Rotary Kiln Process Control: PID Tuning And Cascade Strategies

AUG 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Rotary Kiln Control Evolution and Objectives

Rotary kiln process control has undergone significant evolution since its industrial adoption in the early 20th century. Initially, these massive thermal processing units operated with rudimentary manual controls, relying heavily on operator experience and visual observations of material flow and kiln conditions. The 1950s marked the beginning of automated control with the introduction of basic analog controllers, which provided limited but consistent regulation of key parameters such as temperature and rotation speed.

The 1970s witnessed a paradigm shift with the integration of Proportional-Integral-Derivative (PID) control systems, enabling more precise management of the complex thermal profiles within kilns. This period established PID as the foundational control methodology for rotary kilns across cement, minerals processing, and chemical industries. The subsequent decades saw incremental improvements in PID implementation, particularly in tuning methodologies to address the inherent time delays and nonlinear characteristics of kiln operations.

The 1990s brought distributed control systems (DCS) that facilitated the implementation of more sophisticated control strategies, including cascade control architectures. These systems allowed for hierarchical control loops where primary variables like product quality could govern secondary variables such as temperature profiles or material feed rates. This period also saw the emergence of model predictive control (MPC) applications for kilns, though implementation challenges limited widespread adoption.

The 21st century has been characterized by the integration of advanced sensing technologies, including thermal imaging cameras, laser-based analyzers, and acoustic monitoring systems. These innovations have dramatically improved the quality and quantity of process data available for control systems. Concurrently, computational advances have enabled real-time processing of this expanded data stream, supporting more responsive and adaptive control strategies.

Current objectives in rotary kiln control focus on several key areas: optimizing energy efficiency to reduce operational costs and environmental impact; enhancing product quality consistency through tighter process control; maximizing throughput while maintaining quality parameters; and reducing mechanical stress to extend equipment lifespan. Additionally, there is growing emphasis on predictive maintenance capabilities, where control systems not only regulate processes but also monitor equipment health indicators.

The industry is now moving toward intelligent control systems that combine traditional PID and cascade strategies with machine learning algorithms. These hybrid approaches aim to leverage historical operational data to continuously refine control parameters and adapt to changing process conditions or raw material characteristics. The ultimate goal is to develop self-optimizing control systems that can maintain ideal kiln performance across varying production scenarios with minimal human intervention.

The 1970s witnessed a paradigm shift with the integration of Proportional-Integral-Derivative (PID) control systems, enabling more precise management of the complex thermal profiles within kilns. This period established PID as the foundational control methodology for rotary kilns across cement, minerals processing, and chemical industries. The subsequent decades saw incremental improvements in PID implementation, particularly in tuning methodologies to address the inherent time delays and nonlinear characteristics of kiln operations.

The 1990s brought distributed control systems (DCS) that facilitated the implementation of more sophisticated control strategies, including cascade control architectures. These systems allowed for hierarchical control loops where primary variables like product quality could govern secondary variables such as temperature profiles or material feed rates. This period also saw the emergence of model predictive control (MPC) applications for kilns, though implementation challenges limited widespread adoption.

The 21st century has been characterized by the integration of advanced sensing technologies, including thermal imaging cameras, laser-based analyzers, and acoustic monitoring systems. These innovations have dramatically improved the quality and quantity of process data available for control systems. Concurrently, computational advances have enabled real-time processing of this expanded data stream, supporting more responsive and adaptive control strategies.

Current objectives in rotary kiln control focus on several key areas: optimizing energy efficiency to reduce operational costs and environmental impact; enhancing product quality consistency through tighter process control; maximizing throughput while maintaining quality parameters; and reducing mechanical stress to extend equipment lifespan. Additionally, there is growing emphasis on predictive maintenance capabilities, where control systems not only regulate processes but also monitor equipment health indicators.

The industry is now moving toward intelligent control systems that combine traditional PID and cascade strategies with machine learning algorithms. These hybrid approaches aim to leverage historical operational data to continuously refine control parameters and adapt to changing process conditions or raw material characteristics. The ultimate goal is to develop self-optimizing control systems that can maintain ideal kiln performance across varying production scenarios with minimal human intervention.

Industrial Demand for Advanced Kiln Process Control

The cement, metallurgy, and chemical industries have demonstrated a growing demand for advanced rotary kiln process control systems over the past decade. This demand stems primarily from increasing pressure to optimize energy efficiency, reduce emissions, and maintain consistent product quality while facing volatile raw material characteristics. Traditional manual control methods and basic PID controllers are increasingly inadequate for meeting these complex operational requirements.

Energy consumption represents 30-40% of production costs in cement manufacturing and similar thermal processing industries. Advanced kiln control systems that incorporate optimized PID tuning and cascade control strategies have demonstrated potential to reduce energy consumption by 5-15% compared to conventional control methods. This significant cost reduction potential has become a primary driver for technology adoption, particularly as global energy prices continue to fluctuate.

Environmental regulations worldwide have become increasingly stringent, with many regions implementing carbon pricing mechanisms and emissions caps. Modern rotary kiln operations must maintain precise temperature profiles and combustion conditions to minimize NOx, SOx, and particulate emissions. Advanced control systems that can maintain optimal operating conditions despite disturbances are essential for regulatory compliance and avoiding costly penalties.

Product quality consistency remains a critical competitive factor across industries utilizing rotary kilns. Variations in clinker quality in cement production, for example, directly impact downstream concrete performance. Advanced control systems that can compensate for variations in raw material properties and maintain consistent thermal profiles throughout the kiln have become essential for meeting stringent quality specifications demanded by customers.

The integration of Industry 4.0 concepts has accelerated demand for sophisticated kiln control systems. Manufacturers seek solutions that incorporate predictive maintenance capabilities, real-time optimization, and integration with enterprise resource planning systems. This has expanded requirements beyond traditional PID and cascade control to include machine learning algorithms that can adapt to changing process conditions and predict maintenance needs.

Labor market dynamics have further intensified the need for advanced automation. Experienced kiln operators are becoming increasingly scarce as the workforce ages, creating knowledge gaps in manual operation. Companies are investing in advanced control systems not only for efficiency gains but also to capture operational expertise in algorithmic form, ensuring consistent operation regardless of operator experience levels.

Energy consumption represents 30-40% of production costs in cement manufacturing and similar thermal processing industries. Advanced kiln control systems that incorporate optimized PID tuning and cascade control strategies have demonstrated potential to reduce energy consumption by 5-15% compared to conventional control methods. This significant cost reduction potential has become a primary driver for technology adoption, particularly as global energy prices continue to fluctuate.

Environmental regulations worldwide have become increasingly stringent, with many regions implementing carbon pricing mechanisms and emissions caps. Modern rotary kiln operations must maintain precise temperature profiles and combustion conditions to minimize NOx, SOx, and particulate emissions. Advanced control systems that can maintain optimal operating conditions despite disturbances are essential for regulatory compliance and avoiding costly penalties.

Product quality consistency remains a critical competitive factor across industries utilizing rotary kilns. Variations in clinker quality in cement production, for example, directly impact downstream concrete performance. Advanced control systems that can compensate for variations in raw material properties and maintain consistent thermal profiles throughout the kiln have become essential for meeting stringent quality specifications demanded by customers.

The integration of Industry 4.0 concepts has accelerated demand for sophisticated kiln control systems. Manufacturers seek solutions that incorporate predictive maintenance capabilities, real-time optimization, and integration with enterprise resource planning systems. This has expanded requirements beyond traditional PID and cascade control to include machine learning algorithms that can adapt to changing process conditions and predict maintenance needs.

Labor market dynamics have further intensified the need for advanced automation. Experienced kiln operators are becoming increasingly scarce as the workforce ages, creating knowledge gaps in manual operation. Companies are investing in advanced control systems not only for efficiency gains but also to capture operational expertise in algorithmic form, ensuring consistent operation regardless of operator experience levels.

Current PID Implementation Challenges in Rotary Kilns

The implementation of PID controllers in rotary kiln systems faces several significant challenges that limit optimal performance in industrial settings. Traditional PID control schemes often struggle with the inherent complexity of rotary kiln processes, characterized by substantial thermal inertia, nonlinear dynamics, and multiple interdependent variables. These controllers frequently exhibit inadequate response to disturbances, particularly when dealing with material property variations or fuel quality fluctuations.

One primary challenge is the determination of appropriate tuning parameters. The conventional Ziegler-Nichols method and other empirical approaches often yield suboptimal results due to the non-stationary nature of kiln operations. Engineers report that PID gains tuned for one operating condition frequently perform poorly when production rates change or different raw materials are processed, necessitating constant retuning efforts that disrupt production continuity.

Time delays present another significant obstacle in rotary kiln control systems. The substantial transport delays between control actions and measurable responses—often ranging from several minutes to hours—create difficulties for traditional PID algorithms that lack predictive capabilities. This results in oscillatory behavior or sluggish responses that compromise product quality and energy efficiency.

Cross-coupling effects between control loops further complicate PID implementation. For instance, adjustments to fuel flow rates affect multiple process variables simultaneously, including temperature profiles, oxygen levels, and material residence time. Standard single-loop PID controllers fail to account for these interactions, leading to competing control actions and system instability during transient operations.

The limitations of conventional measurement techniques also hinder effective PID control. Temperature measurements often suffer from spatial variations and sensor lag, while material property measurements may be infrequent or indirect. This measurement uncertainty introduces noise into the control system, causing unnecessary control actions that increase mechanical wear and energy consumption.

Existing PID implementations typically lack adaptive capabilities to handle the gradual changes in kiln behavior due to refractory wear, coating formation, or mechanical alignment shifts. Without continuous adaptation mechanisms, control performance deteriorates over time, requiring manual intervention and system retuning.

Finally, the integration of PID controllers with higher-level optimization systems remains problematic. Most current implementations operate as standalone regulatory controls without effective coordination with production planning or energy management systems, limiting the potential for holistic process optimization and preventing the realization of advanced control strategies that could significantly improve kiln efficiency and product quality.

One primary challenge is the determination of appropriate tuning parameters. The conventional Ziegler-Nichols method and other empirical approaches often yield suboptimal results due to the non-stationary nature of kiln operations. Engineers report that PID gains tuned for one operating condition frequently perform poorly when production rates change or different raw materials are processed, necessitating constant retuning efforts that disrupt production continuity.

Time delays present another significant obstacle in rotary kiln control systems. The substantial transport delays between control actions and measurable responses—often ranging from several minutes to hours—create difficulties for traditional PID algorithms that lack predictive capabilities. This results in oscillatory behavior or sluggish responses that compromise product quality and energy efficiency.

Cross-coupling effects between control loops further complicate PID implementation. For instance, adjustments to fuel flow rates affect multiple process variables simultaneously, including temperature profiles, oxygen levels, and material residence time. Standard single-loop PID controllers fail to account for these interactions, leading to competing control actions and system instability during transient operations.

The limitations of conventional measurement techniques also hinder effective PID control. Temperature measurements often suffer from spatial variations and sensor lag, while material property measurements may be infrequent or indirect. This measurement uncertainty introduces noise into the control system, causing unnecessary control actions that increase mechanical wear and energy consumption.

Existing PID implementations typically lack adaptive capabilities to handle the gradual changes in kiln behavior due to refractory wear, coating formation, or mechanical alignment shifts. Without continuous adaptation mechanisms, control performance deteriorates over time, requiring manual intervention and system retuning.

Finally, the integration of PID controllers with higher-level optimization systems remains problematic. Most current implementations operate as standalone regulatory controls without effective coordination with production planning or energy management systems, limiting the potential for holistic process optimization and preventing the realization of advanced control strategies that could significantly improve kiln efficiency and product quality.

Modern PID and Cascade Control Implementations

01 PID Control Strategies for Rotary Kilns

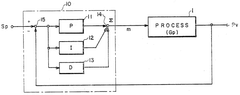

PID (Proportional-Integral-Derivative) control strategies are fundamental for rotary kiln operations. These strategies involve tuning control parameters to optimize temperature regulation, material flow, and energy efficiency. Advanced PID implementations include auto-tuning capabilities that adjust parameters based on process conditions, reducing manual intervention and improving stability during varying operational states.- PID Control Strategies for Rotary Kilns: PID (Proportional-Integral-Derivative) control strategies are fundamental for maintaining optimal performance in rotary kiln operations. These strategies involve tuning control parameters to achieve desired temperature profiles, material flow rates, and product quality. Advanced PID implementations can adapt to changing process conditions and compensate for disturbances in the kiln operation, ensuring stable and efficient production processes.

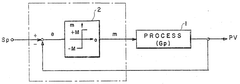

- Cascade Control Systems for Temperature Management: Cascade control systems are particularly effective for temperature management in rotary kilns, where multiple interrelated variables must be controlled simultaneously. These systems typically involve nested control loops where the output of one controller becomes the setpoint for another. This approach allows for more responsive control of the kiln's thermal profile, compensating for the significant thermal lag inherent in large rotary kilns and improving energy efficiency while maintaining product quality.

- Model-Based Tuning Methods for Kiln Control: Model-based tuning methods utilize mathematical models of the rotary kiln process to optimize control parameters. These approaches can include predictive models that anticipate process changes, allowing for proactive adjustments to control settings. By incorporating process dynamics into the control strategy, these methods can significantly improve kiln stability, reduce energy consumption, and enhance product consistency, particularly during transitions between different operating conditions.

- Adaptive Control Algorithms for Process Variability: Adaptive control algorithms automatically adjust control parameters in response to changing process conditions in rotary kilns. These systems continuously monitor process variables and modify control strategies to maintain optimal performance despite variations in raw materials, fuel quality, or environmental conditions. This approach is particularly valuable for cement and mineral processing kilns where input materials can vary significantly, ensuring consistent product quality while minimizing operator intervention.

- Integrated Monitoring and Control Systems: Integrated monitoring and control systems combine real-time data acquisition with advanced control strategies for comprehensive rotary kiln management. These systems incorporate multiple sensors throughout the kiln to monitor temperature profiles, material flow, gas composition, and other critical parameters. The collected data is then used to optimize control decisions, detect potential issues before they affect production, and provide operators with actionable insights for process improvement and maintenance planning.

02 Cascade Control Systems for Kiln Operations

Cascade control systems implement multiple control loops where the output of one controller becomes the setpoint for another. In rotary kiln applications, this typically involves primary loops managing critical parameters like temperature or pressure, while secondary loops control supporting variables such as fuel flow or air supply. This hierarchical approach provides more responsive and stable kiln operation by addressing both slow-responding primary variables and faster-changing secondary variables.Expand Specific Solutions03 Model-Based Predictive Control for Rotary Kilns

Model-based predictive control techniques utilize mathematical models of the kiln process to anticipate future behavior and optimize control actions. These systems analyze historical data, current conditions, and process dynamics to predict outcomes and adjust parameters preemptively. This approach is particularly valuable for rotary kilns due to their significant thermal inertia and time delays, allowing for more efficient energy use and product quality consistency.Expand Specific Solutions04 Advanced Monitoring and Adaptive Control Systems

Advanced monitoring systems incorporate multiple sensor arrays and real-time data analysis to provide comprehensive kiln condition assessment. These systems enable adaptive control strategies that automatically adjust to changing process conditions, material properties, or equipment performance. Features include fault detection algorithms, sensor fusion techniques, and self-learning capabilities that continuously improve control performance based on operational experience.Expand Specific Solutions05 Energy Optimization and Thermal Efficiency Control

Control strategies specifically designed for energy optimization focus on maintaining optimal thermal profiles while minimizing fuel consumption. These approaches incorporate combustion efficiency monitoring, heat recovery management, and precise control of air-to-fuel ratios. Advanced implementations include dynamic setpoint adjustment based on production requirements, ambient conditions, and feed material properties to maximize thermal efficiency throughout varying operational demands.Expand Specific Solutions

Leading Vendors in Rotary Kiln Control Systems

Rotary kiln process control technology is currently in a mature development phase, with a global market size estimated at over $1.5 billion and growing steadily at 5-7% annually. The competitive landscape features established industrial automation leaders like Siemens AG, ABB Group, and Honeywell International Technologies alongside specialized players such as SUPCON Technology. Academic institutions including Central South University and South China University of Technology contribute significant research advancements in PID tuning methodologies. The technology maturity varies across applications, with Rockwell Automation, Woodward, and Fisher-Rosemount Systems demonstrating advanced cascade control implementations, while emerging players like Tianjin Tianduan Press focus on industry-specific adaptations. The integration of AI-enhanced control algorithms represents the current competitive frontier in this field.

SUPCON Technology Co., Ltd.

Technical Solution: 中控科技针对回转窑过程控制开发了SuperECS企业控制系统,采用多级级联PID控制架构。该系统特别针对中国水泥、冶金等行业回转窑的工艺特点进行了优化,开发了专用的窑温控制模块。中控的技术方案采用"三环级联"控制策略:内环控制燃料流量,中环控制窑尾温度,外环控制窑头温度和产品质量指标。系统集成了基于大数据分析的PID参数自优化技术,通过挖掘历史运行数据中的最佳工况参数,实现PID控制的智能调优,提高了控制精度约25%。中控还开发了针对回转窑的智能解耦控制算法,有效处理了温度、压力、风量等多变量之间的耦合关系,减少了相互干扰。系统还集成了基于工业互联网的远程诊断和专家支持功能,为PID调优提供在线技术支持。

优势:系统本地化程度高,特别适应中国工业现场环境和操作习惯;价格相对国际品牌更具竞争力;服务响应速度快,本地化支持强;与中国主流DCS系统兼容性好。劣势:国际市场认可度相对较低;高端功能模块与国际领先企业仍有差距;系统稳定性在极端工况下有待提高;软件迭代速度相对较慢。

ABB Group

Technical Solution: ABB在回转窑过程控制领域开发了先进的Expert Optimizer系统,专门针对水泥和矿物加工行业的回转窑应用。该系统采用多层级联PID控制架构,将温度、压力、流量等关键参数组织成级联控制回路。ABB的方案特别强调自适应PID调优技术,通过实时分析过程响应特性,动态调整PID参数,以适应回转窑负载变化和原料特性波动。系统集成了基于模型预测控制(MPC)的高级控制层,与基础PID控制形成级联结构,实现更精确的温度分布控制。ABB还开发了专门的热成像监测系统,将视觉数据作为级联控制的输入,实现对窑内燃烧状态的实时调整,提高燃料效率约15-20%。

优势:系统集成度高,将专家系统与自适应PID控制无缝结合;具有强大的数据分析能力,支持预测性维护;控制精度高,能适应复杂工况变化。劣势:系统复杂度较高,初始配置和调试周期长;对操作人员技术要求高;实施成本较高,中小型企业可能难以承担。

Key Innovations in Kiln Process Control Algorithms

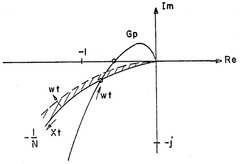

Method of determining PID parameters and an automatic tuning controller using the method

PatentInactiveUS4754391A

Innovation

- A method that monitors a limit cycle generated in a process by inserting a nonlinear element into the PID controller's proportional operation portion and connecting the integral operation portion in parallel, allowing for continuous process control and determination of optimum PID parameters without disrupting normal operation.

Energy Efficiency Optimization in Kiln Operations

Energy efficiency optimization in rotary kiln operations represents a critical frontier in industrial process improvement, particularly for cement, lime, and mineral processing industries. The implementation of advanced PID tuning and cascade control strategies has demonstrated significant potential for reducing energy consumption while maintaining product quality.

Traditional kiln operations often suffer from energy inefficiencies due to suboptimal temperature profiles, excessive fuel consumption, and inconsistent material processing. Recent studies indicate that properly tuned PID controllers can reduce energy consumption by 8-15% compared to manual or poorly tuned automatic control systems. This optimization begins with accurate modeling of the thermal dynamics within the kiln, accounting for the complex heat transfer mechanisms between flame, material bed, and kiln shell.

Cascade control strategies have emerged as particularly effective for energy optimization, allowing for the coordination of multiple process variables that impact energy utilization. The primary-secondary control loop configuration enables precise management of fuel input based on both temperature requirements and material quality parameters. Field implementations have shown that cascade strategies can stabilize temperature profiles more effectively than single-loop controls, reducing temperature fluctuations by up to 40%.

Advanced implementations incorporate feed-forward elements that anticipate load changes, particularly variations in raw material properties or production rate demands. These predictive components allow the control system to adjust fuel rates proactively rather than reactively, minimizing energy waste during transitional states. Data from cement plants indicates that feed-forward-enhanced cascade controls can improve thermal efficiency by an additional 3-7% compared to standard cascade implementations.

Model Predictive Control (MPC) integration with traditional PID and cascade structures represents the cutting edge of kiln energy optimization. These systems utilize dynamic process models to predict future behavior and optimize control actions across multiple time horizons. Early adopters report energy savings of 10-20% while simultaneously improving product consistency and reducing emissions.

The economic implications of these control improvements are substantial. For a medium-sized cement plant producing 4,000 tons per day, optimized control strategies can translate to annual energy cost reductions of $500,000 to $1.2 million, with carbon emission reductions proportional to the energy savings. The return on investment for implementing advanced control strategies typically ranges from 6 to 18 months, making this an attractive option for industries facing increasing energy costs and environmental regulations.

Traditional kiln operations often suffer from energy inefficiencies due to suboptimal temperature profiles, excessive fuel consumption, and inconsistent material processing. Recent studies indicate that properly tuned PID controllers can reduce energy consumption by 8-15% compared to manual or poorly tuned automatic control systems. This optimization begins with accurate modeling of the thermal dynamics within the kiln, accounting for the complex heat transfer mechanisms between flame, material bed, and kiln shell.

Cascade control strategies have emerged as particularly effective for energy optimization, allowing for the coordination of multiple process variables that impact energy utilization. The primary-secondary control loop configuration enables precise management of fuel input based on both temperature requirements and material quality parameters. Field implementations have shown that cascade strategies can stabilize temperature profiles more effectively than single-loop controls, reducing temperature fluctuations by up to 40%.

Advanced implementations incorporate feed-forward elements that anticipate load changes, particularly variations in raw material properties or production rate demands. These predictive components allow the control system to adjust fuel rates proactively rather than reactively, minimizing energy waste during transitional states. Data from cement plants indicates that feed-forward-enhanced cascade controls can improve thermal efficiency by an additional 3-7% compared to standard cascade implementations.

Model Predictive Control (MPC) integration with traditional PID and cascade structures represents the cutting edge of kiln energy optimization. These systems utilize dynamic process models to predict future behavior and optimize control actions across multiple time horizons. Early adopters report energy savings of 10-20% while simultaneously improving product consistency and reducing emissions.

The economic implications of these control improvements are substantial. For a medium-sized cement plant producing 4,000 tons per day, optimized control strategies can translate to annual energy cost reductions of $500,000 to $1.2 million, with carbon emission reductions proportional to the energy savings. The return on investment for implementing advanced control strategies typically ranges from 6 to 18 months, making this an attractive option for industries facing increasing energy costs and environmental regulations.

Digital Twin Integration for Predictive Kiln Control

Digital Twin technology represents a transformative approach to rotary kiln process control, moving beyond traditional PID tuning and cascade strategies toward predictive control paradigms. By creating virtual replicas of physical kilns that operate in real-time synchronization with their physical counterparts, Digital Twins enable unprecedented levels of process visibility and control optimization.

The integration of Digital Twin technology with rotary kiln operations begins with comprehensive sensor deployment throughout the kiln system, capturing thermal profiles, material flow characteristics, and mechanical performance metrics. These data streams feed sophisticated mathematical models that simulate the complex thermodynamic and chemical processes occurring within the kiln.

Machine learning algorithms continuously refine these models by comparing predicted outcomes with actual performance data, gradually improving prediction accuracy and system understanding. This self-improving capability allows the Digital Twin to account for variables that traditional control systems often struggle to incorporate, such as material property variations, equipment wear patterns, and subtle environmental influences.

For predictive kiln control, the Digital Twin serves multiple critical functions. It enables operators to visualize internal kiln conditions that cannot be directly measured, such as material bed behavior and temperature gradients across refractory linings. This enhanced visibility supports more informed decision-making and reduces reliance on operator intuition.

The predictive capabilities extend to maintenance optimization, where the Digital Twin can forecast equipment degradation based on operational patterns, potentially preventing costly unplanned downtime. This predictive maintenance approach represents a significant advancement over traditional schedule-based maintenance protocols.

Perhaps most importantly, Digital Twin integration enables scenario testing without risking actual production. Operators can simulate process adjustments and observe predicted outcomes before implementation, effectively creating a risk-free environment for process optimization. This capability is particularly valuable when tuning complex cascade control strategies, as it allows engineers to visualize the ripple effects of parameter changes throughout interconnected control loops.

The implementation challenges primarily revolve around model accuracy, data integration complexity, and the need for specialized expertise spanning both kiln operations and advanced modeling techniques. However, the potential benefits—including energy efficiency improvements of 5-15%, quality consistency enhancements, and production increases of up to 10%—make Digital Twin integration an increasingly attractive investment for forward-thinking kiln operators.

The integration of Digital Twin technology with rotary kiln operations begins with comprehensive sensor deployment throughout the kiln system, capturing thermal profiles, material flow characteristics, and mechanical performance metrics. These data streams feed sophisticated mathematical models that simulate the complex thermodynamic and chemical processes occurring within the kiln.

Machine learning algorithms continuously refine these models by comparing predicted outcomes with actual performance data, gradually improving prediction accuracy and system understanding. This self-improving capability allows the Digital Twin to account for variables that traditional control systems often struggle to incorporate, such as material property variations, equipment wear patterns, and subtle environmental influences.

For predictive kiln control, the Digital Twin serves multiple critical functions. It enables operators to visualize internal kiln conditions that cannot be directly measured, such as material bed behavior and temperature gradients across refractory linings. This enhanced visibility supports more informed decision-making and reduces reliance on operator intuition.

The predictive capabilities extend to maintenance optimization, where the Digital Twin can forecast equipment degradation based on operational patterns, potentially preventing costly unplanned downtime. This predictive maintenance approach represents a significant advancement over traditional schedule-based maintenance protocols.

Perhaps most importantly, Digital Twin integration enables scenario testing without risking actual production. Operators can simulate process adjustments and observe predicted outcomes before implementation, effectively creating a risk-free environment for process optimization. This capability is particularly valuable when tuning complex cascade control strategies, as it allows engineers to visualize the ripple effects of parameter changes throughout interconnected control loops.

The implementation challenges primarily revolve around model accuracy, data integration complexity, and the need for specialized expertise spanning both kiln operations and advanced modeling techniques. However, the potential benefits—including energy efficiency improvements of 5-15%, quality consistency enhancements, and production increases of up to 10%—make Digital Twin integration an increasingly attractive investment for forward-thinking kiln operators.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!