Rotary Kiln Burner Selection: Flame Shape, Penetration, And Efficiency

AUG 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Rotary Kiln Burner Technology Evolution and Objectives

Rotary kiln burner technology has evolved significantly since its inception in the early 20th century. Initially, simple coal-fired burners dominated the industry, characterized by limited control capabilities and inefficient combustion processes. The 1950s marked a pivotal shift with the introduction of oil-fired burners, offering improved flame control and reduced emissions. By the 1970s, natural gas burners emerged as environmentally preferable alternatives, providing cleaner combustion and enhanced operational flexibility.

The technological revolution in the 1980s and 1990s brought sophisticated multi-channel burners capable of utilizing multiple fuel types simultaneously, representing a significant advancement in adaptability and efficiency. These developments coincided with growing environmental concerns and stricter emissions regulations worldwide, driving innovation toward more sustainable solutions.

Modern rotary kiln burner technology has evolved to incorporate advanced computational fluid dynamics (CFD) modeling, allowing for precise flame shape prediction and optimization. This technological progression has been driven by the dual imperatives of maximizing thermal efficiency while minimizing environmental impact, particularly in energy-intensive industries such as cement, lime, and mineral processing.

The primary objectives of contemporary rotary kiln burner technology center around three critical parameters: flame shape, penetration depth, and thermal efficiency. Flame shape directly influences heat distribution within the kiln, affecting product quality and consistency. Optimal flame penetration ensures heat reaches the material bed effectively, while efficiency considerations address fuel consumption and emissions reduction.

Industry demands have pushed development toward burners with adjustable flame characteristics that can be fine-tuned to specific process requirements. The ability to modify flame length, width, and turbulence patterns has become essential for accommodating varying raw material properties and production targets.

Looking forward, the industry trajectory points toward intelligent burner systems incorporating real-time monitoring and automated adjustment capabilities. These systems aim to optimize combustion parameters continuously based on process feedback, material properties, and production requirements. Integration with digital twin technology and predictive analytics represents the frontier of rotary kiln burner development, promising unprecedented levels of process control and efficiency.

The technological evolution continues to be driven by sustainability imperatives, with increasing focus on hydrogen-ready burners, electrification possibilities, and carbon capture compatibility as industries worldwide pursue decarbonization strategies while maintaining production efficiency.

The technological revolution in the 1980s and 1990s brought sophisticated multi-channel burners capable of utilizing multiple fuel types simultaneously, representing a significant advancement in adaptability and efficiency. These developments coincided with growing environmental concerns and stricter emissions regulations worldwide, driving innovation toward more sustainable solutions.

Modern rotary kiln burner technology has evolved to incorporate advanced computational fluid dynamics (CFD) modeling, allowing for precise flame shape prediction and optimization. This technological progression has been driven by the dual imperatives of maximizing thermal efficiency while minimizing environmental impact, particularly in energy-intensive industries such as cement, lime, and mineral processing.

The primary objectives of contemporary rotary kiln burner technology center around three critical parameters: flame shape, penetration depth, and thermal efficiency. Flame shape directly influences heat distribution within the kiln, affecting product quality and consistency. Optimal flame penetration ensures heat reaches the material bed effectively, while efficiency considerations address fuel consumption and emissions reduction.

Industry demands have pushed development toward burners with adjustable flame characteristics that can be fine-tuned to specific process requirements. The ability to modify flame length, width, and turbulence patterns has become essential for accommodating varying raw material properties and production targets.

Looking forward, the industry trajectory points toward intelligent burner systems incorporating real-time monitoring and automated adjustment capabilities. These systems aim to optimize combustion parameters continuously based on process feedback, material properties, and production requirements. Integration with digital twin technology and predictive analytics represents the frontier of rotary kiln burner development, promising unprecedented levels of process control and efficiency.

The technological evolution continues to be driven by sustainability imperatives, with increasing focus on hydrogen-ready burners, electrification possibilities, and carbon capture compatibility as industries worldwide pursue decarbonization strategies while maintaining production efficiency.

Market Demand Analysis for Advanced Kiln Burner Systems

The global market for advanced rotary kiln burner systems has been experiencing significant growth, driven primarily by increasing demand for energy efficiency and environmental compliance across cement, lime, and mineral processing industries. Current market research indicates that the cement industry alone consumes approximately 2% of global energy production, creating substantial demand for burner technologies that can reduce fuel consumption while maintaining or improving production quality.

Market analysis reveals that industries utilizing rotary kilns are increasingly prioritizing burner systems that offer precise flame shape control and optimal penetration characteristics. This demand stems from the direct correlation between flame characteristics and product quality, particularly in cement production where clinker quality depends heavily on proper heat distribution within the kiln.

Environmental regulations worldwide have become more stringent regarding emissions from industrial processes. The European Union's Industrial Emissions Directive, China's Blue Sky Policy, and the EPA regulations in the United States have all established stricter limits on NOx, SOx, and particulate emissions. This regulatory landscape has created a robust market for burner systems that can achieve lower emission profiles while maintaining operational efficiency.

The market for multi-fuel burner systems has expanded considerably as manufacturers seek flexibility in fuel sourcing. Research indicates growing interest in burners capable of efficiently handling alternative fuels including refuse-derived fuels, biomass, and hydrogen blends. This trend is particularly strong in regions with volatile traditional fuel prices or strong renewable energy initiatives.

Geographically, the Asia-Pacific region represents the largest market for advanced kiln burner systems, with China and India leading demand due to their expanding cement and manufacturing sectors. Europe follows as the second-largest market, driven primarily by replacement of aging infrastructure with more efficient technologies to meet stringent environmental standards.

Industry surveys indicate that end-users are willing to invest in premium burner technologies when demonstrable returns on investment through fuel savings can be achieved within 18-36 months. This has created a competitive landscape where manufacturers focus on developing burners with sophisticated monitoring and control systems that can provide real-time optimization of flame characteristics.

The market for retrofit solutions is particularly strong, as complete kiln replacement is cost-prohibitive for many operators. Burner systems that can be integrated into existing kilns while providing significant improvements in flame shape control, penetration depth, and overall efficiency represent a high-growth segment within the industry.

Market analysis reveals that industries utilizing rotary kilns are increasingly prioritizing burner systems that offer precise flame shape control and optimal penetration characteristics. This demand stems from the direct correlation between flame characteristics and product quality, particularly in cement production where clinker quality depends heavily on proper heat distribution within the kiln.

Environmental regulations worldwide have become more stringent regarding emissions from industrial processes. The European Union's Industrial Emissions Directive, China's Blue Sky Policy, and the EPA regulations in the United States have all established stricter limits on NOx, SOx, and particulate emissions. This regulatory landscape has created a robust market for burner systems that can achieve lower emission profiles while maintaining operational efficiency.

The market for multi-fuel burner systems has expanded considerably as manufacturers seek flexibility in fuel sourcing. Research indicates growing interest in burners capable of efficiently handling alternative fuels including refuse-derived fuels, biomass, and hydrogen blends. This trend is particularly strong in regions with volatile traditional fuel prices or strong renewable energy initiatives.

Geographically, the Asia-Pacific region represents the largest market for advanced kiln burner systems, with China and India leading demand due to their expanding cement and manufacturing sectors. Europe follows as the second-largest market, driven primarily by replacement of aging infrastructure with more efficient technologies to meet stringent environmental standards.

Industry surveys indicate that end-users are willing to invest in premium burner technologies when demonstrable returns on investment through fuel savings can be achieved within 18-36 months. This has created a competitive landscape where manufacturers focus on developing burners with sophisticated monitoring and control systems that can provide real-time optimization of flame characteristics.

The market for retrofit solutions is particularly strong, as complete kiln replacement is cost-prohibitive for many operators. Burner systems that can be integrated into existing kilns while providing significant improvements in flame shape control, penetration depth, and overall efficiency represent a high-growth segment within the industry.

Current Burner Technologies and Technical Challenges

The rotary kiln burner landscape has evolved significantly over the past decades, with several technologies currently dominating the market. Multi-channel burners represent the most widely adopted solution, featuring separate channels for primary air, secondary air, and fuel delivery. These burners offer good control over flame shape but often struggle with maintaining consistent penetration across varying operational conditions.

Low-NOx burners have gained prominence due to increasingly stringent environmental regulations. These systems utilize staged combustion techniques to reduce nitrogen oxide emissions by controlling combustion temperatures and oxygen availability. While environmentally advantageous, these burners frequently require compromises in flame characteristics and may result in reduced thermal efficiency in certain applications.

High-velocity burners deliver exceptional flame penetration through increased momentum of the combustion gases. This technology excels in larger kilns where heat transfer to the material bed presents challenges. However, the high-velocity design often creates more turbulent flame patterns that can be difficult to control precisely, potentially leading to uneven heating profiles along the kiln length.

Oxy-fuel burners represent the cutting edge of current technology, utilizing oxygen-enriched air to achieve higher combustion temperatures and improved efficiency. These systems can reduce fuel consumption by 20-30% compared to conventional air-fuel burners but require significant infrastructure investment for oxygen supply and face challenges related to refractory wear due to higher operating temperatures.

Despite these advancements, several technical challenges persist across all burner technologies. Flame stability remains problematic, particularly during load fluctuations or when using alternative fuels with variable calorific values. Current burners struggle to maintain optimal flame characteristics across the wide operational range required in modern production environments.

Fuel flexibility presents another significant challenge as industries increasingly adopt alternative and waste-derived fuels. Most existing burners are optimized for specific fuel types and struggle to maintain performance when fuel composition varies. This limitation hampers the industry's sustainability efforts and economic optimization strategies.

Heat transfer efficiency continues to be suboptimal in many installations, with significant energy losses occurring due to poor flame shape control and inadequate penetration. Current technologies often fail to achieve the ideal balance between radiative and convective heat transfer needed for optimal material processing in rotary kilns.

Control system integration represents a persistent technical gap, with many burner systems lacking sophisticated feedback mechanisms to dynamically adjust flame characteristics based on real-time process parameters. This limitation prevents truly adaptive combustion control that could optimize efficiency across varying operational conditions.

Low-NOx burners have gained prominence due to increasingly stringent environmental regulations. These systems utilize staged combustion techniques to reduce nitrogen oxide emissions by controlling combustion temperatures and oxygen availability. While environmentally advantageous, these burners frequently require compromises in flame characteristics and may result in reduced thermal efficiency in certain applications.

High-velocity burners deliver exceptional flame penetration through increased momentum of the combustion gases. This technology excels in larger kilns where heat transfer to the material bed presents challenges. However, the high-velocity design often creates more turbulent flame patterns that can be difficult to control precisely, potentially leading to uneven heating profiles along the kiln length.

Oxy-fuel burners represent the cutting edge of current technology, utilizing oxygen-enriched air to achieve higher combustion temperatures and improved efficiency. These systems can reduce fuel consumption by 20-30% compared to conventional air-fuel burners but require significant infrastructure investment for oxygen supply and face challenges related to refractory wear due to higher operating temperatures.

Despite these advancements, several technical challenges persist across all burner technologies. Flame stability remains problematic, particularly during load fluctuations or when using alternative fuels with variable calorific values. Current burners struggle to maintain optimal flame characteristics across the wide operational range required in modern production environments.

Fuel flexibility presents another significant challenge as industries increasingly adopt alternative and waste-derived fuels. Most existing burners are optimized for specific fuel types and struggle to maintain performance when fuel composition varies. This limitation hampers the industry's sustainability efforts and economic optimization strategies.

Heat transfer efficiency continues to be suboptimal in many installations, with significant energy losses occurring due to poor flame shape control and inadequate penetration. Current technologies often fail to achieve the ideal balance between radiative and convective heat transfer needed for optimal material processing in rotary kilns.

Control system integration represents a persistent technical gap, with many burner systems lacking sophisticated feedback mechanisms to dynamically adjust flame characteristics based on real-time process parameters. This limitation prevents truly adaptive combustion control that could optimize efficiency across varying operational conditions.

Current Flame Shape and Penetration Optimization Methods

01 Burner design for optimal flame shape

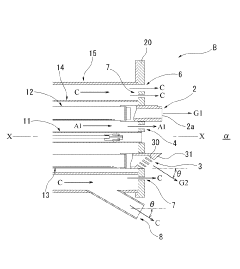

The design of rotary kiln burners significantly impacts flame shape, which is crucial for efficient combustion. Key design elements include nozzle configuration, air distribution channels, and mixing chambers that control the flame's geometry. Advanced burner designs incorporate adjustable components to modify flame characteristics according to process requirements, ensuring optimal heat distribution and reduced fuel consumption. These designs often feature specialized mixing zones that promote turbulence for better fuel-air interaction.- Burner design for optimal flame shape: The design of rotary kiln burners significantly impacts flame shape, which is crucial for efficient combustion. Key design elements include nozzle configuration, air distribution systems, and fuel injection mechanisms. Advanced burner designs incorporate features like adjustable flame patterns, multi-channel fuel delivery, and specialized mixing chambers to create ideal flame geometries. These designs help achieve complete combustion while maintaining the desired flame characteristics for specific kiln operations.

- Flame penetration control techniques: Controlling flame penetration in rotary kilns involves manipulating various operational parameters. Techniques include adjusting fuel-to-air ratios, modifying burner position and angle, and implementing staged combustion. Enhanced penetration can be achieved through high-velocity injection systems, while specialized swirl generators create turbulence patterns that improve flame reach and heat distribution. These control methods ensure optimal heat transfer to the material bed while preventing damage to kiln refractory linings.

- Fuel efficiency optimization systems: Modern rotary kiln burners incorporate various systems to maximize fuel efficiency. These include precise fuel metering devices, automated control systems that adjust combustion parameters in real-time, and heat recovery mechanisms. Advanced monitoring technologies analyze flame characteristics and combustion efficiency, allowing for continuous optimization. Some systems utilize alternative or multiple fuel capabilities, enabling operators to select the most economical and efficient fuel source based on availability and process requirements.

- Innovative burner nozzle configurations: Innovative nozzle configurations play a crucial role in determining flame characteristics in rotary kilns. These designs include multi-channel nozzles that create specific flame patterns, adjustable nozzle geometries that can be optimized during operation, and specialized mixing chambers that enhance fuel-air interaction. Some advanced designs incorporate swirl-inducing elements, staged fuel injection points, or variable-geometry components that allow operators to fine-tune flame shape and penetration based on process requirements.

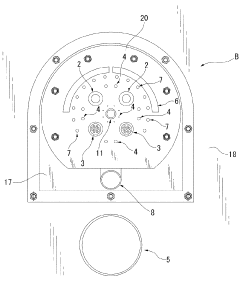

- Monitoring and control systems for flame optimization: Sophisticated monitoring and control systems enable real-time optimization of rotary kiln flames. These systems utilize advanced sensors, including thermal imaging cameras, spectroscopic analyzers, and flow measurement devices to continuously assess flame characteristics. Integrated control algorithms automatically adjust burner parameters to maintain optimal flame shape, penetration, and efficiency. Some systems incorporate predictive modeling capabilities that anticipate required adjustments based on changing kiln conditions or material properties, ensuring consistent performance and energy efficiency.

02 Flame penetration control mechanisms

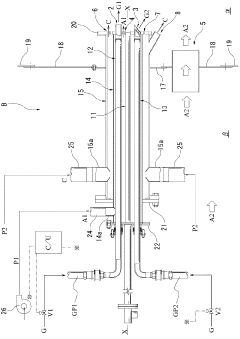

Controlling flame penetration in rotary kilns involves mechanisms that adjust the momentum and direction of the flame. These mechanisms include variable speed fans, adjustable vanes, and specialized injection systems that regulate the depth of flame penetration into the kiln. By optimizing penetration, heat transfer to the material bed is maximized while reducing heat loss through the kiln exit. Advanced systems incorporate sensors and automated controls to maintain optimal penetration based on process conditions and material characteristics.Expand Specific Solutions03 Multi-channel fuel injection systems

Multi-channel fuel injection systems enhance combustion efficiency by precisely controlling the distribution of fuel and air in rotary kiln burners. These systems feature separate channels for primary, secondary, and sometimes tertiary air flows, allowing for staged combustion that optimizes flame characteristics. The strategic positioning of fuel injection points creates ideal mixing conditions, resulting in more complete combustion, reduced emissions, and improved thermal efficiency. Some advanced designs incorporate swirl generators to create rotational flow patterns that enhance fuel-air mixing.Expand Specific Solutions04 Monitoring and control systems for flame optimization

Advanced monitoring and control systems employ sensors, cameras, and computational algorithms to continuously assess and adjust flame characteristics in real-time. These systems analyze parameters such as flame temperature, shape, stability, and emissions to make automatic adjustments to burner settings. Infrared imaging technology allows for visualization of flame patterns inside the kiln, while predictive models anticipate required changes based on material feed properties and production demands. This intelligent control approach maintains optimal combustion conditions throughout varying operational phases.Expand Specific Solutions05 Alternative fuel adaptation for improved efficiency

Rotary kiln burners designed to accommodate alternative and multiple fuels improve operational flexibility and efficiency. These adaptable systems can switch between or simultaneously use different fuel types including natural gas, oil, pulverized coal, biomass, and waste-derived fuels. Special nozzle designs and mixing chambers ensure proper atomization and combustion of various fuels with different physical properties. The ability to optimize flame characteristics when using alternative fuels contributes to reduced operational costs and environmental impact while maintaining production quality.Expand Specific Solutions

Leading Manufacturers and Competitive Landscape

The rotary kiln burner market is currently in a mature growth phase, characterized by incremental technological advancements focused on optimizing flame shape, penetration, and efficiency. The global market size is estimated at approximately $1.2-1.5 billion, driven by cement, lime, and metallurgical industries seeking energy efficiency improvements. Leading players demonstrate varying levels of technical maturity, with European companies like Fives Pillard SA and thyssenkrupp Polysius GmbH offering advanced flame control technologies, while Asian manufacturers such as CISDI Industrial Furnace and Sinosteel Anshan Research Institute are rapidly closing the technology gap. North American firms like ClearSign Technologies are pioneering emissions-focused innovations. FLSmidth, Air Products & Chemicals, and Air Liquide maintain competitive advantages through integrated solutions combining burner technology with comprehensive process optimization capabilities.

Fives Pillard SA

Technical Solution: Fives Pillard has developed advanced rotary kiln burner technology focusing on optimized flame shape and penetration for cement and lime industries. Their Novaflam® burner series utilizes a multi-channel design with separate injection points for primary air, fuel (solid, liquid, or gaseous), and swirl air. This configuration allows precise control over flame geometry, with adjustable momentum and swirl intensity to match specific kiln conditions. The burner incorporates computational fluid dynamics (CFD) modeling to predict flame behavior under various operating parameters, enabling operators to achieve the ideal flame shape for specific production requirements. Their technology includes automatic adjustment systems that modify flame characteristics in real-time based on continuous monitoring of kiln conditions, maintaining optimal heat transfer efficiency even as production parameters change. The burners feature modular construction allowing for customization based on fuel type availability and specific process requirements, with capabilities for multi-fuel operation that can seamlessly transition between different fuel types without compromising flame quality.

Strengths: Superior flame shape control through independent adjustment of multiple parameters; advanced CFD-based design optimization; real-time adaptive control systems; multi-fuel flexibility allowing operational continuity despite fuel supply changes. Weaknesses: Higher initial investment cost compared to conventional burners; requires more sophisticated control systems and operator training; optimal performance depends on accurate initial setup and calibration.

Nippon Furnace Co. Ltd.

Technical Solution: Nippon Furnace has developed specialized rotary kiln burner technology with particular emphasis on flame shape control and combustion efficiency for high-temperature industrial applications. Their NFK-MultiFlame system features a modular design with concentric fuel and air channels that can be independently adjusted to achieve precise flame geometry. The burner incorporates variable-angle swirl generators that create controlled turbulence patterns, enhancing fuel-air mixing while maintaining ideal flame shape and penetration depth. Nippon's technology utilizes advanced ceramic components in critical flame-facing sections, allowing operation at extremely high temperatures while maintaining structural integrity and precise flow characteristics. Their burners feature sophisticated fuel staging capabilities that distribute combustion along the flame length, creating optimized temperature profiles for specific material processing requirements. The company has implemented proprietary flame stabilization technology that maintains consistent flame characteristics despite variations in fuel quality or operating conditions. Nippon Furnace's systems include integrated optical monitoring that provides continuous feedback on flame geometry and temperature distribution, enabling real-time adjustments to maintain optimal combustion parameters. Their burners are designed with fuel flexibility in mind, capable of operating with various gaseous and liquid fuels while maintaining consistent flame properties.

Strengths: Exceptional high-temperature performance and durability; precise flame shape control through multiple independent adjustment parameters; advanced ceramic components extending operational life in extreme conditions; sophisticated monitoring and control integration. Weaknesses: Higher initial cost compared to conventional burners; specialized maintenance requirements for advanced ceramic components; optimal performance depends on integration with sophisticated control systems.

Key Patents and Innovations in Burner Efficiency

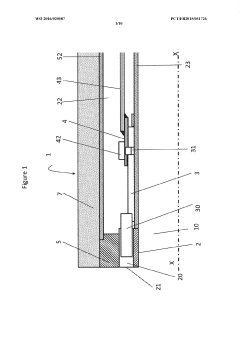

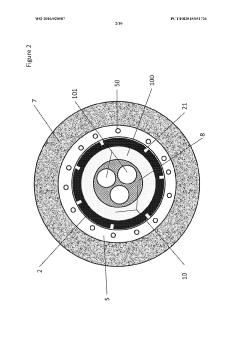

Burner device for rotary kiln and in-furnace combustion method for rotary kiln

PatentActiveJP2017122565A

Innovation

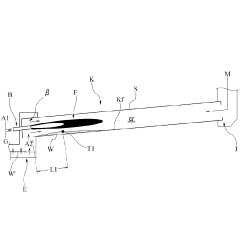

- The burner device employs first and second fuel injection ports that inject fuel in different angular directions, with controlled flow rate ratios to alter the flame's shape, position, and temperature distribution, using a control system to adjust the flow rates and velocities of fuel and air jets without changing the device's structure or using movable vanes.

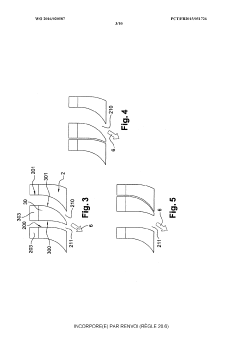

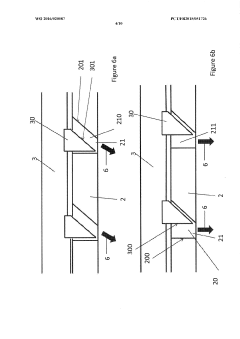

Burner with adjustable air or gas injection

PatentWO2016020587A1

Innovation

- A burner design featuring a primary air or gas duct with a movable ring and axial protrusions forming channels of different angles, allowing for linear adjustment of the radial component without pressure loss, maximizing expansion speed and maintaining momentum.

Environmental Impact and Emissions Reduction Strategies

The environmental impact of rotary kiln operations has become increasingly significant in industrial settings, particularly concerning emissions from burner systems. Traditional rotary kiln burners often produce substantial amounts of nitrogen oxides (NOx), sulfur oxides (SOx), carbon monoxide (CO), and particulate matter, contributing to air pollution and climate change. The selection of appropriate burner technology directly influences these emission profiles, with flame shape and combustion efficiency being critical determinants.

Low-NOx burner technologies have emerged as a primary strategy for emissions reduction in rotary kiln operations. These systems modify flame characteristics to reduce peak flame temperatures and create staged combustion zones, thereby minimizing thermal NOx formation. Advanced burner designs incorporating flue gas recirculation can achieve NOx reductions of 30-50% compared to conventional systems while maintaining optimal flame penetration for efficient material processing.

Fuel selection represents another crucial aspect of environmental impact management. Natural gas-fired burners typically produce fewer emissions compared to coal or petroleum coke alternatives, particularly regarding SOx and particulate matter. However, the transition to cleaner fuels must be balanced with considerations of flame characteristics, as different fuels produce distinct flame shapes and penetration patterns that affect kiln performance and product quality.

Oxygen-enhanced combustion technology offers significant potential for emissions reduction while improving energy efficiency. By increasing oxygen concentration in the combustion air, these systems enable more complete combustion at lower flame temperatures, reducing both fuel consumption and NOx formation. Studies indicate that oxygen-enhanced burners can reduce fuel consumption by 10-15% while simultaneously decreasing CO2 emissions proportionally.

Automated combustion control systems represent a technological advancement with substantial environmental benefits. These systems continuously monitor and adjust air-to-fuel ratios, flame characteristics, and burner positioning to maintain optimal combustion conditions. Real-time adjustments based on process parameters can reduce emissions by ensuring complete combustion and preventing the formation of pollutants associated with combustion inefficiencies.

Carbon capture technologies are increasingly being integrated with rotary kiln operations to address greenhouse gas emissions. Post-combustion capture systems can be retrofitted to existing installations, while more advanced oxy-fuel combustion approaches facilitate more efficient CO2 capture by producing a more concentrated CO2 stream. These technologies, though still evolving, offer pathways to reduce the carbon footprint of rotary kiln operations by 80-90% when fully implemented.

Low-NOx burner technologies have emerged as a primary strategy for emissions reduction in rotary kiln operations. These systems modify flame characteristics to reduce peak flame temperatures and create staged combustion zones, thereby minimizing thermal NOx formation. Advanced burner designs incorporating flue gas recirculation can achieve NOx reductions of 30-50% compared to conventional systems while maintaining optimal flame penetration for efficient material processing.

Fuel selection represents another crucial aspect of environmental impact management. Natural gas-fired burners typically produce fewer emissions compared to coal or petroleum coke alternatives, particularly regarding SOx and particulate matter. However, the transition to cleaner fuels must be balanced with considerations of flame characteristics, as different fuels produce distinct flame shapes and penetration patterns that affect kiln performance and product quality.

Oxygen-enhanced combustion technology offers significant potential for emissions reduction while improving energy efficiency. By increasing oxygen concentration in the combustion air, these systems enable more complete combustion at lower flame temperatures, reducing both fuel consumption and NOx formation. Studies indicate that oxygen-enhanced burners can reduce fuel consumption by 10-15% while simultaneously decreasing CO2 emissions proportionally.

Automated combustion control systems represent a technological advancement with substantial environmental benefits. These systems continuously monitor and adjust air-to-fuel ratios, flame characteristics, and burner positioning to maintain optimal combustion conditions. Real-time adjustments based on process parameters can reduce emissions by ensuring complete combustion and preventing the formation of pollutants associated with combustion inefficiencies.

Carbon capture technologies are increasingly being integrated with rotary kiln operations to address greenhouse gas emissions. Post-combustion capture systems can be retrofitted to existing installations, while more advanced oxy-fuel combustion approaches facilitate more efficient CO2 capture by producing a more concentrated CO2 stream. These technologies, though still evolving, offer pathways to reduce the carbon footprint of rotary kiln operations by 80-90% when fully implemented.

Energy Efficiency Metrics and Performance Benchmarking

Energy efficiency metrics for rotary kiln burners represent critical performance indicators that enable operators to evaluate, compare, and optimize burner systems. The primary efficiency metric is thermal efficiency, which measures the percentage of input energy successfully transferred to the material being processed. In modern rotary kiln operations, well-designed burner systems typically achieve thermal efficiencies between 55-75%, with state-of-the-art systems approaching 80% under optimal conditions.

Specific fuel consumption (SFC) serves as another essential benchmark, measuring the quantity of fuel required per unit of product. Industry standards for cement production, for instance, range from 3.0 to 3.6 GJ/ton of clinker, with best-in-class operations achieving values below 3.0 GJ/ton through advanced burner technology and optimized flame characteristics.

Heat rate, expressed as BTU/kWh or kJ/kg of product, provides a standardized comparison metric across different kiln operations. Performance benchmarking data indicates that flame shape significantly impacts heat rate, with pencil-shaped flames typically delivering 5-8% better heat transfer efficiency compared to short, bushy flames in applications requiring deep heat penetration.

Combustion efficiency metrics focus on the completeness of the fuel burning process, measured through exhaust gas analysis. Modern kiln burners should maintain oxygen levels between 1.5-3% in exhaust gases, with CO levels below 200 ppm. Higher CO levels indicate incomplete combustion and reduced efficiency, often resulting from suboptimal flame characteristics or insufficient air-fuel mixing.

Energy intensity ratios provide comparative benchmarks across different production facilities, typically measured as energy consumption per unit of production output. Leading cement manufacturers achieve energy intensity ratios of 3.3-3.7 GJ/ton, while less efficient operations may exceed 4.5 GJ/ton. The differential is frequently attributed to burner selection and flame management practices.

Heat loss analysis serves as a diagnostic tool for efficiency evaluation, with radiation and convection losses through kiln shells typically accounting for 8-15% of total energy input. Advanced thermal imaging techniques enable precise mapping of these losses, with benchmark data suggesting that optimal burner selection can reduce shell losses by 2-4 percentage points through improved flame distribution.

Carbon footprint metrics have gained importance as sustainability indicators, with efficient burner systems reducing CO2 emissions by 10-15% compared to legacy systems. Performance benchmarking across global operations indicates that flame penetration optimization alone can yield 3-7% reductions in greenhouse gas emissions per unit of production.

Specific fuel consumption (SFC) serves as another essential benchmark, measuring the quantity of fuel required per unit of product. Industry standards for cement production, for instance, range from 3.0 to 3.6 GJ/ton of clinker, with best-in-class operations achieving values below 3.0 GJ/ton through advanced burner technology and optimized flame characteristics.

Heat rate, expressed as BTU/kWh or kJ/kg of product, provides a standardized comparison metric across different kiln operations. Performance benchmarking data indicates that flame shape significantly impacts heat rate, with pencil-shaped flames typically delivering 5-8% better heat transfer efficiency compared to short, bushy flames in applications requiring deep heat penetration.

Combustion efficiency metrics focus on the completeness of the fuel burning process, measured through exhaust gas analysis. Modern kiln burners should maintain oxygen levels between 1.5-3% in exhaust gases, with CO levels below 200 ppm. Higher CO levels indicate incomplete combustion and reduced efficiency, often resulting from suboptimal flame characteristics or insufficient air-fuel mixing.

Energy intensity ratios provide comparative benchmarks across different production facilities, typically measured as energy consumption per unit of production output. Leading cement manufacturers achieve energy intensity ratios of 3.3-3.7 GJ/ton, while less efficient operations may exceed 4.5 GJ/ton. The differential is frequently attributed to burner selection and flame management practices.

Heat loss analysis serves as a diagnostic tool for efficiency evaluation, with radiation and convection losses through kiln shells typically accounting for 8-15% of total energy input. Advanced thermal imaging techniques enable precise mapping of these losses, with benchmark data suggesting that optimal burner selection can reduce shell losses by 2-4 percentage points through improved flame distribution.

Carbon footprint metrics have gained importance as sustainability indicators, with efficient burner systems reducing CO2 emissions by 10-15% compared to legacy systems. Performance benchmarking across global operations indicates that flame penetration optimization alone can yield 3-7% reductions in greenhouse gas emissions per unit of production.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!