Rotary Kiln Maintenance Checklist: Shell, Drive, And Bearing Inspections

AUG 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Rotary Kiln Technology Evolution and Maintenance Objectives

Rotary kilns have evolved significantly since their inception in the late 19th century, transforming from simple cylindrical structures to sophisticated industrial equipment essential in cement, lime, and mineral processing industries. The early designs featured basic rotating cylinders with minimal instrumentation and manual control systems, requiring frequent maintenance interventions and experiencing substantial downtime. Technological advancements in materials science during the mid-20th century introduced heat-resistant alloys and improved refractory materials, significantly extending operational lifespans and thermal efficiency.

The 1970s marked a pivotal shift with the integration of automated monitoring systems, allowing for real-time tracking of critical parameters such as shell temperature, rotational speed, and bearing conditions. This era introduced predictive maintenance concepts, gradually replacing reactive approaches. By the 1990s, digital control systems and computerized maintenance management systems (CMMS) became standard, enabling more sophisticated maintenance scheduling and performance optimization.

Modern rotary kilns incorporate advanced sensor technologies, including thermal imaging cameras, vibration analyzers, and ultrasonic thickness gauges, facilitating comprehensive condition monitoring without operational interruption. The maintenance philosophy has evolved from time-based schedules to condition-based approaches, significantly reducing unnecessary interventions while preventing catastrophic failures through early detection of developing issues.

The primary maintenance objectives for contemporary rotary kilns focus on maximizing operational availability while minimizing lifecycle costs. Shell integrity maintenance aims to prevent deformation, cracking, and excessive wear that could compromise structural stability. Drive system maintenance targets the elimination of mechanical inefficiencies and power transmission losses that increase energy consumption and reduce production capacity.

Bearing inspection protocols have evolved to detect misalignment, lubrication issues, and wear patterns before they progress to failure states. Modern maintenance strategies increasingly incorporate non-destructive testing methods such as ultrasonic testing, magnetic particle inspection, and radiographic examination to assess component integrity without disassembly.

The integration of Industry 4.0 technologies represents the latest evolution in rotary kiln maintenance, with IoT sensors providing continuous data streams for machine learning algorithms to identify subtle changes in operational parameters that precede equipment failure. Digital twins and simulation models now enable maintenance engineers to predict the impact of different operational scenarios and maintenance interventions before implementation.

The maintenance objectives have expanded beyond mere equipment reliability to encompass energy efficiency, emissions reduction, and production quality consistency. This holistic approach recognizes the interconnected nature of mechanical integrity, thermal efficiency, and product quality in rotary kiln operations, driving the development of increasingly sophisticated maintenance protocols and technologies.

The 1970s marked a pivotal shift with the integration of automated monitoring systems, allowing for real-time tracking of critical parameters such as shell temperature, rotational speed, and bearing conditions. This era introduced predictive maintenance concepts, gradually replacing reactive approaches. By the 1990s, digital control systems and computerized maintenance management systems (CMMS) became standard, enabling more sophisticated maintenance scheduling and performance optimization.

Modern rotary kilns incorporate advanced sensor technologies, including thermal imaging cameras, vibration analyzers, and ultrasonic thickness gauges, facilitating comprehensive condition monitoring without operational interruption. The maintenance philosophy has evolved from time-based schedules to condition-based approaches, significantly reducing unnecessary interventions while preventing catastrophic failures through early detection of developing issues.

The primary maintenance objectives for contemporary rotary kilns focus on maximizing operational availability while minimizing lifecycle costs. Shell integrity maintenance aims to prevent deformation, cracking, and excessive wear that could compromise structural stability. Drive system maintenance targets the elimination of mechanical inefficiencies and power transmission losses that increase energy consumption and reduce production capacity.

Bearing inspection protocols have evolved to detect misalignment, lubrication issues, and wear patterns before they progress to failure states. Modern maintenance strategies increasingly incorporate non-destructive testing methods such as ultrasonic testing, magnetic particle inspection, and radiographic examination to assess component integrity without disassembly.

The integration of Industry 4.0 technologies represents the latest evolution in rotary kiln maintenance, with IoT sensors providing continuous data streams for machine learning algorithms to identify subtle changes in operational parameters that precede equipment failure. Digital twins and simulation models now enable maintenance engineers to predict the impact of different operational scenarios and maintenance interventions before implementation.

The maintenance objectives have expanded beyond mere equipment reliability to encompass energy efficiency, emissions reduction, and production quality consistency. This holistic approach recognizes the interconnected nature of mechanical integrity, thermal efficiency, and product quality in rotary kiln operations, driving the development of increasingly sophisticated maintenance protocols and technologies.

Industrial Demand Analysis for Efficient Kiln Operations

The global rotary kiln market has witnessed substantial growth in recent years, driven primarily by expanding cement, lime, and mineral processing industries. Current market analysis indicates that the global rotary kiln equipment market is valued at approximately 7.2 billion USD, with a projected compound annual growth rate of 4.8% through 2028. This growth trajectory is particularly pronounced in emerging economies where infrastructure development continues at a rapid pace.

Industrial demand for efficient kiln operations stems from several key factors. First, energy consumption represents 30-40% of production costs in cement manufacturing, creating significant pressure for operational efficiency improvements. Companies operating rotary kilns face increasing competition, with profit margins typically ranging between 5-15% depending on regional market conditions and operational excellence.

Maintenance-related downtime presents a substantial economic burden, with unplanned kiln stoppages costing operators between 25,000-100,000 USD per day depending on facility size and production capacity. Industry data reveals that facilities implementing comprehensive maintenance programs for shell, drive, and bearing inspections reduce unplanned downtime by up to 70% compared to reactive maintenance approaches.

Environmental regulations have emerged as another significant market driver. In regions with carbon pricing mechanisms, cement producers face additional costs ranging from 3-8 USD per ton of cement produced. Properly maintained kilns operate with 10-15% better fuel efficiency, directly impacting both operational costs and environmental compliance expenses.

The labor market presents additional challenges, with skilled maintenance technicians commanding premium salaries due to specialized knowledge requirements. The average fully-loaded cost for qualified kiln maintenance specialists ranges from 75,000-120,000 USD annually in developed markets, creating incentives for more systematic and efficient maintenance protocols.

Digital transformation is reshaping maintenance practices, with predictive maintenance solutions market for rotary kilns growing at 18% annually. Early adopters report maintenance cost reductions of 15-25% through implementation of sensor-based monitoring systems for critical components like shells, drives, and bearings.

Regional analysis reveals varying levels of maintenance sophistication. While North American and European facilities typically allocate 3-5% of operational budgets to preventive maintenance, emerging markets often operate with 1-2% allocations, creating opportunities for efficiency gains through improved maintenance practices. This regional disparity also influences equipment lifespan, with properly maintained kilns in developed markets achieving 40+ years of service compared to 25-30 years in regions with less rigorous maintenance protocols.

Industrial demand for efficient kiln operations stems from several key factors. First, energy consumption represents 30-40% of production costs in cement manufacturing, creating significant pressure for operational efficiency improvements. Companies operating rotary kilns face increasing competition, with profit margins typically ranging between 5-15% depending on regional market conditions and operational excellence.

Maintenance-related downtime presents a substantial economic burden, with unplanned kiln stoppages costing operators between 25,000-100,000 USD per day depending on facility size and production capacity. Industry data reveals that facilities implementing comprehensive maintenance programs for shell, drive, and bearing inspections reduce unplanned downtime by up to 70% compared to reactive maintenance approaches.

Environmental regulations have emerged as another significant market driver. In regions with carbon pricing mechanisms, cement producers face additional costs ranging from 3-8 USD per ton of cement produced. Properly maintained kilns operate with 10-15% better fuel efficiency, directly impacting both operational costs and environmental compliance expenses.

The labor market presents additional challenges, with skilled maintenance technicians commanding premium salaries due to specialized knowledge requirements. The average fully-loaded cost for qualified kiln maintenance specialists ranges from 75,000-120,000 USD annually in developed markets, creating incentives for more systematic and efficient maintenance protocols.

Digital transformation is reshaping maintenance practices, with predictive maintenance solutions market for rotary kilns growing at 18% annually. Early adopters report maintenance cost reductions of 15-25% through implementation of sensor-based monitoring systems for critical components like shells, drives, and bearings.

Regional analysis reveals varying levels of maintenance sophistication. While North American and European facilities typically allocate 3-5% of operational budgets to preventive maintenance, emerging markets often operate with 1-2% allocations, creating opportunities for efficiency gains through improved maintenance practices. This regional disparity also influences equipment lifespan, with properly maintained kilns in developed markets achieving 40+ years of service compared to 25-30 years in regions with less rigorous maintenance protocols.

Current Maintenance Challenges and Global Best Practices

Rotary kiln maintenance faces significant challenges globally, with equipment downtime costing industries millions annually. The primary challenge lies in the difficulty of predicting component failures, particularly in shell, drive, and bearing systems. Traditional time-based maintenance approaches often result in either premature part replacement or unexpected failures, both leading to substantial financial losses. Maintenance teams frequently struggle with inadequate diagnostic tools that fail to provide early warning of developing issues.

Shell inspection challenges include detecting micro-cracks before they develop into catastrophic failures and accurately measuring shell ovality under varying thermal conditions. Many facilities lack advanced non-destructive testing capabilities, relying instead on visual inspections that miss critical early-stage defects. Temperature variations during operation further complicate accurate assessment of shell integrity.

Drive system maintenance presents unique difficulties due to the complex interaction between mechanical, electrical, and hydraulic components. Alignment issues between gears and motors remain a persistent problem, with misalignment accounting for approximately 30% of drive-related failures. The high-torque requirements of rotary kilns place exceptional stress on drive components, accelerating wear patterns that are difficult to monitor without specialized equipment.

Bearing inspections face challenges related to accessibility and the need for specialized knowledge. The massive scale of kiln bearings makes traditional vibration analysis techniques less effective, requiring modified approaches. Lubrication management remains problematic, with both under and over-lubrication contributing to premature failures. Thermal imaging of bearings is complicated by surrounding refractory materials and variable operating temperatures.

Global best practices have emerged to address these challenges. Condition-based maintenance (CBM) has replaced time-based approaches in leading facilities, utilizing continuous monitoring systems that track multiple parameters simultaneously. Advanced facilities employ machine learning algorithms to detect subtle changes in equipment behavior that precede failures, sometimes providing weeks of advance warning.

Industry leaders have implemented digital twin technology to simulate kiln operation and predict maintenance needs with greater accuracy. These virtual models incorporate real-time data from multiple sensors to create comprehensive health assessments of critical components. Remote monitoring centers staffed by specialists provide 24/7 oversight of multiple facilities, allowing for rapid response to developing issues.

Standardized inspection protocols have been developed by international organizations, establishing clear guidelines for shell, drive, and bearing assessments. These protocols incorporate both traditional methods and advanced technologies, creating a comprehensive approach to maintenance that significantly reduces unexpected failures while optimizing component lifespans.

Shell inspection challenges include detecting micro-cracks before they develop into catastrophic failures and accurately measuring shell ovality under varying thermal conditions. Many facilities lack advanced non-destructive testing capabilities, relying instead on visual inspections that miss critical early-stage defects. Temperature variations during operation further complicate accurate assessment of shell integrity.

Drive system maintenance presents unique difficulties due to the complex interaction between mechanical, electrical, and hydraulic components. Alignment issues between gears and motors remain a persistent problem, with misalignment accounting for approximately 30% of drive-related failures. The high-torque requirements of rotary kilns place exceptional stress on drive components, accelerating wear patterns that are difficult to monitor without specialized equipment.

Bearing inspections face challenges related to accessibility and the need for specialized knowledge. The massive scale of kiln bearings makes traditional vibration analysis techniques less effective, requiring modified approaches. Lubrication management remains problematic, with both under and over-lubrication contributing to premature failures. Thermal imaging of bearings is complicated by surrounding refractory materials and variable operating temperatures.

Global best practices have emerged to address these challenges. Condition-based maintenance (CBM) has replaced time-based approaches in leading facilities, utilizing continuous monitoring systems that track multiple parameters simultaneously. Advanced facilities employ machine learning algorithms to detect subtle changes in equipment behavior that precede failures, sometimes providing weeks of advance warning.

Industry leaders have implemented digital twin technology to simulate kiln operation and predict maintenance needs with greater accuracy. These virtual models incorporate real-time data from multiple sensors to create comprehensive health assessments of critical components. Remote monitoring centers staffed by specialists provide 24/7 oversight of multiple facilities, allowing for rapid response to developing issues.

Standardized inspection protocols have been developed by international organizations, establishing clear guidelines for shell, drive, and bearing assessments. These protocols incorporate both traditional methods and advanced technologies, creating a comprehensive approach to maintenance that significantly reduces unexpected failures while optimizing component lifespans.

Standard Inspection Protocols for Shell, Drive, and Bearings

01 Automated monitoring and predictive maintenance systems

Implementation of automated monitoring systems that use sensors and data analytics to predict maintenance needs for rotary kilns. These systems continuously monitor kiln performance parameters, detect anomalies, and predict potential failures before they occur. By enabling predictive maintenance rather than reactive repairs, these technologies significantly reduce downtime and increase operational efficiency of rotary kilns.- Automated monitoring and maintenance systems: Implementation of automated systems for monitoring rotary kiln conditions and performing maintenance tasks. These systems use sensors to detect abnormalities, predict failures, and schedule maintenance activities. Automation reduces downtime, increases operational efficiency, and extends equipment lifespan by enabling predictive maintenance rather than reactive repairs.

- Improved sealing mechanisms: Enhanced sealing technologies for rotary kilns that prevent leakage and improve thermal efficiency. These innovations include advanced materials and designs for seals that can withstand high temperatures and harsh operating conditions. Better sealing reduces energy loss, prevents contamination, and minimizes the need for frequent maintenance interventions.

- Structural reinforcement and wear protection: Methods and materials for reinforcing kiln structures and protecting against wear. These include specialized linings, coatings, and structural elements that extend component life in high-temperature, abrasive environments. Such reinforcements reduce the frequency of repairs, minimize unexpected failures, and improve overall kiln reliability and operational efficiency.

- Cooling system optimizations: Innovations in cooling systems that maintain optimal operating temperatures for rotary kilns. These include improved heat exchangers, cooling fans, and thermal management strategies that prevent overheating and thermal stress. Efficient cooling extends the service life of kiln components, reduces thermal-related failures, and minimizes maintenance requirements.

- Modular design for quick replacement: Development of modular components and assemblies that can be quickly replaced during maintenance operations. This approach allows for faster part swapping, reducing downtime during repairs. Modular designs also enable more efficient maintenance scheduling, as specific components can be replaced without disassembling the entire kiln system.

02 Improved sealing and support mechanisms

Advanced sealing technologies and support mechanisms that enhance rotary kiln performance and reduce maintenance requirements. These innovations include improved kiln tire designs, enhanced bearing systems, and more effective sealing mechanisms that prevent material leakage and heat loss. These developments extend component lifespan, reduce friction, and minimize energy consumption, resulting in more efficient maintenance schedules.Expand Specific Solutions03 Innovative cleaning and inspection techniques

Novel methods for cleaning and inspecting rotary kilns that improve maintenance efficiency. These techniques include automated cleaning systems, advanced non-destructive testing methods, and specialized tools for refractory inspection and repair. By enabling more thorough and efficient cleaning and inspection processes, these innovations help identify potential issues earlier and reduce the time required for maintenance activities.Expand Specific Solutions04 Modular and quick-replacement components

Development of modular components and quick-replacement systems that reduce maintenance downtime for rotary kilns. These designs allow for faster replacement of worn parts, simplified repair procedures, and more efficient overall maintenance. By minimizing the time required for component replacement and repair, these innovations significantly improve maintenance efficiency and reduce production losses due to downtime.Expand Specific Solutions05 Thermal efficiency and refractory improvements

Advancements in refractory materials and thermal management systems that extend the operational life of rotary kilns and reduce maintenance frequency. These improvements include high-performance refractory linings, optimized heat distribution systems, and thermal insulation technologies. By enhancing thermal efficiency and reducing thermal stress on kiln components, these innovations extend maintenance intervals and improve overall operational efficiency.Expand Specific Solutions

Leading Manufacturers and Service Providers in Kiln Industry

The rotary kiln maintenance market is in a mature growth phase, characterized by established technologies and standardized maintenance protocols. The global market size is estimated at $2-3 billion annually, driven by cement, mining, and metallurgical industries requiring regular maintenance to prevent costly downtime. Leading players include FLSmidth Cement A/S and CITIC Heavy Industries, who have developed comprehensive maintenance solutions integrating digital monitoring technologies. Technological maturity varies, with companies like Timken Co. and Mitsubishi Heavy Industries focusing on advanced bearing systems, while EagleBurgmann specializes in sealing technologies. Emerging players such as TomTom-Tools are introducing condition-based monitoring solutions, while academic institutions like Hunan University of Science & Technology contribute to innovation through research partnerships with industry leaders.

CITIC Heavy Industries Co., Ltd.

Technical Solution: CITIC Heavy Industries has developed a comprehensive rotary kiln maintenance system that combines traditional inspection methods with advanced monitoring technologies. Their shell inspection protocol includes the use of laser profiling technology to create detailed 3D models of the kiln shell, allowing for precise measurement of ovality, alignment, and deformation. For critical areas, they employ ultrasonic thickness testing to monitor shell integrity and identify potential weak points. Their drive maintenance approach focuses on the girth gear and pinion system, utilizing specialized alignment tools and wear pattern analysis to optimize gear mesh and extend component life. CITIC's bearing maintenance protocol incorporates continuous temperature monitoring with infrared imaging to detect hotspots and abnormal thermal patterns. Their maintenance checklist includes detailed inspection of support rollers and tires, with particular attention to tire-to-shell clearance measurements using precision gauges. They've also developed specialized procedures for inspecting the kiln's mechanical seals and thrust mechanisms to prevent air infiltration and axial movement issues.

Strengths: Comprehensive approach that addresses all critical mechanical components of rotary kilns. Strong integration between design knowledge and maintenance practices due to their role as both manufacturer and service provider. Weaknesses: Some of their more advanced monitoring solutions require significant technical expertise to implement and interpret. Their maintenance protocols can be labor-intensive compared to more automated systems.

FLSmidth Cement A/S

Technical Solution: FLSmidth has developed a comprehensive rotary kiln maintenance system that integrates digital monitoring with physical inspections. Their approach includes the KilnLoq Smart Alignment System which uses laser technology to continuously monitor kiln shell alignment and detect deviations in real-time. For shell inspections, they employ thermal imaging cameras that identify hotspots indicating refractory damage or shell deformation. Their drive maintenance protocol incorporates vibration analysis sensors on girth gear and pinion assemblies to detect early signs of wear patterns and misalignment. For bearings, FLSmidth utilizes ultrasonic monitoring technology that detects lubrication issues and bearing wear before catastrophic failure occurs. Their maintenance checklist includes automated tire slip monitoring systems that measure the relative movement between the kiln shell and supporting tires to prevent excessive wear and structural damage.

Strengths: Integrated digital and physical inspection approach allows for continuous monitoring rather than periodic checks. Advanced predictive maintenance capabilities reduce unplanned downtime by up to 30%. Weaknesses: High initial implementation cost for the full digital monitoring suite. Requires specialized training for maintenance personnel to properly interpret the digital data.

Critical Technical Innovations in Kiln Maintenance Systems

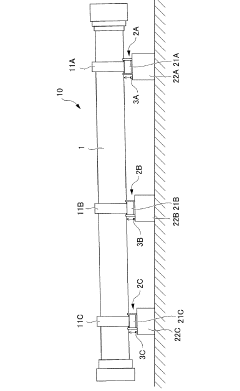

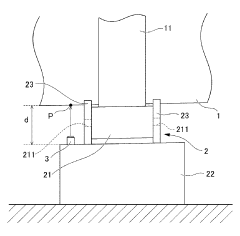

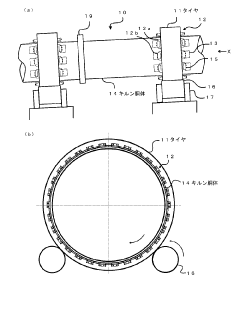

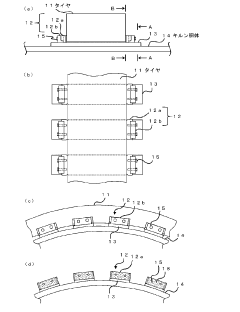

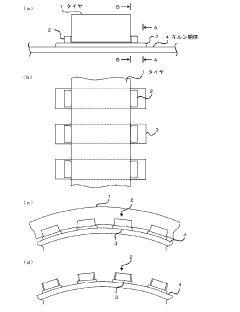

Rotary kiln, and method for driving rotary kiln

PatentActiveJP2020139634A

Innovation

- A rotary kiln equipped with a main body position detection sensor and fulcrum adjustment mechanism that allows continuous measurement and real-time adjustment of the kiln body's position, ensuring alignment without stopping the operation.

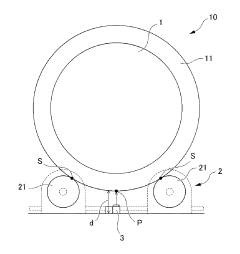

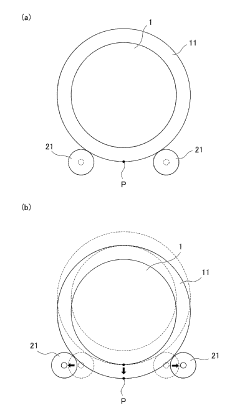

Rotary kiln

PatentInactiveJP2022179995A

Innovation

- A detachable tire stopper design with a contact portion and fixed portion secured by a bolt, allowing easy replacement and adjustment of the contact area, and embedding lubricant in the contact portion to reduce friction.

Environmental Impact and Sustainability Considerations

The environmental impact of rotary kiln operations extends far beyond production efficiency, with maintenance practices playing a crucial role in sustainability outcomes. Regular and thorough maintenance of kiln shells, drives, and bearings significantly reduces energy consumption by maintaining optimal thermal efficiency. When friction increases due to poorly maintained bearings or misaligned drives, energy requirements can increase by 10-15%, directly translating to higher carbon emissions and resource utilization.

Proper maintenance protocols also minimize the risk of catastrophic failures that can lead to environmental incidents. Shell cracks or bearing failures may result in material spillage, potentially releasing harmful substances into surrounding ecosystems. Historical data indicates that preventive maintenance reduces such environmental incidents by approximately 70% compared to reactive maintenance approaches.

The lubricants used in bearing and drive maintenance present another environmental consideration. Modern maintenance practices increasingly incorporate biodegradable lubricants and environmentally friendly cleaning agents, reducing the ecological footprint of maintenance activities. Proper disposal and recycling of used lubricants and replaced parts must be integrated into maintenance checklists to ensure compliance with environmental regulations and minimize waste.

Extending equipment lifespan through regular inspection and maintenance significantly contributes to sustainability by reducing the need for replacement manufacturing. The production of new kiln components—particularly large steel shells—carries substantial embodied carbon costs. Each year of extended service life through proper maintenance prevents approximately 30-40 tons of carbon emissions associated with manufacturing replacement parts.

Energy audits conducted during maintenance inspections can identify opportunities for efficiency improvements. Thermal imaging during shell inspections, for instance, can reveal hotspots indicating refractory damage or insulation failures that increase energy consumption. Implementing findings from these audits can reduce energy usage by 5-8% annually.

Advanced predictive maintenance technologies are transforming the sustainability profile of rotary kiln operations. Continuous monitoring systems that track bearing temperatures, shell deformation, and drive performance enable precisely timed interventions that minimize both environmental impact and resource consumption. These systems reduce unnecessary part replacements while preventing the excessive energy consumption associated with operating deteriorating equipment.

Proper maintenance protocols also minimize the risk of catastrophic failures that can lead to environmental incidents. Shell cracks or bearing failures may result in material spillage, potentially releasing harmful substances into surrounding ecosystems. Historical data indicates that preventive maintenance reduces such environmental incidents by approximately 70% compared to reactive maintenance approaches.

The lubricants used in bearing and drive maintenance present another environmental consideration. Modern maintenance practices increasingly incorporate biodegradable lubricants and environmentally friendly cleaning agents, reducing the ecological footprint of maintenance activities. Proper disposal and recycling of used lubricants and replaced parts must be integrated into maintenance checklists to ensure compliance with environmental regulations and minimize waste.

Extending equipment lifespan through regular inspection and maintenance significantly contributes to sustainability by reducing the need for replacement manufacturing. The production of new kiln components—particularly large steel shells—carries substantial embodied carbon costs. Each year of extended service life through proper maintenance prevents approximately 30-40 tons of carbon emissions associated with manufacturing replacement parts.

Energy audits conducted during maintenance inspections can identify opportunities for efficiency improvements. Thermal imaging during shell inspections, for instance, can reveal hotspots indicating refractory damage or insulation failures that increase energy consumption. Implementing findings from these audits can reduce energy usage by 5-8% annually.

Advanced predictive maintenance technologies are transforming the sustainability profile of rotary kiln operations. Continuous monitoring systems that track bearing temperatures, shell deformation, and drive performance enable precisely timed interventions that minimize both environmental impact and resource consumption. These systems reduce unnecessary part replacements while preventing the excessive energy consumption associated with operating deteriorating equipment.

Safety Standards and Compliance Requirements

Rotary kiln operations are subject to stringent safety standards and compliance requirements across various jurisdictions. The Occupational Safety and Health Administration (OSHA) in the United States mandates comprehensive safety protocols for industrial equipment maintenance, including specific guidelines for confined space entry procedures essential during internal kiln shell inspections. These regulations require proper lockout/tagout procedures, atmospheric testing, and continuous monitoring to protect maintenance personnel from potential hazards.

The American National Standards Institute (ANSI) and the American Society of Mechanical Engineers (ASME) have established critical standards for mechanical equipment maintenance that directly apply to rotary kiln drive systems and bearings. These standards specify torque requirements, alignment tolerances, and inspection frequencies that maintenance teams must adhere to during routine and comprehensive inspections.

European operations must comply with the Machinery Directive 2006/42/EC, which outlines essential health and safety requirements for machinery design and maintenance. This directive emphasizes risk assessment documentation and implementation of preventive maintenance schedules for critical components such as kiln shell, drive mechanisms, and support bearings.

Personal Protective Equipment (PPE) requirements constitute another crucial compliance area, with standards varying by region but typically including heat-resistant clothing, respiratory protection, and specialized equipment for working at heights during shell inspections. Documentation of PPE training and certification is mandatory for maintenance personnel working on rotary kilns.

Environmental compliance has become increasingly important in rotary kiln maintenance operations. Regulations from agencies such as the Environmental Protection Agency (EPA) govern the handling and disposal of lubricants, cleaning solvents, and other maintenance materials that may contain hazardous substances. Proper documentation of waste disposal practices is essential to avoid substantial penalties.

Industry-specific standards from organizations like the Portland Cement Association (PCA) and the American Petroleum Institute (API) provide additional guidance for rotary kiln maintenance in cement and petrochemical applications respectively. These standards often include specific inspection protocols for thermal equipment and rotating machinery that exceed general industrial requirements.

Compliance documentation represents a significant aspect of rotary kiln maintenance programs. Maintenance teams must maintain detailed records of all inspections, repairs, and component replacements to demonstrate regulatory compliance during audits. This documentation should include photographic evidence of inspections, calibration certificates for measurement tools, and verification of inspector qualifications according to applicable standards.

The American National Standards Institute (ANSI) and the American Society of Mechanical Engineers (ASME) have established critical standards for mechanical equipment maintenance that directly apply to rotary kiln drive systems and bearings. These standards specify torque requirements, alignment tolerances, and inspection frequencies that maintenance teams must adhere to during routine and comprehensive inspections.

European operations must comply with the Machinery Directive 2006/42/EC, which outlines essential health and safety requirements for machinery design and maintenance. This directive emphasizes risk assessment documentation and implementation of preventive maintenance schedules for critical components such as kiln shell, drive mechanisms, and support bearings.

Personal Protective Equipment (PPE) requirements constitute another crucial compliance area, with standards varying by region but typically including heat-resistant clothing, respiratory protection, and specialized equipment for working at heights during shell inspections. Documentation of PPE training and certification is mandatory for maintenance personnel working on rotary kilns.

Environmental compliance has become increasingly important in rotary kiln maintenance operations. Regulations from agencies such as the Environmental Protection Agency (EPA) govern the handling and disposal of lubricants, cleaning solvents, and other maintenance materials that may contain hazardous substances. Proper documentation of waste disposal practices is essential to avoid substantial penalties.

Industry-specific standards from organizations like the Portland Cement Association (PCA) and the American Petroleum Institute (API) provide additional guidance for rotary kiln maintenance in cement and petrochemical applications respectively. These standards often include specific inspection protocols for thermal equipment and rotating machinery that exceed general industrial requirements.

Compliance documentation represents a significant aspect of rotary kiln maintenance programs. Maintenance teams must maintain detailed records of all inspections, repairs, and component replacements to demonstrate regulatory compliance during audits. This documentation should include photographic evidence of inspections, calibration certificates for measurement tools, and verification of inspector qualifications according to applicable standards.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!