Rotary Kiln Scale-Up From Pilot To Production: Thermal And Mechanical Considerations

AUG 22, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Rotary Kiln Scale-Up Background and Objectives

Rotary kilns have been a cornerstone technology in various industrial processes for over a century, evolving from simple cylindrical tubes to sophisticated engineering systems. The historical development of rotary kilns traces back to the late 19th century, primarily in cement production, before expanding to applications in minerals processing, waste treatment, and chemical manufacturing. This technological evolution has been characterized by incremental improvements in thermal efficiency, mechanical design, and process control systems.

The scale-up of rotary kilns from pilot to production scale represents one of the most challenging aspects of process engineering. Unlike many other unit operations, rotary kilns exhibit complex non-linear behaviors when dimensions increase, particularly regarding heat transfer mechanisms, material flow patterns, and mechanical stresses. Historical attempts at scale-up have often relied heavily on empirical correlations and experience-based adjustments, leading to inconsistent results and occasional costly failures.

Current industry trends show increasing demand for larger, more efficient kiln systems capable of handling diverse feedstocks while meeting stringent environmental regulations. The push toward sustainable manufacturing has accelerated research into optimizing thermal efficiency and reducing emissions, particularly in energy-intensive industries like cement and lime production. Simultaneously, advancements in computational modeling and simulation technologies have begun to transform the traditionally experience-based scale-up approach into a more scientifically rigorous methodology.

The primary technical objectives of rotary kiln scale-up focus on maintaining process equivalence across different scales while optimizing operational efficiency. This includes preserving key process parameters such as residence time distribution, temperature profiles, and reaction kinetics when transitioning from pilot to production scale. Additionally, scale-up efforts aim to predict and mitigate mechanical challenges including shell deformation, refractory wear, and drive system requirements that emerge at larger dimensions.

Recent technological innovations have introduced new considerations in kiln scale-up, including advanced refractory materials capable of withstanding higher temperatures, improved sealing systems that minimize heat losses, and sophisticated instrumentation for real-time process monitoring. The integration of digital technologies, including machine learning algorithms for predictive maintenance and process optimization, represents the cutting edge of rotary kiln technology development.

The objectives of this technical research report are to comprehensively analyze the thermal and mechanical considerations in rotary kiln scale-up, identify critical parameters that govern successful scale-up, evaluate current methodologies and their limitations, and propose innovative approaches to improve scale-up reliability. By synthesizing theoretical principles with practical engineering insights, this report aims to establish a more systematic framework for rotary kiln scale-up that reduces risk and enhances performance predictability in industrial applications.

The scale-up of rotary kilns from pilot to production scale represents one of the most challenging aspects of process engineering. Unlike many other unit operations, rotary kilns exhibit complex non-linear behaviors when dimensions increase, particularly regarding heat transfer mechanisms, material flow patterns, and mechanical stresses. Historical attempts at scale-up have often relied heavily on empirical correlations and experience-based adjustments, leading to inconsistent results and occasional costly failures.

Current industry trends show increasing demand for larger, more efficient kiln systems capable of handling diverse feedstocks while meeting stringent environmental regulations. The push toward sustainable manufacturing has accelerated research into optimizing thermal efficiency and reducing emissions, particularly in energy-intensive industries like cement and lime production. Simultaneously, advancements in computational modeling and simulation technologies have begun to transform the traditionally experience-based scale-up approach into a more scientifically rigorous methodology.

The primary technical objectives of rotary kiln scale-up focus on maintaining process equivalence across different scales while optimizing operational efficiency. This includes preserving key process parameters such as residence time distribution, temperature profiles, and reaction kinetics when transitioning from pilot to production scale. Additionally, scale-up efforts aim to predict and mitigate mechanical challenges including shell deformation, refractory wear, and drive system requirements that emerge at larger dimensions.

Recent technological innovations have introduced new considerations in kiln scale-up, including advanced refractory materials capable of withstanding higher temperatures, improved sealing systems that minimize heat losses, and sophisticated instrumentation for real-time process monitoring. The integration of digital technologies, including machine learning algorithms for predictive maintenance and process optimization, represents the cutting edge of rotary kiln technology development.

The objectives of this technical research report are to comprehensively analyze the thermal and mechanical considerations in rotary kiln scale-up, identify critical parameters that govern successful scale-up, evaluate current methodologies and their limitations, and propose innovative approaches to improve scale-up reliability. By synthesizing theoretical principles with practical engineering insights, this report aims to establish a more systematic framework for rotary kiln scale-up that reduces risk and enhances performance predictability in industrial applications.

Industrial Market Demand Analysis for Rotary Kiln Technology

The global rotary kiln market demonstrates robust growth driven by expanding applications across multiple industrial sectors. Current market analysis indicates significant demand in cement production, which accounts for approximately 40% of the total rotary kiln market. This dominance is attributed to the continuous infrastructure development in emerging economies, particularly in Asia-Pacific regions where urbanization rates continue to accelerate.

Mining and minerals processing represents the second largest application segment, with particular emphasis on calcination processes for limestone, dolomite, and various metal ores. Environmental regulations worldwide have created substantial demand for thermal treatment solutions for waste materials, positioning rotary kilns as critical equipment in waste management systems.

The chemical industry presents a growing market for specialized rotary kilns, particularly in the production of lightweight aggregates, activated carbon, and specialty chemicals requiring precise thermal processing conditions. This segment values kilns with advanced control systems capable of maintaining exact temperature profiles throughout the processing cycle.

Market research indicates a compound annual growth rate of 4.7% for industrial rotary kiln technology through 2028, with particularly strong growth in regions implementing stricter environmental standards. The ability to scale up from pilot to production while maintaining thermal efficiency has become a critical competitive factor, as manufacturers seek to minimize energy consumption while maximizing throughput.

Customer requirements increasingly emphasize energy efficiency, with industrial users prioritizing kilns that demonstrate reduced fuel consumption per unit of production. This trend is directly correlated with rising energy costs and carbon taxation policies being implemented globally. Consequently, manufacturers capable of demonstrating successful scale-up methodologies that preserve thermal efficiency metrics have gained significant market advantage.

Mechanical reliability during scale-up represents another key demand driver, with end-users willing to pay premium prices for systems that minimize maintenance requirements and unplanned downtime. The cost of production interruptions in continuous processing industries can exceed millions of dollars per day, making mechanical robustness a critical consideration in purchasing decisions.

Customization capabilities have emerged as a significant market differentiator, with customers seeking rotary kiln solutions tailored to specific material characteristics and production requirements. This trend has created market opportunities for manufacturers offering modular designs that can be efficiently scaled while accommodating process-specific modifications.

Mining and minerals processing represents the second largest application segment, with particular emphasis on calcination processes for limestone, dolomite, and various metal ores. Environmental regulations worldwide have created substantial demand for thermal treatment solutions for waste materials, positioning rotary kilns as critical equipment in waste management systems.

The chemical industry presents a growing market for specialized rotary kilns, particularly in the production of lightweight aggregates, activated carbon, and specialty chemicals requiring precise thermal processing conditions. This segment values kilns with advanced control systems capable of maintaining exact temperature profiles throughout the processing cycle.

Market research indicates a compound annual growth rate of 4.7% for industrial rotary kiln technology through 2028, with particularly strong growth in regions implementing stricter environmental standards. The ability to scale up from pilot to production while maintaining thermal efficiency has become a critical competitive factor, as manufacturers seek to minimize energy consumption while maximizing throughput.

Customer requirements increasingly emphasize energy efficiency, with industrial users prioritizing kilns that demonstrate reduced fuel consumption per unit of production. This trend is directly correlated with rising energy costs and carbon taxation policies being implemented globally. Consequently, manufacturers capable of demonstrating successful scale-up methodologies that preserve thermal efficiency metrics have gained significant market advantage.

Mechanical reliability during scale-up represents another key demand driver, with end-users willing to pay premium prices for systems that minimize maintenance requirements and unplanned downtime. The cost of production interruptions in continuous processing industries can exceed millions of dollars per day, making mechanical robustness a critical consideration in purchasing decisions.

Customization capabilities have emerged as a significant market differentiator, with customers seeking rotary kiln solutions tailored to specific material characteristics and production requirements. This trend has created market opportunities for manufacturers offering modular designs that can be efficiently scaled while accommodating process-specific modifications.

Technical Challenges in Rotary Kiln Scale-Up

Scaling up rotary kilns from pilot to production scale presents significant technical challenges that require careful consideration of both thermal and mechanical factors. The transition involves complex engineering problems that must be addressed to ensure operational efficiency, product quality, and equipment longevity.

Thermal scaling considerations represent one of the most critical challenges. Heat transfer mechanisms in rotary kilns—including radiation, conduction, and convection—do not scale linearly with kiln dimensions. The surface-to-volume ratio decreases as kiln diameter increases, resulting in different temperature profiles and residence time distributions. This non-linear scaling affects reaction kinetics, potentially altering product properties and process efficiency.

Material flow behavior changes substantially during scale-up. In pilot kilns, the bed depth and material cascading patterns may not accurately represent those in production-scale equipment. The angle of repose, material segregation, and particle movement patterns all transform with increased diameter and length, affecting heat transfer efficiency and reaction completeness. These differences must be carefully modeled and compensated for in the design phase.

Mechanical integrity presents another significant challenge. Production kilns experience greater thermal gradients across their shells, leading to differential expansion and increased mechanical stress. The supporting structures, drive systems, and seals must be engineered to accommodate these stresses while maintaining proper alignment. Larger kilns also experience more significant shell ovality issues that can affect refractory lining integrity and operational stability.

Refractory selection and design become more critical at production scale. The increased thermal mass and longer heating/cooling cycles create more severe thermal cycling conditions. Refractory expansion joints must be properly designed to prevent cracking while maintaining gas sealing properties. The selection of appropriate materials must balance thermal performance, mechanical strength, and economic considerations.

Control system complexity increases exponentially with scale. Production kilns require more sophisticated instrumentation and control algorithms to manage the increased thermal inertia and process variability. Temperature measurement and control become more challenging due to the larger dimensions and higher thermal gradients. Advanced control strategies, including model predictive control and artificial intelligence approaches, are often necessary to maintain process stability.

Energy efficiency considerations become paramount at production scale. The increased thermal mass and heat losses require careful optimization of burner design, combustion control, and heat recovery systems. Insulation strategies must be reconsidered, as the economic balance between capital costs and operational efficiency shifts significantly with scale.

Environmental impact management also presents unique challenges during scale-up. Emissions control systems must handle larger gas volumes while meeting increasingly stringent regulatory requirements. Dust generation and containment become more difficult with increased material throughput and air velocities.

Thermal scaling considerations represent one of the most critical challenges. Heat transfer mechanisms in rotary kilns—including radiation, conduction, and convection—do not scale linearly with kiln dimensions. The surface-to-volume ratio decreases as kiln diameter increases, resulting in different temperature profiles and residence time distributions. This non-linear scaling affects reaction kinetics, potentially altering product properties and process efficiency.

Material flow behavior changes substantially during scale-up. In pilot kilns, the bed depth and material cascading patterns may not accurately represent those in production-scale equipment. The angle of repose, material segregation, and particle movement patterns all transform with increased diameter and length, affecting heat transfer efficiency and reaction completeness. These differences must be carefully modeled and compensated for in the design phase.

Mechanical integrity presents another significant challenge. Production kilns experience greater thermal gradients across their shells, leading to differential expansion and increased mechanical stress. The supporting structures, drive systems, and seals must be engineered to accommodate these stresses while maintaining proper alignment. Larger kilns also experience more significant shell ovality issues that can affect refractory lining integrity and operational stability.

Refractory selection and design become more critical at production scale. The increased thermal mass and longer heating/cooling cycles create more severe thermal cycling conditions. Refractory expansion joints must be properly designed to prevent cracking while maintaining gas sealing properties. The selection of appropriate materials must balance thermal performance, mechanical strength, and economic considerations.

Control system complexity increases exponentially with scale. Production kilns require more sophisticated instrumentation and control algorithms to manage the increased thermal inertia and process variability. Temperature measurement and control become more challenging due to the larger dimensions and higher thermal gradients. Advanced control strategies, including model predictive control and artificial intelligence approaches, are often necessary to maintain process stability.

Energy efficiency considerations become paramount at production scale. The increased thermal mass and heat losses require careful optimization of burner design, combustion control, and heat recovery systems. Insulation strategies must be reconsidered, as the economic balance between capital costs and operational efficiency shifts significantly with scale.

Environmental impact management also presents unique challenges during scale-up. Emissions control systems must handle larger gas volumes while meeting increasingly stringent regulatory requirements. Dust generation and containment become more difficult with increased material throughput and air velocities.

Current Scale-Up Methodologies and Design Approaches

01 Design and structural optimization for rotary kiln scale-up

The design and structural optimization of rotary kilns is crucial for successful scale-up operations. This includes considerations for the kiln shell design, support structures, and mechanical components that can withstand larger operational demands. Optimized structural designs ensure stability, durability, and efficient heat transfer in scaled-up rotary kilns, while minimizing mechanical stress and deformation under increased thermal loads.- Design and structural improvements for rotary kilns: Various structural improvements can enhance the efficiency and scalability of rotary kilns. These include optimized kiln shell designs, improved support mechanisms, and innovative structural configurations that allow for larger processing capacities while maintaining operational stability. Such design enhancements enable better heat distribution, reduced mechanical stress, and improved durability during scale-up operations.

- Thermal efficiency optimization in scaled-up rotary kilns: When scaling up rotary kilns, thermal efficiency becomes critical. Innovations focus on improved heat transfer mechanisms, advanced refractory materials, and optimized combustion systems. These developments allow for better temperature control, reduced energy consumption, and more uniform heating profiles across larger kiln dimensions, which are essential factors when increasing the size and throughput of rotary kiln operations.

- Material handling and flow control in large-scale kilns: Effective material handling is crucial when scaling up rotary kilns. Innovations include advanced feeding mechanisms, improved material distribution systems, and optimized retention time control. These technologies ensure consistent material flow, prevent agglomeration issues, and maintain product quality even as processing volumes increase substantially during scale-up operations.

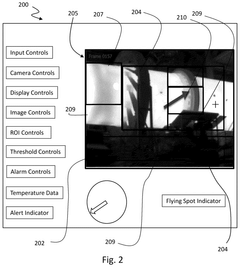

- Monitoring and control systems for scaled-up operations: Advanced monitoring and control systems are essential for successful rotary kiln scale-up. These include sophisticated temperature sensors, automated process control algorithms, and real-time monitoring technologies. Such systems enable precise operation management, predictive maintenance capabilities, and optimization of process parameters across larger kiln dimensions, ensuring consistent product quality despite increased processing volumes.

- Scale-up methodologies and mathematical modeling: Systematic approaches to rotary kiln scale-up involve mathematical modeling, simulation techniques, and empirical scaling factors. These methodologies help predict performance at larger scales, optimize design parameters, and identify potential operational issues before physical implementation. Advanced computational fluid dynamics and heat transfer models enable engineers to accurately forecast how process parameters will change with increased kiln dimensions.

02 Thermal efficiency improvements in scaled-up rotary kilns

Enhancing thermal efficiency is essential when scaling up rotary kilns to maintain or improve performance at larger scales. This involves optimizing heat transfer mechanisms, improving insulation systems, and implementing advanced combustion technologies. Efficient heat recovery systems and strategic placement of heating elements help maintain uniform temperature profiles throughout the larger kiln structure, reducing energy consumption while ensuring consistent product quality.Expand Specific Solutions03 Material handling and flow control in large-scale rotary kilns

Effective material handling and flow control systems are critical for successful rotary kiln scale-up. This includes designing appropriate feed mechanisms, optimizing kiln inclination angles, and implementing advanced retention time control methods. Specialized internal structures such as lifters, dams, and baffles help maintain proper material distribution and movement through the scaled-up kiln, ensuring consistent processing conditions and product quality despite the increased throughput volumes.Expand Specific Solutions04 Monitoring and control systems for scaled-up operations

Advanced monitoring and control systems are essential for managing the increased complexity of scaled-up rotary kiln operations. These systems include sophisticated temperature sensors, pressure monitors, and automated control mechanisms that maintain optimal processing conditions. Real-time data collection and analysis enable precise adjustments to operational parameters, ensuring process stability and product consistency despite the challenges associated with larger-scale operations.Expand Specific Solutions05 Scale-up methodologies and predictive modeling techniques

Systematic scale-up methodologies and predictive modeling techniques are fundamental for successful rotary kiln expansion projects. These approaches include dimensional analysis, computational fluid dynamics, and thermal modeling to predict performance at larger scales. Pilot-scale testing and simulation tools help identify potential issues before full-scale implementation, allowing engineers to optimize design parameters and operational conditions for the scaled-up kiln while minimizing risk and development costs.Expand Specific Solutions

Leading Manufacturers and Engineering Firms in Rotary Kiln Industry

The rotary kiln scale-up market is in a growth phase, with increasing demand driven by industrial expansion in cement, minerals, and chemical processing sectors. The competitive landscape features established engineering firms like Zhongye Changtian and thyssenkrupp Industrial Solutions alongside specialized research institutions such as Fraunhofer-Gesellschaft. Market players are focusing on thermal efficiency optimization and mechanical reliability during scale-up processes. Chinese companies (CITIC Heavy Industries, Luoyang Mining Machinery) have gained significant market share, while European and Japanese firms (Polysius AG, Chugai Ro) contribute advanced technological solutions. The technology maturity varies across applications, with cement and metallurgical applications being more established than newer environmental and chemical processing implementations, creating opportunities for innovation in thermal modeling and mechanical design optimization.

Andritz Oy

Technical Solution: Andritz has developed an advanced rotary kiln scale-up technology centered around their proprietary "Thermal-Mechanical Coupling" methodology. This approach simultaneously addresses heat transfer dynamics and mechanical stress distributions during the transition from pilot to production scale. Their system employs computational fluid dynamics (CFD) models enhanced with proprietary algorithms that accurately predict flame behavior and heat distribution patterns across different kiln geometries. Andritz's mechanical scaling considerations include innovative support structures that accommodate thermal expansion while minimizing shell deformation. The company has pioneered adaptive drive systems that respond to changing torque requirements during scale-up operations, preventing mechanical failures during critical transition periods. Their technology incorporates comprehensive instrumentation packages that provide real-time monitoring of both thermal profiles and mechanical stresses, enabling dynamic adjustments during scale-up implementation. Andritz's approach also includes specialized refractory designs that account for the changing thermal gradients encountered during scale-up.

Strengths: Exceptional automation and control systems integration provides superior operational stability during scale-up transitions. Strong focus on energy efficiency optimization during scale-up process delivers cost benefits. Weaknesses: Solutions often require significant customization for specific applications, increasing implementation time. Higher initial investment compared to some competitors may limit accessibility for smaller operations.

CITIC Heavy Industries Co., Ltd.

Technical Solution: CITIC Heavy Industries has developed a comprehensive rotary kiln scale-up methodology that integrates both thermal and mechanical considerations through their "Dual-Domain Scaling" approach. Their technology employs computational thermal fluid dynamics (CTFD) models that accurately predict heat transfer coefficients across different kiln scales while accounting for material bed behavior changes. CITIC's proprietary mechanical design framework addresses the critical challenges of shell deformation and support system loading during scale-up by implementing variable thickness shell designs and optimized riding ring placements. The company has pioneered advanced refractory systems specifically engineered to withstand the thermal stresses encountered during scale-up transitions, featuring gradient composition linings that accommodate different thermal zones. Their scale-up process incorporates instrumented pilot kilns with comprehensive sensor arrays that capture both thermal profiles and mechanical stress distributions, providing validation data for their computational models.

Strengths: Strong integration of mechanical engineering expertise with thermal modeling provides balanced scale-up solutions. Extensive manufacturing capabilities allow for customized implementation of theoretical designs. Weaknesses: Relatively conservative approach to innovation may result in less cutting-edge solutions compared to some competitors. Documentation and technical support primarily in Chinese may create challenges for international clients.

Critical Thermal and Mechanical Engineering Principles

Rotary kiln brick layer thermal monitoring systems

PatentActiveUS12352499B2

Innovation

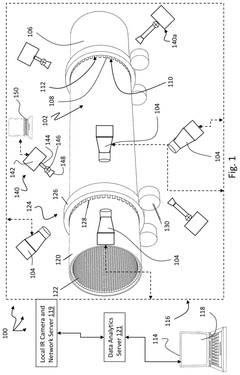

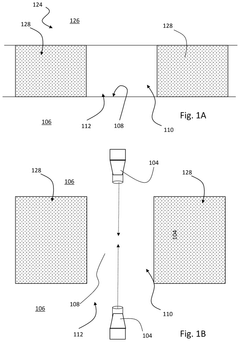

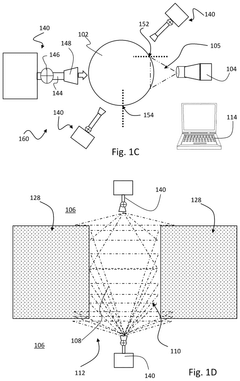

- A system comprising infrared imaging sensors and a computing system that monitors brick thickness and temperature variations by correlating infrared data with brick thickness, using machine learning to predict brick degradation and control a cooling system to mitigate hotspots.

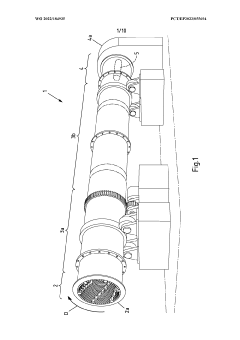

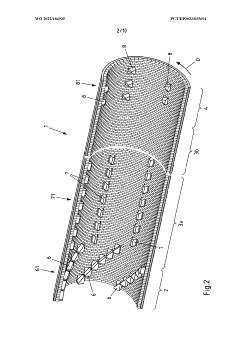

Rotary kiln and method for calcining carbonate-containing material, in particular limestone or dolomite

PatentWO2022184935A1

Innovation

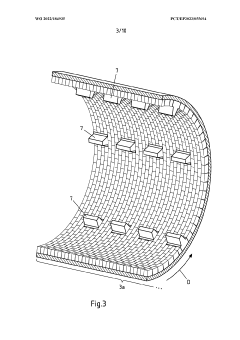

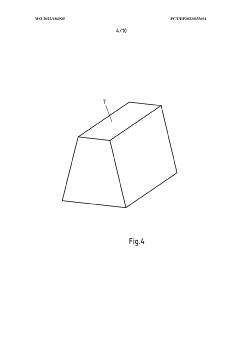

- The rotary kiln design incorporates a series of projections in the preheating zone arranged in a staggered manner to create spiral transport paths, ensuring thorough mixing and rapid calcination, along with refractory materials for high-temperature resistance, and additional projections in the inlet and outlet zones to enhance material conveyance and cooling uniformity.

Material Selection and Refractory Considerations

Material selection and refractory considerations represent critical factors in the successful scale-up of rotary kilns from pilot to production scale. The harsh operating environment within rotary kilns—characterized by extreme temperatures, mechanical stresses, and chemical reactions—demands careful selection of construction materials that can withstand these conditions while maintaining operational efficiency and longevity.

For the shell construction, high-temperature resistant alloy steels are typically employed, with specific grades selected based on the maximum operating temperature and mechanical loads anticipated in the scaled-up kiln. Carbon steel remains suitable for lower temperature zones (below 350°C), while various grades of stainless steel or heat-resistant alloys become necessary for higher temperature sections. The increased diameter and length in production kilns significantly amplify thermal expansion forces, requiring materials with appropriate thermal expansion coefficients.

Refractory linings constitute the primary defense against thermal damage and chemical attack within the kiln. The scale-up process necessitates reconsideration of refractory specifications, as heat transfer dynamics change substantially between pilot and production scales. Alumina-based refractories offer excellent resistance to thermal shock in moderate temperature applications, while magnesia and dolomite refractories provide superior performance in high-temperature, alkaline environments. Zirconia-based materials, though costly, deliver exceptional thermal insulation and chemical resistance for the most demanding applications.

The thickness of refractory linings requires careful optimization during scale-up. While thicker linings provide better insulation and protection, they also increase thermal mass, affecting heating efficiency and operational flexibility. Modern production kilns often implement multi-layer refractory systems, combining dense, abrasion-resistant inner layers with insulating outer layers to optimize both protection and energy efficiency.

Chemical compatibility between process materials and refractories becomes increasingly important at production scale, where longer campaign durations amplify the effects of even minor chemical interactions. Specialized coatings or barrier layers may be incorporated to protect against specific chemical attack mechanisms identified during pilot operations.

Mechanical considerations in material selection include resistance to thermal cycling, abrasion from material movement, and structural integrity under the increased loads of production-scale operations. The joining methods between refractory bricks must accommodate thermal expansion while maintaining gas-tight seals, often requiring specialized mortars or interlocking designs that become more critical as kiln dimensions increase.

Advanced monitoring systems, including embedded thermocouples and strain gauges, are increasingly integrated into modern refractory systems to provide real-time data on material performance and deterioration, enabling predictive maintenance approaches that minimize costly downtime in production-scale operations.

For the shell construction, high-temperature resistant alloy steels are typically employed, with specific grades selected based on the maximum operating temperature and mechanical loads anticipated in the scaled-up kiln. Carbon steel remains suitable for lower temperature zones (below 350°C), while various grades of stainless steel or heat-resistant alloys become necessary for higher temperature sections. The increased diameter and length in production kilns significantly amplify thermal expansion forces, requiring materials with appropriate thermal expansion coefficients.

Refractory linings constitute the primary defense against thermal damage and chemical attack within the kiln. The scale-up process necessitates reconsideration of refractory specifications, as heat transfer dynamics change substantially between pilot and production scales. Alumina-based refractories offer excellent resistance to thermal shock in moderate temperature applications, while magnesia and dolomite refractories provide superior performance in high-temperature, alkaline environments. Zirconia-based materials, though costly, deliver exceptional thermal insulation and chemical resistance for the most demanding applications.

The thickness of refractory linings requires careful optimization during scale-up. While thicker linings provide better insulation and protection, they also increase thermal mass, affecting heating efficiency and operational flexibility. Modern production kilns often implement multi-layer refractory systems, combining dense, abrasion-resistant inner layers with insulating outer layers to optimize both protection and energy efficiency.

Chemical compatibility between process materials and refractories becomes increasingly important at production scale, where longer campaign durations amplify the effects of even minor chemical interactions. Specialized coatings or barrier layers may be incorporated to protect against specific chemical attack mechanisms identified during pilot operations.

Mechanical considerations in material selection include resistance to thermal cycling, abrasion from material movement, and structural integrity under the increased loads of production-scale operations. The joining methods between refractory bricks must accommodate thermal expansion while maintaining gas-tight seals, often requiring specialized mortars or interlocking designs that become more critical as kiln dimensions increase.

Advanced monitoring systems, including embedded thermocouples and strain gauges, are increasingly integrated into modern refractory systems to provide real-time data on material performance and deterioration, enabling predictive maintenance approaches that minimize costly downtime in production-scale operations.

Energy Efficiency and Environmental Impact Assessment

Energy efficiency in rotary kiln operations represents a critical factor in the scale-up process from pilot to production scale. The thermal efficiency of rotary kilns typically ranges from 40% to 60%, with significant energy losses occurring through shell radiation, exhaust gases, and incomplete combustion. When scaling up, these inefficiencies can magnify substantially, resulting in disproportionate increases in energy consumption relative to production capacity.

Advanced heat recovery systems have demonstrated potential to improve energy efficiency by 15-25% in production-scale kilns. These include waste heat recovery boilers, preheaters, and regenerative thermal oxidizers that capture and repurpose thermal energy that would otherwise be lost. Implementation of these systems requires careful integration with the scaled-up kiln design to ensure optimal heat transfer without compromising process stability.

Fuel selection significantly impacts both energy efficiency and environmental footprint. Natural gas offers cleaner combustion with lower particulate emissions compared to coal or petroleum coke, though economic considerations often influence fuel choices in production environments. Hybrid firing systems that can alternate between multiple fuel types provide operational flexibility while optimizing efficiency based on process requirements and fuel availability.

Environmental impact assessments for scaled-up rotary kiln operations must address several critical emissions categories. Particulate matter emissions typically increase from 50-100 mg/Nm³ at pilot scale to 150-300 mg/Nm³ in production without proper mitigation technologies. NOx emissions similarly scale up, often requiring selective catalytic reduction (SCR) or selective non-catalytic reduction (SNCR) systems in production facilities to maintain regulatory compliance.

Carbon footprint considerations become increasingly important at production scale. Life cycle assessment studies indicate that energy consumption during kiln operation accounts for 60-80% of the total carbon footprint of products manufactured using rotary kilns. Implementation of carbon capture technologies remains technically challenging but represents a frontier for environmental impact reduction in large-scale operations.

Water usage and wastewater management present additional environmental challenges during scale-up. Cooling systems for larger kilns typically require 2-5 m³ of water per ton of product, necessitating closed-loop water recycling systems to minimize environmental impact. Advanced water treatment technologies, including membrane filtration and biological treatment processes, have demonstrated effectiveness in managing increased wastewater volumes associated with production-scale operations.

Advanced heat recovery systems have demonstrated potential to improve energy efficiency by 15-25% in production-scale kilns. These include waste heat recovery boilers, preheaters, and regenerative thermal oxidizers that capture and repurpose thermal energy that would otherwise be lost. Implementation of these systems requires careful integration with the scaled-up kiln design to ensure optimal heat transfer without compromising process stability.

Fuel selection significantly impacts both energy efficiency and environmental footprint. Natural gas offers cleaner combustion with lower particulate emissions compared to coal or petroleum coke, though economic considerations often influence fuel choices in production environments. Hybrid firing systems that can alternate between multiple fuel types provide operational flexibility while optimizing efficiency based on process requirements and fuel availability.

Environmental impact assessments for scaled-up rotary kiln operations must address several critical emissions categories. Particulate matter emissions typically increase from 50-100 mg/Nm³ at pilot scale to 150-300 mg/Nm³ in production without proper mitigation technologies. NOx emissions similarly scale up, often requiring selective catalytic reduction (SCR) or selective non-catalytic reduction (SNCR) systems in production facilities to maintain regulatory compliance.

Carbon footprint considerations become increasingly important at production scale. Life cycle assessment studies indicate that energy consumption during kiln operation accounts for 60-80% of the total carbon footprint of products manufactured using rotary kilns. Implementation of carbon capture technologies remains technically challenging but represents a frontier for environmental impact reduction in large-scale operations.

Water usage and wastewater management present additional environmental challenges during scale-up. Cooling systems for larger kilns typically require 2-5 m³ of water per ton of product, necessitating closed-loop water recycling systems to minimize environmental impact. Advanced water treatment technologies, including membrane filtration and biological treatment processes, have demonstrated effectiveness in managing increased wastewater volumes associated with production-scale operations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!