How To Perform Thermal Profiling On A Rotary Kiln

AUG 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Rotary Kiln Thermal Profiling Background and Objectives

Thermal profiling of rotary kilns has evolved significantly over the past several decades, transitioning from rudimentary temperature measurement techniques to sophisticated monitoring systems. Initially, thermal assessment relied on basic thermocouples and visual inspections, which provided limited data points and required kiln shutdowns for comprehensive evaluations. The advancement of infrared technology in the 1970s marked a pivotal shift, enabling continuous temperature monitoring across the kiln shell without operational interruptions.

The evolution continued with the integration of digital technologies in the 1990s, allowing for real-time data collection and analysis. Modern thermal profiling systems now incorporate multiple measurement technologies, including infrared scanners, thermal imaging cameras, and wireless sensor networks, creating comprehensive thermal maps of rotary kilns during operation.

Current technological trends point toward increased automation, enhanced data analytics capabilities, and the integration of artificial intelligence for predictive maintenance. The industry is moving toward systems that not only measure temperatures but also interpret thermal patterns to identify potential issues before they escalate into critical failures.

The primary objective of rotary kiln thermal profiling is to optimize operational efficiency while extending equipment lifespan. By accurately mapping temperature distributions, operators can identify hotspots, refractory damage, and coating irregularities that may compromise kiln integrity. This proactive approach to thermal monitoring enables timely interventions, reducing unplanned downtime and associated production losses.

Additional objectives include energy conservation through optimized combustion processes, quality control of final products by maintaining ideal thermal conditions, and compliance with increasingly stringent environmental regulations by ensuring complete combustion and minimizing emissions.

In cement production specifically, thermal profiling aims to maintain optimal clinker formation temperatures while preventing shell overheating. For industries utilizing rotary kilns in calcination processes, precise temperature control ensures proper chemical reactions while protecting the mechanical integrity of the equipment.

The technological goals for advancing thermal profiling include developing more accurate, durable, and cost-effective measurement systems capable of withstanding the harsh environments typical of rotary kiln operations. Research efforts are focused on creating comprehensive monitoring solutions that integrate with broader plant management systems, providing actionable insights rather than merely temperature data.

As industrial processes become increasingly automated, thermal profiling technologies are expected to evolve toward fully integrated systems that autonomously adjust operational parameters based on real-time thermal analysis, representing the next frontier in rotary kiln optimization.

The evolution continued with the integration of digital technologies in the 1990s, allowing for real-time data collection and analysis. Modern thermal profiling systems now incorporate multiple measurement technologies, including infrared scanners, thermal imaging cameras, and wireless sensor networks, creating comprehensive thermal maps of rotary kilns during operation.

Current technological trends point toward increased automation, enhanced data analytics capabilities, and the integration of artificial intelligence for predictive maintenance. The industry is moving toward systems that not only measure temperatures but also interpret thermal patterns to identify potential issues before they escalate into critical failures.

The primary objective of rotary kiln thermal profiling is to optimize operational efficiency while extending equipment lifespan. By accurately mapping temperature distributions, operators can identify hotspots, refractory damage, and coating irregularities that may compromise kiln integrity. This proactive approach to thermal monitoring enables timely interventions, reducing unplanned downtime and associated production losses.

Additional objectives include energy conservation through optimized combustion processes, quality control of final products by maintaining ideal thermal conditions, and compliance with increasingly stringent environmental regulations by ensuring complete combustion and minimizing emissions.

In cement production specifically, thermal profiling aims to maintain optimal clinker formation temperatures while preventing shell overheating. For industries utilizing rotary kilns in calcination processes, precise temperature control ensures proper chemical reactions while protecting the mechanical integrity of the equipment.

The technological goals for advancing thermal profiling include developing more accurate, durable, and cost-effective measurement systems capable of withstanding the harsh environments typical of rotary kiln operations. Research efforts are focused on creating comprehensive monitoring solutions that integrate with broader plant management systems, providing actionable insights rather than merely temperature data.

As industrial processes become increasingly automated, thermal profiling technologies are expected to evolve toward fully integrated systems that autonomously adjust operational parameters based on real-time thermal analysis, representing the next frontier in rotary kiln optimization.

Industrial Applications and Market Demand Analysis

Thermal profiling in rotary kilns represents a critical process monitoring technology across multiple industries, with cement manufacturing, mineral processing, and waste incineration leading adoption rates. The global rotary kiln market was valued at $7.2 billion in 2022 and is projected to reach $9.8 billion by 2028, driven significantly by increasing demand for precise thermal control systems. Within this market, thermal profiling equipment and services constitute approximately $650 million, with annual growth rates exceeding 6.5%.

The cement industry remains the largest application sector, accounting for nearly 42% of thermal profiling implementations. As environmental regulations tighten globally, particularly in Europe and North America, demand for advanced thermal monitoring solutions has surged to ensure compliance with emissions standards while optimizing energy efficiency. The mineral processing sector follows closely at 28% market share, where precise temperature control directly impacts product quality and operational costs.

Customer needs analysis reveals three primary market drivers: energy efficiency optimization, product quality consistency, and regulatory compliance. Energy costs typically represent 30-40% of operational expenses in kiln-dependent industries, making efficiency improvements through accurate thermal profiling a significant economic incentive. Studies indicate that properly implemented thermal profiling systems can reduce energy consumption by 8-15% while extending refractory life by up to 30%.

Emerging markets, particularly in Asia-Pacific and Latin America, show accelerating adoption rates as industrialization continues and environmental standards evolve. China alone has seen a 22% increase in advanced thermal profiling system installations between 2020-2023, primarily in its expansive cement manufacturing sector.

The waste-to-energy sector represents the fastest-growing application segment, with 11.3% annual growth in thermal profiling technology adoption. This trend aligns with global sustainability initiatives and circular economy principles, creating new market opportunities for specialized high-temperature monitoring solutions capable of withstanding particularly harsh operating environments.

Customer feedback indicates growing demand for real-time monitoring capabilities, wireless data transmission, and integration with plant-wide control systems. The ability to provide predictive maintenance insights through thermal data analysis has emerged as a key differentiator among solution providers, with 76% of surveyed plant managers citing this capability as "very important" or "critical" in purchasing decisions.

The cement industry remains the largest application sector, accounting for nearly 42% of thermal profiling implementations. As environmental regulations tighten globally, particularly in Europe and North America, demand for advanced thermal monitoring solutions has surged to ensure compliance with emissions standards while optimizing energy efficiency. The mineral processing sector follows closely at 28% market share, where precise temperature control directly impacts product quality and operational costs.

Customer needs analysis reveals three primary market drivers: energy efficiency optimization, product quality consistency, and regulatory compliance. Energy costs typically represent 30-40% of operational expenses in kiln-dependent industries, making efficiency improvements through accurate thermal profiling a significant economic incentive. Studies indicate that properly implemented thermal profiling systems can reduce energy consumption by 8-15% while extending refractory life by up to 30%.

Emerging markets, particularly in Asia-Pacific and Latin America, show accelerating adoption rates as industrialization continues and environmental standards evolve. China alone has seen a 22% increase in advanced thermal profiling system installations between 2020-2023, primarily in its expansive cement manufacturing sector.

The waste-to-energy sector represents the fastest-growing application segment, with 11.3% annual growth in thermal profiling technology adoption. This trend aligns with global sustainability initiatives and circular economy principles, creating new market opportunities for specialized high-temperature monitoring solutions capable of withstanding particularly harsh operating environments.

Customer feedback indicates growing demand for real-time monitoring capabilities, wireless data transmission, and integration with plant-wide control systems. The ability to provide predictive maintenance insights through thermal data analysis has emerged as a key differentiator among solution providers, with 76% of surveyed plant managers citing this capability as "very important" or "critical" in purchasing decisions.

Current Thermal Profiling Technologies and Limitations

Thermal profiling in rotary kilns currently employs several established technologies, each with specific capabilities and limitations. Contact measurement systems, including thermocouples and resistance temperature detectors (RTDs), provide direct temperature readings at specific points. While these offer high accuracy (±1-2°C) and reliability at relatively low cost, they only capture data at fixed locations and suffer from wear due to the harsh kiln environment, requiring frequent maintenance and replacement.

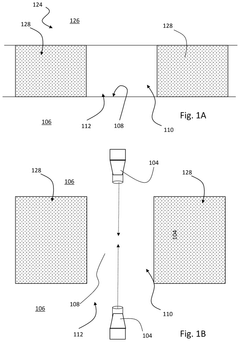

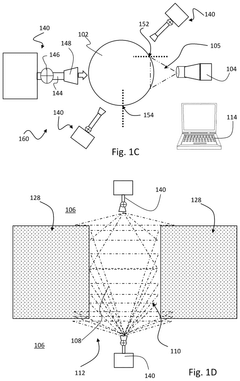

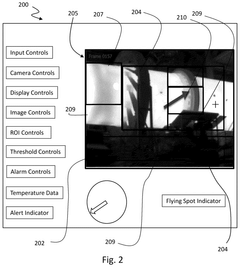

Non-contact infrared thermometry has gained significant traction, utilizing pyrometers and infrared cameras to measure surface temperatures without physical contact. These systems can scan larger areas and operate continuously without degradation from the kiln's abrasive environment. However, they face challenges with accuracy due to varying emissivity of materials, dust interference, and line-of-sight requirements. Advanced models with spectral filtering and automatic emissivity compensation improve performance but at substantially higher costs.

Thermal imaging cameras represent the current state-of-the-art, providing comprehensive temperature distribution visualization across the kiln surface. These systems generate detailed thermal maps that help identify hotspots, refractory damage, and process inefficiencies. Despite their advantages, thermal cameras require significant expertise for proper calibration and interpretation, and their high cost (ranging from $20,000 to $100,000) limits widespread adoption in smaller operations.

Fiber optic distributed temperature sensing (DTS) has emerged as an innovative solution, using optical fibers to measure temperatures continuously along the kiln length. This technology offers excellent spatial resolution and can withstand harsh environments when properly protected. However, installation complexities and high initial investment costs restrict its application primarily to new kiln installations or major retrofits.

Acoustic pyrometry, measuring temperature by analyzing sound wave propagation through gases, provides non-intrusive average temperature readings across kiln sections. While valuable for overall process monitoring, this technology lacks the spatial resolution needed for detailed thermal profiling and requires complex signal processing algorithms.

A significant limitation across all current technologies is data integration and real-time analysis. Most systems operate as standalone units with proprietary software, complicating the creation of comprehensive thermal profiles that combine multiple measurement techniques. Additionally, the dynamic nature of rotary kilns—with constant material movement and changing process conditions—makes continuous, accurate profiling challenging even with advanced technologies.

The harsh operating environment of rotary kilns, with temperatures exceeding 1400°C, abrasive materials, and dusty conditions, continues to pose significant challenges for sensor durability and measurement accuracy. This necessitates frequent recalibration and maintenance, increasing operational costs and potentially introducing measurement inconsistencies.

Non-contact infrared thermometry has gained significant traction, utilizing pyrometers and infrared cameras to measure surface temperatures without physical contact. These systems can scan larger areas and operate continuously without degradation from the kiln's abrasive environment. However, they face challenges with accuracy due to varying emissivity of materials, dust interference, and line-of-sight requirements. Advanced models with spectral filtering and automatic emissivity compensation improve performance but at substantially higher costs.

Thermal imaging cameras represent the current state-of-the-art, providing comprehensive temperature distribution visualization across the kiln surface. These systems generate detailed thermal maps that help identify hotspots, refractory damage, and process inefficiencies. Despite their advantages, thermal cameras require significant expertise for proper calibration and interpretation, and their high cost (ranging from $20,000 to $100,000) limits widespread adoption in smaller operations.

Fiber optic distributed temperature sensing (DTS) has emerged as an innovative solution, using optical fibers to measure temperatures continuously along the kiln length. This technology offers excellent spatial resolution and can withstand harsh environments when properly protected. However, installation complexities and high initial investment costs restrict its application primarily to new kiln installations or major retrofits.

Acoustic pyrometry, measuring temperature by analyzing sound wave propagation through gases, provides non-intrusive average temperature readings across kiln sections. While valuable for overall process monitoring, this technology lacks the spatial resolution needed for detailed thermal profiling and requires complex signal processing algorithms.

A significant limitation across all current technologies is data integration and real-time analysis. Most systems operate as standalone units with proprietary software, complicating the creation of comprehensive thermal profiles that combine multiple measurement techniques. Additionally, the dynamic nature of rotary kilns—with constant material movement and changing process conditions—makes continuous, accurate profiling challenging even with advanced technologies.

The harsh operating environment of rotary kilns, with temperatures exceeding 1400°C, abrasive materials, and dusty conditions, continues to pose significant challenges for sensor durability and measurement accuracy. This necessitates frequent recalibration and maintenance, increasing operational costs and potentially introducing measurement inconsistencies.

Contemporary Thermal Profiling Methodologies

01 Temperature monitoring and control systems

Advanced monitoring systems are employed to track and control the thermal profile within rotary kilns. These systems utilize sensors and measurement devices to collect real-time temperature data at various points along the kiln. The collected data enables precise control of the thermal conditions, ensuring optimal processing conditions and energy efficiency. Control algorithms can adjust heating elements and cooling systems to maintain the desired thermal profile throughout the kiln's operation.- Temperature monitoring and control systems: Advanced monitoring systems are employed to track and control the thermal profile within rotary kilns. These systems utilize various sensors and measurement devices to collect real-time temperature data across different zones of the kiln. The collected data enables precise control of the heating process, ensuring optimal thermal conditions for material processing. Automated control mechanisms adjust fuel input, airflow, and rotation speed based on the monitored thermal profile to maintain desired temperature gradients throughout the kiln.

- Thermal zone optimization techniques: Rotary kilns are designed with distinct thermal zones to achieve specific processing objectives. These zones include preheating, calcination, sintering, and cooling sections, each with carefully controlled temperature profiles. Optimization techniques focus on establishing ideal temperature gradients between zones to maximize energy efficiency and product quality. Methods include strategic placement of burners, internal heat exchangers, and specialized refractory materials to create and maintain the desired thermal profile throughout the kiln length.

- Refractory design and thermal insulation: The design and selection of refractory materials significantly impact the thermal profile of rotary kilns. Advanced refractory systems incorporate multiple layers with varying thermal properties to optimize heat retention and distribution. Specialized insulation materials are strategically placed to reduce heat loss through the kiln shell while maintaining structural integrity at high temperatures. Innovative refractory designs include features such as thermal barriers, heat-reflective coatings, and composite materials that enhance temperature stability and extend equipment lifespan.

- Computational modeling of thermal profiles: Computational fluid dynamics (CFD) and finite element analysis (FEA) are employed to model and predict thermal profiles within rotary kilns. These simulation techniques account for complex heat transfer mechanisms including conduction, convection, and radiation. Advanced models incorporate material properties, kiln geometry, rotation dynamics, and combustion characteristics to generate accurate thermal profile predictions. Computational modeling enables optimization of kiln design and operating parameters without costly physical testing, facilitating improvements in energy efficiency and process control.

- Burner technology and flame characteristics: Specialized burner systems are critical for establishing and maintaining desired thermal profiles in rotary kilns. Advanced burner technologies feature adjustable flame characteristics, including length, shape, and temperature distribution. Multi-fuel burners allow for flexible operation and optimization of the combustion process to achieve specific thermal requirements. Flame positioning and angle can be precisely controlled to target specific zones within the kiln, enabling tailored heat distribution patterns that enhance processing efficiency and product quality.

02 Thermal zone optimization techniques

Rotary kilns are designed with distinct thermal zones to achieve specific processing objectives. These zones include preheating, calcination, sintering, and cooling sections, each with carefully controlled temperature profiles. Optimization techniques focus on adjusting the length, temperature, and transition between these zones to enhance product quality and process efficiency. Advanced mathematical models are used to predict and optimize the thermal behavior within each zone based on material properties and desired outcomes.Expand Specific Solutions03 Burner configuration and fuel efficiency

The arrangement and design of burners significantly impact the thermal profile in rotary kilns. Modern kiln systems employ strategically positioned burners with adjustable flame characteristics to create precise temperature distributions. Innovations in burner technology focus on improving fuel efficiency, reducing emissions, and enabling flexible operation with various fuel types. Advanced combustion control systems can dynamically adjust burner parameters to maintain optimal thermal conditions despite variations in feed material or production requirements.Expand Specific Solutions04 Material flow and residence time management

The movement of material through the rotary kiln directly affects its exposure to the thermal profile. Techniques for controlling material flow include adjusting kiln rotation speed, internal dam rings, lifters, and slope angle. These parameters determine the residence time of materials in different thermal zones, ensuring proper heat transfer and reaction completion. Advanced systems can dynamically adjust material flow based on real-time thermal profile data to optimize processing conditions for varying material characteristics.Expand Specific Solutions05 Structural design innovations for thermal efficiency

Innovative structural designs enhance thermal efficiency in rotary kilns. These include improved refractory linings that reduce heat loss, specialized heat shields, and thermal insulation systems. Some designs incorporate heat recovery systems that capture and reuse waste heat from the kiln shell or exhaust gases. Advanced kiln shell designs with cooling systems help maintain structural integrity while optimizing the internal thermal profile. These structural innovations contribute to energy savings, extended equipment life, and more precise thermal control.Expand Specific Solutions

Leading Manufacturers and Technology Providers

Thermal profiling in rotary kilns is currently in a mature development phase, with a growing market driven by industrial efficiency demands. The technology has reached significant maturity, evidenced by sophisticated solutions from established players like KHD Humboldt Wedag GmbH and Chugai Ro Co., Ltd., who offer advanced thermal monitoring systems. Chinese entities including Zhongye Changtian International Engineering and academic institutions like Zhejiang University are making substantial contributions to the field. Western companies such as Quantum IR Technologies LLC are advancing the technology through infrared sensing innovations. The competitive landscape features a mix of traditional industrial equipment manufacturers and specialized thermal technology providers, with increasing integration of automation and data analytics capabilities to enhance kiln performance monitoring and optimization.

IBU-tec advanced materials AG

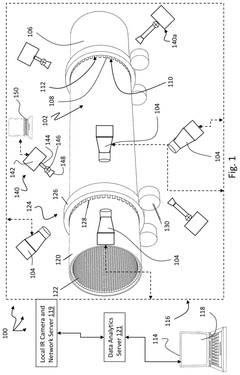

Technical Solution: IBU-tec has developed a comprehensive thermal profiling system for rotary kilns that combines multiple temperature measurement technologies. Their approach utilizes a network of fixed thermocouples installed at strategic points along the kiln shell, complemented by advanced infrared thermal imaging cameras that continuously scan the kiln's rotating surface. The system incorporates proprietary algorithms that compensate for rotational effects and environmental factors to create accurate thermal maps. IBU-tec's solution includes specialized software that processes real-time temperature data to generate 3D thermal profiles, allowing operators to identify hotspots, refractory damage, and coating conditions. Their technology enables continuous monitoring without production interruptions, with measurement accuracy within ±2°C even at temperatures exceeding 1400°C.

Strengths: Exceptional precision in high-temperature environments with minimal production disruption. Their integrated approach combines multiple measurement technologies for comprehensive profiling. Weaknesses: The system requires significant initial investment and specialized technical expertise for installation and calibration.

Lhoist Recherche et Développement SA

Technical Solution: Lhoist has pioneered a fiber-optic based thermal profiling system specifically designed for rotary kilns in limestone and dolomite processing. Their technology embeds specialized high-temperature resistant fiber optic sensors within the refractory lining that can withstand temperatures up to 1600°C. These sensors transmit real-time temperature data from multiple points inside the kiln, providing direct measurement of internal process conditions rather than just external shell temperatures. The system includes proprietary signal processing algorithms that filter out noise caused by material movement and combustion fluctuations. Lhoist's approach enables operators to visualize temperature gradients across different zones of the kiln and correlates thermal data with material quality parameters, allowing for precise process optimization and energy efficiency improvements.

Strengths: Direct internal temperature measurement provides more accurate process control data than external-only systems. The fiber optic technology is immune to electromagnetic interference common in industrial environments. Weaknesses: Sensor replacement requires kiln shutdown, and the system has higher maintenance requirements compared to non-contact methods.

Critical Sensor Technologies and Data Acquisition Systems

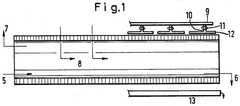

Rotary kiln brick layer thermal monitoring systems

PatentActiveUS12352499B2

Innovation

- A system comprising infrared imaging sensors and a computing system that monitors brick thickness and temperature variations by correlating infrared data with brick thickness, using machine learning to predict brick degradation and control a cooling system to mitigate hotspots.

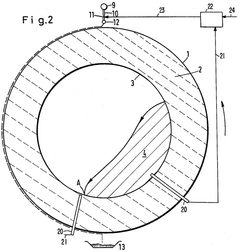

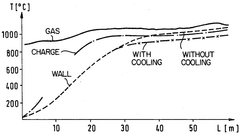

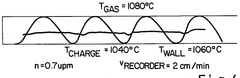

Process of thermally treating bulk materials in a rotary kiln

PatentInactiveUS4391583A

Innovation

- Implementing a controlled cooling system where sections of the rotary kiln are cooled to maintain the inside surface temperature up to 50°C below the charge temperature, using water sprinkling or cooling pipes to prevent crust formation, with automatic initiation during temperature fluctuations or power failures.

Energy Efficiency and Optimization Opportunities

Thermal profiling of rotary kilns reveals significant opportunities for energy efficiency improvements and operational optimization. The energy consumption in rotary kilns, particularly in cement and mineral processing industries, accounts for approximately 30-40% of total production costs. Implementing targeted optimization strategies based on accurate thermal profiles can reduce energy consumption by 10-15% while maintaining or improving product quality.

Advanced thermal mapping techniques enable identification of heat loss hotspots, which typically occur at the kiln shell, ends, and through exhaust gases. By addressing these specific areas, facilities can achieve substantial energy savings. For instance, improving refractory lining based on thermal profile data can reduce radiation losses by up to 8%, translating to significant cost reductions in large-scale operations.

Combustion optimization represents another critical opportunity revealed through thermal profiling. Analysis of flame characteristics and temperature distribution allows for fine-tuning of fuel-air ratios, burner positioning, and fuel selection. Studies indicate that optimized combustion parameters can improve thermal efficiency by 5-7% while simultaneously reducing harmful emissions such as NOx and CO2.

Process control enhancements derived from continuous thermal monitoring enable real-time adjustments to operational parameters. Implementation of advanced control systems utilizing thermal profile data has demonstrated productivity increases of 3-5% alongside energy savings of 4-6% across various industrial applications. These systems can automatically adjust rotation speed, feed rate, and burner settings to maintain optimal thermal conditions throughout production cycles.

Heat recovery systems present substantial optimization opportunities when designed based on comprehensive thermal profiles. Waste heat from kiln exhaust gases, typically ranging from 250-400°C, can be captured for preheating raw materials, generating electricity, or supporting other facility processes. Well-designed heat recovery systems can reclaim 20-30% of otherwise wasted thermal energy, significantly improving overall plant efficiency.

Alternative fuel utilization becomes more viable with precise thermal profiling capabilities. Detailed temperature mapping allows operators to safely introduce alternative fuels such as biomass, waste-derived fuels, or hydrogen blends while maintaining process stability. This transition can reduce both energy costs and carbon footprint, with some facilities reporting fossil fuel replacement rates of up to 60% without compromising product quality.

Advanced thermal mapping techniques enable identification of heat loss hotspots, which typically occur at the kiln shell, ends, and through exhaust gases. By addressing these specific areas, facilities can achieve substantial energy savings. For instance, improving refractory lining based on thermal profile data can reduce radiation losses by up to 8%, translating to significant cost reductions in large-scale operations.

Combustion optimization represents another critical opportunity revealed through thermal profiling. Analysis of flame characteristics and temperature distribution allows for fine-tuning of fuel-air ratios, burner positioning, and fuel selection. Studies indicate that optimized combustion parameters can improve thermal efficiency by 5-7% while simultaneously reducing harmful emissions such as NOx and CO2.

Process control enhancements derived from continuous thermal monitoring enable real-time adjustments to operational parameters. Implementation of advanced control systems utilizing thermal profile data has demonstrated productivity increases of 3-5% alongside energy savings of 4-6% across various industrial applications. These systems can automatically adjust rotation speed, feed rate, and burner settings to maintain optimal thermal conditions throughout production cycles.

Heat recovery systems present substantial optimization opportunities when designed based on comprehensive thermal profiles. Waste heat from kiln exhaust gases, typically ranging from 250-400°C, can be captured for preheating raw materials, generating electricity, or supporting other facility processes. Well-designed heat recovery systems can reclaim 20-30% of otherwise wasted thermal energy, significantly improving overall plant efficiency.

Alternative fuel utilization becomes more viable with precise thermal profiling capabilities. Detailed temperature mapping allows operators to safely introduce alternative fuels such as biomass, waste-derived fuels, or hydrogen blends while maintaining process stability. This transition can reduce both energy costs and carbon footprint, with some facilities reporting fossil fuel replacement rates of up to 60% without compromising product quality.

Safety Standards and Environmental Compliance

Thermal profiling operations in rotary kilns must adhere to stringent safety standards and environmental regulations to ensure worker protection and minimize ecological impact. The Occupational Safety and Health Administration (OSHA) mandates comprehensive safety protocols for high-temperature industrial environments, including proper personal protective equipment (PPE) such as heat-resistant clothing, face shields, and respiratory protection when working near kiln openings or handling thermal profiling equipment.

International standards like ISO 13577 specifically address safety requirements for industrial furnaces and associated thermal processing equipment, providing guidelines for thermal profiling activities. These standards emphasize the importance of proper training for personnel involved in thermal measurements and the implementation of lockout/tagout procedures during equipment installation or maintenance.

Environmental compliance for rotary kiln operations is governed by regulations such as the Clean Air Act in the United States and similar legislation internationally. These regulations establish emission limits for particulate matter, nitrogen oxides (NOx), sulfur dioxide (SO2), and other pollutants. Thermal profiling activities must be conducted without compromising the kiln's emission control systems or causing additional environmental impact.

Modern thermal profiling systems incorporate safety features such as automatic data transmission to reduce the need for personnel exposure to high-temperature zones. Wireless technologies enable remote monitoring, significantly decreasing safety risks associated with manual temperature measurements. Additionally, thermal imaging cameras allow for external temperature assessment without direct contact with the kiln surface.

Risk assessment protocols must be established before conducting thermal profiling, identifying potential hazards such as extreme heat exposure, moving mechanical parts, and toxic gas emissions. Emergency response procedures should be clearly documented and practiced regularly by all personnel involved in thermal profiling operations.

Environmental management systems compliant with ISO 14001 standards are increasingly being implemented in facilities utilizing rotary kilns. These systems require continuous monitoring of environmental impacts and the establishment of improvement targets. Thermal profiling activities should be integrated into these management systems to ensure they contribute to overall environmental performance objectives.

Documentation and record-keeping are essential components of compliance with both safety and environmental regulations. All thermal profiling activities should be logged, including equipment calibration records, measurement results, and any incidents or anomalies observed during the process. This documentation serves as evidence of compliance during regulatory inspections and provides valuable data for continuous improvement initiatives.

International standards like ISO 13577 specifically address safety requirements for industrial furnaces and associated thermal processing equipment, providing guidelines for thermal profiling activities. These standards emphasize the importance of proper training for personnel involved in thermal measurements and the implementation of lockout/tagout procedures during equipment installation or maintenance.

Environmental compliance for rotary kiln operations is governed by regulations such as the Clean Air Act in the United States and similar legislation internationally. These regulations establish emission limits for particulate matter, nitrogen oxides (NOx), sulfur dioxide (SO2), and other pollutants. Thermal profiling activities must be conducted without compromising the kiln's emission control systems or causing additional environmental impact.

Modern thermal profiling systems incorporate safety features such as automatic data transmission to reduce the need for personnel exposure to high-temperature zones. Wireless technologies enable remote monitoring, significantly decreasing safety risks associated with manual temperature measurements. Additionally, thermal imaging cameras allow for external temperature assessment without direct contact with the kiln surface.

Risk assessment protocols must be established before conducting thermal profiling, identifying potential hazards such as extreme heat exposure, moving mechanical parts, and toxic gas emissions. Emergency response procedures should be clearly documented and practiced regularly by all personnel involved in thermal profiling operations.

Environmental management systems compliant with ISO 14001 standards are increasingly being implemented in facilities utilizing rotary kilns. These systems require continuous monitoring of environmental impacts and the establishment of improvement targets. Thermal profiling activities should be integrated into these management systems to ensure they contribute to overall environmental performance objectives.

Documentation and record-keeping are essential components of compliance with both safety and environmental regulations. All thermal profiling activities should be logged, including equipment calibration records, measurement results, and any incidents or anomalies observed during the process. This documentation serves as evidence of compliance during regulatory inspections and provides valuable data for continuous improvement initiatives.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!