Rotary Kiln Versus Fluidized Bed: Which One Fits Your Feedstock

AUG 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermal Processing Technology Evolution and Objectives

Thermal processing technologies have evolved significantly over the past century, transforming from rudimentary heating methods to sophisticated systems capable of precise temperature control and material transformation. The journey began with simple batch kilns in the early 20th century, which were primarily used for ceramics and cement production. These early systems suffered from inefficiencies in heat distribution and material handling, leading to inconsistent product quality.

The mid-20th century witnessed a paradigm shift with the introduction of continuous processing systems, notably the rotary kiln. This innovation revolutionized industries such as cement, lime, and minerals processing by enabling uninterrupted operation and improved thermal efficiency. The rotary kiln's ability to handle diverse feedstocks while maintaining consistent temperature profiles established it as the industry standard for decades.

Parallel to rotary kiln development, fluidized bed technology emerged in the 1940s, initially for coal gasification applications. By the 1970s, this technology had expanded into various thermal processing applications, offering advantages in heat transfer efficiency and reaction control. The oil crisis of the 1970s accelerated innovation in both technologies, driving improvements in energy efficiency and emissions control.

The digital revolution of the 1990s brought sophisticated control systems to thermal processing equipment, enabling real-time monitoring and precise adjustment of operating parameters. This period also saw increased focus on environmental performance, with both rotary kilns and fluidized beds incorporating advanced emission control systems to meet stringent regulatory requirements.

Recent technological advancements have focused on optimizing these systems for specific feedstock characteristics. Modern rotary kilns feature improved refractory materials, enhanced heat recovery systems, and variable speed drives for optimal residence time control. Similarly, fluidized bed technology has evolved with innovations in bed material selection, air distribution systems, and multi-stage processing capabilities.

The primary objective of current thermal processing technology development is to achieve maximum resource efficiency while minimizing environmental impact. This includes reducing energy consumption, lowering greenhouse gas emissions, and enabling the processing of alternative and waste feedstocks. Additionally, there is growing emphasis on system flexibility to accommodate varying feedstock qualities and production requirements.

Another critical objective is process intensification – achieving higher throughput and conversion efficiency within smaller equipment footprints. This trend is particularly evident in industries facing space constraints or seeking to reduce capital expenditure. Simultaneously, the integration of digital technologies such as AI-driven predictive maintenance and digital twins is becoming increasingly important for optimizing operational performance and extending equipment lifespan.

The mid-20th century witnessed a paradigm shift with the introduction of continuous processing systems, notably the rotary kiln. This innovation revolutionized industries such as cement, lime, and minerals processing by enabling uninterrupted operation and improved thermal efficiency. The rotary kiln's ability to handle diverse feedstocks while maintaining consistent temperature profiles established it as the industry standard for decades.

Parallel to rotary kiln development, fluidized bed technology emerged in the 1940s, initially for coal gasification applications. By the 1970s, this technology had expanded into various thermal processing applications, offering advantages in heat transfer efficiency and reaction control. The oil crisis of the 1970s accelerated innovation in both technologies, driving improvements in energy efficiency and emissions control.

The digital revolution of the 1990s brought sophisticated control systems to thermal processing equipment, enabling real-time monitoring and precise adjustment of operating parameters. This period also saw increased focus on environmental performance, with both rotary kilns and fluidized beds incorporating advanced emission control systems to meet stringent regulatory requirements.

Recent technological advancements have focused on optimizing these systems for specific feedstock characteristics. Modern rotary kilns feature improved refractory materials, enhanced heat recovery systems, and variable speed drives for optimal residence time control. Similarly, fluidized bed technology has evolved with innovations in bed material selection, air distribution systems, and multi-stage processing capabilities.

The primary objective of current thermal processing technology development is to achieve maximum resource efficiency while minimizing environmental impact. This includes reducing energy consumption, lowering greenhouse gas emissions, and enabling the processing of alternative and waste feedstocks. Additionally, there is growing emphasis on system flexibility to accommodate varying feedstock qualities and production requirements.

Another critical objective is process intensification – achieving higher throughput and conversion efficiency within smaller equipment footprints. This trend is particularly evident in industries facing space constraints or seeking to reduce capital expenditure. Simultaneously, the integration of digital technologies such as AI-driven predictive maintenance and digital twins is becoming increasingly important for optimizing operational performance and extending equipment lifespan.

Market Demand Analysis for Industrial Calcination Systems

The global industrial calcination systems market is experiencing robust growth, driven by increasing demand across multiple sectors including cement production, mineral processing, and chemical manufacturing. Current market valuation stands at approximately 4.2 billion USD with projections indicating a compound annual growth rate of 5.7% through 2028, reflecting the essential role these systems play in modern industrial processes.

Demand for calcination systems is particularly strong in emerging economies where rapid industrialization and infrastructure development continue to fuel the cement and construction materials sectors. China, India, and Southeast Asian nations collectively represent over 40% of the global market demand, with China alone accounting for nearly 25% of worldwide calcination equipment installations.

Environmental regulations are significantly reshaping market requirements, with stricter emissions standards driving demand for more efficient and cleaner calcination technologies. This regulatory pressure has created a distinct market segment for advanced calcination systems that can demonstrate reduced carbon footprints and lower particulate emissions, commanding premium pricing despite higher initial capital investments.

The choice between rotary kiln and fluidized bed technologies represents a critical decision point for end-users, with market analysis revealing distinct preference patterns based on industry application. Rotary kilns continue to dominate in traditional cement and lime production, holding approximately 65% market share in these sectors due to their robustness and ability to handle varied feedstock qualities.

Fluidized bed technology, however, is gaining significant traction in specialized applications where precise temperature control and uniform heat distribution are paramount. Market data indicates a 12% annual growth rate for fluidized bed systems, outpacing the overall market, particularly in pharmaceutical, specialty chemicals, and advanced materials processing sectors.

Feedstock characteristics are increasingly recognized as the primary determinant in technology selection, creating market segmentation based on material properties rather than just industry verticals. This trend has prompted equipment manufacturers to develop more versatile systems capable of processing wider ranges of feedstock characteristics, with customization services emerging as a high-margin market segment.

Energy efficiency has become a dominant purchasing criterion, with market surveys indicating that 78% of procurement decisions now include total cost of ownership calculations that heavily weight operational energy consumption. This shift has created premium market positioning for systems demonstrating superior thermal efficiency, particularly in regions with high energy costs.

Demand for calcination systems is particularly strong in emerging economies where rapid industrialization and infrastructure development continue to fuel the cement and construction materials sectors. China, India, and Southeast Asian nations collectively represent over 40% of the global market demand, with China alone accounting for nearly 25% of worldwide calcination equipment installations.

Environmental regulations are significantly reshaping market requirements, with stricter emissions standards driving demand for more efficient and cleaner calcination technologies. This regulatory pressure has created a distinct market segment for advanced calcination systems that can demonstrate reduced carbon footprints and lower particulate emissions, commanding premium pricing despite higher initial capital investments.

The choice between rotary kiln and fluidized bed technologies represents a critical decision point for end-users, with market analysis revealing distinct preference patterns based on industry application. Rotary kilns continue to dominate in traditional cement and lime production, holding approximately 65% market share in these sectors due to their robustness and ability to handle varied feedstock qualities.

Fluidized bed technology, however, is gaining significant traction in specialized applications where precise temperature control and uniform heat distribution are paramount. Market data indicates a 12% annual growth rate for fluidized bed systems, outpacing the overall market, particularly in pharmaceutical, specialty chemicals, and advanced materials processing sectors.

Feedstock characteristics are increasingly recognized as the primary determinant in technology selection, creating market segmentation based on material properties rather than just industry verticals. This trend has prompted equipment manufacturers to develop more versatile systems capable of processing wider ranges of feedstock characteristics, with customization services emerging as a high-margin market segment.

Energy efficiency has become a dominant purchasing criterion, with market surveys indicating that 78% of procurement decisions now include total cost of ownership calculations that heavily weight operational energy consumption. This shift has created premium market positioning for systems demonstrating superior thermal efficiency, particularly in regions with high energy costs.

Current Technical Challenges in Feedstock Processing

Feedstock processing technologies face several significant challenges in today's industrial landscape. The selection between rotary kilns and fluidized beds represents a critical decision point that impacts operational efficiency, product quality, and economic viability. One of the primary challenges is feedstock heterogeneity, which creates inconsistent processing conditions. Both rotary kilns and fluidized beds struggle with varying particle sizes, moisture content, and chemical compositions, though in different ways.

Temperature control presents another substantial challenge. Rotary kilns often exhibit temperature gradients along their length, making uniform heat treatment difficult for sensitive materials. Fluidized beds offer better temperature uniformity but may struggle with extremely high-temperature applications where material sintering can disrupt fluidization dynamics.

Energy efficiency remains a persistent concern across processing technologies. Rotary kilns typically consume significant energy due to their large thermal mass and heat losses through the rotating shell. While fluidized beds generally demonstrate better heat transfer efficiency, they require considerable energy input for gas fluidization, particularly with dense or cohesive feedstocks.

Scaling issues represent a significant technical hurdle. Laboratory-scale successes often fail to translate directly to industrial implementation. Rotary kilns face challenges in maintaining consistent bed depth and residence time distribution at larger scales, while fluidized beds encounter difficulties with gas distribution uniformity and potential defluidization zones in scaled-up operations.

Material handling complications further exacerbate processing challenges. Sticky, agglomerating feedstocks can cause buildup on kiln walls or defluidization in fluidized beds. Abrasive materials accelerate equipment wear in both systems, though the impact manifests differently—shell and lifter wear in kilns versus distributor plate and cyclone erosion in fluidized beds.

Emissions control has become increasingly important with stricter environmental regulations. Both technologies struggle with capturing fine particulates and volatile compounds, though fluidized beds typically offer better opportunities for in-situ emissions treatment due to their favorable gas-solid contact characteristics.

Process control and automation present ongoing challenges. Rotary kilns suffer from limited real-time monitoring capabilities inside the rotating vessel, while fluidized beds require sophisticated control systems to maintain stable fluidization regimes across varying feedstock conditions. The development of reliable, non-invasive sensing technologies remains an active area of research for both processing methods.

Cross-contamination between batches poses particular difficulties in multi-product facilities, with cleaning procedures being more straightforward but time-consuming for rotary kilns compared to the complex internal structures of fluidized bed systems.

Temperature control presents another substantial challenge. Rotary kilns often exhibit temperature gradients along their length, making uniform heat treatment difficult for sensitive materials. Fluidized beds offer better temperature uniformity but may struggle with extremely high-temperature applications where material sintering can disrupt fluidization dynamics.

Energy efficiency remains a persistent concern across processing technologies. Rotary kilns typically consume significant energy due to their large thermal mass and heat losses through the rotating shell. While fluidized beds generally demonstrate better heat transfer efficiency, they require considerable energy input for gas fluidization, particularly with dense or cohesive feedstocks.

Scaling issues represent a significant technical hurdle. Laboratory-scale successes often fail to translate directly to industrial implementation. Rotary kilns face challenges in maintaining consistent bed depth and residence time distribution at larger scales, while fluidized beds encounter difficulties with gas distribution uniformity and potential defluidization zones in scaled-up operations.

Material handling complications further exacerbate processing challenges. Sticky, agglomerating feedstocks can cause buildup on kiln walls or defluidization in fluidized beds. Abrasive materials accelerate equipment wear in both systems, though the impact manifests differently—shell and lifter wear in kilns versus distributor plate and cyclone erosion in fluidized beds.

Emissions control has become increasingly important with stricter environmental regulations. Both technologies struggle with capturing fine particulates and volatile compounds, though fluidized beds typically offer better opportunities for in-situ emissions treatment due to their favorable gas-solid contact characteristics.

Process control and automation present ongoing challenges. Rotary kilns suffer from limited real-time monitoring capabilities inside the rotating vessel, while fluidized beds require sophisticated control systems to maintain stable fluidization regimes across varying feedstock conditions. The development of reliable, non-invasive sensing technologies remains an active area of research for both processing methods.

Cross-contamination between batches poses particular difficulties in multi-product facilities, with cleaning procedures being more straightforward but time-consuming for rotary kilns compared to the complex internal structures of fluidized bed systems.

Comparative Analysis of Rotary Kiln and Fluidized Bed Systems

01 Design improvements for rotary kilns

Various design improvements can enhance the efficiency of rotary kilns for feedstock processing. These include optimized kiln geometry, improved heat transfer mechanisms, and specialized internal structures. Such modifications can lead to better temperature control, reduced energy consumption, and increased throughput. Design innovations focus on maximizing contact between the feedstock and heating elements while ensuring uniform processing conditions throughout the kiln.- Design improvements for rotary kilns: Various design improvements can enhance the processing efficiency of rotary kilns. These include optimized kiln geometry, improved heat transfer mechanisms, and specialized internal structures. Modified kiln designs can reduce energy consumption while increasing throughput capacity. Advanced sealing systems and refractory materials also contribute to better thermal efficiency and extended operational life of the equipment.

- Fluidized bed technology advancements: Advancements in fluidized bed technology focus on improving the contact between feedstock and processing medium. Enhanced fluidization techniques ensure uniform temperature distribution and better mass transfer. Innovations include specialized bed materials, optimized air distribution systems, and controlled turbulence patterns. These improvements lead to more efficient processing of various feedstock materials with reduced energy requirements.

- Feedstock preparation and handling systems: Efficient feedstock preparation and handling systems significantly impact processing efficiency. Pre-treatment methods such as drying, sizing, and homogenization improve the consistency of the feed material. Automated feeding systems with precise control mechanisms ensure optimal feed rates and distribution. Advanced monitoring technologies allow for real-time adjustments based on feedstock characteristics, enhancing overall process stability.

- Integration of thermal recovery systems: Integration of thermal recovery systems captures and reuses waste heat from rotary kilns and fluidized beds. Heat exchangers, regenerative systems, and waste heat boilers convert thermal energy into useful forms. Recovered heat can be utilized for preheating feedstock, generating steam, or producing electricity. These systems significantly reduce energy consumption and improve the overall thermal efficiency of the processing operations.

- Process control and automation technologies: Advanced process control and automation technologies optimize the operation of rotary kilns and fluidized beds. Sophisticated sensors monitor critical parameters such as temperature profiles, residence time, and material flow. Artificial intelligence and machine learning algorithms analyze operational data to identify optimization opportunities. Automated control systems make real-time adjustments to maintain optimal processing conditions, resulting in improved efficiency, product quality, and reduced environmental impact.

02 Fluidized bed technology advancements

Advanced fluidized bed technologies offer significant improvements in feedstock processing efficiency. These systems utilize optimized air distribution, specialized bed materials, and enhanced fluidization techniques to improve heat transfer and reaction kinetics. Modern fluidized bed designs incorporate features that minimize energy consumption while maximizing processing capacity and product quality. These advancements enable more uniform treatment of feedstock materials and better control over processing parameters.Expand Specific Solutions03 Integration of rotary kiln and fluidized bed systems

Hybrid systems that integrate rotary kiln and fluidized bed technologies can achieve superior processing efficiency. These combined approaches leverage the strengths of both technologies: the excellent mixing capabilities of rotary kilns and the superior heat transfer characteristics of fluidized beds. Integrated systems can handle a wider variety of feedstock materials and provide more flexible processing conditions. This integration often results in reduced energy consumption, improved product quality, and increased throughput rates.Expand Specific Solutions04 Feedstock preparation and handling techniques

Proper feedstock preparation and handling significantly impact processing efficiency in both rotary kiln and fluidized bed systems. Techniques such as size reduction, moisture control, and pre-treatment processes can optimize feedstock characteristics for more efficient processing. Advanced feeding mechanisms ensure consistent material flow and distribution, preventing operational issues like clogging or uneven processing. These techniques can substantially improve overall system performance and reduce energy requirements.Expand Specific Solutions05 Process control and monitoring systems

Advanced process control and monitoring systems play a crucial role in optimizing the efficiency of rotary kiln and fluidized bed operations. These systems utilize sensors, automated controls, and data analytics to maintain optimal processing conditions. Real-time monitoring of parameters such as temperature, pressure, and material flow allows for immediate adjustments to maximize efficiency. Modern control systems can predict maintenance needs, prevent operational disruptions, and ensure consistent product quality while minimizing energy consumption.Expand Specific Solutions

Leading Manufacturers and Technology Providers

The rotary kiln versus fluidized bed technology landscape is currently in a mature development phase, with a global market size estimated to exceed $5 billion. Technical maturity varies by application, with fluidized bed technology showing advantages in processing efficiency for certain feedstocks. Leading players shaping the competitive landscape include FLSmidth A/S and Bühler AG, who have established strong positions in industrial applications, while ExxonMobil and China Petroleum & Chemical Corp. focus on petrochemical implementations. Research institutions like Zhejiang University and the Institute of Process Engineering (Chinese Academy of Sciences) are driving innovation in process optimization. The market shows regional specialization with European companies (Thyssen Industrie, Primetals Technologies) focusing on metallurgical applications while Asian players emphasize energy efficiency improvements.

Institute of Process Engineering, Chinese Academy of Sciences

Technical Solution: The Institute of Process Engineering (IPE) at the Chinese Academy of Sciences has developed innovative fluidized bed technologies specifically designed for challenging feedstocks. Their multi-zone fluidized bed system features distinct processing regions with independently controlled temperature and gas flow parameters, allowing for precise thermal treatment profiles tailored to specific feedstock requirements. IPE's research has yielded advanced distributor plate designs that achieve uniform fluidization even with heterogeneous materials, reducing channeling and improving processing consistency. Their systems incorporate sophisticated computational models that predict fluidization behavior based on particle characteristics, enabling optimization for specific feedstocks. IPE has also pioneered hybrid fluidized bed configurations that combine bubbling and circulating regimes to maximize processing efficiency for materials with complex physical properties. Additionally, their research includes novel catalyst integration methods for fluidized beds that enhance reaction kinetics while minimizing catalyst attrition and loss.

Strengths: Superior heat and mass transfer efficiency, excellent temperature uniformity, and rapid process adjustability for varying feedstock conditions. Weaknesses: Challenges with processing highly cohesive or sticky materials, potential for particle attrition with friable feedstocks, and higher complexity in scaling up compared to rotary kiln systems.

Bühler AG

Technical Solution: Bühler AG has pioneered hybrid processing systems that combine elements of both rotary kiln and fluidized bed technologies to optimize feedstock processing. Their AeroDry™ technology utilizes a modified fluidized bed approach with proprietary air distribution plates that create controlled turbulence zones, achieving up to 40% higher heat transfer rates than conventional systems. For challenging feedstocks, Bühler has developed the FlexiKiln™ system that features adjustable internal baffles and variable speed rotation, allowing operators to fine-tune residence time and mixing intensity based on specific material characteristics. Their systems incorporate advanced thermal recovery units that capture and recirculate process heat, reducing energy consumption by up to 25%. Bühler's process control systems utilize real-time monitoring of multiple parameters including temperature profiles, gas composition, and material moisture content to automatically adjust operating conditions for optimal performance.

Strengths: Exceptional versatility for handling multiple feedstock types, precise temperature control capabilities, and modular design allowing for capacity expansion. Weaknesses: Higher complexity requiring more specialized maintenance expertise, and potentially higher operating costs for certain applications compared to simpler technologies.

Key Patents and Innovations in Thermal Processing

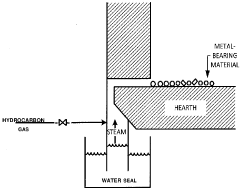

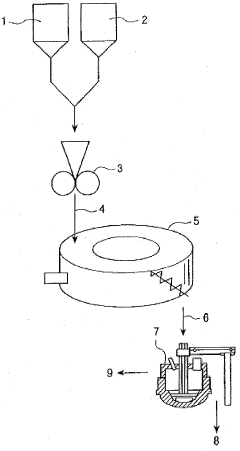

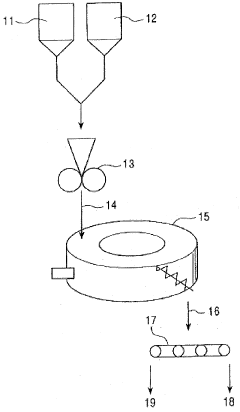

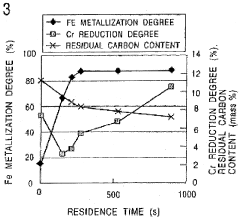

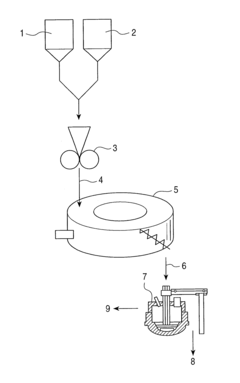

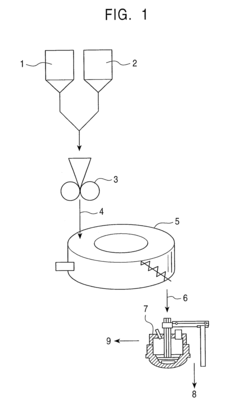

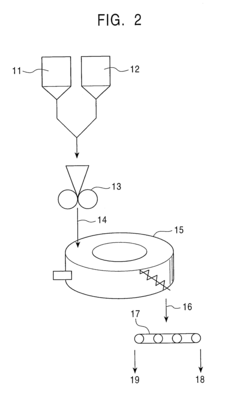

Methods and systems for reducing chromium containing raw material

PatentInactiveIN7218DELNP2015A

Innovation

- A method involving a moving hearth furnace with rapid temperature rise, where chromium oxide is reduced before iron oxide, using a carbonaceous reductant and a carbonaceous atmosphere-adjusting agent to maintain contact and prevent oxidation, along with agglomeration techniques to enhance heat transfer and reduce equipment needs.

Method for reducing chromium containing raw material

PatentInactiveUS8262766B2

Innovation

- A method involving mixing chromium-containing materials with a carbonaceous reductant and heating them in a moving hearth furnace with rapid temperature rise by radiation heating, ensuring chromium oxide reduction occurs before iron oxide reduction, thereby maintaining carbon contact and achieving higher chromium reduction degrees, while also reducing equipment size and energy consumption.

Energy Efficiency and Sustainability Considerations

Energy efficiency and sustainability have become critical factors in the selection between rotary kilns and fluidized beds for processing various feedstocks. Rotary kilns typically operate at higher temperatures (800-1400°C) compared to fluidized beds (700-950°C), which directly impacts their energy consumption profiles. The thermal efficiency of rotary kilns generally ranges from 30-55%, while fluidized beds can achieve 60-80% efficiency due to their superior heat transfer characteristics and more uniform temperature distribution.

Carbon footprint considerations reveal significant differences between these technologies. Rotary kilns often produce higher CO2 emissions due to their greater fuel requirements, especially when processing materials that demand extended residence times. Conversely, fluidized beds can reduce greenhouse gas emissions by 15-30% for comparable applications, primarily through reduced fuel consumption and more efficient combustion processes.

Waste heat recovery opportunities differ substantially between these systems. Rotary kilns generate high-temperature exhaust gases that present excellent opportunities for heat recovery through waste heat boilers or preheating systems. Fluidized beds, while operating at lower temperatures, offer more consistent heat recovery potential due to their steady-state operation characteristics.

Fuel flexibility represents another important sustainability dimension. Modern fluidized bed systems can efficiently utilize alternative and renewable fuels including biomass, refuse-derived fuels, and even certain waste materials. Rotary kilns typically require more consistent fuel quality, though advanced designs have improved their flexibility in recent years.

Water consumption patterns also differ markedly. Rotary kilns generally require less cooling water than fluidized beds, which can be advantageous in water-scarce regions. However, fluidized beds often demonstrate superior capabilities in terms of emissions control, particularly for NOx and SOx, potentially reducing the water needed for downstream gas cleaning processes.

Life cycle assessment studies indicate that the optimal choice between these technologies depends heavily on feedstock characteristics and processing requirements. For energy-intensive applications processing consistent materials, the higher thermal efficiency of fluidized beds often translates to lower lifetime environmental impacts. For applications requiring high temperatures or processing highly variable feedstocks, rotary kilns may offer better sustainability profiles despite their lower thermal efficiency.

Recent technological innovations have narrowed the sustainability gap between these systems, with hybrid designs and advanced control systems improving the environmental performance of both technologies. The integration of renewable energy sources and smart energy management systems represents the next frontier in enhancing the sustainability credentials of both rotary kilns and fluidized beds.

Carbon footprint considerations reveal significant differences between these technologies. Rotary kilns often produce higher CO2 emissions due to their greater fuel requirements, especially when processing materials that demand extended residence times. Conversely, fluidized beds can reduce greenhouse gas emissions by 15-30% for comparable applications, primarily through reduced fuel consumption and more efficient combustion processes.

Waste heat recovery opportunities differ substantially between these systems. Rotary kilns generate high-temperature exhaust gases that present excellent opportunities for heat recovery through waste heat boilers or preheating systems. Fluidized beds, while operating at lower temperatures, offer more consistent heat recovery potential due to their steady-state operation characteristics.

Fuel flexibility represents another important sustainability dimension. Modern fluidized bed systems can efficiently utilize alternative and renewable fuels including biomass, refuse-derived fuels, and even certain waste materials. Rotary kilns typically require more consistent fuel quality, though advanced designs have improved their flexibility in recent years.

Water consumption patterns also differ markedly. Rotary kilns generally require less cooling water than fluidized beds, which can be advantageous in water-scarce regions. However, fluidized beds often demonstrate superior capabilities in terms of emissions control, particularly for NOx and SOx, potentially reducing the water needed for downstream gas cleaning processes.

Life cycle assessment studies indicate that the optimal choice between these technologies depends heavily on feedstock characteristics and processing requirements. For energy-intensive applications processing consistent materials, the higher thermal efficiency of fluidized beds often translates to lower lifetime environmental impacts. For applications requiring high temperatures or processing highly variable feedstocks, rotary kilns may offer better sustainability profiles despite their lower thermal efficiency.

Recent technological innovations have narrowed the sustainability gap between these systems, with hybrid designs and advanced control systems improving the environmental performance of both technologies. The integration of renewable energy sources and smart energy management systems represents the next frontier in enhancing the sustainability credentials of both rotary kilns and fluidized beds.

Feedstock Characterization and Selection Methodology

Effective feedstock characterization is fundamental to determining the optimal thermal processing technology between rotary kilns and fluidized beds. The selection methodology begins with comprehensive physical property analysis, including particle size distribution, bulk density, moisture content, and flowability characteristics. These parameters directly influence the equipment's operational efficiency and processing capabilities.

Particle size distribution is particularly critical, as rotary kilns generally accommodate larger, more heterogeneous feedstock (typically 5-150 mm), while fluidized beds require smaller, more uniform particles (usually 0.1-5 mm) to maintain proper fluidization. Moisture content analysis helps predict drying requirements and energy consumption, with rotary kilns typically handling materials with moisture content up to 25%, whereas fluidized beds perform optimally with drier feedstock below 15%.

Chemical composition assessment forms the second pillar of characterization, focusing on elemental analysis, calorific value, ash content, and potential contaminants. This analysis determines reaction kinetics and potential emissions, guiding technology selection based on processing objectives. Feedstocks with high ash content or contaminants may benefit from the continuous ash removal capabilities of fluidized beds, while materials requiring precise temperature control for specific chemical transformations might favor rotary kilns.

Thermal behavior characterization through thermogravimetric analysis (TGA) and differential scanning calorimetry (DSC) provides insights into decomposition temperatures, reaction enthalpies, and phase transitions. These data points are essential for designing appropriate temperature profiles and residence times in either technology. Materials exhibiting complex multi-stage thermal decomposition may require the controlled environment of a rotary kiln, while those with rapid, uniform reaction profiles might benefit from the excellent heat transfer characteristics of fluidized beds.

The selection methodology culminates in bench-scale testing, where small quantities of feedstock undergo processing in laboratory-scale equipment to validate theoretical predictions. These tests measure conversion efficiencies, product quality, and operational stability under various conditions, providing empirical data to support the final technology selection decision.

Economic considerations must also factor into the methodology, including feedstock preparation requirements, energy consumption projections, and capital versus operational expenditure balances. Fluidized beds typically require more extensive feedstock preparation but offer higher thermal efficiency, while rotary kilns generally accommodate feedstock with minimal preprocessing but may have higher energy requirements for certain applications.

Particle size distribution is particularly critical, as rotary kilns generally accommodate larger, more heterogeneous feedstock (typically 5-150 mm), while fluidized beds require smaller, more uniform particles (usually 0.1-5 mm) to maintain proper fluidization. Moisture content analysis helps predict drying requirements and energy consumption, with rotary kilns typically handling materials with moisture content up to 25%, whereas fluidized beds perform optimally with drier feedstock below 15%.

Chemical composition assessment forms the second pillar of characterization, focusing on elemental analysis, calorific value, ash content, and potential contaminants. This analysis determines reaction kinetics and potential emissions, guiding technology selection based on processing objectives. Feedstocks with high ash content or contaminants may benefit from the continuous ash removal capabilities of fluidized beds, while materials requiring precise temperature control for specific chemical transformations might favor rotary kilns.

Thermal behavior characterization through thermogravimetric analysis (TGA) and differential scanning calorimetry (DSC) provides insights into decomposition temperatures, reaction enthalpies, and phase transitions. These data points are essential for designing appropriate temperature profiles and residence times in either technology. Materials exhibiting complex multi-stage thermal decomposition may require the controlled environment of a rotary kiln, while those with rapid, uniform reaction profiles might benefit from the excellent heat transfer characteristics of fluidized beds.

The selection methodology culminates in bench-scale testing, where small quantities of feedstock undergo processing in laboratory-scale equipment to validate theoretical predictions. These tests measure conversion efficiencies, product quality, and operational stability under various conditions, providing empirical data to support the final technology selection decision.

Economic considerations must also factor into the methodology, including feedstock preparation requirements, energy consumption projections, and capital versus operational expenditure balances. Fluidized beds typically require more extensive feedstock preparation but offer higher thermal efficiency, while rotary kilns generally accommodate feedstock with minimal preprocessing but may have higher energy requirements for certain applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!