Best Practices For Rotary Kiln Combustion Optimization And Emissions Control

AUG 22, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Rotary Kiln Combustion Technology Evolution and Objectives

Rotary kiln combustion technology has evolved significantly over the past century, transforming from rudimentary coal-fired systems to sophisticated multi-fuel platforms with advanced control mechanisms. The initial development phase in the early 20th century focused primarily on achieving consistent temperature profiles using coal as the primary fuel source. By the 1950s, the industry witnessed a shift toward oil-based combustion systems, offering improved thermal efficiency and reduced maintenance requirements.

The 1970s energy crisis marked a pivotal moment in rotary kiln technology evolution, prompting manufacturers to explore alternative fuel options and develop more energy-efficient designs. This period saw the introduction of natural gas firing systems and the first generation of computerized control mechanisms aimed at optimizing fuel consumption while maintaining product quality.

The 1990s brought significant advancements in combustion technology with the implementation of low-NOx burners and oxygen-enriched combustion processes. These innovations addressed growing environmental concerns while simultaneously improving thermal efficiency. The early 2000s witnessed the integration of computational fluid dynamics (CFD) modeling into kiln design and operation, enabling more precise flame control and heat distribution analysis.

Recent technological developments have centered on multi-fuel flexibility, allowing operators to switch between conventional and alternative fuels based on availability and economic considerations. Waste-derived fuels, biomass, and hydrogen blends have gained traction as viable options for reducing carbon footprint while maintaining operational performance. Advanced sensor technologies, including infrared thermography and laser-based gas analyzers, have revolutionized real-time monitoring capabilities.

The primary objectives of modern rotary kiln combustion technology focus on three interconnected areas: operational efficiency, environmental compliance, and product quality consistency. Efficiency improvements target reduced specific energy consumption through enhanced heat transfer mechanisms, minimized heat losses, and optimized combustion parameters. Environmental objectives include minimizing greenhouse gas emissions, reducing NOx and SOx formation, and eliminating particulate matter release.

Looking forward, the industry trajectory points toward fully automated combustion systems incorporating artificial intelligence and machine learning algorithms to continuously optimize operating parameters. These systems aim to predict maintenance requirements, adapt to varying raw material characteristics, and maintain optimal combustion conditions despite fluctuating production demands. The ultimate goal remains achieving carbon-neutral operation through a combination of alternative fuels, carbon capture technologies, and process innovations while maintaining competitive production costs and product quality.

The 1970s energy crisis marked a pivotal moment in rotary kiln technology evolution, prompting manufacturers to explore alternative fuel options and develop more energy-efficient designs. This period saw the introduction of natural gas firing systems and the first generation of computerized control mechanisms aimed at optimizing fuel consumption while maintaining product quality.

The 1990s brought significant advancements in combustion technology with the implementation of low-NOx burners and oxygen-enriched combustion processes. These innovations addressed growing environmental concerns while simultaneously improving thermal efficiency. The early 2000s witnessed the integration of computational fluid dynamics (CFD) modeling into kiln design and operation, enabling more precise flame control and heat distribution analysis.

Recent technological developments have centered on multi-fuel flexibility, allowing operators to switch between conventional and alternative fuels based on availability and economic considerations. Waste-derived fuels, biomass, and hydrogen blends have gained traction as viable options for reducing carbon footprint while maintaining operational performance. Advanced sensor technologies, including infrared thermography and laser-based gas analyzers, have revolutionized real-time monitoring capabilities.

The primary objectives of modern rotary kiln combustion technology focus on three interconnected areas: operational efficiency, environmental compliance, and product quality consistency. Efficiency improvements target reduced specific energy consumption through enhanced heat transfer mechanisms, minimized heat losses, and optimized combustion parameters. Environmental objectives include minimizing greenhouse gas emissions, reducing NOx and SOx formation, and eliminating particulate matter release.

Looking forward, the industry trajectory points toward fully automated combustion systems incorporating artificial intelligence and machine learning algorithms to continuously optimize operating parameters. These systems aim to predict maintenance requirements, adapt to varying raw material characteristics, and maintain optimal combustion conditions despite fluctuating production demands. The ultimate goal remains achieving carbon-neutral operation through a combination of alternative fuels, carbon capture technologies, and process innovations while maintaining competitive production costs and product quality.

Market Demand for Efficient Kiln Operation and Emissions Reduction

The global market for rotary kiln optimization and emissions control technologies has experienced significant growth in recent years, driven by increasingly stringent environmental regulations and the industry's focus on operational efficiency. The cement industry alone, which is a major user of rotary kilns, accounts for approximately 8% of global CO2 emissions, creating substantial pressure for emissions reduction solutions.

Industrial sectors utilizing rotary kilns, including cement, lime, minerals processing, and waste incineration, face mounting challenges from regulatory bodies worldwide. The European Union's Emissions Trading System (EU ETS) and similar carbon pricing mechanisms in other regions have created direct financial incentives for emissions reduction. Companies operating in these sectors now view emissions control not merely as a compliance issue but as a critical factor affecting their bottom line.

Energy efficiency represents another major market driver, as fuel costs typically constitute 30-40% of operational expenses in cement production. The volatility in energy markets has intensified the demand for combustion optimization technologies that can reduce fuel consumption while maintaining product quality. Industries are increasingly seeking solutions that offer dual benefits of emissions reduction and energy savings.

Market research indicates that the global market for industrial combustion control equipment is growing at a compound annual growth rate of 5.7%, with particular acceleration in developing economies where rapid industrialization coincides with the implementation of new environmental standards. China and India, as the world's largest cement producers, represent especially significant markets for these technologies.

The demand for retrofit solutions is particularly strong, as many existing facilities seek to extend their operational life while meeting new emissions standards. These solutions must be adaptable to various kiln designs and operational parameters, creating opportunities for customizable technology packages rather than one-size-fits-all approaches.

Stakeholders across the value chain are increasingly prioritizing sustainability metrics in their decision-making processes. End users of cement and other kiln-produced materials are demanding products with lower carbon footprints, while investors are scrutinizing companies' environmental performance as part of ESG (Environmental, Social, and Governance) evaluations.

The market is also witnessing growing demand for advanced monitoring and control systems that enable real-time optimization of combustion processes. These systems, often incorporating artificial intelligence and machine learning capabilities, allow operators to maintain optimal conditions continuously, reducing both emissions and energy consumption while improving product quality and consistency.

Industrial sectors utilizing rotary kilns, including cement, lime, minerals processing, and waste incineration, face mounting challenges from regulatory bodies worldwide. The European Union's Emissions Trading System (EU ETS) and similar carbon pricing mechanisms in other regions have created direct financial incentives for emissions reduction. Companies operating in these sectors now view emissions control not merely as a compliance issue but as a critical factor affecting their bottom line.

Energy efficiency represents another major market driver, as fuel costs typically constitute 30-40% of operational expenses in cement production. The volatility in energy markets has intensified the demand for combustion optimization technologies that can reduce fuel consumption while maintaining product quality. Industries are increasingly seeking solutions that offer dual benefits of emissions reduction and energy savings.

Market research indicates that the global market for industrial combustion control equipment is growing at a compound annual growth rate of 5.7%, with particular acceleration in developing economies where rapid industrialization coincides with the implementation of new environmental standards. China and India, as the world's largest cement producers, represent especially significant markets for these technologies.

The demand for retrofit solutions is particularly strong, as many existing facilities seek to extend their operational life while meeting new emissions standards. These solutions must be adaptable to various kiln designs and operational parameters, creating opportunities for customizable technology packages rather than one-size-fits-all approaches.

Stakeholders across the value chain are increasingly prioritizing sustainability metrics in their decision-making processes. End users of cement and other kiln-produced materials are demanding products with lower carbon footprints, while investors are scrutinizing companies' environmental performance as part of ESG (Environmental, Social, and Governance) evaluations.

The market is also witnessing growing demand for advanced monitoring and control systems that enable real-time optimization of combustion processes. These systems, often incorporating artificial intelligence and machine learning capabilities, allow operators to maintain optimal conditions continuously, reducing both emissions and energy consumption while improving product quality and consistency.

Current Combustion Optimization Challenges and Limitations

Despite significant advancements in rotary kiln technology, combustion optimization faces several persistent challenges. Current control systems often rely on limited sensor data that provides only partial visibility into the complex combustion processes occurring within kilns. Temperature measurements typically capture only surface or exit gas conditions, failing to accurately represent the internal thermal profile where critical reactions occur. This data limitation creates significant blind spots in process monitoring and control.

Fuel quality inconsistency presents another major obstacle, particularly in industries utilizing alternative or waste-derived fuels. Variations in calorific value, moisture content, and chemical composition create unpredictable combustion dynamics that existing control systems struggle to accommodate in real-time. These fluctuations directly impact flame stability, heat distribution, and ultimately product quality.

Conventional PID control systems, while reliable for basic operations, lack the predictive capabilities necessary for truly optimized combustion. Their reactive nature means adjustments occur only after deviations are detected, resulting in inherent inefficiencies and potential quality issues during transition states. This limitation becomes particularly problematic during production changes or when responding to fuel property variations.

Emissions control requirements have grown increasingly stringent worldwide, with regulations targeting NOx, SOx, particulate matter, and greenhouse gases. Current abatement technologies often create operational trade-offs between emissions reduction and energy efficiency. For instance, lower combustion temperatures may reduce NOx formation but can negatively impact production efficiency and increase CO emissions, creating competing optimization objectives.

Heat transfer inefficiencies remain a significant challenge, with many kilns operating below optimal thermal efficiency. Inadequate insulation, suboptimal burner positioning, and improper air-to-fuel ratios contribute to energy losses that increase operational costs and environmental impact. Existing monitoring systems often lack the spatial resolution to identify specific heat transfer bottlenecks within the kiln.

Integration challenges between combustion systems and broader plant operations further complicate optimization efforts. Many facilities operate with siloed control systems that prevent holistic process optimization. Without integrated data platforms connecting upstream and downstream processes, operators lack the comprehensive view needed to make truly optimal combustion decisions that balance production requirements, energy efficiency, and emissions control.

Lastly, the industry faces a knowledge gap as experienced operators retire without adequate knowledge transfer to newer personnel. Modern control systems often fail to capture the tacit knowledge and intuition developed through years of hands-on experience, resulting in over-reliance on automated systems without sufficient understanding of their limitations and operational nuances.

Fuel quality inconsistency presents another major obstacle, particularly in industries utilizing alternative or waste-derived fuels. Variations in calorific value, moisture content, and chemical composition create unpredictable combustion dynamics that existing control systems struggle to accommodate in real-time. These fluctuations directly impact flame stability, heat distribution, and ultimately product quality.

Conventional PID control systems, while reliable for basic operations, lack the predictive capabilities necessary for truly optimized combustion. Their reactive nature means adjustments occur only after deviations are detected, resulting in inherent inefficiencies and potential quality issues during transition states. This limitation becomes particularly problematic during production changes or when responding to fuel property variations.

Emissions control requirements have grown increasingly stringent worldwide, with regulations targeting NOx, SOx, particulate matter, and greenhouse gases. Current abatement technologies often create operational trade-offs between emissions reduction and energy efficiency. For instance, lower combustion temperatures may reduce NOx formation but can negatively impact production efficiency and increase CO emissions, creating competing optimization objectives.

Heat transfer inefficiencies remain a significant challenge, with many kilns operating below optimal thermal efficiency. Inadequate insulation, suboptimal burner positioning, and improper air-to-fuel ratios contribute to energy losses that increase operational costs and environmental impact. Existing monitoring systems often lack the spatial resolution to identify specific heat transfer bottlenecks within the kiln.

Integration challenges between combustion systems and broader plant operations further complicate optimization efforts. Many facilities operate with siloed control systems that prevent holistic process optimization. Without integrated data platforms connecting upstream and downstream processes, operators lack the comprehensive view needed to make truly optimal combustion decisions that balance production requirements, energy efficiency, and emissions control.

Lastly, the industry faces a knowledge gap as experienced operators retire without adequate knowledge transfer to newer personnel. Modern control systems often fail to capture the tacit knowledge and intuition developed through years of hands-on experience, resulting in over-reliance on automated systems without sufficient understanding of their limitations and operational nuances.

Current Optimization Strategies and Control Systems

01 Combustion control systems for rotary kilns

Advanced control systems are implemented to optimize the combustion process in rotary kilns. These systems monitor and adjust various parameters such as temperature, air flow, fuel injection, and kiln rotation speed in real-time. By maintaining optimal combustion conditions, these control systems can improve energy efficiency, reduce fuel consumption, and minimize emissions. Some systems incorporate predictive modeling and artificial intelligence to anticipate changes in operating conditions and make proactive adjustments.- Combustion optimization systems for rotary kilns: Advanced control systems that optimize the combustion process in rotary kilns by monitoring and adjusting key parameters such as temperature, air flow, and fuel input. These systems use sensors and algorithms to maintain optimal combustion conditions, resulting in improved energy efficiency and reduced emissions. The optimization systems can include real-time monitoring, predictive controls, and automated adjustment mechanisms to ensure consistent performance under varying operating conditions.

- Emissions reduction technologies for rotary kilns: Specialized technologies designed to reduce harmful emissions from rotary kiln operations, including NOx, SOx, particulate matter, and greenhouse gases. These technologies may involve flue gas treatment systems, selective catalytic reduction (SCR), selective non-catalytic reduction (SNCR), and advanced filtration methods. By implementing these emission control technologies, rotary kiln operations can meet stringent environmental regulations while maintaining production efficiency.

- Alternative fuel utilization in rotary kilns: Methods and systems for effectively using alternative fuels in rotary kilns to reduce environmental impact and operational costs. These innovations enable the substitution of traditional fossil fuels with waste-derived fuels, biomass, or other sustainable alternatives while maintaining combustion stability and product quality. The technologies include specialized feeding systems, fuel preparation techniques, and combustion chamber modifications to accommodate the different burning characteristics of alternative fuels.

- Advanced burner designs for rotary kilns: Innovative burner designs specifically engineered for rotary kiln applications that improve flame stability, heat distribution, and combustion efficiency. These advanced burners feature optimized nozzle configurations, improved mixing of fuel and air, and precise control mechanisms to achieve complete combustion. The designs may incorporate multi-channel systems, adjustable flame patterns, and specialized materials to withstand the harsh operating conditions while minimizing emissions and maximizing thermal efficiency.

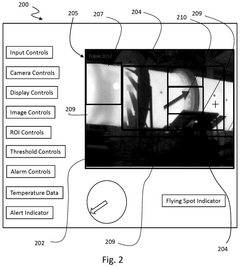

- Monitoring and control systems for emissions management: Sophisticated monitoring and control systems that continuously track emissions levels and automatically adjust kiln operations to maintain compliance with environmental standards. These systems utilize advanced sensors, data analytics, and feedback control loops to detect deviations from optimal performance and implement corrective actions. The technologies may include predictive maintenance capabilities, remote monitoring options, and integration with plant-wide control systems to provide comprehensive emissions management throughout the rotary kiln operation.

02 Emissions reduction technologies

Various technologies are employed to reduce harmful emissions from rotary kiln operations. These include selective catalytic reduction (SCR) systems, electrostatic precipitators, bag filters, and wet scrubbers that can remove pollutants such as nitrogen oxides (NOx), sulfur dioxide (SO2), particulate matter, and volatile organic compounds. Some solutions involve the injection of reagents or additives into the combustion zone to neutralize pollutants before they are released. These technologies help rotary kiln operations comply with increasingly stringent environmental regulations.Expand Specific Solutions03 Fuel efficiency and alternative fuel utilization

Innovations in rotary kiln design and operation focus on improving fuel efficiency and enabling the use of alternative fuels. These include modifications to burner designs, fuel preparation systems, and combustion chamber configurations. Some technologies allow for the co-processing of conventional fuels with biomass, waste-derived fuels, or other alternative energy sources. By optimizing the fuel mix and combustion conditions, these innovations can reduce fossil fuel consumption, lower operating costs, and decrease the carbon footprint of rotary kiln operations.Expand Specific Solutions04 Monitoring and sensing technologies

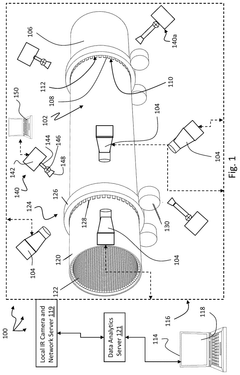

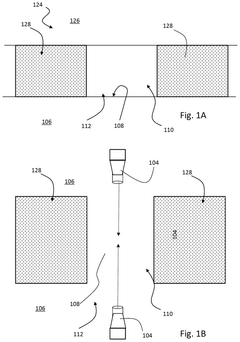

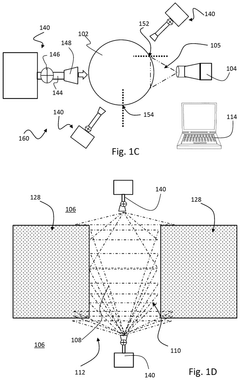

Advanced monitoring and sensing technologies are implemented to provide real-time data on rotary kiln operations. These include thermal imaging cameras, gas analyzers, acoustic sensors, and laser-based measurement systems that can detect temperature profiles, gas compositions, material flow patterns, and equipment conditions. The data collected by these sensors is used to optimize combustion parameters, detect abnormalities, and prevent equipment failures. Some systems incorporate wireless communication and cloud-based analytics to enable remote monitoring and diagnostics.Expand Specific Solutions05 Heat recovery and energy optimization

Heat recovery systems are integrated into rotary kiln operations to capture and utilize waste heat from the combustion process. These systems can include heat exchangers, waste heat boilers, and preheating equipment that transfer thermal energy from exhaust gases to incoming materials or other processes. By recovering waste heat, these technologies improve overall energy efficiency, reduce fuel consumption, and lower greenhouse gas emissions. Some advanced systems also incorporate energy storage solutions to manage fluctuations in heat availability and demand.Expand Specific Solutions

Leading Manufacturers and Technology Providers in Kiln Industry

The rotary kiln combustion optimization and emissions control market is in a mature growth phase, with increasing focus on sustainability and regulatory compliance driving innovation. The global market size is estimated at $3-4 billion annually, growing steadily as cement and industrial sectors seek efficiency improvements. Technologically, the field has reached moderate maturity with established solutions from industry leaders like thyssenkrupp Polysius, Air Liquide, and Fives Pillard, who offer comprehensive combustion systems. Chinese companies such as Zhongye Changtian and Yantai Longyuan are rapidly advancing with cost-effective solutions, while specialized players like Quantum IR Technologies provide cutting-edge monitoring systems. Research institutions including North China University of Technology and Karlsruher Institut für Technologie continue pushing boundaries in emissions reduction technologies, creating a competitive landscape balanced between established Western firms and emerging Asian manufacturers.

Fives Pillard SA

Technical Solution: Fives Pillard has developed the NovaFlam® rotary kiln burner system that incorporates advanced aerodynamic principles to optimize flame shape, stability, and heat transfer characteristics. Their technology features a modular design with adjustable primary and secondary air channels that can be fine-tuned to specific kiln conditions and material requirements. The company's burners incorporate sophisticated fuel atomization technology that ensures complete combustion even with lower-grade or alternative fuels, achieving combustion efficiencies exceeding 99%. Fives Pillard's EcoFlam™ low-NOx technology employs staged combustion principles with precise fuel distribution across multiple injection points, creating fuel-rich and fuel-lean zones that minimize thermal NOx formation while maintaining optimal flame temperature profiles. Their integrated control system uses advanced imaging technology to monitor flame characteristics in real-time, with automated adjustments to maintain optimal combustion parameters under varying load conditions. For emissions control, Fives Pillard has developed a comprehensive approach combining low-NOx burner technology with selective non-catalytic reduction (SNCR) systems and advanced filtration technologies.

Strengths: Exceptional flame stability and control across a wide range of operational conditions, making their technology suitable for processes requiring precise temperature profiles. Their modular design allows for customization to specific kiln configurations and production requirements. Weaknesses: Higher initial investment compared to conventional burner systems, and optimal performance requires precise installation and regular maintenance by specialized technicians.

Air Liquide SA

Technical Solution: Air Liquide has developed the ALGLASS™ oxy-combustion technology specifically adapted for rotary kiln applications in various industries. Their system replaces conventional air with oxygen-enriched air or pure oxygen, significantly improving combustion efficiency and heat transfer characteristics. The company's proprietary burner designs feature multiple oxygen injection points that create optimized flame patterns for different kiln zones and material processing requirements. Air Liquide's technology enables precise control of flame temperature and length, with demonstrated fuel savings of 20-35% compared to conventional air-fuel systems. Their integrated control platform incorporates advanced sensors for real-time monitoring of oxygen levels, temperature profiles, and emissions, with automated adjustment algorithms to maintain optimal combustion parameters. For emissions control, Air Liquide has pioneered oxygen-enhanced SNCR (Selective Non-Catalytic Reduction) technology that improves NOx reduction efficiency by up to 25% compared to conventional SNCR systems. The company's oxy-combustion approach inherently reduces the volume of flue gases by up to 70%, significantly decreasing the size requirements for downstream emissions control equipment.

Strengths: Significant reduction in flue gas volume simplifies emissions control and reduces capital costs for gas treatment systems. Their technology enables higher processing temperatures when needed, potentially increasing throughput in capacity-limited operations. Weaknesses: Requires reliable oxygen supply infrastructure and introduces additional operational costs associated with oxygen production or purchase. Implementation may require significant modifications to existing kiln systems and control infrastructure.

Key Innovations in Combustion Efficiency and Emissions Reduction

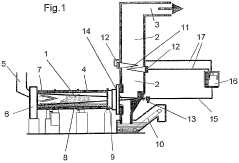

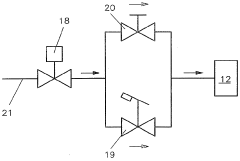

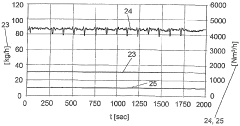

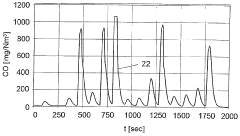

Method for increasing the package throughput in rotary kiln plants

PatentWO2006089693A1

Innovation

- Implementing in-situ optical measurement techniques for rapid detection of combustion species like CO, soot, and O2 in the rotary kiln, with real-time feedback to adjust fuel and air supply to optimize stoichiometry and mixing, reducing CO emissions without altering flue gas volume flow.

Rotary kiln monitoring systems for fuel consumption and emissions

PatentPendingUS20250244078A1

Innovation

- A system using infrared imaging sensors and computing systems to monitor temperature variations, model fuel consumption, and predict emissions by correlating brick and coating thickness with fuel usage, enabling scheduled maintenance and optimized operation.

Environmental Compliance and Regulatory Framework

The regulatory landscape governing rotary kiln operations has become increasingly stringent worldwide, with particular focus on emissions control and environmental protection. In the United States, the Environmental Protection Agency (EPA) has established comprehensive frameworks under the Clean Air Act, including the National Emission Standards for Hazardous Air Pollutants (NESHAP) and New Source Performance Standards (NSPS) that directly impact rotary kiln operations in cement manufacturing, waste incineration, and other industrial applications.

The European Union's Industrial Emissions Directive (IED) represents one of the most rigorous regulatory frameworks globally, mandating Best Available Techniques (BAT) for pollution prevention and control. For rotary kiln operators, this translates to specific emission limit values for particulate matter, nitrogen oxides (NOx), sulfur dioxide (SO2), and various heavy metals that must be continuously monitored and reported.

Emerging economies, particularly China and India, have also strengthened their environmental regulations in response to severe air quality challenges. China's Ultra-Low Emission standards now approach or exceed those of developed nations in certain parameters, creating a global convergence toward stricter emissions control requirements for industrial facilities utilizing rotary kilns.

Compliance strategies necessitate a multi-faceted approach, beginning with comprehensive emissions monitoring systems. Continuous Emissions Monitoring Systems (CEMS) have become standard requirements in most jurisdictions, providing real-time data on stack emissions and facilitating both regulatory reporting and process optimization. These systems must be regularly calibrated and maintained to ensure accuracy and reliability.

Permitting requirements vary significantly by jurisdiction but typically involve detailed documentation of process parameters, emissions control technologies, and contingency plans. Many regulatory frameworks now incorporate risk-based approaches, with more stringent requirements for facilities located near sensitive receptors or in non-attainment areas for specific pollutants.

The financial implications of non-compliance have escalated dramatically, with penalties potentially reaching millions of dollars for serious violations. Beyond direct fines, facilities may face production restrictions, mandatory technology upgrades, or even closure orders. This economic reality has transformed environmental compliance from a peripheral concern to a core business imperative for rotary kiln operators.

Looking forward, regulatory trends indicate continued tightening of emission limits, expansion of regulated pollutants, and greater emphasis on greenhouse gas emissions. Carbon pricing mechanisms, whether through direct taxation or cap-and-trade systems, are increasingly affecting the economics of rotary kiln operations, driving investment in more efficient combustion technologies and alternative fuels.

The European Union's Industrial Emissions Directive (IED) represents one of the most rigorous regulatory frameworks globally, mandating Best Available Techniques (BAT) for pollution prevention and control. For rotary kiln operators, this translates to specific emission limit values for particulate matter, nitrogen oxides (NOx), sulfur dioxide (SO2), and various heavy metals that must be continuously monitored and reported.

Emerging economies, particularly China and India, have also strengthened their environmental regulations in response to severe air quality challenges. China's Ultra-Low Emission standards now approach or exceed those of developed nations in certain parameters, creating a global convergence toward stricter emissions control requirements for industrial facilities utilizing rotary kilns.

Compliance strategies necessitate a multi-faceted approach, beginning with comprehensive emissions monitoring systems. Continuous Emissions Monitoring Systems (CEMS) have become standard requirements in most jurisdictions, providing real-time data on stack emissions and facilitating both regulatory reporting and process optimization. These systems must be regularly calibrated and maintained to ensure accuracy and reliability.

Permitting requirements vary significantly by jurisdiction but typically involve detailed documentation of process parameters, emissions control technologies, and contingency plans. Many regulatory frameworks now incorporate risk-based approaches, with more stringent requirements for facilities located near sensitive receptors or in non-attainment areas for specific pollutants.

The financial implications of non-compliance have escalated dramatically, with penalties potentially reaching millions of dollars for serious violations. Beyond direct fines, facilities may face production restrictions, mandatory technology upgrades, or even closure orders. This economic reality has transformed environmental compliance from a peripheral concern to a core business imperative for rotary kiln operators.

Looking forward, regulatory trends indicate continued tightening of emission limits, expansion of regulated pollutants, and greater emphasis on greenhouse gas emissions. Carbon pricing mechanisms, whether through direct taxation or cap-and-trade systems, are increasingly affecting the economics of rotary kiln operations, driving investment in more efficient combustion technologies and alternative fuels.

Energy Efficiency and Carbon Footprint Reduction Approaches

Energy efficiency and carbon footprint reduction in rotary kiln operations represent critical pathways toward sustainable industrial practices. The cement and lime industries, which heavily rely on rotary kilns, account for approximately 8% of global CO2 emissions, making optimization efforts particularly significant for environmental impact reduction.

Advanced combustion control systems offer substantial efficiency improvements through real-time monitoring and adjustment of fuel-air ratios. Implementation of oxygen-enriched combustion technology has demonstrated energy savings of 10-15% while simultaneously reducing CO2 emissions by comparable percentages. These systems utilize artificial intelligence and machine learning algorithms to continuously optimize combustion parameters based on operational conditions and raw material characteristics.

Waste heat recovery systems present another significant opportunity for energy conservation. Modern rotary kiln installations increasingly incorporate heat exchangers and waste heat boilers that capture thermal energy from exhaust gases. This recovered energy can generate electricity or provide heating for other processes, improving overall plant efficiency by 15-25% depending on system design and integration level.

Alternative fuel utilization represents a dual approach to both energy cost reduction and carbon footprint minimization. Progressive facilities have achieved substitution rates of up to 80% of conventional fossil fuels with alternatives such as refuse-derived fuels, biomass, and industrial waste. This practice not only diverts waste from landfills but also significantly reduces net carbon emissions through the utilization of biogenic carbon sources.

Process optimization through computational fluid dynamics (CFD) modeling enables operators to identify inefficiencies in combustion zones and optimize flame characteristics. These simulations can reduce fuel consumption by 5-8% when coupled with appropriate control system modifications. Additionally, advanced refractory materials with improved thermal properties minimize heat losses through kiln shells, contributing to energy conservation.

Carbon capture technologies are increasingly being integrated into rotary kiln operations, with pilot projects demonstrating capture efficiencies of 80-90%. Post-combustion capture using amine-based solvents represents the most mature technology, while calcium looping and direct separation methods show promise for future applications. The captured CO2 can be utilized in concrete curing processes, creating a circular carbon economy within the same industry.

Digitalization and Industry 4.0 approaches enable comprehensive energy management systems that identify optimization opportunities across entire production facilities. These systems typically yield additional 3-5% efficiency improvements through the elimination of operational inconsistencies and enhanced predictive maintenance capabilities.

Advanced combustion control systems offer substantial efficiency improvements through real-time monitoring and adjustment of fuel-air ratios. Implementation of oxygen-enriched combustion technology has demonstrated energy savings of 10-15% while simultaneously reducing CO2 emissions by comparable percentages. These systems utilize artificial intelligence and machine learning algorithms to continuously optimize combustion parameters based on operational conditions and raw material characteristics.

Waste heat recovery systems present another significant opportunity for energy conservation. Modern rotary kiln installations increasingly incorporate heat exchangers and waste heat boilers that capture thermal energy from exhaust gases. This recovered energy can generate electricity or provide heating for other processes, improving overall plant efficiency by 15-25% depending on system design and integration level.

Alternative fuel utilization represents a dual approach to both energy cost reduction and carbon footprint minimization. Progressive facilities have achieved substitution rates of up to 80% of conventional fossil fuels with alternatives such as refuse-derived fuels, biomass, and industrial waste. This practice not only diverts waste from landfills but also significantly reduces net carbon emissions through the utilization of biogenic carbon sources.

Process optimization through computational fluid dynamics (CFD) modeling enables operators to identify inefficiencies in combustion zones and optimize flame characteristics. These simulations can reduce fuel consumption by 5-8% when coupled with appropriate control system modifications. Additionally, advanced refractory materials with improved thermal properties minimize heat losses through kiln shells, contributing to energy conservation.

Carbon capture technologies are increasingly being integrated into rotary kiln operations, with pilot projects demonstrating capture efficiencies of 80-90%. Post-combustion capture using amine-based solvents represents the most mature technology, while calcium looping and direct separation methods show promise for future applications. The captured CO2 can be utilized in concrete curing processes, creating a circular carbon economy within the same industry.

Digitalization and Industry 4.0 approaches enable comprehensive energy management systems that identify optimization opportunities across entire production facilities. These systems typically yield additional 3-5% efficiency improvements through the elimination of operational inconsistencies and enhanced predictive maintenance capabilities.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!