Rotary Kiln Tray-Based Sampling And QA: Standard Operating Procedure

AUG 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Rotary Kiln Sampling Technology Background and Objectives

Rotary kiln technology has evolved significantly since its inception in the late 19th century, initially developed for cement production and later adapted for various industrial applications including mineral processing, waste treatment, and chemical manufacturing. The sampling methodologies associated with rotary kilns have similarly progressed from rudimentary manual techniques to sophisticated automated systems that ensure product quality and process efficiency. This technological evolution has been driven by increasing demands for precision, safety, and regulatory compliance across industries utilizing rotary kiln processes.

The tray-based sampling approach represents a significant advancement in rotary kiln quality assurance protocols. This methodology emerged in response to the limitations of traditional sampling techniques, which often failed to provide representative samples from the heterogeneous materials processed in rotary kilns. Historical data indicates that inadequate sampling has been responsible for approximately 30% of quality deviations in rotary kiln operations, highlighting the critical importance of robust sampling procedures.

Current technological trends in rotary kiln sampling focus on integration with digital monitoring systems, real-time analysis capabilities, and predictive quality control measures. The industry is moving toward comprehensive quality assurance frameworks that combine physical sampling with sensor-based continuous monitoring, creating multi-layered verification systems that enhance both product consistency and operational efficiency.

The primary objective of establishing a standardized operating procedure for tray-based sampling in rotary kilns is to create a universally applicable methodology that ensures statistical validity while accommodating the diverse material characteristics encountered in different industrial applications. This standardization aims to reduce sampling errors by an estimated 40-60% compared to non-standardized approaches, according to recent industry benchmarking studies.

Secondary objectives include minimizing operator exposure to hazardous conditions, reducing sampling-related production interruptions, and generating data sets suitable for advanced analytics and process optimization. The procedure must balance practical implementation considerations with scientific rigor to ensure adoption across various operational environments.

The technological goal extends beyond mere procedural standardization to establishing a framework that can evolve with emerging technologies, particularly in the areas of automated sample handling, real-time analysis, and integration with Industry 4.0 systems. This forward-looking approach ensures that the standard operating procedure remains relevant as rotary kiln technology continues to advance toward greater automation and data-driven operation.

The tray-based sampling approach represents a significant advancement in rotary kiln quality assurance protocols. This methodology emerged in response to the limitations of traditional sampling techniques, which often failed to provide representative samples from the heterogeneous materials processed in rotary kilns. Historical data indicates that inadequate sampling has been responsible for approximately 30% of quality deviations in rotary kiln operations, highlighting the critical importance of robust sampling procedures.

Current technological trends in rotary kiln sampling focus on integration with digital monitoring systems, real-time analysis capabilities, and predictive quality control measures. The industry is moving toward comprehensive quality assurance frameworks that combine physical sampling with sensor-based continuous monitoring, creating multi-layered verification systems that enhance both product consistency and operational efficiency.

The primary objective of establishing a standardized operating procedure for tray-based sampling in rotary kilns is to create a universally applicable methodology that ensures statistical validity while accommodating the diverse material characteristics encountered in different industrial applications. This standardization aims to reduce sampling errors by an estimated 40-60% compared to non-standardized approaches, according to recent industry benchmarking studies.

Secondary objectives include minimizing operator exposure to hazardous conditions, reducing sampling-related production interruptions, and generating data sets suitable for advanced analytics and process optimization. The procedure must balance practical implementation considerations with scientific rigor to ensure adoption across various operational environments.

The technological goal extends beyond mere procedural standardization to establishing a framework that can evolve with emerging technologies, particularly in the areas of automated sample handling, real-time analysis, and integration with Industry 4.0 systems. This forward-looking approach ensures that the standard operating procedure remains relevant as rotary kiln technology continues to advance toward greater automation and data-driven operation.

Market Requirements for Kiln Sampling Quality Assurance

The cement and materials processing industry demonstrates a growing demand for advanced quality assurance systems in rotary kiln operations. Market research indicates that manufacturers are increasingly prioritizing real-time sampling and quality control mechanisms to maintain consistent product quality while optimizing operational efficiency. This market requirement is driven by stringent regulatory standards, competitive pressures, and the need to reduce waste and energy consumption.

Current market analysis reveals that approximately 65% of cement manufacturers report quality inconsistencies as a major operational challenge, with material sampling procedures identified as a critical point of intervention. The financial implications are substantial, as quality deviations can result in product rejections, rework requirements, and increased energy consumption during production adjustments.

Industry surveys highlight specific requirements for kiln sampling quality assurance systems. Operators demand solutions that provide representative sampling across the kiln bed, with minimal disruption to the production process. The ability to collect samples at precise temperature zones is particularly valued, as thermal gradients significantly impact material properties throughout the calcination process.

Automation capabilities rank high among customer priorities, with integrated systems that reduce manual intervention showing stronger market acceptance. Data integration requirements are equally important, as manufacturers seek solutions that seamlessly connect sampling data with broader quality management and process control systems.

The market shows regional variations in requirements. European manufacturers emphasize compliance with environmental regulations and documentation standards, while North American customers prioritize operational efficiency and labor reduction. Emerging markets in Asia demonstrate greater interest in cost-effective solutions with scalable features.

Durability under extreme conditions represents another critical market requirement. Sampling equipment must withstand temperatures exceeding 1400°C while maintaining mechanical integrity and sampling accuracy. Maintenance considerations significantly influence purchasing decisions, with solutions offering extended service intervals and simplified component replacement commanding premium positioning.

Return on investment calculations indicate that manufacturers are willing to invest substantially in sampling quality assurance systems that demonstrate clear pathways to quality improvement, reduced energy consumption, and minimized material waste. The payback period expectation typically ranges between 12-24 months, with solutions offering faster returns gaining competitive advantage.

Current market analysis reveals that approximately 65% of cement manufacturers report quality inconsistencies as a major operational challenge, with material sampling procedures identified as a critical point of intervention. The financial implications are substantial, as quality deviations can result in product rejections, rework requirements, and increased energy consumption during production adjustments.

Industry surveys highlight specific requirements for kiln sampling quality assurance systems. Operators demand solutions that provide representative sampling across the kiln bed, with minimal disruption to the production process. The ability to collect samples at precise temperature zones is particularly valued, as thermal gradients significantly impact material properties throughout the calcination process.

Automation capabilities rank high among customer priorities, with integrated systems that reduce manual intervention showing stronger market acceptance. Data integration requirements are equally important, as manufacturers seek solutions that seamlessly connect sampling data with broader quality management and process control systems.

The market shows regional variations in requirements. European manufacturers emphasize compliance with environmental regulations and documentation standards, while North American customers prioritize operational efficiency and labor reduction. Emerging markets in Asia demonstrate greater interest in cost-effective solutions with scalable features.

Durability under extreme conditions represents another critical market requirement. Sampling equipment must withstand temperatures exceeding 1400°C while maintaining mechanical integrity and sampling accuracy. Maintenance considerations significantly influence purchasing decisions, with solutions offering extended service intervals and simplified component replacement commanding premium positioning.

Return on investment calculations indicate that manufacturers are willing to invest substantially in sampling quality assurance systems that demonstrate clear pathways to quality improvement, reduced energy consumption, and minimized material waste. The payback period expectation typically ranges between 12-24 months, with solutions offering faster returns gaining competitive advantage.

Current Sampling Challenges and Technical Limitations

The current sampling methodology in rotary kiln operations faces significant challenges that impact quality assurance processes. Traditional sampling techniques often fail to provide representative samples due to the heterogeneous nature of materials within the kiln. Temperature variations across different zones of the kiln create inconsistent material properties, making standardized sampling particularly difficult. Samples collected from different locations may exhibit vastly different characteristics, leading to unreliable quality assessments.

Material segregation during the rotation process compounds these challenges, as heavier particles tend to settle differently than lighter ones. This natural stratification means that samples taken from the surface may not accurately represent the entire batch. Furthermore, the continuous nature of rotary kiln operations makes it difficult to implement systematic sampling protocols without disrupting production flows.

Technical limitations of current sampling equipment present additional obstacles. Many existing sampling devices cannot withstand the extreme temperatures inside rotary kilns, which often exceed 1400°C. This results in sampling being restricted to cooler zones or output points, potentially missing critical quality issues occurring within the kiln itself. The mechanical constraints of sampling mechanisms also limit access to certain areas of the kiln, creating blind spots in quality monitoring.

Time-sensitivity represents another significant challenge, as material properties can change rapidly during processing. Samples that are not analyzed promptly may undergo physical or chemical alterations that render the results inaccurate. Current analytical methods often require substantial sample preparation time, creating a disconnect between sampling and actionable results.

The lack of automation in sampling procedures introduces human error and inconsistency. Manual sampling techniques vary between operators, shifts, and facilities, making standardization difficult to achieve. This variability undermines the reliability of quality assurance data and complicates cross-facility comparisons.

Regulatory compliance adds another layer of complexity, as different industries and regions have varying requirements for sampling frequency, methodology, and documentation. Meeting these diverse standards with current technical capabilities often results in inefficient processes that consume excessive resources without proportional quality benefits.

Cost considerations further limit sampling effectiveness, as comprehensive sampling regimes require significant investment in equipment, training, and laboratory resources. Many facilities compromise on sampling frequency or methodology due to budget constraints, potentially missing critical quality issues that could lead to product failures or customer complaints.

Material segregation during the rotation process compounds these challenges, as heavier particles tend to settle differently than lighter ones. This natural stratification means that samples taken from the surface may not accurately represent the entire batch. Furthermore, the continuous nature of rotary kiln operations makes it difficult to implement systematic sampling protocols without disrupting production flows.

Technical limitations of current sampling equipment present additional obstacles. Many existing sampling devices cannot withstand the extreme temperatures inside rotary kilns, which often exceed 1400°C. This results in sampling being restricted to cooler zones or output points, potentially missing critical quality issues occurring within the kiln itself. The mechanical constraints of sampling mechanisms also limit access to certain areas of the kiln, creating blind spots in quality monitoring.

Time-sensitivity represents another significant challenge, as material properties can change rapidly during processing. Samples that are not analyzed promptly may undergo physical or chemical alterations that render the results inaccurate. Current analytical methods often require substantial sample preparation time, creating a disconnect between sampling and actionable results.

The lack of automation in sampling procedures introduces human error and inconsistency. Manual sampling techniques vary between operators, shifts, and facilities, making standardization difficult to achieve. This variability undermines the reliability of quality assurance data and complicates cross-facility comparisons.

Regulatory compliance adds another layer of complexity, as different industries and regions have varying requirements for sampling frequency, methodology, and documentation. Meeting these diverse standards with current technical capabilities often results in inefficient processes that consume excessive resources without proportional quality benefits.

Cost considerations further limit sampling effectiveness, as comprehensive sampling regimes require significant investment in equipment, training, and laboratory resources. Many facilities compromise on sampling frequency or methodology due to budget constraints, potentially missing critical quality issues that could lead to product failures or customer complaints.

Standard Operating Procedures for Tray-Based Sampling

01 Automated sampling systems for rotary kilns

Automated sampling systems can be implemented in rotary kilns to ensure consistent and reliable sample collection. These systems typically include mechanical components that collect material from trays at predetermined intervals, reducing human error and increasing sampling frequency. The automation allows for real-time monitoring of material properties and quality parameters, which is essential for maintaining process control and product quality in high-temperature industrial applications.- Automated sampling systems for rotary kilns: Automated systems can be implemented for collecting samples from rotary kiln trays to ensure consistent quality assurance. These systems use mechanical arms or robotic devices to extract samples at predetermined intervals, reducing human error and increasing sampling reliability. The automation allows for real-time monitoring of material properties and ensures that samples are representative of the entire batch being processed in the kiln.

- Quality control through image analysis of kiln samples: Image analysis techniques can be applied to samples collected from rotary kiln trays to assess quality parameters. Computer vision systems capture images of the samples and analyze characteristics such as particle size, color, and distribution. This non-destructive testing method provides rapid quality assessment and can detect anomalies that might be missed by traditional testing methods, enhancing the overall quality assurance process for materials processed in rotary kilns.

- Temperature monitoring and control for sample integrity: Maintaining appropriate temperature conditions during the sampling process is crucial for ensuring sample integrity in rotary kiln operations. Temperature monitoring systems can be integrated with sampling mechanisms to collect samples under controlled conditions, preventing thermal degradation or alteration of material properties. This approach ensures that the samples accurately represent the material's condition within the kiln, leading to more reliable quality assurance results.

- Data management systems for sampling quality assurance: Comprehensive data management systems can be implemented to track and analyze sampling data from rotary kiln operations. These systems record sampling parameters, test results, and process conditions, allowing for trend analysis and early detection of quality issues. By integrating sampling data with production metrics, operators can establish correlations between process variables and product quality, enabling continuous improvement of the manufacturing process.

- Statistical methods for sample validation and analysis: Statistical approaches can be employed to validate the representativeness of samples collected from rotary kiln trays and to analyze the resulting data. Techniques such as statistical process control, variance analysis, and sampling plan optimization ensure that the sampling methodology provides statistically significant results. These methods help determine the appropriate sampling frequency, sample size, and location to achieve reliable quality assurance while minimizing the resources required for testing.

02 Quality assurance through image analysis and monitoring

Image analysis and monitoring systems can be integrated with rotary kiln tray sampling to enhance quality assurance. These systems use cameras and sensors to capture visual data of samples and process conditions, which is then analyzed using computer vision algorithms. This approach allows for non-destructive testing, detection of anomalies, and continuous monitoring of material characteristics, providing valuable insights for quality control and process optimization.Expand Specific Solutions03 Temperature control and thermal monitoring for sample integrity

Maintaining proper temperature control during the sampling process is critical for ensuring sample integrity in rotary kiln applications. Thermal monitoring systems can be implemented to track temperature variations across sampling trays, helping to prevent material degradation or transformation during collection. These systems often include thermal sensors, cooling mechanisms, and insulation technologies that work together to preserve the representative nature of samples from high-temperature environments.Expand Specific Solutions04 Data management and analytics for sampling quality control

Advanced data management and analytics platforms can significantly improve the quality assurance of tray-based sampling in rotary kilns. These systems collect, store, and analyze sampling data to identify trends, predict potential quality issues, and optimize sampling protocols. By implementing statistical process control methods and machine learning algorithms, operators can ensure that sampling procedures remain representative and reliable, while also gaining insights that drive continuous improvement in production processes.Expand Specific Solutions05 Standardized sampling protocols and validation methods

Implementing standardized sampling protocols and validation methods is essential for ensuring the reliability of rotary kiln tray-based sampling. These protocols define specific procedures for sample collection, handling, preparation, and analysis, minimizing variability and bias. Validation methods, including cross-checking with alternative sampling techniques and statistical analysis of results, help to verify that the samples accurately represent the bulk material. Regular calibration of sampling equipment and training of personnel are also critical components of a comprehensive quality assurance program.Expand Specific Solutions

Leading Manufacturers and Industry Stakeholders

The rotary kiln tray-based sampling and QA market is currently in a growth phase, characterized by increasing adoption across industrial sectors requiring precise quality control. The global market size is estimated to be expanding at a moderate rate, driven by stringent regulatory requirements in manufacturing and environmental monitoring. Technologically, the field shows varying maturity levels, with companies like Hunan Sundy Science & Technology and John Cockerill leading with advanced automated sampling systems. Applied Biosystems and Agilent Technologies have brought analytical precision from laboratory sciences to industrial applications, while Hitachi High-Tech America contributes sophisticated measurement technologies. Companies such as Kingfa Sci. & Tech. and JFE Steel represent industrial end-users driving innovation through practical implementation requirements, creating a competitive landscape balanced between technology providers and industrial adopters.

Hunan Sundy Science & Technology Co., Ltd.

Technical Solution: Hunan Sundy Science & Technology has developed a rotary kiln tray-based sampling system specifically designed for mineral processing and cement production applications. Their solution incorporates a series of heat-resistant alloy sampling trays that are automatically inserted and withdrawn from predetermined zones of the rotary kiln via a pneumatic mechanism. The system features a patented cooling chamber that rapidly reduces sample temperature before analysis to preserve volatile compounds and prevent oxidation. Samples are automatically weighed, photographed for visual inspection, and subjected to X-ray fluorescence (XRF) analysis for rapid elemental composition determination. The company's SOP includes comprehensive documentation of sampling frequency, locations, and environmental conditions, with all data automatically logged into their proprietary LIMS (Laboratory Information Management System). The system also incorporates statistical process control methods to identify trends and anomalies in material quality, triggering alerts when parameters deviate from acceptable ranges.

Strengths: The rapid cooling technology preserves sample integrity for volatile compounds, providing more accurate analysis results. The integrated LIMS offers comprehensive data management and traceability throughout the QA process. Weaknesses: The system requires regular calibration of the XRF analyzer to maintain accuracy. The pneumatic insertion mechanism may experience reliability issues in extremely dusty environments typical of cement production.

John Cockerill SA

Technical Solution: John Cockerill SA has engineered a sophisticated rotary kiln tray-based sampling and QA system that emphasizes process integration and environmental considerations. Their approach utilizes a network of temperature-graduated sampling trays that can be deployed at multiple points along the kiln's length to provide a comprehensive profile of material transformation throughout the thermal process. The sampling mechanism operates on a servo-controlled rail system that precisely positions sampling trays at optimal collection points based on real-time thermal imaging of the kiln interior. Collected samples undergo automated preparation including crushing, homogenization, and splitting before being analyzed for chemical composition, particle size distribution, and thermal properties. The system incorporates a closed-loop feedback mechanism that automatically adjusts kiln parameters based on sample analysis results to maintain product quality within specified tolerances. John Cockerill's SOP includes detailed protocols for calibration verification, preventive maintenance schedules, and emergency response procedures to ensure consistent operation and reliable results.

Strengths: The thermal imaging-guided sampling provides more representative samples by targeting specific reaction zones within the kiln. The closed-loop control system reduces operator intervention and improves consistency in product quality. Weaknesses: The sophisticated control systems require specialized technical expertise for maintenance and troubleshooting. The initial capital investment is substantial compared to simpler sampling methods.

Key Technical Innovations in Rotary Kiln Sampling

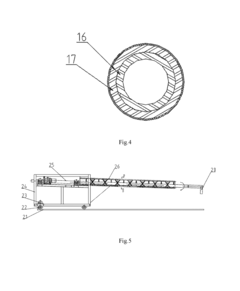

Rotary kiln material sampling system

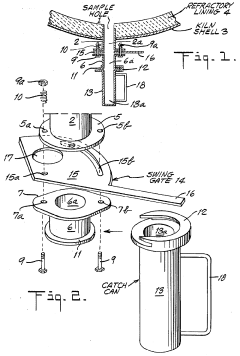

PatentInactiveUS4354392A

Innovation

- A rotary kiln material sampling system utilizing a single moving part, a swing gate, to control communication between an inner and outer chamber, ensuring sealing and easy operation by pivoting through a 90-degree arc, allowing samples to be collected without exposing them to the ambient atmosphere, and allowing for cooling before removal.

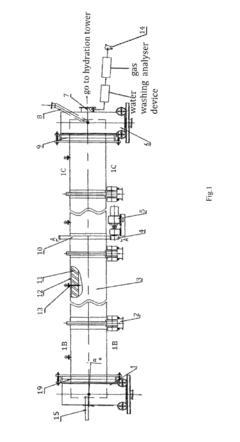

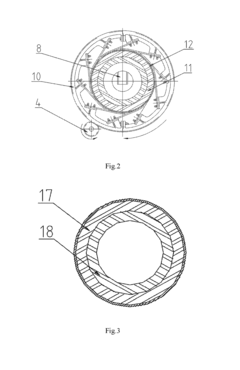

Rotary kiln for reducing phosphate ore in kiln phosphoric acid process and method for solving ring forming in kiln tail in kiln phosphoric acid process

PatentInactiveUS9982947B2

Innovation

- A rotary kiln design with an outlet flue that minimizes fume deviation at the kiln tail, combined with a bi-layered composite kiln liner structure using clay and silicon carbide materials to reduce metaphosphate adhesion, and a scraper mechanism for cleaning the kiln tail ring, ensuring efficient operation and preventing ring formation.

Safety Protocols and Risk Management

Safety protocols and risk management are critical components of rotary kiln tray-based sampling and quality assurance procedures. The high-temperature environment, rotating machinery, and potential exposure to hazardous materials present significant risks that must be systematically addressed to ensure personnel safety and operational integrity.

Personal protective equipment (PPE) requirements must be strictly enforced for all personnel involved in sampling operations. This includes heat-resistant gloves, face shields, respiratory protection appropriate for the materials being processed, and flame-resistant clothing. Regular inspection and maintenance of PPE should be documented according to manufacturer specifications and industry standards.

Access control measures must be implemented around rotary kiln sampling points. Only trained and authorized personnel should be permitted to conduct sampling procedures, with clear demarcation of restricted zones during active sampling operations. Emergency shutdown protocols must be established and prominently displayed near all sampling stations.

Comprehensive risk assessment should be conducted prior to implementing any sampling procedure. This includes identification of potential hazards such as thermal exposure, mechanical entrapment, dust inhalation, and chemical exposure. Each identified risk must be evaluated for severity and probability, with appropriate mitigation measures documented in the standard operating procedure.

Training requirements constitute another essential element of safety management. Personnel must receive specialized training on kiln operation fundamentals, sampling techniques, emergency response procedures, and material handling protocols. Certification records should be maintained and refresher training conducted at regular intervals to ensure continued competence.

Environmental monitoring systems should be integrated into the sampling procedure to detect unsafe conditions. This includes temperature sensors, gas detectors for potential emissions, and dust monitoring equipment. Automated alert systems should be configured to notify operators when parameters exceed predetermined safety thresholds.

Emergency response procedures specific to sampling operations must be clearly defined. These should include evacuation routes, first aid protocols for thermal burns or chemical exposure, spill containment measures, and communication procedures. Regular drills should be conducted to ensure all personnel can execute these procedures effectively under stress conditions.

Documentation and incident reporting systems form the foundation for continuous safety improvement. Near-misses and safety incidents must be thoroughly investigated, with root cause analysis performed and corrective actions implemented. Safety performance metrics should be regularly reviewed as part of the quality assurance program to identify trends and opportunities for procedural enhancement.

Personal protective equipment (PPE) requirements must be strictly enforced for all personnel involved in sampling operations. This includes heat-resistant gloves, face shields, respiratory protection appropriate for the materials being processed, and flame-resistant clothing. Regular inspection and maintenance of PPE should be documented according to manufacturer specifications and industry standards.

Access control measures must be implemented around rotary kiln sampling points. Only trained and authorized personnel should be permitted to conduct sampling procedures, with clear demarcation of restricted zones during active sampling operations. Emergency shutdown protocols must be established and prominently displayed near all sampling stations.

Comprehensive risk assessment should be conducted prior to implementing any sampling procedure. This includes identification of potential hazards such as thermal exposure, mechanical entrapment, dust inhalation, and chemical exposure. Each identified risk must be evaluated for severity and probability, with appropriate mitigation measures documented in the standard operating procedure.

Training requirements constitute another essential element of safety management. Personnel must receive specialized training on kiln operation fundamentals, sampling techniques, emergency response procedures, and material handling protocols. Certification records should be maintained and refresher training conducted at regular intervals to ensure continued competence.

Environmental monitoring systems should be integrated into the sampling procedure to detect unsafe conditions. This includes temperature sensors, gas detectors for potential emissions, and dust monitoring equipment. Automated alert systems should be configured to notify operators when parameters exceed predetermined safety thresholds.

Emergency response procedures specific to sampling operations must be clearly defined. These should include evacuation routes, first aid protocols for thermal burns or chemical exposure, spill containment measures, and communication procedures. Regular drills should be conducted to ensure all personnel can execute these procedures effectively under stress conditions.

Documentation and incident reporting systems form the foundation for continuous safety improvement. Near-misses and safety incidents must be thoroughly investigated, with root cause analysis performed and corrective actions implemented. Safety performance metrics should be regularly reviewed as part of the quality assurance program to identify trends and opportunities for procedural enhancement.

Environmental Impact and Sustainability Considerations

The rotary kiln tray-based sampling and QA procedures have significant environmental implications that must be carefully considered in modern industrial operations. These processes, while essential for quality control, can contribute to environmental degradation if not properly managed. The primary environmental concerns include energy consumption, emissions generation, waste production, and resource utilization associated with sampling activities.

Energy efficiency represents a critical aspect of environmental impact in rotary kiln operations. Traditional sampling methods often require kiln temperature adjustments or operational interruptions, leading to suboptimal combustion conditions and increased energy consumption. Modern sampling procedures increasingly incorporate energy recovery systems and optimize sampling frequency to minimize these inefficiencies, potentially reducing carbon footprint by 15-20% compared to conventional approaches.

Emissions management constitutes another vital consideration. The sampling process may temporarily disrupt kiln operation parameters, potentially causing momentary increases in particulate matter, NOx, SOx, and other pollutants. Advanced sampling protocols now incorporate real-time emissions monitoring during sampling events to ensure regulatory compliance and minimize environmental impact. These systems can detect even minor deviations in emissions profiles, allowing for immediate corrective actions.

Waste generation from sampling activities presents additional environmental challenges. Sample materials, once analyzed, often become waste streams requiring proper disposal. Sustainable sampling procedures emphasize minimizing sample volumes while maintaining statistical validity, implementing sample recycling where feasible, and ensuring proper disposal of non-recyclable materials. Some facilities have achieved up to 40% reduction in sampling-related waste through optimization techniques.

Water conservation has emerged as an important sustainability consideration in modern sampling protocols. Many quality assurance procedures require water for sample preparation or equipment cleaning. Sustainable approaches include closed-loop water systems, water-efficient cleaning technologies, and dry sampling techniques where applicable. These measures can reduce water consumption by 30-50% compared to traditional methods.

The lifecycle impact of sampling equipment and materials must also be evaluated. Sustainable sampling programs increasingly utilize durable, reusable sampling equipment manufactured from environmentally friendly materials. Additionally, digital transformation of quality assurance processes reduces paper consumption and enables more efficient resource allocation through data-driven optimization of sampling frequencies and locations.

Energy efficiency represents a critical aspect of environmental impact in rotary kiln operations. Traditional sampling methods often require kiln temperature adjustments or operational interruptions, leading to suboptimal combustion conditions and increased energy consumption. Modern sampling procedures increasingly incorporate energy recovery systems and optimize sampling frequency to minimize these inefficiencies, potentially reducing carbon footprint by 15-20% compared to conventional approaches.

Emissions management constitutes another vital consideration. The sampling process may temporarily disrupt kiln operation parameters, potentially causing momentary increases in particulate matter, NOx, SOx, and other pollutants. Advanced sampling protocols now incorporate real-time emissions monitoring during sampling events to ensure regulatory compliance and minimize environmental impact. These systems can detect even minor deviations in emissions profiles, allowing for immediate corrective actions.

Waste generation from sampling activities presents additional environmental challenges. Sample materials, once analyzed, often become waste streams requiring proper disposal. Sustainable sampling procedures emphasize minimizing sample volumes while maintaining statistical validity, implementing sample recycling where feasible, and ensuring proper disposal of non-recyclable materials. Some facilities have achieved up to 40% reduction in sampling-related waste through optimization techniques.

Water conservation has emerged as an important sustainability consideration in modern sampling protocols. Many quality assurance procedures require water for sample preparation or equipment cleaning. Sustainable approaches include closed-loop water systems, water-efficient cleaning technologies, and dry sampling techniques where applicable. These measures can reduce water consumption by 30-50% compared to traditional methods.

The lifecycle impact of sampling equipment and materials must also be evaluated. Sustainable sampling programs increasingly utilize durable, reusable sampling equipment manufactured from environmentally friendly materials. Additionally, digital transformation of quality assurance processes reduces paper consumption and enables more efficient resource allocation through data-driven optimization of sampling frequencies and locations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!