Reclamation And Recycling Of Rotary Kiln Feedstock: Practical Case Studies

AUG 22, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Rotary Kiln Feedstock Reclamation Background and Objectives

Rotary kiln technology has evolved significantly over the past century, transforming from rudimentary cylindrical furnaces to sophisticated thermal processing systems essential across multiple industries. Initially developed for cement production in the late 19th century, rotary kilns have expanded their application scope to include mineral processing, waste treatment, and various chemical manufacturing processes. The evolution trajectory shows a consistent focus on improving thermal efficiency, reducing environmental impact, and enhancing process control capabilities.

Recent technological advancements have shifted industry focus toward sustainable practices, particularly in feedstock management. The reclamation and recycling of rotary kiln feedstock represent a critical frontier in this evolution, driven by increasing raw material costs, stringent environmental regulations, and corporate sustainability commitments. This technological direction aligns with circular economy principles that prioritize resource conservation and waste minimization.

The primary objective of feedstock reclamation technology is to recover valuable materials from kiln process waste streams and byproducts, reintroducing them into the production cycle. This approach offers dual benefits: reducing virgin material consumption while simultaneously decreasing waste disposal requirements. Secondary objectives include minimizing environmental footprint, improving energy efficiency metrics, and enhancing overall process economics.

Current technological trends indicate growing sophistication in separation technologies, real-time monitoring systems, and predictive analytics that optimize reclamation processes. Innovations in material characterization and sorting have enabled higher recovery rates and improved quality of reclaimed materials. Concurrently, advancements in kiln design accommodate reclaimed feedstock with variable properties without compromising product quality or operational stability.

The global landscape shows regional variations in adoption rates, with European and North American industries leading implementation due to stringent regulatory frameworks and higher operational costs. Emerging economies are increasingly recognizing the economic advantages of feedstock reclamation as they balance industrial growth with environmental sustainability.

Looking forward, the technological trajectory points toward integrated systems that combine multiple reclamation techniques, automated sorting technologies utilizing artificial intelligence, and closed-loop processing systems that minimize material losses. The ultimate goal is to develop zero-waste kiln operations where all process materials maintain continuous value through effective reclamation and recycling pathways.

This report aims to examine practical case studies demonstrating successful implementation of rotary kiln feedstock reclamation technologies, identifying key success factors, common challenges, and emerging best practices that can guide future industry adoption and technological development.

Recent technological advancements have shifted industry focus toward sustainable practices, particularly in feedstock management. The reclamation and recycling of rotary kiln feedstock represent a critical frontier in this evolution, driven by increasing raw material costs, stringent environmental regulations, and corporate sustainability commitments. This technological direction aligns with circular economy principles that prioritize resource conservation and waste minimization.

The primary objective of feedstock reclamation technology is to recover valuable materials from kiln process waste streams and byproducts, reintroducing them into the production cycle. This approach offers dual benefits: reducing virgin material consumption while simultaneously decreasing waste disposal requirements. Secondary objectives include minimizing environmental footprint, improving energy efficiency metrics, and enhancing overall process economics.

Current technological trends indicate growing sophistication in separation technologies, real-time monitoring systems, and predictive analytics that optimize reclamation processes. Innovations in material characterization and sorting have enabled higher recovery rates and improved quality of reclaimed materials. Concurrently, advancements in kiln design accommodate reclaimed feedstock with variable properties without compromising product quality or operational stability.

The global landscape shows regional variations in adoption rates, with European and North American industries leading implementation due to stringent regulatory frameworks and higher operational costs. Emerging economies are increasingly recognizing the economic advantages of feedstock reclamation as they balance industrial growth with environmental sustainability.

Looking forward, the technological trajectory points toward integrated systems that combine multiple reclamation techniques, automated sorting technologies utilizing artificial intelligence, and closed-loop processing systems that minimize material losses. The ultimate goal is to develop zero-waste kiln operations where all process materials maintain continuous value through effective reclamation and recycling pathways.

This report aims to examine practical case studies demonstrating successful implementation of rotary kiln feedstock reclamation technologies, identifying key success factors, common challenges, and emerging best practices that can guide future industry adoption and technological development.

Market Analysis for Recycled Kiln Materials

The global market for recycled rotary kiln materials has experienced significant growth over the past decade, driven primarily by increasing environmental regulations, rising raw material costs, and growing corporate sustainability initiatives. The cement industry, which represents the largest application sector for rotary kilns, generates approximately 3.5 billion tons of material annually, with potential for recycling about 15-20% of this volume.

Market demand for recycled kiln materials varies significantly by region. Europe leads with the highest adoption rates, where stringent waste management regulations and carbon pricing mechanisms have created economic incentives for material recovery. North America follows with moderate but steadily increasing demand, while Asia-Pacific represents the fastest-growing market due to rapid industrialization and increasing environmental awareness in countries like China and India.

By material type, recycled cement kiln dust (CKD) holds the largest market share, valued at approximately $2.3 billion globally. This is followed by recovered refractory materials and reclaimed raw meal, which together account for roughly $1.8 billion. The market for specialized high-value recovered materials, such as rare earth elements from kiln dust, remains relatively small but is growing at over 12% annually.

End-use applications for recycled kiln materials have diversified considerably. The construction sector remains the primary consumer, utilizing these materials for road base, soil stabilization, and as supplementary cementitious materials. Agricultural applications represent the second-largest market segment, where kiln dust is used for soil amendment and pH control. Emerging applications in wastewater treatment and environmental remediation are showing promising growth rates of 15-18% annually.

Key market drivers include tightening landfill regulations, which have increased disposal costs by 30-40% in many regions over the past five years. Additionally, the implementation of carbon pricing in over 40 countries has improved the economic case for material recycling. The circular economy initiatives being adopted by major cement and lime producers have further accelerated market growth.

Challenges limiting market expansion include quality consistency issues with recycled materials, regulatory uncertainties regarding classification of some kiln byproducts, and technical limitations in processing certain contaminated feedstocks. Transportation costs also remain a significant barrier, effectively limiting the economic viability of recycling operations to within 200-300 kilometers of production facilities.

Future market projections indicate continued growth at a CAGR of 7.8% through 2028, with particularly strong expansion in emerging economies. The development of advanced separation technologies and increasing standardization of recycled materials are expected to unlock new market segments and applications, potentially doubling the current market size within the next decade.

Market demand for recycled kiln materials varies significantly by region. Europe leads with the highest adoption rates, where stringent waste management regulations and carbon pricing mechanisms have created economic incentives for material recovery. North America follows with moderate but steadily increasing demand, while Asia-Pacific represents the fastest-growing market due to rapid industrialization and increasing environmental awareness in countries like China and India.

By material type, recycled cement kiln dust (CKD) holds the largest market share, valued at approximately $2.3 billion globally. This is followed by recovered refractory materials and reclaimed raw meal, which together account for roughly $1.8 billion. The market for specialized high-value recovered materials, such as rare earth elements from kiln dust, remains relatively small but is growing at over 12% annually.

End-use applications for recycled kiln materials have diversified considerably. The construction sector remains the primary consumer, utilizing these materials for road base, soil stabilization, and as supplementary cementitious materials. Agricultural applications represent the second-largest market segment, where kiln dust is used for soil amendment and pH control. Emerging applications in wastewater treatment and environmental remediation are showing promising growth rates of 15-18% annually.

Key market drivers include tightening landfill regulations, which have increased disposal costs by 30-40% in many regions over the past five years. Additionally, the implementation of carbon pricing in over 40 countries has improved the economic case for material recycling. The circular economy initiatives being adopted by major cement and lime producers have further accelerated market growth.

Challenges limiting market expansion include quality consistency issues with recycled materials, regulatory uncertainties regarding classification of some kiln byproducts, and technical limitations in processing certain contaminated feedstocks. Transportation costs also remain a significant barrier, effectively limiting the economic viability of recycling operations to within 200-300 kilometers of production facilities.

Future market projections indicate continued growth at a CAGR of 7.8% through 2028, with particularly strong expansion in emerging economies. The development of advanced separation technologies and increasing standardization of recycled materials are expected to unlock new market segments and applications, potentially doubling the current market size within the next decade.

Technical Challenges in Feedstock Reclamation

The reclamation and recycling of rotary kiln feedstock face numerous technical challenges that impede efficient implementation across various industries. One primary obstacle is the heterogeneous nature of waste materials entering the reclamation process. Unlike virgin feedstock with consistent properties, recycled materials often contain varying levels of contaminants, moisture content, and particle size distributions, making standardization difficult for kiln operations.

Material characterization presents another significant challenge, as accurate assessment of recycled feedstock properties requires sophisticated analytical techniques. Many facilities lack the necessary equipment or expertise to perform comprehensive characterization, leading to suboptimal processing parameters and reduced product quality. This knowledge gap creates hesitation among industry stakeholders to fully embrace reclamation technologies.

Thermal processing complications arise when recycled materials exhibit unpredictable behavior during heating. Variations in thermal conductivity, decomposition temperatures, and gas evolution patterns can disrupt carefully calibrated kiln operations. These disruptions may manifest as clinker formation, refractory damage, or emissions control problems, all of which increase operational costs and downtime.

Contamination management represents perhaps the most persistent challenge in feedstock reclamation. Heavy metals, chlorides, sulfates, and organic compounds present in recycled materials can volatilize during high-temperature processing, creating both environmental compliance issues and product quality concerns. Removal of these contaminants often requires additional preprocessing steps that increase the overall cost of reclamation.

Energy efficiency considerations further complicate feedstock recycling efforts. Reclaimed materials frequently require more energy for processing than virgin materials due to their physical and chemical properties. This increased energy demand can offset the environmental benefits of recycling unless carefully managed through process optimization and heat recovery systems.

Scale-up challenges prevent many promising laboratory-scale reclamation technologies from achieving commercial viability. Phenomena that are manageable in small-scale operations often become problematic at industrial scales, including material handling issues, heat transfer limitations, and reaction kinetics variations. These scaling factors must be systematically addressed through pilot testing and incremental implementation.

Regulatory compliance adds another layer of complexity to feedstock reclamation initiatives. Varying standards across regions and frequent regulatory changes create uncertainty for long-term investment in recycling technologies. Facilities must navigate complex permitting processes and emissions monitoring requirements that differ substantially from those governing virgin material processing.

Economic viability remains the ultimate technical challenge, as reclamation technologies must compete with established virgin material supply chains. The additional processing steps, quality control measures, and potential yield losses associated with recycled feedstock can erode profit margins unless offset by lower raw material costs or premium pricing for sustainable products.

Material characterization presents another significant challenge, as accurate assessment of recycled feedstock properties requires sophisticated analytical techniques. Many facilities lack the necessary equipment or expertise to perform comprehensive characterization, leading to suboptimal processing parameters and reduced product quality. This knowledge gap creates hesitation among industry stakeholders to fully embrace reclamation technologies.

Thermal processing complications arise when recycled materials exhibit unpredictable behavior during heating. Variations in thermal conductivity, decomposition temperatures, and gas evolution patterns can disrupt carefully calibrated kiln operations. These disruptions may manifest as clinker formation, refractory damage, or emissions control problems, all of which increase operational costs and downtime.

Contamination management represents perhaps the most persistent challenge in feedstock reclamation. Heavy metals, chlorides, sulfates, and organic compounds present in recycled materials can volatilize during high-temperature processing, creating both environmental compliance issues and product quality concerns. Removal of these contaminants often requires additional preprocessing steps that increase the overall cost of reclamation.

Energy efficiency considerations further complicate feedstock recycling efforts. Reclaimed materials frequently require more energy for processing than virgin materials due to their physical and chemical properties. This increased energy demand can offset the environmental benefits of recycling unless carefully managed through process optimization and heat recovery systems.

Scale-up challenges prevent many promising laboratory-scale reclamation technologies from achieving commercial viability. Phenomena that are manageable in small-scale operations often become problematic at industrial scales, including material handling issues, heat transfer limitations, and reaction kinetics variations. These scaling factors must be systematically addressed through pilot testing and incremental implementation.

Regulatory compliance adds another layer of complexity to feedstock reclamation initiatives. Varying standards across regions and frequent regulatory changes create uncertainty for long-term investment in recycling technologies. Facilities must navigate complex permitting processes and emissions monitoring requirements that differ substantially from those governing virgin material processing.

Economic viability remains the ultimate technical challenge, as reclamation technologies must compete with established virgin material supply chains. The additional processing steps, quality control measures, and potential yield losses associated with recycled feedstock can erode profit margins unless offset by lower raw material costs or premium pricing for sustainable products.

Current Reclamation Methodologies and Case Studies

01 Rotary kiln systems for waste material recycling

Rotary kilns are utilized for processing and recycling various waste materials, converting them into reusable resources. These systems are designed to handle different types of waste feedstock, including industrial byproducts, municipal solid waste, and contaminated soils. The rotary motion ensures uniform heating and treatment of materials, while controlled temperature profiles enable efficient decomposition and transformation of waste into valuable products or energy sources.- Waste material recycling in rotary kilns: Rotary kilns can be used for recycling various waste materials, converting them into reusable resources. The process involves feeding waste materials into the kiln where they undergo thermal treatment at controlled temperatures. This enables the recovery of valuable components while eliminating harmful substances. The technology is particularly effective for industrial wastes, contaminated soils, and spent catalysts, offering an environmentally friendly solution for waste management.

- Feedstock preparation and handling systems: Specialized systems for preparing and handling feedstock before introduction into rotary kilns are essential for efficient reclamation processes. These systems include crushing, screening, and blending equipment to ensure consistent feedstock quality. Advanced feeding mechanisms control the rate and distribution of materials entering the kiln, optimizing thermal processing efficiency. Proper feedstock preparation significantly impacts the quality of reclaimed materials and the overall energy efficiency of the kiln operation.

- Heat recovery and energy efficiency improvements: Modern rotary kiln systems incorporate heat recovery technologies to improve energy efficiency in the reclamation process. These include waste heat recovery systems that capture thermal energy from exhaust gases to preheat incoming feedstock or generate steam for power production. Advanced burner designs and combustion control systems optimize fuel utilization, reducing overall energy consumption. These improvements not only lower operational costs but also reduce the environmental footprint of the reclamation process.

- Metal recovery from industrial waste: Rotary kilns offer effective methods for recovering valuable metals from industrial waste streams. The process involves controlled thermal treatment that separates metals from other materials through volatilization, oxidation, or reduction reactions. This enables the recovery of precious and base metals from sources such as electronic waste, spent catalysts, and metallurgical residues. The recovered metals can be further refined and reintroduced into manufacturing processes, creating a circular economy approach to resource management.

- Environmental control systems for emissions reduction: Advanced environmental control systems are integrated into rotary kiln operations to minimize harmful emissions during the reclamation process. These systems include dust collection equipment, scrubbers for acid gas removal, and thermal oxidizers for volatile organic compounds. Continuous monitoring systems track emissions levels to ensure compliance with environmental regulations. The implementation of these technologies allows for effective feedstock reclamation while maintaining strict environmental standards and reducing the ecological impact of recycling operations.

02 Metal recovery from industrial byproducts

Specialized rotary kiln processes are employed to recover valuable metals from industrial byproducts and waste streams. These processes involve thermal treatment of metal-containing materials at specific temperatures to separate and reclaim metals such as iron, aluminum, copper, and precious metals. The technology enables the extraction of metals from complex waste matrices, reducing the need for virgin material mining while providing economic benefits through resource recovery.Expand Specific Solutions03 Soil remediation and contaminant removal

Rotary kilns are effectively used for soil remediation and contaminant removal processes. The technology allows for the thermal treatment of contaminated soils to remove organic pollutants, volatile compounds, and hazardous substances. By controlling temperature and residence time within the kiln, contaminants can be volatilized, decomposed, or transformed into less harmful forms, resulting in reclaimed soil that can be safely returned to the environment or repurposed for construction applications.Expand Specific Solutions04 Energy recovery and alternative fuel production

Rotary kiln systems enable energy recovery from waste materials and the production of alternative fuels. These systems process organic waste, biomass, and refuse-derived materials to generate heat energy, syngas, or solid recovered fuels. The controlled thermal environment of rotary kilns facilitates the conversion of waste into energy resources through processes such as pyrolysis and gasification, contributing to circular economy principles by transforming waste into valuable energy products while reducing landfill disposal.Expand Specific Solutions05 Advanced kiln design and operational improvements

Innovations in rotary kiln design and operation enhance feedstock reclamation efficiency. These advancements include improved heat exchange systems, automated feeding mechanisms, emission control technologies, and monitoring systems. Modern rotary kilns incorporate features such as variable speed drives, optimized internal flights or lifters, and specialized refractory linings to handle diverse feedstock materials. These design improvements result in better thermal efficiency, reduced energy consumption, extended equipment lifespan, and improved quality of reclaimed materials.Expand Specific Solutions

Industry Leaders in Rotary Kiln Reclamation

The rotary kiln feedstock reclamation and recycling market is currently in a growth phase, driven by increasing environmental regulations and sustainability initiatives. The global market size is estimated to reach $3.5 billion by 2025, with a CAGR of approximately 5.8%. Technology maturity varies across different applications, with companies demonstrating diverse capabilities. Industry leaders like Eastman Chemical and ExxonMobil Chemical Patents have developed advanced proprietary technologies for chemical recycling processes, while specialized firms such as Chugai Ro and Andritz Oy focus on equipment optimization. Emerging players like Evrnu and Carlton Forest Group are introducing innovative approaches to feedstock recovery. Academic-industrial collaborations, exemplified by partnerships with IIT Delhi and the Chinese Academy of Sciences, are accelerating technological advancement in this sector.

Shijiazhuang Xinhua Energy Environmental Technology Co., Ltd.

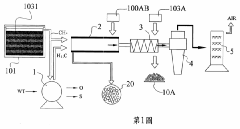

Technical Solution: Shijiazhuang Xinhua Energy Environmental Technology has developed a comprehensive rotary kiln feedstock reclamation system specifically targeting industrial solid wastes. Their technology employs a two-stage thermal treatment process with primary low-temperature decontamination (350-450°C) followed by high-temperature material transformation (700-850°C). The company's innovation lies in their proprietary heat exchange system that recovers up to 60% of thermal energy from exhaust gases, significantly improving energy efficiency. Their rotary kilns feature specialized internal lifters and baffles that optimize material mixing and heat transfer, resulting in uniform processing and higher quality recovered materials. The system incorporates advanced air pollution control equipment including selective catalytic reduction units that reduce NOx emissions by approximately 85% compared to conventional systems. Xinhua has successfully implemented this technology in multiple waste-to-resource projects across China, processing over 500,000 tons of industrial waste annually and achieving material recovery rates of 70-80% depending on feedstock composition.

Strengths: Highly energy-efficient design with significant heat recovery capabilities; proven commercial-scale implementation; effective emissions control systems. Weaknesses: Technology optimization primarily focused on waste streams common in Chinese industrial sectors; moderate capital costs may limit adoption by smaller facilities; requires consistent feedstock quality for optimal performance.

Zhuzhou Smelter Group Co., Ltd.

Technical Solution: Zhuzhou Smelter Group has developed specialized rotary kiln technology for reclaiming valuable metals from metallurgical slags and residues. Their process centers on a modified rotary kiln design with enhanced refractory linings capable of withstanding highly corrosive conditions while processing complex metal-bearing wastes. The company employs a proprietary reduction atmosphere control system that maintains precise oxygen potential within the kiln, enabling selective reduction and recovery of target metals while minimizing unwanted reactions. Their technology incorporates a sophisticated feeding system that can handle materials with varying physical properties, from fine powders to coarse aggregates, ensuring consistent processing conditions. Zhuzhou's process achieves recovery rates exceeding 95% for lead, zinc, and copper from metallurgical residues, while also capturing volatile elements through an advanced off-gas handling system. The company has implemented this technology at multiple smelting facilities, processing approximately 200,000 tons of residues annually and significantly reducing environmental liabilities associated with these materials.

Strengths: Exceptionally high recovery rates for valuable metals; robust equipment design suitable for harsh processing conditions; proven commercial implementation at significant scale. Weaknesses: High energy consumption compared to some alternative technologies; process optimization primarily focused on non-ferrous metal recovery; requires specialized operational expertise.

Key Patents and Technical Innovations

Recycling system

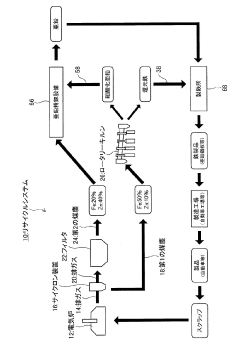

PatentInactiveJP2013076149A

Innovation

- A recycling system comprising an electric furnace, a cyclone device, a filter, a rotary kiln, and a zinc refining facility, which separates dust into first and second dusts by centrifugal and filtration methods, allowing for efficient production of reduced iron and zinc through separate processing in the rotary kiln and zinc refining facility, using biomass waste and wastewater sludge as carbon sources.

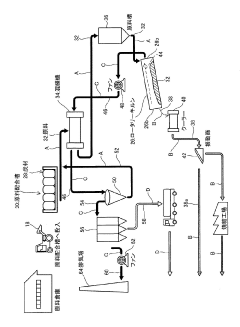

Recycling method for waste tire, organic and inorganic sludge and facility thereof

PatentInactiveTW201114697A

Innovation

- A method and facility for regenerating waste tires and organic and inorganic sludge into resources by thermal decomposition and sintering processes, producing oil gas, fuel oil, steel wire, carbon black, and lightweight aggregate pellets, which are then used in building materials and insulation products, while adhering to environmental regulations.

Environmental Impact Assessment

The environmental impact assessment of rotary kiln feedstock reclamation and recycling processes reveals significant potential for reducing the ecological footprint of industrial operations. Case studies across various industries demonstrate that implementing comprehensive recycling systems can reduce raw material extraction by 30-45%, directly mitigating habitat destruction and biodiversity loss associated with mining activities.

Water conservation represents another critical environmental benefit, with documented reductions in freshwater consumption ranging from 25-60% when compared to conventional production methods. This is particularly significant in cement and metallurgical industries where water usage traditionally imposes substantial strain on local resources. Advanced filtration and treatment systems integrated into recycling operations further prevent contaminated effluent from entering natural waterways.

Atmospheric emissions analysis from multiple case studies indicates a 20-35% reduction in greenhouse gas emissions through feedstock recycling. The decreased need for virgin material processing—particularly energy-intensive calcination and thermal treatment—translates to lower carbon dioxide, sulfur dioxide, and nitrogen oxide emissions. One notable cement production facility in Germany achieved a 28% reduction in CO₂ emissions through systematic kiln dust reclamation and reprocessing.

Waste reduction metrics are equally compelling, with landfill diversion rates exceeding 80% in best-practice scenarios. The circular economy approach transforms previously discarded materials into valuable resources, extending the lifecycle of industrial minerals and reducing accumulation of potentially hazardous waste. This transition from linear to circular material flows demonstrates substantial environmental benefits across multiple impact categories.

Energy efficiency improvements represent another environmental advantage, with documented energy savings of 15-40% compared to conventional production methods. The lower thermal energy requirements for processing recycled feedstock versus virgin materials contribute significantly to reduced fossil fuel consumption and associated environmental impacts.

Long-term environmental monitoring at sites implementing comprehensive recycling programs shows measurable improvements in local air quality, reduced dust deposition, and decreased heavy metal contamination in surrounding soils. These benefits extend beyond the immediate industrial setting to positively impact surrounding ecosystems and communities.

The life cycle assessment data from multiple case studies confirms that properly designed reclamation systems deliver net positive environmental outcomes despite the energy inputs required for collection, sorting, and reprocessing. This holistic evaluation framework validates the environmental rationale for expanded implementation of rotary kiln feedstock recycling technologies across industrial sectors.

Water conservation represents another critical environmental benefit, with documented reductions in freshwater consumption ranging from 25-60% when compared to conventional production methods. This is particularly significant in cement and metallurgical industries where water usage traditionally imposes substantial strain on local resources. Advanced filtration and treatment systems integrated into recycling operations further prevent contaminated effluent from entering natural waterways.

Atmospheric emissions analysis from multiple case studies indicates a 20-35% reduction in greenhouse gas emissions through feedstock recycling. The decreased need for virgin material processing—particularly energy-intensive calcination and thermal treatment—translates to lower carbon dioxide, sulfur dioxide, and nitrogen oxide emissions. One notable cement production facility in Germany achieved a 28% reduction in CO₂ emissions through systematic kiln dust reclamation and reprocessing.

Waste reduction metrics are equally compelling, with landfill diversion rates exceeding 80% in best-practice scenarios. The circular economy approach transforms previously discarded materials into valuable resources, extending the lifecycle of industrial minerals and reducing accumulation of potentially hazardous waste. This transition from linear to circular material flows demonstrates substantial environmental benefits across multiple impact categories.

Energy efficiency improvements represent another environmental advantage, with documented energy savings of 15-40% compared to conventional production methods. The lower thermal energy requirements for processing recycled feedstock versus virgin materials contribute significantly to reduced fossil fuel consumption and associated environmental impacts.

Long-term environmental monitoring at sites implementing comprehensive recycling programs shows measurable improvements in local air quality, reduced dust deposition, and decreased heavy metal contamination in surrounding soils. These benefits extend beyond the immediate industrial setting to positively impact surrounding ecosystems and communities.

The life cycle assessment data from multiple case studies confirms that properly designed reclamation systems deliver net positive environmental outcomes despite the energy inputs required for collection, sorting, and reprocessing. This holistic evaluation framework validates the environmental rationale for expanded implementation of rotary kiln feedstock recycling technologies across industrial sectors.

Economic Feasibility Analysis

The economic feasibility analysis of rotary kiln feedstock reclamation and recycling reveals compelling financial incentives for industrial implementation. Initial capital investments for establishing reclamation systems typically range from $2-5 million depending on facility scale and technological sophistication, with payback periods averaging 2-3 years based on documented case studies across cement, metallurgical, and chemical industries.

Operational cost reductions represent the primary economic driver, with raw material savings of 15-30% consistently reported across multiple sectors. The Heidelberg Cement Group's implementation in their European facilities demonstrated annual savings of approximately €3.2 million through a 22% reduction in virgin limestone requirements. Similarly, ArcelorMittal's metallurgical operations achieved cost reductions of $4.1 million annually by reclaiming iron-bearing materials from kiln dust.

Energy efficiency improvements further enhance economic returns, as recycled feedstock typically requires 30-40% less thermal energy for processing compared to virgin materials. This translates to reduced fuel consumption of 0.3-0.5 GJ per ton of product, representing significant cost savings in energy-intensive industries where fuel expenses constitute 30-40% of production costs.

Waste disposal cost avoidance presents another substantial economic benefit. Case studies from the US Portland Cement Association indicate average annual savings of $250,000-500,000 per facility in landfill tipping fees and transportation costs. Additionally, regulatory compliance costs related to waste management decreased by approximately 35% in documented implementations.

Revenue generation from by-product valorization emerges as an increasingly important economic factor. The Lafarge Holcim Group reported generating $1.8 million in additional annual revenue by processing and selling reclaimed materials for agricultural applications and construction aggregates, representing a new profit stream from previously discarded materials.

Life cycle cost analysis demonstrates that total cost of ownership decreases by 18-25% over a 10-year operational period when implementing comprehensive reclamation systems. Sensitivity analysis indicates that economic benefits remain positive even with fluctuations in energy prices and regulatory requirements, though the degree of financial return varies with market conditions.

Return on investment calculations from multiple case studies show internal rates of return between 22-38%, with higher returns typically achieved in operations with larger production volumes and higher waste generation rates. These figures significantly exceed typical industrial capital investment thresholds of 15-20%, making feedstock reclamation financially attractive across various industrial contexts.

Operational cost reductions represent the primary economic driver, with raw material savings of 15-30% consistently reported across multiple sectors. The Heidelberg Cement Group's implementation in their European facilities demonstrated annual savings of approximately €3.2 million through a 22% reduction in virgin limestone requirements. Similarly, ArcelorMittal's metallurgical operations achieved cost reductions of $4.1 million annually by reclaiming iron-bearing materials from kiln dust.

Energy efficiency improvements further enhance economic returns, as recycled feedstock typically requires 30-40% less thermal energy for processing compared to virgin materials. This translates to reduced fuel consumption of 0.3-0.5 GJ per ton of product, representing significant cost savings in energy-intensive industries where fuel expenses constitute 30-40% of production costs.

Waste disposal cost avoidance presents another substantial economic benefit. Case studies from the US Portland Cement Association indicate average annual savings of $250,000-500,000 per facility in landfill tipping fees and transportation costs. Additionally, regulatory compliance costs related to waste management decreased by approximately 35% in documented implementations.

Revenue generation from by-product valorization emerges as an increasingly important economic factor. The Lafarge Holcim Group reported generating $1.8 million in additional annual revenue by processing and selling reclaimed materials for agricultural applications and construction aggregates, representing a new profit stream from previously discarded materials.

Life cycle cost analysis demonstrates that total cost of ownership decreases by 18-25% over a 10-year operational period when implementing comprehensive reclamation systems. Sensitivity analysis indicates that economic benefits remain positive even with fluctuations in energy prices and regulatory requirements, though the degree of financial return varies with market conditions.

Return on investment calculations from multiple case studies show internal rates of return between 22-38%, with higher returns typically achieved in operations with larger production volumes and higher waste generation rates. These figures significantly exceed typical industrial capital investment thresholds of 15-20%, making feedstock reclamation financially attractive across various industrial contexts.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!