Rotary Kiln Start-Up And Shutdown Procedures For Safety And Longevity

AUG 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Rotary Kiln Technology Background and Operational Goals

Rotary kilns have evolved significantly since their inception in the late 19th century, originally developed for cement production but now widely utilized across various industries including minerals processing, waste management, and chemical manufacturing. These cylindrical vessels, slightly inclined and rotating on their horizontal axis, facilitate heat transfer and material transformation through controlled thermal processing. The technology has progressed from simple coal-fired systems to sophisticated operations incorporating advanced automation, alternative fuels, and precise thermal profiling capabilities.

The evolution of rotary kiln technology has been driven by increasing demands for energy efficiency, environmental compliance, and operational reliability. Modern kilns feature improved refractory materials, enhanced heat recovery systems, and sophisticated burner technologies that optimize fuel consumption while minimizing emissions. The integration of digital monitoring systems and predictive maintenance protocols represents the latest advancement in this technological progression, enabling real-time performance optimization and extended equipment lifespan.

Start-up and shutdown procedures have emerged as critical aspects of rotary kiln operation, directly impacting both safety parameters and equipment longevity. Historical data indicates that approximately 60% of kiln structural failures and refractory damage occur during these transitional operational phases, highlighting their significance in the overall operational framework. The technical complexity of these procedures stems from the need to manage thermal gradients, mechanical stresses, and material flow dynamics during non-steady-state conditions.

The primary operational goals for rotary kiln start-up and shutdown procedures encompass several interconnected objectives. First, ensuring personnel safety by preventing thermal incidents, mechanical failures, or hazardous material releases. Second, preserving equipment integrity by minimizing thermal shock to refractory linings and mechanical stress on structural components. Third, optimizing energy consumption during these transitional phases, which can account for up to 15% of total operational energy usage. Fourth, reducing environmental impact through controlled emissions management during these potentially volatile operational transitions.

Additionally, these procedures aim to minimize production downtime by establishing efficient, standardized protocols that can be executed consistently across operational teams and shifts. The economic implications are substantial, with industry analyses suggesting that optimized start-up and shutdown procedures can extend refractory life by 20-30% and reduce annual maintenance costs by 15-25%, representing significant operational savings for facilities employing this technology.

The technological trajectory points toward increasingly automated start-up and shutdown sequences, guided by artificial intelligence systems capable of adapting to varying material characteristics, environmental conditions, and production requirements. This represents the next frontier in rotary kiln operational excellence, promising further improvements in safety metrics, equipment longevity, and process efficiency.

The evolution of rotary kiln technology has been driven by increasing demands for energy efficiency, environmental compliance, and operational reliability. Modern kilns feature improved refractory materials, enhanced heat recovery systems, and sophisticated burner technologies that optimize fuel consumption while minimizing emissions. The integration of digital monitoring systems and predictive maintenance protocols represents the latest advancement in this technological progression, enabling real-time performance optimization and extended equipment lifespan.

Start-up and shutdown procedures have emerged as critical aspects of rotary kiln operation, directly impacting both safety parameters and equipment longevity. Historical data indicates that approximately 60% of kiln structural failures and refractory damage occur during these transitional operational phases, highlighting their significance in the overall operational framework. The technical complexity of these procedures stems from the need to manage thermal gradients, mechanical stresses, and material flow dynamics during non-steady-state conditions.

The primary operational goals for rotary kiln start-up and shutdown procedures encompass several interconnected objectives. First, ensuring personnel safety by preventing thermal incidents, mechanical failures, or hazardous material releases. Second, preserving equipment integrity by minimizing thermal shock to refractory linings and mechanical stress on structural components. Third, optimizing energy consumption during these transitional phases, which can account for up to 15% of total operational energy usage. Fourth, reducing environmental impact through controlled emissions management during these potentially volatile operational transitions.

Additionally, these procedures aim to minimize production downtime by establishing efficient, standardized protocols that can be executed consistently across operational teams and shifts. The economic implications are substantial, with industry analyses suggesting that optimized start-up and shutdown procedures can extend refractory life by 20-30% and reduce annual maintenance costs by 15-25%, representing significant operational savings for facilities employing this technology.

The technological trajectory points toward increasingly automated start-up and shutdown sequences, guided by artificial intelligence systems capable of adapting to varying material characteristics, environmental conditions, and production requirements. This represents the next frontier in rotary kiln operational excellence, promising further improvements in safety metrics, equipment longevity, and process efficiency.

Market Demand Analysis for Efficient Kiln Operations

The global rotary kiln market has experienced significant growth in recent years, driven primarily by expanding cement, lime, and mineral processing industries. Market research indicates that the global rotary kiln equipment market was valued at approximately $7.2 billion in 2022 and is projected to reach $9.8 billion by 2028, growing at a CAGR of 5.3% during the forecast period.

The demand for efficient kiln operations has intensified due to several key factors. Rising energy costs represent a critical market driver, as rotary kilns are notoriously energy-intensive, with fuel expenses accounting for 30-40% of operational costs in cement production. This economic pressure has created substantial market demand for optimized start-up and shutdown procedures that minimize fuel consumption and thermal stress.

Environmental regulations have emerged as another significant market force. Stringent emissions standards in North America, Europe, and increasingly in Asia have compelled manufacturers to adopt more efficient operational practices. Improper kiln start-up and shutdown procedures can result in excessive emissions, potentially leading to regulatory penalties that can exceed $100,000 per violation in some jurisdictions.

Equipment longevity concerns represent a third major market driver. Premature equipment failure due to improper thermal management during critical operational transitions can cost facilities millions in replacement parts and unplanned downtime. Industry data suggests that implementing proper start-up and shutdown protocols can extend kiln refractory life by 15-25%, representing substantial cost savings given that a complete refractory replacement can cost between $500,000 to $2 million depending on kiln size.

The market for advanced kiln operation solutions shows distinct regional characteristics. North America and Europe primarily focus on retrofitting existing kilns with advanced control systems, while Asia-Pacific regions, particularly China and India, are installing new kiln capacity with integrated safety and efficiency systems. This regional variation creates diverse market opportunities for technology providers.

Industry surveys indicate that over 65% of kiln operators report challenges with standardizing start-up and shutdown procedures, highlighting a significant market gap. This has created demand for comprehensive procedural documentation, training programs, and automated control systems that can ensure consistent execution of these critical operational phases.

The COVID-19 pandemic temporarily disrupted the market but has ultimately accelerated demand for automation solutions that reduce reliance on manual operations. This trend is expected to continue, with the market for automated kiln control systems projected to grow at 7.8% annually through 2028, outpacing the overall kiln equipment market.

The demand for efficient kiln operations has intensified due to several key factors. Rising energy costs represent a critical market driver, as rotary kilns are notoriously energy-intensive, with fuel expenses accounting for 30-40% of operational costs in cement production. This economic pressure has created substantial market demand for optimized start-up and shutdown procedures that minimize fuel consumption and thermal stress.

Environmental regulations have emerged as another significant market force. Stringent emissions standards in North America, Europe, and increasingly in Asia have compelled manufacturers to adopt more efficient operational practices. Improper kiln start-up and shutdown procedures can result in excessive emissions, potentially leading to regulatory penalties that can exceed $100,000 per violation in some jurisdictions.

Equipment longevity concerns represent a third major market driver. Premature equipment failure due to improper thermal management during critical operational transitions can cost facilities millions in replacement parts and unplanned downtime. Industry data suggests that implementing proper start-up and shutdown protocols can extend kiln refractory life by 15-25%, representing substantial cost savings given that a complete refractory replacement can cost between $500,000 to $2 million depending on kiln size.

The market for advanced kiln operation solutions shows distinct regional characteristics. North America and Europe primarily focus on retrofitting existing kilns with advanced control systems, while Asia-Pacific regions, particularly China and India, are installing new kiln capacity with integrated safety and efficiency systems. This regional variation creates diverse market opportunities for technology providers.

Industry surveys indicate that over 65% of kiln operators report challenges with standardizing start-up and shutdown procedures, highlighting a significant market gap. This has created demand for comprehensive procedural documentation, training programs, and automated control systems that can ensure consistent execution of these critical operational phases.

The COVID-19 pandemic temporarily disrupted the market but has ultimately accelerated demand for automation solutions that reduce reliance on manual operations. This trend is expected to continue, with the market for automated kiln control systems projected to grow at 7.8% annually through 2028, outpacing the overall kiln equipment market.

Technical Challenges in Kiln Start-Up and Shutdown

Rotary kilns present significant technical challenges during start-up and shutdown phases that can impact both safety and equipment longevity. The thermal stress management during these transitional periods represents one of the most critical challenges. Rapid temperature changes can induce thermal shock, causing material expansion and contraction at different rates across the kiln structure. This differential expansion creates mechanical stresses that may lead to refractory damage, shell deformation, and potential structural failures over time.

The refractory lining integrity poses another substantial challenge. During cold starts, the refractory material is particularly vulnerable as moisture trapped within its structure can rapidly convert to steam, creating pressure that may cause spalling or cracking. Conversely, during shutdown, if cooling occurs too rapidly, thermal contraction can create gaps between refractory bricks, compromising the protective lining system.

Mechanical system alignment presents persistent difficulties during transitional operations. The kiln shell, support rollers, and drive mechanisms must maintain precise alignment despite thermal expansion and contraction cycles. Misalignment during these phases can accelerate wear on mechanical components, increase energy consumption, and potentially lead to catastrophic failures if not properly managed.

Combustion control systems face unique challenges during start-up and shutdown. Establishing stable flame patterns and maintaining optimal air-to-fuel ratios is particularly difficult during these non-steady-state conditions. Incomplete combustion can lead to explosive conditions, while poor flame control may cause localized overheating and damage to the refractory lining.

Material handling dynamics change significantly during transitional operations. During start-up, material may not flow properly through a cold kiln, creating potential for blockages or uneven material distribution. During shutdown, residual material may continue to react or degrade if not properly managed, potentially damaging internal components or creating hazardous conditions.

Instrumentation and control systems often struggle with the non-linear behavior of kilns during these phases. Temperature sensors, pressure monitors, and flow meters must accurately track rapidly changing conditions to enable proper control responses. Many legacy systems lack the sophistication to properly manage these transitional states, increasing reliance on operator experience and judgment.

Environmental compliance represents an emerging challenge, as emissions profiles during start-up and shutdown often differ significantly from normal operations. Regulatory frameworks increasingly scrutinize these transitional emissions, requiring more sophisticated monitoring and control strategies to maintain compliance during these critical phases.

The refractory lining integrity poses another substantial challenge. During cold starts, the refractory material is particularly vulnerable as moisture trapped within its structure can rapidly convert to steam, creating pressure that may cause spalling or cracking. Conversely, during shutdown, if cooling occurs too rapidly, thermal contraction can create gaps between refractory bricks, compromising the protective lining system.

Mechanical system alignment presents persistent difficulties during transitional operations. The kiln shell, support rollers, and drive mechanisms must maintain precise alignment despite thermal expansion and contraction cycles. Misalignment during these phases can accelerate wear on mechanical components, increase energy consumption, and potentially lead to catastrophic failures if not properly managed.

Combustion control systems face unique challenges during start-up and shutdown. Establishing stable flame patterns and maintaining optimal air-to-fuel ratios is particularly difficult during these non-steady-state conditions. Incomplete combustion can lead to explosive conditions, while poor flame control may cause localized overheating and damage to the refractory lining.

Material handling dynamics change significantly during transitional operations. During start-up, material may not flow properly through a cold kiln, creating potential for blockages or uneven material distribution. During shutdown, residual material may continue to react or degrade if not properly managed, potentially damaging internal components or creating hazardous conditions.

Instrumentation and control systems often struggle with the non-linear behavior of kilns during these phases. Temperature sensors, pressure monitors, and flow meters must accurately track rapidly changing conditions to enable proper control responses. Many legacy systems lack the sophistication to properly manage these transitional states, increasing reliance on operator experience and judgment.

Environmental compliance represents an emerging challenge, as emissions profiles during start-up and shutdown often differ significantly from normal operations. Regulatory frameworks increasingly scrutinize these transitional emissions, requiring more sophisticated monitoring and control strategies to maintain compliance during these critical phases.

Current Best Practices for Kiln Operation Transitions

01 Thermal management and insulation systems

Effective thermal management is crucial for rotary kiln safety and longevity. This includes advanced insulation systems that prevent heat loss, maintain optimal operating temperatures, and protect the outer shell from thermal stress. Proper insulation reduces energy consumption, prevents hotspots, and extends the service life of refractory linings. Thermal monitoring systems can detect abnormal temperature patterns that might indicate refractory damage or operational issues before they lead to catastrophic failures.- Thermal management and insulation systems: Effective thermal management is crucial for rotary kiln longevity. Advanced insulation systems help maintain optimal operating temperatures while preventing heat loss. These systems include refractory linings, heat shields, and thermal barriers that protect the kiln shell from excessive temperatures. Proper thermal management prevents thermal stress, reduces energy consumption, and extends the service life of the kiln by minimizing thermal expansion and contraction cycles that can lead to structural damage.

- Monitoring and control systems for safety: Advanced monitoring and control systems are essential for rotary kiln safety. These systems include temperature sensors, pressure monitors, gas analyzers, and automated control mechanisms that continuously track kiln performance and operating conditions. Real-time monitoring allows for early detection of potential issues, enabling operators to take preventive actions before failures occur. Automated safety protocols can initiate emergency shutdowns when dangerous conditions are detected, protecting both equipment and personnel from hazardous situations.

- Structural integrity and support systems: Maintaining structural integrity is fundamental for rotary kiln safety and longevity. This includes robust support systems such as riding rings, rollers, and thrust rollers that ensure proper alignment and weight distribution. Advanced bearing designs and lubrication systems reduce friction and wear on moving parts. Regular inspection and maintenance of structural components prevent catastrophic failures and extend operational life. Proper alignment systems minimize vibration and mechanical stress that could lead to premature failure.

- Wear protection and material selection: Specialized wear protection systems and appropriate material selection significantly extend rotary kiln lifespan. This includes wear-resistant linings, protective coatings, and strategic use of high-temperature alloys in critical areas. Advanced ceramic materials and composite linings resist abrasion, corrosion, and thermal degradation. Modular design approaches allow for targeted replacement of high-wear components without complete system overhaul. Proper material selection based on specific operating conditions ensures optimal performance and longevity.

- Sealing systems and emission control: Effective sealing systems and emission control mechanisms are vital for both safety and environmental compliance in rotary kiln operations. Advanced sealing technologies prevent the escape of hot gases, particulates, and hazardous materials. These include mechanical seals, labyrinth seals, and pneumatic sealing systems at kiln ends. Integrated emission control systems capture and treat exhaust gases before release, reducing environmental impact and workplace hazards. Proper sealing also improves thermal efficiency by preventing heat loss and unwanted air infiltration.

02 Refractory lining design and maintenance

The refractory lining is critical to rotary kiln longevity as it protects the steel shell from extreme temperatures and chemical attack. Advanced refractory materials and installation techniques can significantly extend kiln service life. Regular inspection and maintenance of refractory linings help identify wear patterns, cracks, or spalling before they lead to shell damage. Innovative lining systems with specialized anchoring mechanisms improve stability during thermal cycling and reduce the risk of catastrophic lining failures.Expand Specific Solutions03 Mechanical integrity and drive systems

Maintaining mechanical integrity is essential for safe kiln operation and longevity. This includes proper alignment of support rollers, thrust rollers, and drive gears to prevent uneven wear and structural stress. Advanced monitoring systems can detect misalignment, excessive vibration, or abnormal load distribution. Improved drive systems with variable speed controls allow for optimal rotation speeds based on process requirements, reducing mechanical stress during operation and startup. Regular inspection of mechanical components helps identify wear patterns before they lead to operational failures.Expand Specific Solutions04 Sealing systems and emission control

Effective sealing systems at the kiln ends prevent hot gas leakage, improving energy efficiency and workplace safety. Advanced sealing technologies reduce air infiltration and dust emissions while accommodating thermal expansion and kiln movement. Integrated emission control systems capture particulates and harmful gases, ensuring compliance with environmental regulations and improving workplace air quality. Proper sealing also prevents ambient air infiltration that can cause temperature fluctuations and thermal stress in the kiln structure.Expand Specific Solutions05 Monitoring and predictive maintenance systems

Advanced monitoring systems using sensors, cameras, and data analytics enable real-time assessment of kiln conditions. These systems track critical parameters such as temperature profiles, shell deformation, vibration patterns, and rotation speed. Predictive maintenance algorithms analyze operational data to forecast potential failures before they occur, allowing for planned interventions rather than emergency repairs. Thermal imaging and laser scanning technologies provide detailed information about refractory condition without requiring kiln shutdown, significantly extending operational campaigns and overall kiln lifespan.Expand Specific Solutions

Major Manufacturers and Industry Leaders in Kiln Technology

The rotary kiln start-up and shutdown procedures market is currently in a growth phase, driven by increasing safety regulations and focus on equipment longevity across industrial sectors. The global market size is estimated to exceed $500 million, with steady annual growth as industries prioritize operational efficiency and risk mitigation. Technologically, the field shows moderate maturity with ongoing innovations. Leading players include Andritz Oy and Mitsubishi Heavy Industries with advanced automation solutions, CITIC Heavy Industries and Luoyang Mining Machinery offering specialized kiln control systems, while Holcim Technology and Air Products & Chemicals focus on energy-efficient procedures. Academic institutions like Central South University contribute research advancements, creating a competitive landscape balanced between established industrial giants and specialized technology providers.

CITIC Heavy Industries Co., Ltd.

Technical Solution: CITIC Heavy Industries has engineered a rotary kiln management system focused on mechanical integrity during start-up and shutdown operations. Their approach emphasizes controlled thermal expansion through a proprietary burner management system that modulates flame characteristics based on shell temperature feedback. The procedure includes a specialized shell alignment monitoring system that continuously tracks kiln geometry during heating phases to detect and compensate for uneven expansion. CITIC's start-up protocol incorporates variable speed drive technology to maintain optimal rotation speeds during different heating phases, preventing mechanical stress on drive components and support rollers. Their shutdown methodology includes a staged cooling process with intermediate temperature plateaus to allow for gradual and uniform contraction of the kiln shell and refractory. The system also features emergency shutdown protocols that prioritize equipment protection while minimizing thermal shock.

Strengths: Exceptional focus on mechanical integrity and alignment during thermal transitions helps prevent costly structural damage to kiln components. Their variable speed technology optimizes rotation parameters for different operational phases. Weaknesses: The system places heavy emphasis on mechanical considerations sometimes at the expense of energy efficiency during transition phases. Implementation requires significant modifications to existing control systems.

LUOYANG MINING MACHINERY ENGINEERING DESIGN INSTITUTE CO LTD

Technical Solution: Luoyang Mining Machinery has developed a comprehensive rotary kiln operational management system specifically designed for mining applications. Their start-up and shutdown procedures incorporate a three-stage heating protocol that carefully balances thermal gradients across different kiln zones. The system features specialized burner positioning technology that directs heat precisely where needed during critical phases to prevent localized overheating. Their approach includes a proprietary refractory protection algorithm that calculates optimal rotation speeds and heating rates based on refractory type, age, and condition history. For shutdown procedures, Luoyang has engineered a controlled cooling sequence with automated damper adjustments to maintain negative pressure while preventing cold air infiltration that could damage hot refractory. The system also incorporates emergency shutdown protocols with fail-safe mechanisms that prioritize equipment protection while minimizing thermal shock to critical components.

Strengths: Highly specialized for mining industry applications with consideration for variable material processing requirements. Their zone-specific heating approach provides excellent protection for refractory investments. Weaknesses: The system requires extensive customization for each installation, increasing implementation time and costs. The specialized nature of their approach makes standardization across multiple facilities challenging.

Critical Patents and Innovations in Kiln Safety Systems

Rotary kiln and operation method thereof

PatentActiveJP2018194275A

Innovation

- A method involving a rotary kiln operation that includes a refresh operation where high-temperature gas with lower dust concentration and higher temperature than normal operation flows through the heating channel, interrupting material supply to remove deposits, and resuming after a predetermined time to maintain system stability.

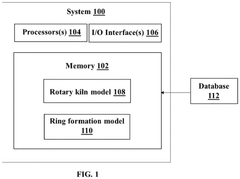

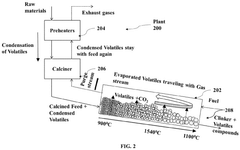

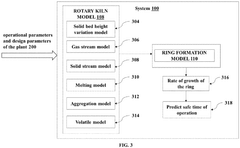

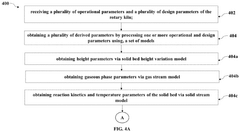

Method and system of predicting safe time of operation for a rotary kiln

PatentPendingEP4521050A1

Innovation

- A method and system that utilize a set of models, including the solid bed height variation model, gas stream model, solid stream model, melt model, aggregation model, and volatile model, to process operational and design parameters of the rotary kiln, thereby predicting safe time of operation by estimating ring thickness, growth rate, and strength.

Thermal Stress Management in Kiln Lifecycle Operations

Thermal stress management represents a critical aspect of rotary kiln operations throughout its lifecycle, particularly during the vulnerable phases of startup and shutdown. The temperature gradients that develop across the kiln shell and refractory lining during these transitional periods can induce significant thermal stresses that, if not properly managed, lead to premature equipment failure and safety hazards.

During startup, the controlled heating rate is paramount to prevent thermal shock. Industry best practices recommend temperature increases of no more than 50°C per hour for the first 200°C, followed by rates of 75-100°C per hour until reaching operational temperature. This gradual approach allows for uniform thermal expansion across the kiln components, minimizing differential stresses that could cause refractory spalling or shell deformation.

Shutdown procedures require equally meticulous thermal management strategies. Rapid cooling can create severe contraction stresses at the interface between the refractory lining and steel shell. Modern kiln operations implement controlled cooling protocols, typically maintaining cooling rates below 70°C per hour until temperatures drop below 500°C, after which natural cooling may proceed.

Advanced monitoring systems play an essential role in thermal stress management. Distributed temperature sensing using fiber optic technology and thermal imaging cameras provide real-time data on temperature distributions across the kiln structure. These technologies enable operators to detect hotspots or abnormal thermal gradients before they develop into critical issues.

Computational fluid dynamics (CFD) and finite element analysis (FEA) have revolutionized thermal stress prediction and management. These simulation tools allow engineers to model thermal behavior during transient operations, optimizing heating and cooling protocols specific to individual kiln designs and operational parameters. Several cement and lime production facilities have reported 15-30% increases in refractory lifespan after implementing simulation-guided thermal management protocols.

Material selection represents another frontier in thermal stress management. Advanced refractory materials with engineered thermal expansion properties and enhanced thermal shock resistance have emerged as valuable solutions. Composite refractory systems that incorporate expansion joints and flexible layers help accommodate thermal cycling stresses, significantly extending operational lifespans in facilities experiencing frequent startups and shutdowns.

During startup, the controlled heating rate is paramount to prevent thermal shock. Industry best practices recommend temperature increases of no more than 50°C per hour for the first 200°C, followed by rates of 75-100°C per hour until reaching operational temperature. This gradual approach allows for uniform thermal expansion across the kiln components, minimizing differential stresses that could cause refractory spalling or shell deformation.

Shutdown procedures require equally meticulous thermal management strategies. Rapid cooling can create severe contraction stresses at the interface between the refractory lining and steel shell. Modern kiln operations implement controlled cooling protocols, typically maintaining cooling rates below 70°C per hour until temperatures drop below 500°C, after which natural cooling may proceed.

Advanced monitoring systems play an essential role in thermal stress management. Distributed temperature sensing using fiber optic technology and thermal imaging cameras provide real-time data on temperature distributions across the kiln structure. These technologies enable operators to detect hotspots or abnormal thermal gradients before they develop into critical issues.

Computational fluid dynamics (CFD) and finite element analysis (FEA) have revolutionized thermal stress prediction and management. These simulation tools allow engineers to model thermal behavior during transient operations, optimizing heating and cooling protocols specific to individual kiln designs and operational parameters. Several cement and lime production facilities have reported 15-30% increases in refractory lifespan after implementing simulation-guided thermal management protocols.

Material selection represents another frontier in thermal stress management. Advanced refractory materials with engineered thermal expansion properties and enhanced thermal shock resistance have emerged as valuable solutions. Composite refractory systems that incorporate expansion joints and flexible layers help accommodate thermal cycling stresses, significantly extending operational lifespans in facilities experiencing frequent startups and shutdowns.

Environmental Impact and Regulatory Compliance

Rotary kiln operations are subject to stringent environmental regulations due to their potential impact on air quality, water resources, and surrounding ecosystems. During start-up and shutdown procedures, emissions can spike significantly as optimal combustion conditions have not yet been established or are being deliberately altered. These transitional phases often produce higher levels of particulate matter, nitrogen oxides (NOx), sulfur dioxide (SO2), carbon monoxide (CO), and volatile organic compounds (VOCs) compared to steady-state operation.

Regulatory frameworks worldwide, including the U.S. EPA's NESHAP (National Emission Standards for Hazardous Air Pollutants) and the European Union's Industrial Emissions Directive (IED), specifically address these transitional operational phases. These regulations typically require continuous emissions monitoring systems (CEMS) that must remain operational during start-up and shutdown events, with data logging requirements to demonstrate compliance even during these non-standard operating conditions.

Water discharge considerations are equally important during these transitional phases. Cooling systems and quench operations during emergency shutdowns can generate contaminated wastewater that requires proper treatment before discharge. Facilities must maintain compliance with local water quality standards and discharge permits even during these irregular operational periods.

Noise pollution represents another environmental concern, particularly during start-up when equipment may operate outside normal parameters. Many jurisdictions impose time-of-day restrictions on high-noise operations, which may influence scheduling of planned start-ups and shutdowns to minimize community impact.

Modern environmental management systems increasingly incorporate specific protocols for these transitional phases. Best practices include gradual temperature ramping during start-up to minimize thermal shock emissions, optimized fuel-air ratios throughout the transition process, and controlled cooling procedures during shutdown to prevent unnecessary emissions from incomplete combustion.

Regulatory compliance during these phases often requires detailed documentation and reporting. Operators must maintain comprehensive logs of all start-up and shutdown events, including duration, emissions data, and any abnormal conditions encountered. Many regulatory frameworks now require facilities to develop specific start-up, shutdown, and malfunction (SSM) plans that detail procedures designed to minimize environmental impact during these transitional phases.

Failure to maintain environmental compliance during these critical operational transitions can result in significant penalties, including fines, operational restrictions, or even facility closure in severe cases. Therefore, environmental considerations must be fully integrated into all start-up and shutdown procedures, not treated as secondary concerns to operational efficiency or equipment longevity.

Regulatory frameworks worldwide, including the U.S. EPA's NESHAP (National Emission Standards for Hazardous Air Pollutants) and the European Union's Industrial Emissions Directive (IED), specifically address these transitional operational phases. These regulations typically require continuous emissions monitoring systems (CEMS) that must remain operational during start-up and shutdown events, with data logging requirements to demonstrate compliance even during these non-standard operating conditions.

Water discharge considerations are equally important during these transitional phases. Cooling systems and quench operations during emergency shutdowns can generate contaminated wastewater that requires proper treatment before discharge. Facilities must maintain compliance with local water quality standards and discharge permits even during these irregular operational periods.

Noise pollution represents another environmental concern, particularly during start-up when equipment may operate outside normal parameters. Many jurisdictions impose time-of-day restrictions on high-noise operations, which may influence scheduling of planned start-ups and shutdowns to minimize community impact.

Modern environmental management systems increasingly incorporate specific protocols for these transitional phases. Best practices include gradual temperature ramping during start-up to minimize thermal shock emissions, optimized fuel-air ratios throughout the transition process, and controlled cooling procedures during shutdown to prevent unnecessary emissions from incomplete combustion.

Regulatory compliance during these phases often requires detailed documentation and reporting. Operators must maintain comprehensive logs of all start-up and shutdown events, including duration, emissions data, and any abnormal conditions encountered. Many regulatory frameworks now require facilities to develop specific start-up, shutdown, and malfunction (SSM) plans that detail procedures designed to minimize environmental impact during these transitional phases.

Failure to maintain environmental compliance during these critical operational transitions can result in significant penalties, including fines, operational restrictions, or even facility closure in severe cases. Therefore, environmental considerations must be fully integrated into all start-up and shutdown procedures, not treated as secondary concerns to operational efficiency or equipment longevity.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!