densities (e.g., <5 defects per cm² for particles >1μm). Additionally, accelerated aging tests should be performed to verify long-term optical stability, with standards requiring less than 2% change in optical properties after exposure to defined temperature, humidity, and UV radiation conditions for specified durations.

Statistical process control methodologies should be implemented throughout the production process, with control charts maintained for critical parameters and capability indices (Cpk) exceeding 1.33 for key optical characteristics. Regular calibration of measurement equipment against certified reference materials ensures the reliability of quality data, with traceability to international standards such as those from NIST or equivalent organizations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!