Rotary Kiln Retrofit Playbook: Sensors, Drives, And Control Upgrades

AUG 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Rotary Kiln Technology Evolution and Retrofit Objectives

Rotary kilns have evolved significantly since their inception in the late 19th century, transforming from simple cylindrical furnaces to sophisticated industrial systems critical to cement, lime, and mineral processing industries. The early 20th century saw basic mechanical designs with limited temperature control and manual operation. By mid-century, improvements in refractory materials and mechanical engineering enabled larger kilns with improved thermal efficiency, though still lacking precise control systems.

The 1970s-1980s marked a pivotal shift with the introduction of basic electronic monitoring and rudimentary automated control systems. This period saw the first integration of sensors for temperature and pressure monitoring, establishing the foundation for modern kiln operation. The 1990s brought computerized control systems and more advanced sensor technologies, enabling real-time process monitoring and adjustment.

Today's rotary kilns represent the culmination of this technological evolution, featuring sophisticated digital control systems, advanced materials, and high-precision sensors. Modern kilns incorporate distributed control systems (DCS), programmable logic controllers (PLCs), and artificial intelligence algorithms for process optimization. These advancements have significantly improved energy efficiency, reduced emissions, and enhanced product quality.

Despite these improvements, many operational rotary kilns worldwide remain equipped with outdated technology. These legacy systems face increasing challenges in meeting modern efficiency standards, environmental regulations, and production quality requirements. The aging infrastructure presents opportunities for strategic retrofitting rather than complete replacement, which would require substantial capital investment.

The primary objectives of rotary kiln retrofitting include enhancing operational efficiency through modern sensor integration, upgrading drive systems for improved mechanical performance, and implementing advanced control technologies. Specifically, retrofits aim to reduce energy consumption by 15-30%, decrease maintenance costs by 20-40%, extend equipment lifespan by 10-15 years, and ensure compliance with increasingly stringent environmental regulations.

Additional retrofit goals include improving product quality consistency through more precise temperature and process control, enhancing operational safety through better monitoring systems, and enabling data-driven decision-making through advanced analytics. The integration of Industry 4.0 technologies represents a significant opportunity to transform legacy rotary kilns into modern, connected manufacturing assets capable of participating in smart factory ecosystems.

The technological evolution of rotary kilns reflects broader industrial trends toward digitalization, sustainability, and operational excellence. Modern retrofit strategies must balance technological advancement with practical implementation considerations, ensuring that upgrades deliver measurable improvements in performance, efficiency, and environmental impact.

The 1970s-1980s marked a pivotal shift with the introduction of basic electronic monitoring and rudimentary automated control systems. This period saw the first integration of sensors for temperature and pressure monitoring, establishing the foundation for modern kiln operation. The 1990s brought computerized control systems and more advanced sensor technologies, enabling real-time process monitoring and adjustment.

Today's rotary kilns represent the culmination of this technological evolution, featuring sophisticated digital control systems, advanced materials, and high-precision sensors. Modern kilns incorporate distributed control systems (DCS), programmable logic controllers (PLCs), and artificial intelligence algorithms for process optimization. These advancements have significantly improved energy efficiency, reduced emissions, and enhanced product quality.

Despite these improvements, many operational rotary kilns worldwide remain equipped with outdated technology. These legacy systems face increasing challenges in meeting modern efficiency standards, environmental regulations, and production quality requirements. The aging infrastructure presents opportunities for strategic retrofitting rather than complete replacement, which would require substantial capital investment.

The primary objectives of rotary kiln retrofitting include enhancing operational efficiency through modern sensor integration, upgrading drive systems for improved mechanical performance, and implementing advanced control technologies. Specifically, retrofits aim to reduce energy consumption by 15-30%, decrease maintenance costs by 20-40%, extend equipment lifespan by 10-15 years, and ensure compliance with increasingly stringent environmental regulations.

Additional retrofit goals include improving product quality consistency through more precise temperature and process control, enhancing operational safety through better monitoring systems, and enabling data-driven decision-making through advanced analytics. The integration of Industry 4.0 technologies represents a significant opportunity to transform legacy rotary kilns into modern, connected manufacturing assets capable of participating in smart factory ecosystems.

The technological evolution of rotary kilns reflects broader industrial trends toward digitalization, sustainability, and operational excellence. Modern retrofit strategies must balance technological advancement with practical implementation considerations, ensuring that upgrades deliver measurable improvements in performance, efficiency, and environmental impact.

Market Demand Analysis for Advanced Kiln Systems

The global rotary kiln market is experiencing significant growth driven by increasing demand for advanced kiln systems across multiple industries. The cement industry remains the largest consumer of rotary kilns, accounting for approximately 60% of the market share, followed by mining and metallurgy at 25%, and chemical processing at 15%. With global cement production exceeding 4 billion tons annually, the demand for more efficient and environmentally friendly kiln operations has become paramount.

Environmental regulations are a primary market driver, with stringent emission standards being implemented worldwide. The European Union's carbon neutrality goals by 2050 and China's commitment to peak carbon emissions by 2030 are pushing manufacturers to retrofit existing kilns rather than investing in entirely new systems. This retrofit market is projected to grow at a compound annual growth rate of 7.2% through 2028, significantly outpacing the 4.5% growth rate for new kiln installations.

Energy efficiency concerns represent another crucial market factor. Rotary kilns typically consume between 3,000-6,500 MJ per ton of clinker produced, with energy costs accounting for 30-40% of cement production expenses. Advanced sensor systems, optimized drives, and intelligent control upgrades can reduce energy consumption by 15-20%, offering substantial operational savings that typically provide return on investment within 18-36 months.

The digital transformation trend is reshaping market demands for kiln systems. Industry 4.0 integration has become a competitive necessity rather than a luxury, with 78% of cement producers reporting plans to implement advanced digital monitoring and control systems within the next five years. Predictive maintenance capabilities enabled by sensor arrays and AI analytics are particularly valued, as unplanned kiln downtime costs can exceed $100,000 per day for large operations.

Regional market analysis reveals varying demand patterns. Asia-Pacific dominates with over 45% market share, driven by China and India's infrastructure development. North America and Europe focus primarily on retrofitting existing kilns with advanced control systems to extend operational life while meeting environmental standards. The Middle East and Africa represent the fastest-growing markets, with 9.3% annual growth in advanced kiln system adoption.

Customer requirements are increasingly sophisticated, with buyers prioritizing total cost of ownership over initial investment costs. Key purchasing criteria include energy efficiency improvements, emissions reduction capabilities, integration with existing plant systems, and remote monitoring functionality. Vendor support for implementation and training has also emerged as a critical factor, with 65% of buyers rating post-installation support as "very important" in purchasing decisions.

Environmental regulations are a primary market driver, with stringent emission standards being implemented worldwide. The European Union's carbon neutrality goals by 2050 and China's commitment to peak carbon emissions by 2030 are pushing manufacturers to retrofit existing kilns rather than investing in entirely new systems. This retrofit market is projected to grow at a compound annual growth rate of 7.2% through 2028, significantly outpacing the 4.5% growth rate for new kiln installations.

Energy efficiency concerns represent another crucial market factor. Rotary kilns typically consume between 3,000-6,500 MJ per ton of clinker produced, with energy costs accounting for 30-40% of cement production expenses. Advanced sensor systems, optimized drives, and intelligent control upgrades can reduce energy consumption by 15-20%, offering substantial operational savings that typically provide return on investment within 18-36 months.

The digital transformation trend is reshaping market demands for kiln systems. Industry 4.0 integration has become a competitive necessity rather than a luxury, with 78% of cement producers reporting plans to implement advanced digital monitoring and control systems within the next five years. Predictive maintenance capabilities enabled by sensor arrays and AI analytics are particularly valued, as unplanned kiln downtime costs can exceed $100,000 per day for large operations.

Regional market analysis reveals varying demand patterns. Asia-Pacific dominates with over 45% market share, driven by China and India's infrastructure development. North America and Europe focus primarily on retrofitting existing kilns with advanced control systems to extend operational life while meeting environmental standards. The Middle East and Africa represent the fastest-growing markets, with 9.3% annual growth in advanced kiln system adoption.

Customer requirements are increasingly sophisticated, with buyers prioritizing total cost of ownership over initial investment costs. Key purchasing criteria include energy efficiency improvements, emissions reduction capabilities, integration with existing plant systems, and remote monitoring functionality. Vendor support for implementation and training has also emerged as a critical factor, with 65% of buyers rating post-installation support as "very important" in purchasing decisions.

Current Challenges in Rotary Kiln Monitoring and Control

Rotary kilns face significant monitoring and control challenges that impede optimal performance in modern industrial applications. Temperature monitoring remains one of the most critical issues, as traditional contact thermocouples often fail prematurely due to the extreme operating conditions, while non-contact infrared systems struggle with accuracy due to dust, steam, and varying emissivity across kiln surfaces. This creates substantial blind spots in thermal profile management, leading to inefficient operation and potential product quality issues.

Material flow monitoring presents another persistent challenge, with conventional weight and volume measurement systems proving inadequate for real-time tracking of material progression through the kiln. The inability to precisely monitor material residence time and distribution patterns results in process inefficiencies and inconsistent product quality, particularly in cement and minerals processing applications.

Mechanical condition monitoring suffers from limitations in existing vibration analysis systems, which often fail to detect early-stage misalignments or component wear before they escalate into costly failures. The harsh operating environment, characterized by high temperatures and abrasive dust, accelerates sensor degradation and reduces reliability of traditional monitoring approaches.

Control system integration challenges are equally significant, with many facilities operating legacy control systems that lack the capability to incorporate modern sensor data or implement advanced control algorithms. This fragmentation between monitoring and control systems creates operational silos that prevent holistic process optimization and adaptive control strategies.

Data management and analysis represent a growing challenge as the volume of process data increases. Many operations lack the infrastructure to effectively collect, store, and analyze high-frequency sensor data, preventing the implementation of predictive maintenance strategies and advanced process optimization techniques. The absence of standardized data models further complicates cross-system integration efforts.

Energy efficiency monitoring remains problematic, with insufficient instrumentation to accurately measure and optimize fuel consumption relative to production output. This limitation becomes increasingly critical as environmental regulations tighten and energy costs rise, yet many kilns operate with only basic energy monitoring capabilities.

Emissions monitoring technology often falls short of regulatory requirements, with existing systems struggling to provide continuous, accurate measurements of complex gas mixtures under varying operating conditions. The integration of emissions data with process control parameters represents a significant technical gap in current systems.

Human-machine interface limitations further compound these challenges, with many control rooms still relying on outdated visualization tools that fail to present complex process relationships in an intuitive manner, hampering operator decision-making during critical process deviations.

Material flow monitoring presents another persistent challenge, with conventional weight and volume measurement systems proving inadequate for real-time tracking of material progression through the kiln. The inability to precisely monitor material residence time and distribution patterns results in process inefficiencies and inconsistent product quality, particularly in cement and minerals processing applications.

Mechanical condition monitoring suffers from limitations in existing vibration analysis systems, which often fail to detect early-stage misalignments or component wear before they escalate into costly failures. The harsh operating environment, characterized by high temperatures and abrasive dust, accelerates sensor degradation and reduces reliability of traditional monitoring approaches.

Control system integration challenges are equally significant, with many facilities operating legacy control systems that lack the capability to incorporate modern sensor data or implement advanced control algorithms. This fragmentation between monitoring and control systems creates operational silos that prevent holistic process optimization and adaptive control strategies.

Data management and analysis represent a growing challenge as the volume of process data increases. Many operations lack the infrastructure to effectively collect, store, and analyze high-frequency sensor data, preventing the implementation of predictive maintenance strategies and advanced process optimization techniques. The absence of standardized data models further complicates cross-system integration efforts.

Energy efficiency monitoring remains problematic, with insufficient instrumentation to accurately measure and optimize fuel consumption relative to production output. This limitation becomes increasingly critical as environmental regulations tighten and energy costs rise, yet many kilns operate with only basic energy monitoring capabilities.

Emissions monitoring technology often falls short of regulatory requirements, with existing systems struggling to provide continuous, accurate measurements of complex gas mixtures under varying operating conditions. The integration of emissions data with process control parameters represents a significant technical gap in current systems.

Human-machine interface limitations further compound these challenges, with many control rooms still relying on outdated visualization tools that fail to present complex process relationships in an intuitive manner, hampering operator decision-making during critical process deviations.

Modern Sensor Integration and Drive System Solutions

01 Temperature monitoring and control systems for rotary kilns

Advanced temperature monitoring systems are crucial for rotary kiln retrofits to ensure optimal operation and energy efficiency. These systems typically include thermal sensors, infrared cameras, and temperature profiling technology that provide real-time data on kiln shell temperatures and internal conditions. By implementing precise temperature control mechanisms, operators can prevent hotspots, optimize fuel consumption, and extend the refractory lining life. Modern control algorithms can automatically adjust firing rates based on temperature readings, maintaining ideal thermal conditions throughout the kiln.- Temperature monitoring and control systems for rotary kilns: Advanced temperature monitoring systems are essential for rotary kiln retrofits to ensure optimal operation and product quality. These systems utilize various sensors to measure temperature profiles throughout the kiln, enabling precise control of the thermal process. Modern temperature control upgrades include infrared sensors, thermocouples, and thermal imaging cameras that provide real-time data for automated control systems. These technologies help maintain consistent temperature distributions, reduce energy consumption, and extend the service life of refractory materials.

- Drive system upgrades for rotary kilns: Modernizing drive systems in rotary kilns involves replacing or upgrading motors, gearboxes, and control mechanisms to improve efficiency and reliability. Advanced variable frequency drives (VFDs) allow for precise speed control, smoother operation, and reduced mechanical stress on kiln components. These upgrades often include torque monitoring systems, load balancing technologies, and emergency backup systems to prevent unexpected shutdowns. Modern drive systems also incorporate energy recovery features and intelligent power management to optimize electricity consumption during operation.

- Advanced control and automation systems: Implementing advanced control and automation systems in rotary kiln retrofits enables sophisticated process optimization and operational efficiency. These systems integrate distributed control systems (DCS), programmable logic controllers (PLCs), and supervisory control and data acquisition (SCADA) platforms to manage all aspects of kiln operation. Modern control upgrades include predictive maintenance algorithms, artificial intelligence for process optimization, and remote monitoring capabilities. These technologies allow for real-time adjustments to operating parameters, improved product quality consistency, and reduced operator intervention.

- Material flow and quality monitoring sensors: Specialized sensors for monitoring material flow and quality are crucial components in rotary kiln retrofits. These include acoustic sensors for detecting material buildup, laser-based systems for measuring material bed depth, and advanced imaging systems for real-time quality assessment. Modern retrofits also incorporate load cells, flow meters, and particle size analyzers to provide comprehensive data on material processing. These monitoring systems help optimize feed rates, residence time, and processing conditions to achieve consistent product quality while maximizing throughput.

- Energy efficiency and emissions control upgrades: Retrofitting rotary kilns with energy efficiency and emissions control technologies involves installing advanced sensors and control systems to optimize fuel consumption and reduce environmental impact. These upgrades include oxygen analyzers, combustion efficiency monitors, and emissions measurement systems that provide data for automated burner management. Modern retrofits also incorporate heat recovery systems, alternative fuel capabilities, and advanced sealing mechanisms to minimize heat loss. These technologies help facilities meet stringent environmental regulations while reducing operational costs through improved energy utilization.

02 Drive system upgrades for rotary kilns

Modernizing drive systems is a key aspect of rotary kiln retrofits, focusing on improved efficiency and reliability. Upgrades typically include variable frequency drives (VFDs) that allow for precise speed control and smoother operation, reducing mechanical stress on kiln components. Advanced drive systems incorporate torque monitoring capabilities to detect operational anomalies and prevent damage. These retrofits often feature redundant drive mechanisms to minimize downtime and include intelligent control systems that can automatically adjust rotation speed based on process requirements, leading to optimized production and extended equipment life.Expand Specific Solutions03 Advanced process control and automation systems

Implementing advanced process control and automation systems significantly enhances rotary kiln performance. These upgrades include distributed control systems (DCS) with sophisticated algorithms for process optimization, predictive maintenance capabilities, and real-time monitoring dashboards. Modern control systems integrate multiple process variables including feed rate, temperature profiles, and exhaust gas composition to maintain optimal operating conditions. Machine learning and artificial intelligence components can be incorporated to continuously improve process efficiency, reduce emissions, and ensure consistent product quality while minimizing operator intervention.Expand Specific Solutions04 Sensor integration and monitoring networks

Comprehensive sensor networks are essential components of modern rotary kiln retrofits. These systems integrate various sensor types including pressure transducers, gas analyzers, vibration monitors, and position sensors to provide complete operational visibility. Wireless sensor technologies enable installation in previously inaccessible locations, while robust data transmission systems ensure reliable information flow even in harsh industrial environments. Advanced monitoring networks feature self-diagnostic capabilities to verify sensor health and data integrity. The integration of these diverse sensors into a unified monitoring platform allows for holistic kiln performance analysis and early detection of potential issues.Expand Specific Solutions05 Energy efficiency and emissions control upgrades

Retrofitting rotary kilns with energy efficiency and emissions control technologies addresses both operational costs and environmental compliance. These upgrades include improved burner designs that optimize fuel-air mixing for more complete combustion and lower emissions. Heat recovery systems capture waste heat from kiln exhaust for preheating materials or generating power. Advanced sealing systems minimize false air infiltration, improving thermal efficiency. Continuous emissions monitoring systems provide real-time data on pollutant levels, while automated control systems adjust operating parameters to maintain emissions within regulatory limits while maximizing production efficiency.Expand Specific Solutions

Leading Manufacturers and Solution Providers

The rotary kiln retrofit market is currently in a growth phase, characterized by increasing adoption of advanced sensors, drives, and control systems to enhance operational efficiency and reduce environmental impact. The market size is expanding steadily, driven by industrial modernization initiatives and stringent emission regulations. From a technological maturity perspective, the landscape shows varying degrees of advancement. Academic institutions like Wuhan University of Technology and Hunan University of Science & Technology are contributing fundamental research, while companies such as Beijing Kehuide Automation Technology and Nanjing Gongda CNC Technology lead in control system innovations. Established industrial players including Sumitomo Metal Mining, Novelis, and NIDEC Corp. are implementing comprehensive retrofit solutions, while specialized firms like iMFLUX focus on process optimization technologies. This competitive environment indicates a maturing market with significant potential for further technological advancement.

Beijing Kehuide Automation Technology Co., Ltd.

Technical Solution: Beijing Kehuide has developed an integrated rotary kiln control system that combines advanced sensor arrays with intelligent control algorithms. Their solution incorporates thermal imaging cameras positioned strategically along the kiln to monitor temperature profiles in real-time, paired with laser-based gas analyzers that provide continuous monitoring of exhaust composition. The system utilizes a distributed control architecture with redundant PLCs (Programmable Logic Controllers) that maintain operation even during partial system failures. Their proprietary software implements model predictive control algorithms that anticipate process changes and adjust parameters proactively rather than reactively. The system includes variable frequency drives (VFDs) for precise motor control, reducing mechanical stress during startup and optimizing energy consumption during operation. Data from all sensors is integrated into a comprehensive dashboard that provides operators with actionable insights while storing historical data for trend analysis and predictive maintenance.

Strengths: Highly integrated system with seamless communication between sensors and control systems; advanced predictive algorithms reduce energy consumption by 15-20% compared to conventional systems; robust redundancy features ensure continuous operation. Weaknesses: Higher initial implementation cost compared to piecemeal upgrades; requires specialized training for maintenance personnel; system optimization requires extensive historical data collection.

Acre Coking & Refractory Engineering Consulting (Dalian)

Technical Solution: Acre Coking has developed a specialized retrofit solution for rotary kilns in the metallurgical and cement industries. Their approach centers on a modular upgrade path that allows facilities to implement improvements incrementally while maintaining production. The system features high-temperature resistant wireless sensor networks that eliminate the need for complex wiring in hostile environments. These sensors monitor critical parameters including shell temperature distribution, material flow characteristics, and bearing conditions. The drive system incorporates advanced soft-start technology with regenerative braking capabilities that recover energy during deceleration phases. Their control system utilizes a hybrid approach combining traditional PID control with machine learning algorithms that continuously optimize combustion efficiency based on material properties and production targets. A notable innovation is their acoustic monitoring system that detects changes in kiln operation through sound pattern analysis, providing early warning of refractory damage or material buildup before conventional sensors detect problems.

Strengths: Modular approach allows phased implementation without production interruption; specialized expertise in refractory management extends kiln lining life by up to 30%; energy recovery systems reduce overall power consumption. Weaknesses: Wireless sensor networks may experience interference in facilities with multiple kilns; machine learning components require extensive calibration periods to achieve optimal performance; acoustic monitoring requires regular recalibration in changing ambient conditions.

Key Patents and Innovations in Kiln Control Technology

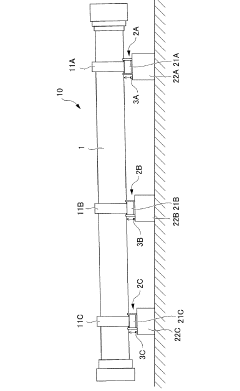

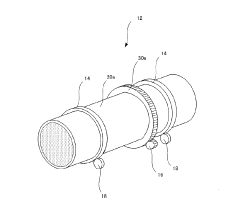

Rotary kiln, and method for driving rotary kiln

PatentActiveJP2020139634A

Innovation

- A rotary kiln equipped with a main body position detection sensor and fulcrum adjustment mechanism that allows continuous measurement and real-time adjustment of the kiln body's position, ensuring alignment without stopping the operation.

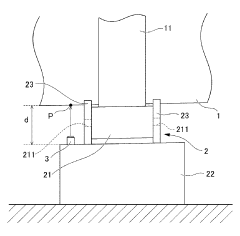

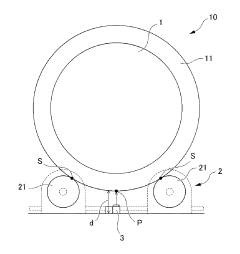

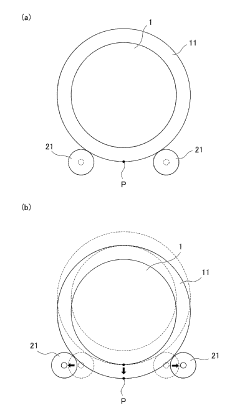

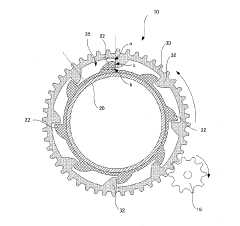

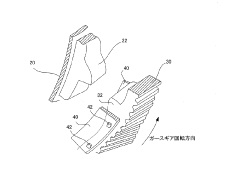

Rotary kiln driving mechanism

PatentActiveJP2021063623A

Innovation

- A rotary kiln drive mechanism featuring kiln-side and girth gear-side protrusions that mesh and rotate the body, with a free space between them to absorb deformation, and a cover to prevent the girth gear from detaching, facilitating easy attachment and maintenance.

Energy Efficiency and Sustainability Considerations

Retrofitting rotary kilns with advanced sensors, drives, and control systems presents significant opportunities for enhancing energy efficiency and sustainability in industrial operations. The cement and minerals processing industries, which heavily rely on rotary kilns, account for approximately 8% of global CO2 emissions, with energy consumption representing up to 40% of production costs. Modernizing these systems can yield substantial environmental and economic benefits.

Energy consumption patterns in traditional rotary kiln operations reveal inefficiencies primarily in thermal energy utilization and electrical systems. Thermal losses occur through radiation, convection, and incomplete combustion, while electrical inefficiencies stem from outdated motor systems and suboptimal control strategies. Advanced sensor implementations, particularly those monitoring temperature profiles and gas compositions, enable real-time combustion optimization that can reduce fuel consumption by 5-15% depending on baseline conditions.

Variable frequency drives (VFDs) represent a critical upgrade component, offering energy savings of 10-30% compared to fixed-speed alternatives. These systems optimize motor operation based on process demands, eliminating energy waste during partial load conditions. The integration of VFDs with intelligent control systems further enhances efficiency by maintaining optimal kiln rotation speeds relative to material throughput and thermal conditions.

Sustainability benefits extend beyond direct energy savings. Reduced fuel consumption directly correlates to lower greenhouse gas emissions, with typical retrofits achieving CO2 reductions of 5-20%. Advanced control systems also enable the increased use of alternative fuels, including biomass and waste-derived fuels, further reducing the carbon footprint of operations. Modern sensor systems improve emissions monitoring capabilities, supporting compliance with increasingly stringent environmental regulations.

The economic case for energy efficiency retrofits is compelling, with typical payback periods ranging from 1-3 years for control system upgrades and 2-5 years for comprehensive retrofits including advanced drives and sensor networks. Life-cycle assessment studies indicate that modernized kilns can achieve 15-25% reductions in overall environmental impact across multiple sustainability indicators, including carbon footprint, resource depletion, and acidification potential.

Implementation strategies should prioritize a phased approach, beginning with non-invasive monitoring systems to establish baseline performance metrics before proceeding to more substantial mechanical and control system upgrades. This methodology minimizes production disruptions while maximizing return on investment through data-driven decision making and continuous optimization.

Energy consumption patterns in traditional rotary kiln operations reveal inefficiencies primarily in thermal energy utilization and electrical systems. Thermal losses occur through radiation, convection, and incomplete combustion, while electrical inefficiencies stem from outdated motor systems and suboptimal control strategies. Advanced sensor implementations, particularly those monitoring temperature profiles and gas compositions, enable real-time combustion optimization that can reduce fuel consumption by 5-15% depending on baseline conditions.

Variable frequency drives (VFDs) represent a critical upgrade component, offering energy savings of 10-30% compared to fixed-speed alternatives. These systems optimize motor operation based on process demands, eliminating energy waste during partial load conditions. The integration of VFDs with intelligent control systems further enhances efficiency by maintaining optimal kiln rotation speeds relative to material throughput and thermal conditions.

Sustainability benefits extend beyond direct energy savings. Reduced fuel consumption directly correlates to lower greenhouse gas emissions, with typical retrofits achieving CO2 reductions of 5-20%. Advanced control systems also enable the increased use of alternative fuels, including biomass and waste-derived fuels, further reducing the carbon footprint of operations. Modern sensor systems improve emissions monitoring capabilities, supporting compliance with increasingly stringent environmental regulations.

The economic case for energy efficiency retrofits is compelling, with typical payback periods ranging from 1-3 years for control system upgrades and 2-5 years for comprehensive retrofits including advanced drives and sensor networks. Life-cycle assessment studies indicate that modernized kilns can achieve 15-25% reductions in overall environmental impact across multiple sustainability indicators, including carbon footprint, resource depletion, and acidification potential.

Implementation strategies should prioritize a phased approach, beginning with non-invasive monitoring systems to establish baseline performance metrics before proceeding to more substantial mechanical and control system upgrades. This methodology minimizes production disruptions while maximizing return on investment through data-driven decision making and continuous optimization.

ROI Analysis for Rotary Kiln Modernization Projects

Investing in rotary kiln modernization requires thorough financial analysis to justify capital expenditure. Our comprehensive ROI analysis reveals that modernization projects typically achieve payback periods of 12-24 months, with variations based on industry sector and upgrade scope.

Energy efficiency improvements represent the most significant financial benefit, with sensor and control upgrades reducing fuel consumption by 5-15%. Modern kiln operations with optimized combustion systems and advanced thermal profiling demonstrate average energy savings of $250,000-$750,000 annually for medium-sized operations, depending on fuel costs and production volume.

Production capacity increases of 8-12% are commonly achieved through modernization, primarily through reduced downtime and optimized throughput. Advanced drive systems with variable speed capabilities enable precise rotation control, resulting in more consistent product quality and reduced rejection rates. The financial impact of these improvements typically ranges from $300,000-$900,000 annually in additional production value.

Maintenance cost reduction represents another significant ROI factor. Modern sensor systems enable predictive maintenance approaches, reducing emergency repairs by up to 60%. Facilities implementing comprehensive monitoring solutions report average maintenance savings of $150,000-$400,000 annually, with extended equipment lifespan providing additional long-term value.

Quality improvements deliver substantial financial benefits through reduced waste and higher-value products. Advanced control systems maintaining optimal thermal profiles result in more consistent product characteristics, with quality-related savings typically ranging from $200,000-$500,000 annually depending on product specifications and market positioning.

Environmental compliance benefits must also factor into ROI calculations. Modernized kilns with improved combustion control and monitoring systems reduce emissions by 10-30%, potentially avoiding regulatory penalties and enabling carbon credit opportunities in applicable markets. These benefits can contribute $50,000-$300,000 annually to the ROI equation.

Total ROI calculations must consider implementation costs, including equipment procurement, installation, commissioning, and staff training. Our analysis indicates that comprehensive modernization projects typically cost between $500,000-$2,500,000 depending on kiln size and upgrade scope. When all financial benefits are considered, most projects achieve ROI between 25-45% annually, making them highly attractive capital investments for forward-thinking manufacturers seeking competitive advantages in efficiency, quality, and sustainability.

Energy efficiency improvements represent the most significant financial benefit, with sensor and control upgrades reducing fuel consumption by 5-15%. Modern kiln operations with optimized combustion systems and advanced thermal profiling demonstrate average energy savings of $250,000-$750,000 annually for medium-sized operations, depending on fuel costs and production volume.

Production capacity increases of 8-12% are commonly achieved through modernization, primarily through reduced downtime and optimized throughput. Advanced drive systems with variable speed capabilities enable precise rotation control, resulting in more consistent product quality and reduced rejection rates. The financial impact of these improvements typically ranges from $300,000-$900,000 annually in additional production value.

Maintenance cost reduction represents another significant ROI factor. Modern sensor systems enable predictive maintenance approaches, reducing emergency repairs by up to 60%. Facilities implementing comprehensive monitoring solutions report average maintenance savings of $150,000-$400,000 annually, with extended equipment lifespan providing additional long-term value.

Quality improvements deliver substantial financial benefits through reduced waste and higher-value products. Advanced control systems maintaining optimal thermal profiles result in more consistent product characteristics, with quality-related savings typically ranging from $200,000-$500,000 annually depending on product specifications and market positioning.

Environmental compliance benefits must also factor into ROI calculations. Modernized kilns with improved combustion control and monitoring systems reduce emissions by 10-30%, potentially avoiding regulatory penalties and enabling carbon credit opportunities in applicable markets. These benefits can contribute $50,000-$300,000 annually to the ROI equation.

Total ROI calculations must consider implementation costs, including equipment procurement, installation, commissioning, and staff training. Our analysis indicates that comprehensive modernization projects typically cost between $500,000-$2,500,000 depending on kiln size and upgrade scope. When all financial benefits are considered, most projects achieve ROI between 25-45% annually, making them highly attractive capital investments for forward-thinking manufacturers seeking competitive advantages in efficiency, quality, and sustainability.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!