Refractory Lining Selection For Rotary Kilns: Materials, Life, And Costs

AUG 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Rotary Kiln Refractory Technology Background and Objectives

Rotary kilns have been a cornerstone of industrial processing since their inception in the late 19th century, initially developed for cement production but subsequently adapted for various applications including lime production, mineral processing, and waste treatment. The evolution of refractory technology for these kilns has been closely tied to advancements in material science and engineering, progressing from simple clay-based linings to sophisticated multi-component systems designed to withstand extreme thermal, mechanical, and chemical stresses.

The historical trajectory of refractory development shows distinct phases, beginning with basic fireclay materials in the early 20th century, transitioning to high-alumina formulations by mid-century, and advancing to specialized magnesia, spinel, and zirconia-based materials in recent decades. This progression has been driven by increasing demands for kiln efficiency, productivity, and service life in ever more challenging operating environments.

Current technological trends in rotary kiln refractories focus on enhancing durability while optimizing thermal efficiency. Key developments include nano-engineered materials with superior thermal shock resistance, advanced bonding systems that improve structural integrity, and composite refractory designs that strategically combine different materials to address specific zones of wear and thermal stress within the kiln.

The global refractory market for rotary kilns represents a significant segment of the broader industrial refractory sector, with annual growth rates consistently outpacing general industrial averages. This growth is fueled by expansion in cement production capacity, particularly in developing economies, as well as increasing adoption of rotary kiln technology in environmental applications such as hazardous waste treatment and resource recovery.

The primary technical objectives in refractory lining selection center on maximizing service life while minimizing total operational costs. This involves balancing initial material and installation expenses against long-term considerations including maintenance requirements, energy efficiency impacts, and production downtime during relining operations. Secondary objectives include optimizing thermal profiles within the kiln to enhance process efficiency and product quality.

Emerging challenges in the field include addressing increasingly stringent environmental regulations affecting both manufacturing processes and end-use applications, adapting to alternative fuels with variable combustion characteristics, and developing predictive maintenance approaches that leverage advanced monitoring technologies and data analytics to optimize refractory performance and replacement scheduling.

The convergence of traditional refractory engineering with digital technologies represents a promising frontier, with potential for significant advancements in both material design and operational management of rotary kiln refractory systems. This integration aims to transform refractory selection from a periodic capital decision to a continuously optimized component of industrial process management.

The historical trajectory of refractory development shows distinct phases, beginning with basic fireclay materials in the early 20th century, transitioning to high-alumina formulations by mid-century, and advancing to specialized magnesia, spinel, and zirconia-based materials in recent decades. This progression has been driven by increasing demands for kiln efficiency, productivity, and service life in ever more challenging operating environments.

Current technological trends in rotary kiln refractories focus on enhancing durability while optimizing thermal efficiency. Key developments include nano-engineered materials with superior thermal shock resistance, advanced bonding systems that improve structural integrity, and composite refractory designs that strategically combine different materials to address specific zones of wear and thermal stress within the kiln.

The global refractory market for rotary kilns represents a significant segment of the broader industrial refractory sector, with annual growth rates consistently outpacing general industrial averages. This growth is fueled by expansion in cement production capacity, particularly in developing economies, as well as increasing adoption of rotary kiln technology in environmental applications such as hazardous waste treatment and resource recovery.

The primary technical objectives in refractory lining selection center on maximizing service life while minimizing total operational costs. This involves balancing initial material and installation expenses against long-term considerations including maintenance requirements, energy efficiency impacts, and production downtime during relining operations. Secondary objectives include optimizing thermal profiles within the kiln to enhance process efficiency and product quality.

Emerging challenges in the field include addressing increasingly stringent environmental regulations affecting both manufacturing processes and end-use applications, adapting to alternative fuels with variable combustion characteristics, and developing predictive maintenance approaches that leverage advanced monitoring technologies and data analytics to optimize refractory performance and replacement scheduling.

The convergence of traditional refractory engineering with digital technologies represents a promising frontier, with potential for significant advancements in both material design and operational management of rotary kiln refractory systems. This integration aims to transform refractory selection from a periodic capital decision to a continuously optimized component of industrial process management.

Market Analysis of Refractory Materials for Industrial Kilns

The global refractory materials market for industrial kilns has experienced steady growth, valued at approximately $23.4 billion in 2022, with projections indicating a compound annual growth rate (CAGR) of 3.8% through 2028. This growth is primarily driven by expanding cement, steel, and glass industries, particularly in developing economies across Asia-Pacific and Latin America.

China dominates the market landscape, accounting for over 40% of global refractory production and consumption. This dominance stems from the country's massive infrastructure development and industrial manufacturing base. India follows as a rapidly growing market, with its refractory demand increasing at nearly 6% annually due to government initiatives promoting domestic manufacturing and infrastructure development.

The rotary kiln segment represents approximately 18% of the total refractory materials market, with specialized high-temperature applications commanding premium pricing. Magnesia-based refractories hold the largest market share at 32%, followed by alumina-based products at 28% and silica-based materials at 22%. The remaining market comprises specialty refractories including zirconia, chromite, and carbon-based products.

Recent market trends reveal increasing demand for monolithic refractories over traditional brick linings, growing at 5.2% annually compared to 2.7% for shaped refractories. This shift is attributed to faster installation times, reduced maintenance requirements, and improved thermal efficiency. Additionally, environmentally friendly and energy-efficient refractory solutions are gaining traction, with manufacturers investing in sustainable production methods and recycling technologies.

Cost considerations remain paramount for end-users, with refractory expenses typically representing 8-12% of operational costs in cement production and 5-8% in steel manufacturing. The market exhibits price sensitivity to raw material fluctuations, particularly for high-grade bauxite, magnesite, and graphite, which have experienced supply constraints in recent years.

Customer preferences increasingly favor total cost of ownership over initial purchase price, with extended service life and reduced downtime becoming critical selection factors. This has spurred innovation in wear-resistant formulations and advanced installation techniques that minimize maintenance requirements and extend refractory lining lifespans by up to 40%.

Regional variations in market dynamics are significant, with North American and European customers prioritizing performance and longevity, while developing markets often balance cost considerations with gradually increasing quality requirements. This dichotomy has led to market segmentation with tiered product offerings tailored to specific regional needs and economic constraints.

China dominates the market landscape, accounting for over 40% of global refractory production and consumption. This dominance stems from the country's massive infrastructure development and industrial manufacturing base. India follows as a rapidly growing market, with its refractory demand increasing at nearly 6% annually due to government initiatives promoting domestic manufacturing and infrastructure development.

The rotary kiln segment represents approximately 18% of the total refractory materials market, with specialized high-temperature applications commanding premium pricing. Magnesia-based refractories hold the largest market share at 32%, followed by alumina-based products at 28% and silica-based materials at 22%. The remaining market comprises specialty refractories including zirconia, chromite, and carbon-based products.

Recent market trends reveal increasing demand for monolithic refractories over traditional brick linings, growing at 5.2% annually compared to 2.7% for shaped refractories. This shift is attributed to faster installation times, reduced maintenance requirements, and improved thermal efficiency. Additionally, environmentally friendly and energy-efficient refractory solutions are gaining traction, with manufacturers investing in sustainable production methods and recycling technologies.

Cost considerations remain paramount for end-users, with refractory expenses typically representing 8-12% of operational costs in cement production and 5-8% in steel manufacturing. The market exhibits price sensitivity to raw material fluctuations, particularly for high-grade bauxite, magnesite, and graphite, which have experienced supply constraints in recent years.

Customer preferences increasingly favor total cost of ownership over initial purchase price, with extended service life and reduced downtime becoming critical selection factors. This has spurred innovation in wear-resistant formulations and advanced installation techniques that minimize maintenance requirements and extend refractory lining lifespans by up to 40%.

Regional variations in market dynamics are significant, with North American and European customers prioritizing performance and longevity, while developing markets often balance cost considerations with gradually increasing quality requirements. This dichotomy has led to market segmentation with tiered product offerings tailored to specific regional needs and economic constraints.

Current Refractory Lining Technologies and Challenges

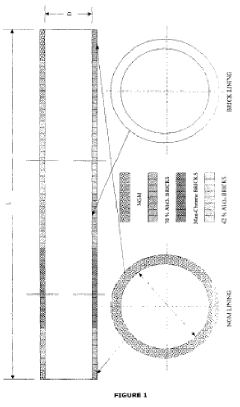

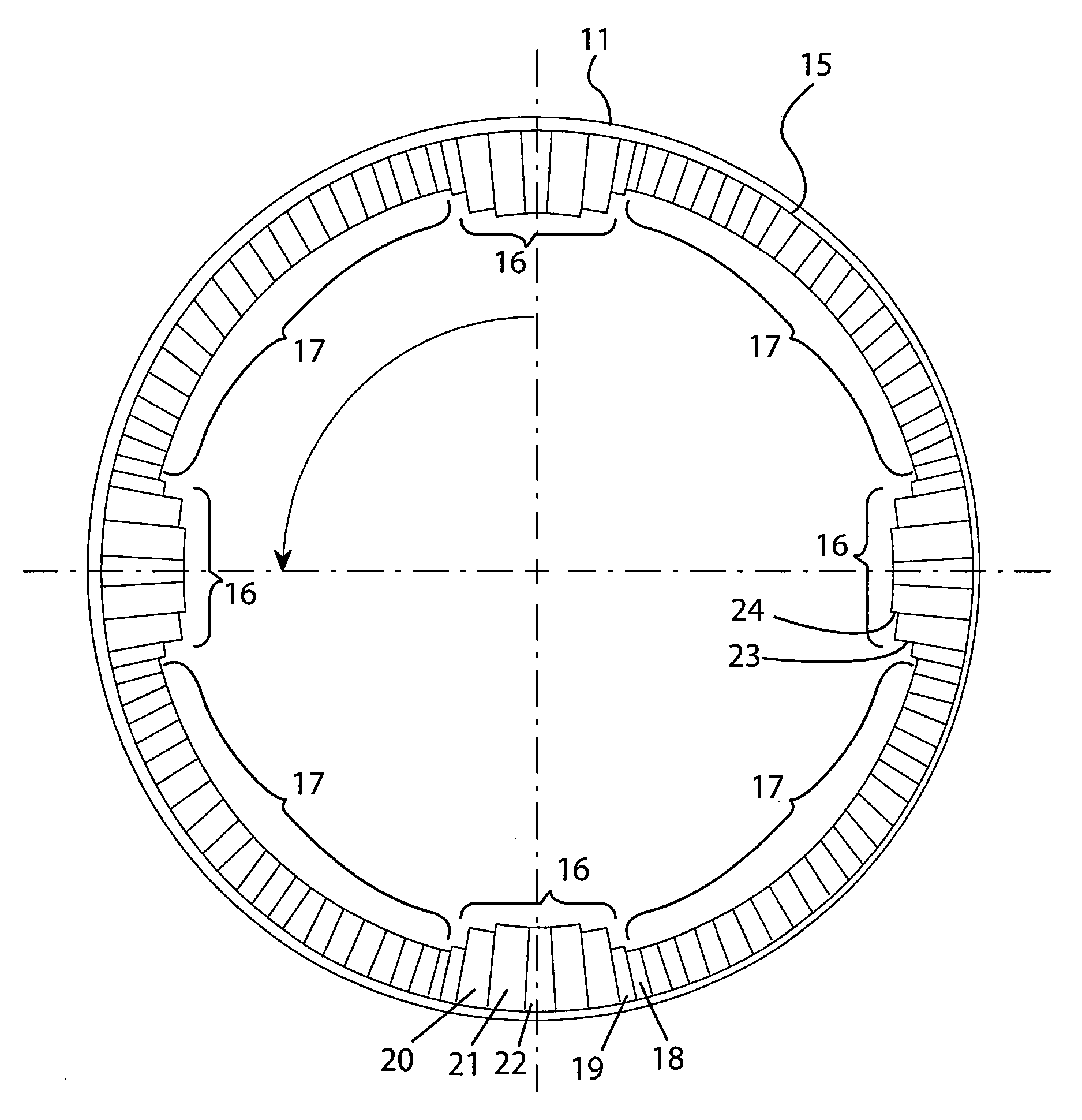

Refractory linings in rotary kilns are critical components that protect the steel shell from high temperatures and chemical attack while maintaining thermal efficiency. Current technologies predominantly utilize basic, acidic, and neutral refractory materials, each selected based on specific operational conditions. Magnesia-based refractories dominate in cement and lime production due to their excellent resistance to alkaline environments, while alumina-based materials are preferred in applications with acidic slags.

The industry faces significant challenges in extending refractory life while managing costs. Thermal cycling—the repeated heating and cooling during operation and maintenance—creates substantial stress on refractory materials, leading to cracking and spalling. Chemical attack from process materials, particularly in cement kilns where alkali salts can penetrate and deteriorate the refractory structure, remains a persistent issue.

Mechanical stresses present another major challenge. The rotation of kilns subjects linings to continuous mechanical loading, while the movement of material inside creates abrasion and impact damage. Modern kilns operating at higher temperatures to improve efficiency place additional demands on refractory performance, requiring materials that can withstand more extreme conditions.

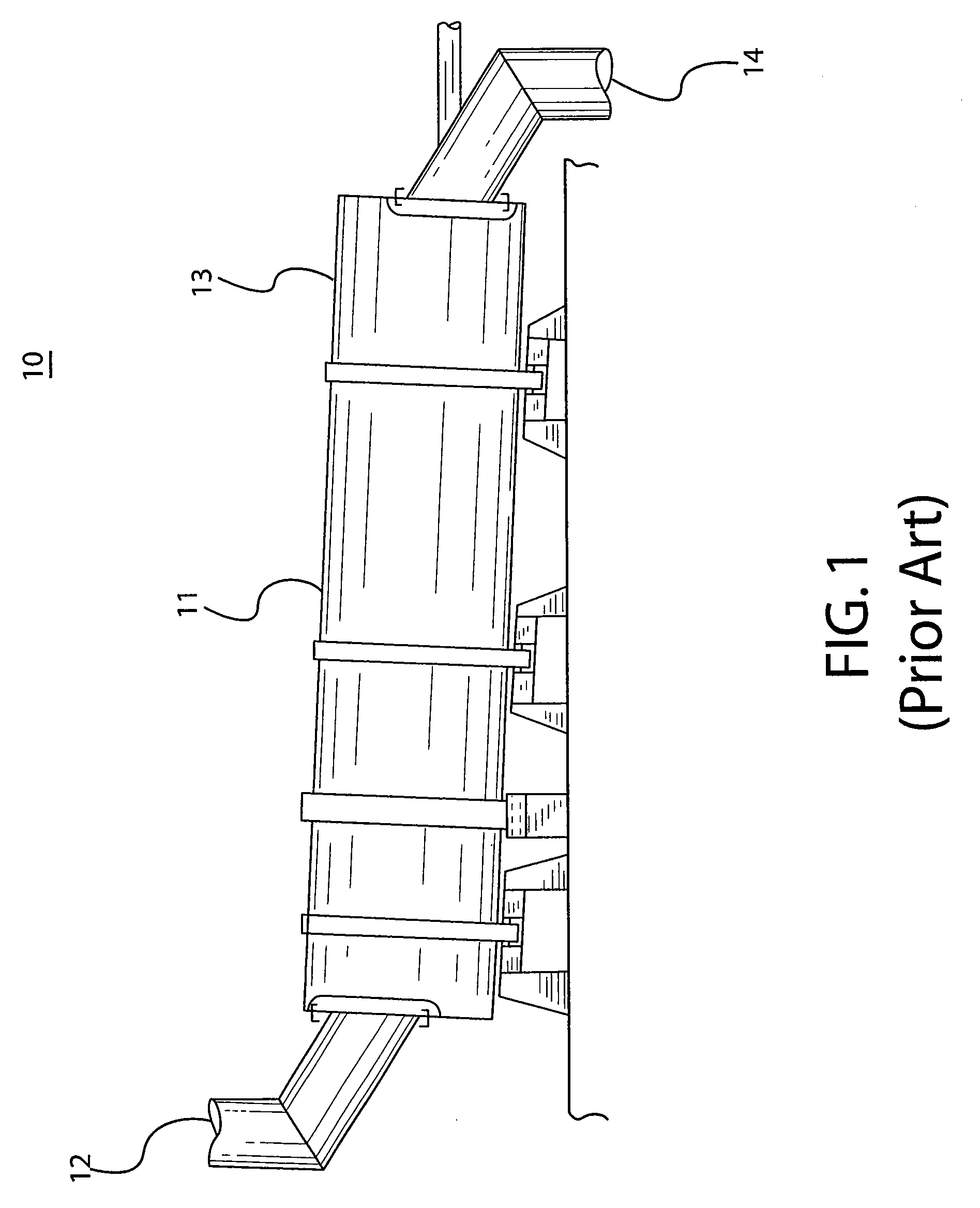

Installation quality significantly impacts refractory performance. Improper installation techniques can create weak points in the lining, leading to premature failure. The industry continues to develop improved installation methodologies, including better brick laying techniques and advanced monolithic casting procedures.

Recent technological advancements include the development of composite refractories that combine multiple materials to achieve optimal performance characteristics. These may incorporate zirconia, silicon carbide, or carbon to enhance specific properties. Nano-enhanced refractories represent another frontier, with nanomaterials added to traditional formulations to improve thermal shock resistance and mechanical strength.

Monitoring technologies have evolved substantially, with thermal imaging systems now capable of detecting hot spots before catastrophic failure occurs. Some advanced systems incorporate embedded sensors that provide real-time data on refractory condition, though these remain costly and are primarily used in critical applications.

Cost-performance optimization remains a central focus, with manufacturers developing tiered solutions that balance initial investment against expected service life. The total cost of ownership approach has gained traction, considering not just material costs but also installation expenses, maintenance requirements, and production losses during relining operations.

The industry faces significant challenges in extending refractory life while managing costs. Thermal cycling—the repeated heating and cooling during operation and maintenance—creates substantial stress on refractory materials, leading to cracking and spalling. Chemical attack from process materials, particularly in cement kilns where alkali salts can penetrate and deteriorate the refractory structure, remains a persistent issue.

Mechanical stresses present another major challenge. The rotation of kilns subjects linings to continuous mechanical loading, while the movement of material inside creates abrasion and impact damage. Modern kilns operating at higher temperatures to improve efficiency place additional demands on refractory performance, requiring materials that can withstand more extreme conditions.

Installation quality significantly impacts refractory performance. Improper installation techniques can create weak points in the lining, leading to premature failure. The industry continues to develop improved installation methodologies, including better brick laying techniques and advanced monolithic casting procedures.

Recent technological advancements include the development of composite refractories that combine multiple materials to achieve optimal performance characteristics. These may incorporate zirconia, silicon carbide, or carbon to enhance specific properties. Nano-enhanced refractories represent another frontier, with nanomaterials added to traditional formulations to improve thermal shock resistance and mechanical strength.

Monitoring technologies have evolved substantially, with thermal imaging systems now capable of detecting hot spots before catastrophic failure occurs. Some advanced systems incorporate embedded sensors that provide real-time data on refractory condition, though these remain costly and are primarily used in critical applications.

Cost-performance optimization remains a central focus, with manufacturers developing tiered solutions that balance initial investment against expected service life. The total cost of ownership approach has gained traction, considering not just material costs but also installation expenses, maintenance requirements, and production losses during relining operations.

Comparative Analysis of Current Refractory Lining Solutions

01 Refractory material composition for extended lifespan

Specific compositions of refractory materials can significantly extend the lifespan of linings in high-temperature industrial applications. These compositions typically include combinations of alumina, magnesia, silica, and other oxides in optimized ratios. Advanced formulations may incorporate special binders and additives that enhance thermal shock resistance and structural integrity under extreme conditions, resulting in reduced replacement frequency and lower long-term operational costs.- Refractory material composition for extended lifespan: Specific compositions of refractory materials can significantly extend the lifespan of linings in high-temperature industrial applications. These compositions typically include combinations of alumina, magnesia, silica, and other oxides in optimized ratios. Advanced formulations may incorporate special binders and additives that enhance thermal shock resistance and structural integrity under extreme conditions, resulting in longer service life and reduced replacement frequency.

- Cost-effective installation techniques: Various installation methods can reduce both initial costs and long-term maintenance expenses for refractory linings. These techniques include monolithic casting, gunning, and modular installation systems that minimize labor requirements and installation time. Proper curing protocols and heating schedules during initial installation significantly impact the ultimate performance and lifespan of the refractory lining, providing better value over the operational lifetime of the equipment.

- Maintenance strategies to extend service life: Preventive maintenance approaches can substantially extend refractory lining life and optimize cost efficiency. These strategies include regular inspection protocols, targeted repair methodologies, and controlled cooling during maintenance shutdowns. Advanced monitoring systems can detect early signs of wear or failure, allowing for timely intervention before catastrophic failure occurs, thereby extending the overall service life and reducing total ownership costs.

- Innovative design features for cost reduction: Novel design approaches to refractory lining systems can significantly reduce both installation and operational costs. These include zoned lining designs that place more expensive, high-performance materials only where absolutely necessary, anchor systems that facilitate easier replacement of worn sections, and thermal gradient management features. Designs that accommodate thermal expansion while maintaining structural integrity can prevent premature cracking and spalling, thereby extending service life and improving cost-effectiveness.

- Advanced materials for extreme conditions: Specialized refractory materials designed for extreme operating conditions offer improved cost-benefit ratios despite higher initial investment. These materials include nano-enhanced ceramics, carbon-containing refractories with improved oxidation resistance, and composite structures that combine the benefits of multiple material types. While initially more expensive, these advanced materials can significantly reduce total lifecycle costs through extended service intervals, improved energy efficiency, and reduced downtime for replacements.

02 Installation techniques affecting cost-efficiency

The method of installation significantly impacts both the initial cost and lifespan of refractory linings. Proper installation techniques include controlled drying and heating processes, precise application methods, and appropriate curing procedures. Advanced installation approaches such as vibration casting, gunning, or specialized brick laying can reduce installation time while improving lining quality and durability, leading to better cost-performance ratios over the operational lifetime.Expand Specific Solutions03 Maintenance strategies for extending service life

Implementing strategic maintenance protocols can substantially extend refractory lining life while optimizing costs. These strategies include regular inspection routines, preventive repairs, and targeted patching of vulnerable areas before catastrophic failure occurs. Advanced monitoring systems can detect early signs of wear, allowing for scheduled maintenance during planned downtime rather than emergency repairs, thereby reducing overall operational costs and extending the effective service life of the refractory lining.Expand Specific Solutions04 Novel refractory designs for cost reduction

Innovative designs in refractory linings can significantly reduce costs while maintaining or improving performance. These designs include multi-layer systems with graduated compositions, interlocking shapes that minimize mortar joints, and modular components that facilitate targeted replacement of worn sections. Some designs incorporate cooling systems or protective sacrificial layers that shield the main refractory material from extreme conditions, thereby extending the overall lining life and improving the cost-benefit ratio.Expand Specific Solutions05 Economic analysis of refractory selection

Comprehensive economic analysis methods help optimize refractory selection by balancing initial investment against long-term operational costs. These analyses consider factors such as material costs, installation expenses, expected service life, maintenance requirements, and production downtime during replacements. Advanced modeling techniques can predict the total cost of ownership for different refractory options under specific operational conditions, enabling informed decision-making that minimizes overall costs while maintaining required performance standards.Expand Specific Solutions

Major Manufacturers and Suppliers in Refractory Industry

The refractory lining selection for rotary kilns market is currently in a mature growth phase, with an estimated global market size of $2-3 billion annually. The technical landscape shows varying degrees of maturity across different material solutions, with companies demonstrating specialized expertise. Industry leaders like Siemens AG and Magnesita Refractories provide advanced solutions with extended service life, while regional specialists such as Zhongye Changtian, Shandong Luming, and Shinagawa Refractories focus on cost-effective innovations. The competitive landscape is characterized by a balance between established global players (Resco Products, Foseco International) and specialized regional manufacturers, with increasing emphasis on high-temperature performance, cost optimization, and sustainability. Recent technological developments from Shenyang Aluminum & Magnesium Engineering and Steel Authority of India indicate a trend toward composite materials that offer superior thermal resistance and extended operational lifespans.

Shandong Luming High Temperature Material Co., Ltd.

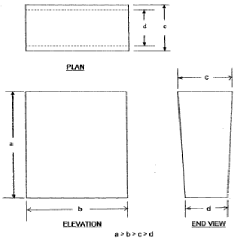

Technical Solution: Shandong Luming has developed the LUMITHERM refractory system specifically engineered for rotary kilns operating in cement, lime, and mineral processing applications. Their technology features a composite brick design that incorporates multiple material layers within each brick, creating a thermal gradient that reduces thermal stress and extends service life. Luming's manufacturing process includes a high-pressure forming technique that achieves exceptional density and dimensional precision, resulting in tighter joints and reduced infiltration of corrosive materials. Their refractory solutions include specialized magnesia-spinel formulations with controlled porosity that balance thermal insulation with mechanical strength. The company has pioneered the use of nano-scale additives that enhance grain boundary strength at high temperatures, improving resistance to creep and deformation under load. Shandong Luming's installation system includes proprietary mortar formulations that create chemical bonds between bricks, forming a more cohesive lining structure that resists displacement during operation.

Strengths: Composite brick design creates optimal thermal gradients; excellent dimensional precision enables tighter joints; proprietary mortar systems enhance overall lining integrity. Weaknesses: Limited global technical support network compared to larger competitors; some specialized formulations have longer lead times; higher material costs for advanced compositions.

Magnesita Refractories Co.

Technical Solution: Magnesita Refractories has developed a comprehensive refractory lining system specifically engineered for rotary kilns called ANKERTAB. This system features a combination of magnesia-spinel and magnesia-chrome bricks strategically positioned throughout different kiln zones based on thermal and chemical stress profiles. Their technology incorporates a proprietary brick design with flexible expansion joints that accommodate thermal cycling while maintaining structural integrity. Magnesita's advanced manufacturing process ensures consistent quality through precise control of raw material selection, with high-purity magnesia sourced from their own mines. Their refractory solutions include specialized coating materials that form protective layers against alkali attack in the burning zone, extending lining life by up to 40% compared to conventional materials. The company employs computational fluid dynamics and finite element analysis to optimize brick shapes for specific operational conditions.

Strengths: Vertically integrated supply chain ensures consistent raw material quality; proprietary brick designs with flexible expansion joints accommodate thermal cycling; comprehensive technical support including thermal imaging monitoring. Weaknesses: Higher initial investment cost compared to standard refractories; requires specialized installation expertise; some solutions are less suitable for kilns with frequent production changes.

Key Innovations in High-Temperature Resistant Materials

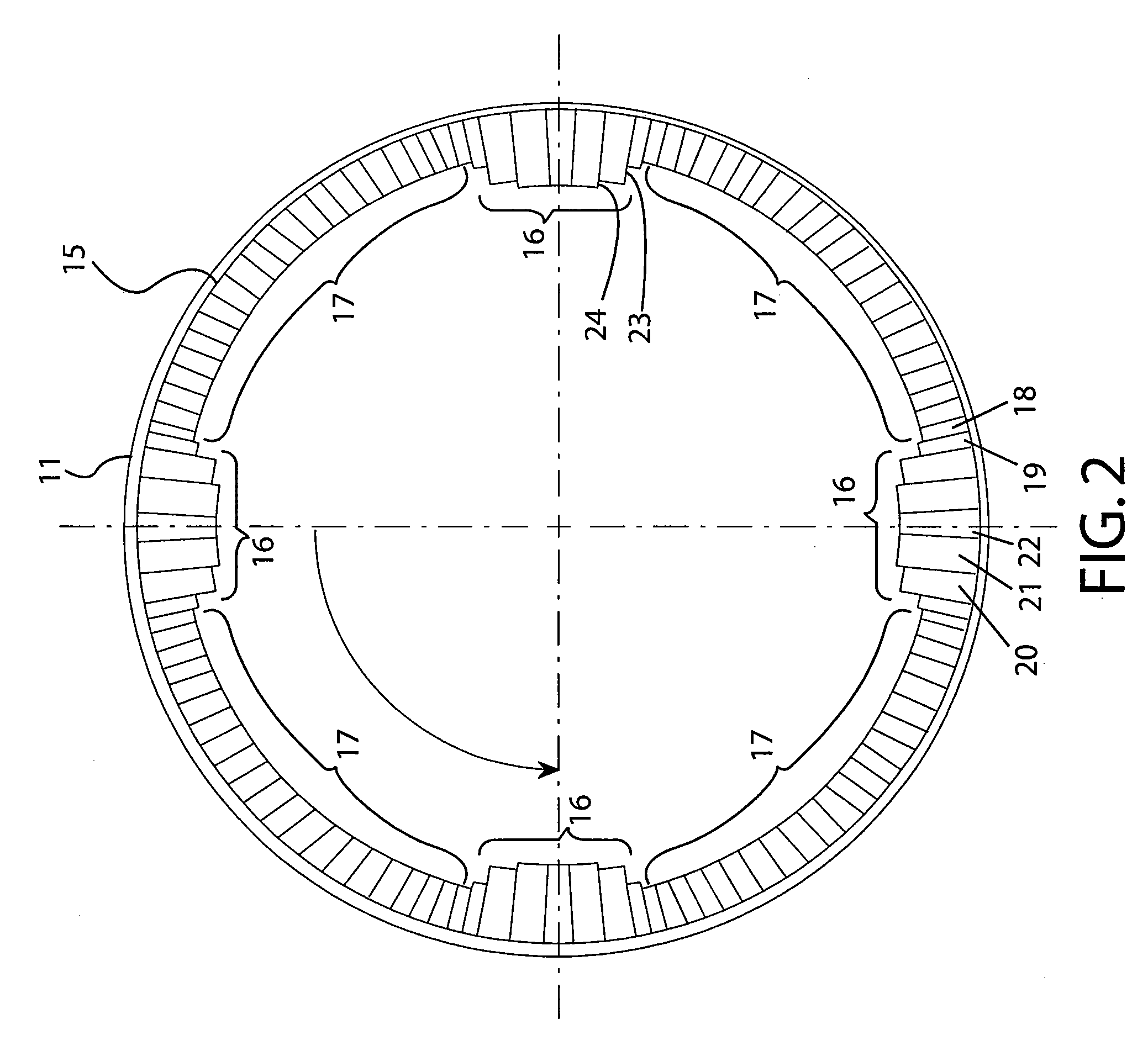

Rotary kiln having refractory lining adapted for superior thermomechanical properties

PatentInactiveIN97KOL2008A

Innovation

- A selective refractory lining configuration using 70% Al2O3 new generation monolithic castables and low-silica, low-iron mag-chrome bricks, along with ceramic paper between the shell and working lining, to enhance thermo-mechanical properties and reduce shell temperature, thereby increasing lining life and productivity.

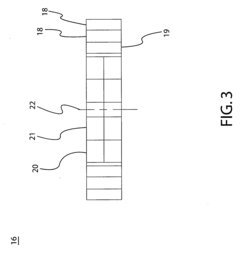

Rotary kiln lining and method

PatentInactiveUS20120282563A1

Innovation

- Incorporating refractory shapes from the steel industry into the kiln lining and lifter sections, using materials with compositions like MgO, CaO, ZrO2, SiO2, Al2O3, and Fe2O3, to create a durable and flexible design that can maintain position under compressive forces, allowing for effective agitation and heat transfer in the hottest zones.

Thermal Efficiency and Energy Conservation Considerations

The thermal efficiency of rotary kilns is a critical factor that directly impacts operational costs, production capacity, and environmental footprint. Proper selection of refractory linings plays a pivotal role in optimizing thermal efficiency and promoting energy conservation in these high-temperature industrial systems.

Refractory materials with lower thermal conductivity can significantly reduce heat loss through the kiln shell, thereby improving overall thermal efficiency. However, this must be balanced with the material's ability to withstand the harsh operating conditions inside the kiln. Modern insulating refractories can reduce heat loss by up to 30% compared to traditional dense refractories, translating to substantial energy savings over the kiln's operational lifetime.

The thickness of refractory lining is another crucial parameter affecting thermal efficiency. While thicker linings provide better insulation, they also reduce the effective internal diameter of the kiln, potentially limiting production capacity. Advanced computational fluid dynamics (CFD) modeling now enables engineers to optimize lining thickness for specific operational parameters, balancing thermal efficiency with production requirements.

Thermal cycling resistance of refractory materials directly impacts energy conservation. Materials that can withstand frequent heating and cooling cycles without developing cracks maintain their insulating properties longer, reducing the need for energy-intensive repairs and replacements. Silicon carbide-based refractories have shown superior thermal cycling resistance, maintaining consistent thermal performance for extended periods.

The implementation of multi-layer lining systems represents a significant advancement in energy conservation for rotary kilns. These systems typically combine a high-temperature resistant working layer with an insulating backup layer, optimizing both durability and thermal efficiency. Studies indicate that properly designed multi-layer systems can reduce fuel consumption by 8-15% compared to single-layer linings.

Surface emissivity of refractory materials affects radiant heat transfer within the kiln. Materials with optimized emissivity properties can enhance heat transfer to the material being processed while minimizing heat loss to the environment. Recent developments in ceramic technology have produced refractories with tailored emissivity characteristics for specific kiln applications, further improving energy utilization.

Maintenance practices significantly impact the thermal efficiency of refractory linings. Regular thermal imaging inspections can identify hot spots indicating lining degradation before they lead to significant energy losses. Preventive maintenance programs focused on maintaining lining integrity have demonstrated return on investment through energy savings alone, independent of the benefits of reduced downtime.

Refractory materials with lower thermal conductivity can significantly reduce heat loss through the kiln shell, thereby improving overall thermal efficiency. However, this must be balanced with the material's ability to withstand the harsh operating conditions inside the kiln. Modern insulating refractories can reduce heat loss by up to 30% compared to traditional dense refractories, translating to substantial energy savings over the kiln's operational lifetime.

The thickness of refractory lining is another crucial parameter affecting thermal efficiency. While thicker linings provide better insulation, they also reduce the effective internal diameter of the kiln, potentially limiting production capacity. Advanced computational fluid dynamics (CFD) modeling now enables engineers to optimize lining thickness for specific operational parameters, balancing thermal efficiency with production requirements.

Thermal cycling resistance of refractory materials directly impacts energy conservation. Materials that can withstand frequent heating and cooling cycles without developing cracks maintain their insulating properties longer, reducing the need for energy-intensive repairs and replacements. Silicon carbide-based refractories have shown superior thermal cycling resistance, maintaining consistent thermal performance for extended periods.

The implementation of multi-layer lining systems represents a significant advancement in energy conservation for rotary kilns. These systems typically combine a high-temperature resistant working layer with an insulating backup layer, optimizing both durability and thermal efficiency. Studies indicate that properly designed multi-layer systems can reduce fuel consumption by 8-15% compared to single-layer linings.

Surface emissivity of refractory materials affects radiant heat transfer within the kiln. Materials with optimized emissivity properties can enhance heat transfer to the material being processed while minimizing heat loss to the environment. Recent developments in ceramic technology have produced refractories with tailored emissivity characteristics for specific kiln applications, further improving energy utilization.

Maintenance practices significantly impact the thermal efficiency of refractory linings. Regular thermal imaging inspections can identify hot spots indicating lining degradation before they lead to significant energy losses. Preventive maintenance programs focused on maintaining lining integrity have demonstrated return on investment through energy savings alone, independent of the benefits of reduced downtime.

Total Cost of Ownership and Lifecycle Assessment

When evaluating refractory lining options for rotary kilns, a comprehensive Total Cost of Ownership (TCO) and Lifecycle Assessment approach is essential for making economically sound decisions. This analysis extends beyond the initial purchase price to encompass all costs associated with the refractory lining throughout its operational life.

The acquisition cost represents only 20-30% of the total lifecycle expense for refractory materials in rotary kilns. Installation costs, which include labor, equipment, and downtime during installation, can account for an additional 15-25% of the total expenditure. These figures highlight the importance of considering installation efficiency when selecting refractory materials.

Operational costs constitute a significant portion of the TCO, primarily through energy consumption. High-quality refractory materials with superior insulation properties can reduce heat loss by 10-15%, translating to substantial energy savings over the kiln's operational life. For a typical cement plant, this could represent annual savings of $100,000-$500,000 depending on kiln size and operational parameters.

Maintenance expenses and replacement frequency dramatically impact the long-term economics of refractory selection. Premium materials may cost 30-50% more initially but can offer 2-3 times longer service life in demanding applications. This extended lifespan significantly reduces the frequency of kiln shutdowns, which typically cost $50,000-$100,000 per day in lost production for medium to large operations.

Environmental considerations are increasingly important in TCO calculations. Modern lifecycle assessments incorporate carbon footprint analysis, with some advanced refractory materials offering 15-20% lower embodied carbon compared to traditional options. Additionally, end-of-life disposal or recycling costs must be factored into comprehensive economic evaluations.

Risk assessment represents another critical dimension of TCO analysis. Premature refractory failure can lead to catastrophic consequences, including unplanned shutdowns and potential damage to the kiln shell. The financial impact of such failures often exceeds the cost difference between standard and premium refractory solutions by an order of magnitude.

Optimization models incorporating these factors demonstrate that selecting higher-quality refractory materials typically results in 15-25% lower total lifecycle costs despite higher initial investments. These models account for regional variations in energy costs, labor rates, and operational parameters to provide customized TCO projections for specific installations.

The acquisition cost represents only 20-30% of the total lifecycle expense for refractory materials in rotary kilns. Installation costs, which include labor, equipment, and downtime during installation, can account for an additional 15-25% of the total expenditure. These figures highlight the importance of considering installation efficiency when selecting refractory materials.

Operational costs constitute a significant portion of the TCO, primarily through energy consumption. High-quality refractory materials with superior insulation properties can reduce heat loss by 10-15%, translating to substantial energy savings over the kiln's operational life. For a typical cement plant, this could represent annual savings of $100,000-$500,000 depending on kiln size and operational parameters.

Maintenance expenses and replacement frequency dramatically impact the long-term economics of refractory selection. Premium materials may cost 30-50% more initially but can offer 2-3 times longer service life in demanding applications. This extended lifespan significantly reduces the frequency of kiln shutdowns, which typically cost $50,000-$100,000 per day in lost production for medium to large operations.

Environmental considerations are increasingly important in TCO calculations. Modern lifecycle assessments incorporate carbon footprint analysis, with some advanced refractory materials offering 15-20% lower embodied carbon compared to traditional options. Additionally, end-of-life disposal or recycling costs must be factored into comprehensive economic evaluations.

Risk assessment represents another critical dimension of TCO analysis. Premature refractory failure can lead to catastrophic consequences, including unplanned shutdowns and potential damage to the kiln shell. The financial impact of such failures often exceeds the cost difference between standard and premium refractory solutions by an order of magnitude.

Optimization models incorporating these factors demonstrate that selecting higher-quality refractory materials typically results in 15-25% lower total lifecycle costs despite higher initial investments. These models account for regional variations in energy costs, labor rates, and operational parameters to provide customized TCO projections for specific installations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!