Benchmarking Conformal Coating Performance in Aerospace Applications

SEP 17, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Aerospace Conformal Coating Evolution and Objectives

Conformal coating technology in aerospace applications has evolved significantly over the past seven decades, beginning with rudimentary protective materials in the 1950s. Initially, these coatings served basic moisture protection functions for military electronics. The 1960s and 1970s witnessed substantial advancements with the introduction of silicone and acrylic-based formulations, coinciding with the rapid development of aerospace technology during the Space Race era.

The 1980s and 1990s marked a transition toward environmentally conscious solutions, as regulations began restricting volatile organic compounds (VOCs) and ozone-depleting substances. This regulatory shift catalyzed research into water-based and UV-curable alternatives, fundamentally changing the industry's technological trajectory. By the early 2000s, nano-enhanced coatings emerged, offering superior protection against extreme temperature fluctuations, radiation exposure, and chemical contaminants.

Current technological trends focus on multi-functional coatings that provide not only traditional protection but also enhanced properties such as self-healing capabilities, thermal management, and electromagnetic interference (EMI) shielding. The miniaturization of aerospace electronics has simultaneously driven demand for thinner, more precise coating applications that maintain protection without compromising component performance or adding excessive weight.

The primary objective of modern aerospace conformal coating benchmarking is to establish standardized performance metrics that accurately predict coating behavior under the extreme conditions encountered in aerospace environments. These include thermal cycling from -65°C to +150°C, vacuum exposure, radiation resistance, and vibration tolerance. Secondary objectives include quantifying coating longevity through accelerated aging protocols and establishing correlations between laboratory testing and real-world performance.

Additional benchmarking goals involve evaluating coating compatibility with next-generation substrate materials, including advanced composites and flexible electronics. The industry also seeks to develop testing methodologies that can accurately assess coating performance for emerging aerospace applications, such as small satellites, unmanned aerial vehicles, and hypersonic platforms, where traditional testing standards may prove inadequate.

The ultimate technological aim is to develop conformal coating solutions that maintain integrity throughout the entire lifecycle of aerospace systems—often spanning decades—while accommodating increasingly demanding operational parameters and environmental regulations. This requires not only advances in coating chemistry but also in application techniques, inspection methodologies, and performance prediction models.

The 1980s and 1990s marked a transition toward environmentally conscious solutions, as regulations began restricting volatile organic compounds (VOCs) and ozone-depleting substances. This regulatory shift catalyzed research into water-based and UV-curable alternatives, fundamentally changing the industry's technological trajectory. By the early 2000s, nano-enhanced coatings emerged, offering superior protection against extreme temperature fluctuations, radiation exposure, and chemical contaminants.

Current technological trends focus on multi-functional coatings that provide not only traditional protection but also enhanced properties such as self-healing capabilities, thermal management, and electromagnetic interference (EMI) shielding. The miniaturization of aerospace electronics has simultaneously driven demand for thinner, more precise coating applications that maintain protection without compromising component performance or adding excessive weight.

The primary objective of modern aerospace conformal coating benchmarking is to establish standardized performance metrics that accurately predict coating behavior under the extreme conditions encountered in aerospace environments. These include thermal cycling from -65°C to +150°C, vacuum exposure, radiation resistance, and vibration tolerance. Secondary objectives include quantifying coating longevity through accelerated aging protocols and establishing correlations between laboratory testing and real-world performance.

Additional benchmarking goals involve evaluating coating compatibility with next-generation substrate materials, including advanced composites and flexible electronics. The industry also seeks to develop testing methodologies that can accurately assess coating performance for emerging aerospace applications, such as small satellites, unmanned aerial vehicles, and hypersonic platforms, where traditional testing standards may prove inadequate.

The ultimate technological aim is to develop conformal coating solutions that maintain integrity throughout the entire lifecycle of aerospace systems—often spanning decades—while accommodating increasingly demanding operational parameters and environmental regulations. This requires not only advances in coating chemistry but also in application techniques, inspection methodologies, and performance prediction models.

Market Requirements Analysis for Aerospace Protective Coatings

The aerospace industry demands exceptional protective coatings due to the extreme operational environments aircraft encounter. Market analysis reveals a growing demand for advanced conformal coatings, driven by the expansion of commercial aviation and increasing defense budgets globally. The global aerospace coatings market is currently valued at approximately 2.1 billion USD, with protective conformal coatings representing a significant growth segment expected to expand at a compound annual growth rate of 3.8% through 2028.

Primary market requirements for aerospace conformal coatings center on performance under extreme conditions. These coatings must withstand temperature fluctuations ranging from -65°C at high altitudes to over 150°C near engine components. Additionally, they must provide protection against moisture, salt spray, and chemical exposure while maintaining electrical insulation properties critical for avionics systems.

Regulatory compliance represents another significant market driver. Environmental regulations, particularly in Europe and North America, are pushing manufacturers toward water-based and low-VOC coating formulations. The aerospace industry's shift toward more environmentally sustainable practices has accelerated development of compliant coating technologies that maintain or exceed performance standards of traditional solvent-based systems.

Durability requirements continue to intensify as aircraft service lives extend. Airlines and military operators seek coatings that can maintain protection for 10+ years without significant degradation, reducing maintenance costs and aircraft downtime. This has spurred innovation in self-healing coating technologies and condition-monitoring capabilities integrated into coating systems.

Weight reduction remains a critical market requirement, with each kilogram saved translating to significant fuel savings over an aircraft's operational life. Modern conformal coating formulations must balance protective properties with minimal weight contribution, driving research into nanomaterial-enhanced coatings that offer superior protection at reduced application thicknesses.

Application efficiency has emerged as a key market consideration. Coating processes that reduce curing time, minimize overspray, and allow for precise application in complex geometries are increasingly valued. Automated application systems and coatings designed for robotic dispensing are gaining market share as manufacturers seek to improve consistency and reduce labor costs.

The military aerospace segment presents specialized requirements for coatings that provide electromagnetic interference (EMI) shielding, radar absorption properties, and resistance to chemical/biological agents. These specialized applications command premium pricing and represent high-growth niches within the broader aerospace coatings market.

Primary market requirements for aerospace conformal coatings center on performance under extreme conditions. These coatings must withstand temperature fluctuations ranging from -65°C at high altitudes to over 150°C near engine components. Additionally, they must provide protection against moisture, salt spray, and chemical exposure while maintaining electrical insulation properties critical for avionics systems.

Regulatory compliance represents another significant market driver. Environmental regulations, particularly in Europe and North America, are pushing manufacturers toward water-based and low-VOC coating formulations. The aerospace industry's shift toward more environmentally sustainable practices has accelerated development of compliant coating technologies that maintain or exceed performance standards of traditional solvent-based systems.

Durability requirements continue to intensify as aircraft service lives extend. Airlines and military operators seek coatings that can maintain protection for 10+ years without significant degradation, reducing maintenance costs and aircraft downtime. This has spurred innovation in self-healing coating technologies and condition-monitoring capabilities integrated into coating systems.

Weight reduction remains a critical market requirement, with each kilogram saved translating to significant fuel savings over an aircraft's operational life. Modern conformal coating formulations must balance protective properties with minimal weight contribution, driving research into nanomaterial-enhanced coatings that offer superior protection at reduced application thicknesses.

Application efficiency has emerged as a key market consideration. Coating processes that reduce curing time, minimize overspray, and allow for precise application in complex geometries are increasingly valued. Automated application systems and coatings designed for robotic dispensing are gaining market share as manufacturers seek to improve consistency and reduce labor costs.

The military aerospace segment presents specialized requirements for coatings that provide electromagnetic interference (EMI) shielding, radar absorption properties, and resistance to chemical/biological agents. These specialized applications command premium pricing and represent high-growth niches within the broader aerospace coatings market.

Global Conformal Coating Technology Assessment and Barriers

The global conformal coating market is experiencing significant growth, driven primarily by the aerospace and defense sectors where electronic components require superior protection against harsh environmental conditions. Current market analysis indicates a compound annual growth rate of approximately 5.8% from 2021 to 2026, with the market value projected to reach $15.2 billion by 2026. Aerospace applications represent nearly 30% of this market, highlighting the critical importance of conformal coating technologies in this sector.

Geographically, North America dominates the conformal coating market with approximately 35% market share, followed by Europe and Asia-Pacific regions. This distribution reflects the concentration of aerospace manufacturing facilities and defense contractors in these regions. However, emerging economies in Asia, particularly China and India, are showing accelerated growth rates as their aerospace industries expand.

Despite technological advancements, several significant barriers impede the optimal implementation of conformal coating technologies in aerospace applications. Material limitations represent a primary challenge, as existing coating formulations struggle to simultaneously provide excellent protection against multiple environmental stressors while maintaining flexibility, adhesion, and thermal stability across extreme temperature ranges (-65°C to +200°C) encountered in aerospace environments.

Regulatory constraints pose another substantial barrier. The aerospace industry faces increasingly stringent environmental regulations regarding volatile organic compounds (VOCs) and hazardous air pollutants. Traditional solvent-based conformal coatings are being phased out, necessitating the development of environmentally friendly alternatives that maintain or exceed performance specifications.

Application precision challenges persist across the industry. The miniaturization of aerospace electronics has created difficulties in achieving uniform coating thickness and complete coverage without compromising sensitive components. Current automated application systems struggle with complex three-dimensional circuit boards featuring high component density.

Quality control and testing standardization remain inconsistent globally. While standards such as IPC-CC-830, MIL-I-46058C, and UL 746E exist, there is limited harmonization between different regional requirements, creating compliance challenges for manufacturers operating in multiple markets.

Cost factors continue to impact widespread adoption of advanced coating technologies. High-performance conformal coatings suitable for extreme aerospace environments typically command premium prices, with some specialized formulations costing 3-5 times more than standard industrial alternatives. This cost differential creates adoption barriers, particularly for smaller aerospace suppliers and maintenance operations.

Geographically, North America dominates the conformal coating market with approximately 35% market share, followed by Europe and Asia-Pacific regions. This distribution reflects the concentration of aerospace manufacturing facilities and defense contractors in these regions. However, emerging economies in Asia, particularly China and India, are showing accelerated growth rates as their aerospace industries expand.

Despite technological advancements, several significant barriers impede the optimal implementation of conformal coating technologies in aerospace applications. Material limitations represent a primary challenge, as existing coating formulations struggle to simultaneously provide excellent protection against multiple environmental stressors while maintaining flexibility, adhesion, and thermal stability across extreme temperature ranges (-65°C to +200°C) encountered in aerospace environments.

Regulatory constraints pose another substantial barrier. The aerospace industry faces increasingly stringent environmental regulations regarding volatile organic compounds (VOCs) and hazardous air pollutants. Traditional solvent-based conformal coatings are being phased out, necessitating the development of environmentally friendly alternatives that maintain or exceed performance specifications.

Application precision challenges persist across the industry. The miniaturization of aerospace electronics has created difficulties in achieving uniform coating thickness and complete coverage without compromising sensitive components. Current automated application systems struggle with complex three-dimensional circuit boards featuring high component density.

Quality control and testing standardization remain inconsistent globally. While standards such as IPC-CC-830, MIL-I-46058C, and UL 746E exist, there is limited harmonization between different regional requirements, creating compliance challenges for manufacturers operating in multiple markets.

Cost factors continue to impact widespread adoption of advanced coating technologies. High-performance conformal coatings suitable for extreme aerospace environments typically command premium prices, with some specialized formulations costing 3-5 times more than standard industrial alternatives. This cost differential creates adoption barriers, particularly for smaller aerospace suppliers and maintenance operations.

Current Benchmarking Methodologies for Conformal Coatings

01 Protective properties of conformal coatings

Conformal coatings provide protection to electronic components against environmental factors such as moisture, dust, chemicals, and temperature fluctuations. These coatings form a protective barrier that enhances the reliability and longevity of electronic devices. The performance of conformal coatings is measured by their ability to maintain protection under various environmental conditions while preserving the functionality of the coated components.- Environmental protection and durability of conformal coatings: Conformal coatings can be formulated to provide protection against various environmental factors such as moisture, chemicals, and temperature fluctuations. These coatings create a protective barrier that enhances the durability and reliability of electronic components and circuit boards. Advanced formulations may include specific additives that improve resistance to humidity, salt spray, and thermal cycling, extending the operational life of coated devices in harsh environments.

- Application methods and coating uniformity: Various application techniques can be employed to achieve optimal conformal coating performance, including spray coating, dip coating, and automated selective coating. The method selected significantly impacts coating thickness uniformity and coverage of complex geometries. Proper application parameters and equipment settings are crucial for ensuring consistent coating performance across the substrate, particularly for high-density electronic assemblies with fine-pitch components and intricate topographies.

- Thermal management and heat dissipation properties: Conformal coatings can be engineered to provide effective thermal management by incorporating thermally conductive materials. These specialized formulations help dissipate heat from electronic components while maintaining electrical insulation properties. The thermal performance of conformal coatings is particularly important for high-power electronics and densely packed assemblies where heat buildup can compromise reliability and operational lifespan.

- Chemical composition and material selection: The performance of conformal coatings is heavily influenced by their chemical composition, which may include acrylics, silicones, polyurethanes, epoxies, or parylene. Each material offers distinct advantages in terms of moisture resistance, dielectric strength, flexibility, chemical resistance, and operating temperature range. Material selection should be based on specific application requirements, environmental conditions, and compatibility with the substrate and components being protected.

- Testing and qualification standards for conformal coatings: Rigorous testing protocols are essential for evaluating conformal coating performance, including adhesion testing, moisture resistance, dielectric strength, and thermal cycling. Industry standards such as IPC-CC-830, MIL-I-46058C, and UL 746E provide guidelines for testing and qualifying conformal coatings for various applications. These standardized tests ensure that coatings meet specific performance criteria and reliability requirements before implementation in critical electronic systems.

02 Application methods for conformal coatings

Various application methods are used to apply conformal coatings to electronic components, including spraying, dipping, brushing, and automated selective coating. Each method offers different advantages in terms of coverage, thickness control, and production efficiency. The application technique significantly impacts the coating's performance, with factors such as uniformity, thickness, and adhesion being critical to the coating's protective capabilities.Expand Specific Solutions03 Material composition and properties

The performance of conformal coatings is largely determined by their material composition. Common types include acrylic, silicone, polyurethane, epoxy, and parylene, each offering different properties such as flexibility, chemical resistance, dielectric strength, and thermal stability. Advanced formulations may incorporate additives to enhance specific properties like UV resistance, flame retardancy, or thermal conductivity, allowing for customization based on application requirements.Expand Specific Solutions04 Environmental and thermal performance

Conformal coatings must maintain their protective properties across a wide range of environmental conditions. High-performance coatings offer resistance to extreme temperatures, humidity, salt spray, and thermal cycling. The ability of a coating to maintain adhesion and flexibility during thermal expansion and contraction is crucial for long-term reliability, particularly in applications exposed to temperature fluctuations or harsh environments.Expand Specific Solutions05 Testing and qualification methods

Standardized testing methods are employed to evaluate conformal coating performance, including adhesion tests, moisture resistance tests, thermal cycling, and electrical property measurements. These tests help determine the coating's ability to protect electronic components under various conditions and ensure compliance with industry standards. Qualification processes may include accelerated aging tests to predict long-term performance and reliability in field applications.Expand Specific Solutions

Leading Manufacturers and Competitive Landscape Analysis

The conformal coating market in aerospace applications is currently in a mature growth phase, with increasing demand driven by stringent reliability requirements. The global market size is estimated to exceed $1 billion, growing at 5-7% annually due to expanding commercial and military aircraft production. Technologically, the field shows varying maturity levels across different coating types. Industry leaders Boeing and Airbus dominate as end-users, while specialized coating manufacturers like PPG Industries, PRC-DeSoto, and Sherwin-Williams lead in innovation. Chinese players including CNOOC Changzhou and aerospace institutions are rapidly advancing their capabilities, particularly in environmentally-friendly solutions. Academic-industry partnerships with institutions like Zhejiang University and Beihang University are accelerating technological development in high-performance, sustainable coating systems.

The Boeing Co.

Technical Solution: Boeing has developed advanced conformal coating systems specifically designed for aerospace applications, focusing on environmental protection and electrical insulation. Their proprietary coating technologies incorporate multi-layer protection schemes that combine silicone and acrylic-based formulations to achieve optimal performance across varying altitudes and temperature ranges (-65°C to +150°C). Boeing's approach includes automated spray application systems with precise thickness control (25-75 μm) and accelerated UV curing processes that reduce production time by up to 40% compared to traditional methods. Their coatings feature self-healing capabilities for minor scratches and incorporate nano-additives that enhance moisture resistance while maintaining flexibility during thermal cycling. Boeing has established comprehensive testing protocols that exceed industry standards (MIL-I-46058C and IPC-CC-830B) and utilize environmental stress screening to validate long-term performance under extreme aerospace conditions.

Strengths: Superior protection against moisture, salt fog, and thermal cycling; excellent adhesion to complex geometries; reduced production time through advanced application methods. Weaknesses: Higher initial cost compared to standard industrial coatings; requires specialized application equipment; some formulations have limited repairability in field conditions.

PPG Industries Ohio, Inc.

Technical Solution: PPG Industries has pioneered aerospace-specific conformal coating solutions through their AEROCRON™ and PERMACRON® product lines, specifically engineered for critical avionics and electronic components in commercial and military aircraft. Their technology utilizes electrodeposition techniques that ensure uniform coating thickness (15-25 μm) even on complex circuit geometries, achieving 100% coverage of edges and recessed areas that traditional spray methods often miss. PPG's formulations incorporate fluoropolymer modifications that provide exceptional chemical resistance while maintaining dielectric strength exceeding 1500V/mil across operating temperatures from -65°C to +200°C. Their coatings feature advanced hydrophobic properties with water contact angles >110° and extremely low moisture vapor transmission rates (<0.05 g/m²/day). PPG has developed accelerated testing protocols that simulate 20+ years of service life under combined stressors including UV exposure, salt fog, humidity cycling, and vibration, demonstrating less than 5% degradation in protective properties over the simulated lifetime.

Strengths: Exceptional edge coverage and penetration into tight spaces; superior chemical and moisture resistance; excellent adhesion to multiple substrate materials; proven long-term performance in extreme environments. Weaknesses: Requires specialized application equipment and training; higher initial investment compared to conventional coatings; some formulations have limited field repairability.

Critical Patents and Research in Aerospace Coating Performance

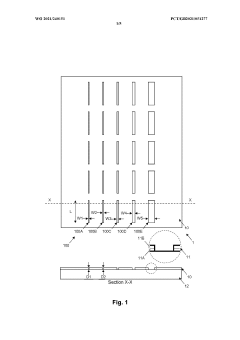

Method and specimen

PatentWO2021240151A1

Innovation

- A method and specimen design involving a substrate with a coating that includes a set of perforations of different dimensions, exposed to a corrosive environment, allowing for the quantitative evaluation of corrosion protection by determining corrosion within these perforations, specifically assessing pitting corrosion.

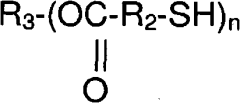

Multilayer coatings suitable for aerospace applications

PatentActiveCN101827660A

Innovation

- A polyene and polythiol composition is used as a primer, which is cured by radiation to form a continuous film, and a topcoat is applied on the aluminum substrate. A UV initiator is used to accelerate the curing process, and appropriate additives are combined to improve adhesion and resistance. corrosive.

Environmental Compliance and Sustainability Considerations

The aerospace industry faces increasing regulatory pressure to reduce environmental impacts while maintaining the highest safety and performance standards. Conformal coating materials traditionally used in aerospace applications often contain volatile organic compounds (VOCs), hazardous air pollutants (HAPs), and other chemicals of concern that are becoming subject to stricter global regulations. The European Union's REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) regulation and the RoHS (Restriction of Hazardous Substances) directive have significantly impacted material selection for aerospace manufacturers operating globally.

Recent benchmarking studies indicate a clear industry shift toward water-based and UV-curable conformal coating systems that offer reduced environmental footprints while maintaining critical performance parameters. These environmentally preferable alternatives have demonstrated up to 95% reduction in VOC emissions compared to traditional solvent-based systems, while still providing adequate protection against moisture, chemicals, and temperature extremes essential for aerospace applications.

Life cycle assessment (LCA) data from leading aerospace manufacturers reveals that environmental impacts extend beyond the application phase to include raw material extraction, manufacturing processes, and end-of-life considerations. Boeing and Airbus have both implemented comprehensive sustainability programs that include conformal coating material selection criteria based on full life cycle environmental performance metrics.

Waste management presents another critical environmental consideration, as many traditional conformal coating materials generate hazardous waste requiring specialized disposal procedures. Benchmarking data indicates that aerospace companies implementing solvent recovery systems and closed-loop application processes have reduced hazardous waste generation by up to 70% while simultaneously reducing material costs by 15-25%.

Energy consumption during curing processes represents a significant environmental impact factor that varies substantially between coating technologies. Thermal cure systems typically require higher energy inputs compared to UV-curable alternatives, with some next-generation UV systems demonstrating energy reductions of 40-60% in controlled benchmarking studies. These energy efficiencies translate directly to reduced carbon footprints for manufacturing operations.

Supply chain sustainability has emerged as an important benchmarking criterion, with aerospace OEMs increasingly requiring environmental performance data from coating suppliers. This includes documentation of sustainable sourcing practices, manufacturing energy efficiency, and chemical hazard reduction efforts. Leading suppliers now provide Environmental Product Declarations (EPDs) that quantify environmental impacts across multiple categories including global warming potential, ozone depletion, and resource depletion.

Future sustainability trends in aerospace conformal coatings point toward bio-based materials derived from renewable resources, further reductions in hazardous substances, and coating systems designed for easier disassembly and recycling at end-of-life. These innovations will be critical as the aerospace industry works toward ambitious carbon reduction targets while maintaining the exceptional reliability requirements unique to flight applications.

Recent benchmarking studies indicate a clear industry shift toward water-based and UV-curable conformal coating systems that offer reduced environmental footprints while maintaining critical performance parameters. These environmentally preferable alternatives have demonstrated up to 95% reduction in VOC emissions compared to traditional solvent-based systems, while still providing adequate protection against moisture, chemicals, and temperature extremes essential for aerospace applications.

Life cycle assessment (LCA) data from leading aerospace manufacturers reveals that environmental impacts extend beyond the application phase to include raw material extraction, manufacturing processes, and end-of-life considerations. Boeing and Airbus have both implemented comprehensive sustainability programs that include conformal coating material selection criteria based on full life cycle environmental performance metrics.

Waste management presents another critical environmental consideration, as many traditional conformal coating materials generate hazardous waste requiring specialized disposal procedures. Benchmarking data indicates that aerospace companies implementing solvent recovery systems and closed-loop application processes have reduced hazardous waste generation by up to 70% while simultaneously reducing material costs by 15-25%.

Energy consumption during curing processes represents a significant environmental impact factor that varies substantially between coating technologies. Thermal cure systems typically require higher energy inputs compared to UV-curable alternatives, with some next-generation UV systems demonstrating energy reductions of 40-60% in controlled benchmarking studies. These energy efficiencies translate directly to reduced carbon footprints for manufacturing operations.

Supply chain sustainability has emerged as an important benchmarking criterion, with aerospace OEMs increasingly requiring environmental performance data from coating suppliers. This includes documentation of sustainable sourcing practices, manufacturing energy efficiency, and chemical hazard reduction efforts. Leading suppliers now provide Environmental Product Declarations (EPDs) that quantify environmental impacts across multiple categories including global warming potential, ozone depletion, and resource depletion.

Future sustainability trends in aerospace conformal coatings point toward bio-based materials derived from renewable resources, further reductions in hazardous substances, and coating systems designed for easier disassembly and recycling at end-of-life. These innovations will be critical as the aerospace industry works toward ambitious carbon reduction targets while maintaining the exceptional reliability requirements unique to flight applications.

Qualification Standards and Testing Protocols for Aerospace Coatings

The aerospace industry demands exceptionally high standards for conformal coatings due to the extreme environmental conditions these components must withstand. Qualification standards for aerospace coatings are primarily governed by key industry specifications including IPC-CC-830, MIL-I-46058C, and the more recent AS9100 quality management system specifically tailored for aerospace applications. These standards establish rigorous baseline requirements for coating materials, application processes, and performance metrics.

Testing protocols for aerospace conformal coatings typically follow a multi-tiered approach. Environmental testing forms the foundation, with thermal cycling tests (-65°C to +125°C) evaluating coating integrity through extreme temperature fluctuations. Humidity resistance testing (typically 95% RH at elevated temperatures for 1000+ hours) assesses moisture protection capabilities, while salt fog exposure tests determine corrosion resistance in maritime and coastal deployment scenarios.

Mechanical testing constitutes another critical evaluation dimension, including adhesion testing (per ASTM D3359), abrasion resistance, and flexibility assessments to ensure coatings maintain integrity during vibration and physical stress. Electrical property verification includes insulation resistance measurements, dielectric strength testing, and surface resistivity evaluations across varying environmental conditions.

Chemical compatibility testing evaluates coating resistance to fuels, hydraulic fluids, de-icing chemicals, and cleaning solvents commonly encountered in aerospace operations. These tests typically involve immersion followed by visual inspection and electrical property re-verification to ensure maintained performance.

Specialized aerospace-specific tests include altitude testing in depressurized chambers to simulate high-altitude conditions, outgassing measurements critical for space applications (ASTM E595), and radiation resistance testing for components deployed in orbit or deep space missions.

Accelerated aging protocols attempt to compress decades of service life into manageable test timeframes, with UV exposure, thermal aging, and combined environmental stress testing providing predictive data on long-term performance. Many aerospace manufacturers supplement these standard tests with customized protocols addressing specific application requirements or operational environments.

Certification processes typically require comprehensive documentation of all testing results, material traceability, and process controls. Third-party verification through independent testing laboratories is increasingly common, particularly for critical flight systems where coating failure could compromise safety or mission success.

Testing protocols for aerospace conformal coatings typically follow a multi-tiered approach. Environmental testing forms the foundation, with thermal cycling tests (-65°C to +125°C) evaluating coating integrity through extreme temperature fluctuations. Humidity resistance testing (typically 95% RH at elevated temperatures for 1000+ hours) assesses moisture protection capabilities, while salt fog exposure tests determine corrosion resistance in maritime and coastal deployment scenarios.

Mechanical testing constitutes another critical evaluation dimension, including adhesion testing (per ASTM D3359), abrasion resistance, and flexibility assessments to ensure coatings maintain integrity during vibration and physical stress. Electrical property verification includes insulation resistance measurements, dielectric strength testing, and surface resistivity evaluations across varying environmental conditions.

Chemical compatibility testing evaluates coating resistance to fuels, hydraulic fluids, de-icing chemicals, and cleaning solvents commonly encountered in aerospace operations. These tests typically involve immersion followed by visual inspection and electrical property re-verification to ensure maintained performance.

Specialized aerospace-specific tests include altitude testing in depressurized chambers to simulate high-altitude conditions, outgassing measurements critical for space applications (ASTM E595), and radiation resistance testing for components deployed in orbit or deep space missions.

Accelerated aging protocols attempt to compress decades of service life into manageable test timeframes, with UV exposure, thermal aging, and combined environmental stress testing providing predictive data on long-term performance. Many aerospace manufacturers supplement these standard tests with customized protocols addressing specific application requirements or operational environments.

Certification processes typically require comprehensive documentation of all testing results, material traceability, and process controls. Third-party verification through independent testing laboratories is increasingly common, particularly for critical flight systems where coating failure could compromise safety or mission success.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!