Failure Analysis For Kiln Components: Cracks, Wear And Root Causes

AUG 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Kiln Component Failure Background and Objectives

Industrial kilns are critical components in various manufacturing processes, particularly in cement, lime, and ceramics production. Over the past several decades, these thermal processing units have evolved significantly in design and operational capacity, yet component failure remains a persistent challenge that impacts productivity, maintenance costs, and safety across industries worldwide.

The history of kiln technology dates back to ancient civilizations, but modern rotary kilns emerged in the late 19th century, revolutionizing industrial processes. Since then, continuous improvements in materials science and engineering have attempted to address recurring failure issues. Despite these advancements, component degradation continues to plague operations, with an estimated 15-20% of unplanned downtime in cement plants attributed to kiln component failures.

Cracks, wear patterns, and material degradation in kiln components represent multifaceted technical challenges influenced by extreme thermal conditions, mechanical stress, and chemical reactions. These kilns typically operate at temperatures exceeding 1400°C while rotating at variable speeds, creating a uniquely harsh environment for structural materials. The economic impact of such failures is substantial, with the global cement industry alone losing approximately $3-5 billion annually due to kiln-related downtime.

Current technical objectives in this field focus on developing comprehensive failure analysis methodologies that can accurately identify root causes of component degradation. This includes establishing standardized protocols for examining thermal fatigue, mechanical wear, and chemical attack mechanisms. Additionally, there is growing interest in predictive maintenance approaches that leverage advanced monitoring technologies to detect early signs of failure.

The evolution of failure analysis techniques has progressed from basic visual inspection to sophisticated non-destructive testing methods, including thermography, ultrasonic testing, and advanced material characterization. These developments reflect the industry's recognition that component longevity directly impacts operational efficiency and sustainability metrics.

This technical investigation aims to systematically analyze the primary failure modes affecting kiln components, identify their underlying causes, and evaluate potential mitigation strategies. By understanding the complex interplay between operational parameters, material properties, and failure mechanisms, this research seeks to establish a foundation for extending component lifespan, optimizing maintenance schedules, and reducing the environmental footprint associated with premature component replacement.

The history of kiln technology dates back to ancient civilizations, but modern rotary kilns emerged in the late 19th century, revolutionizing industrial processes. Since then, continuous improvements in materials science and engineering have attempted to address recurring failure issues. Despite these advancements, component degradation continues to plague operations, with an estimated 15-20% of unplanned downtime in cement plants attributed to kiln component failures.

Cracks, wear patterns, and material degradation in kiln components represent multifaceted technical challenges influenced by extreme thermal conditions, mechanical stress, and chemical reactions. These kilns typically operate at temperatures exceeding 1400°C while rotating at variable speeds, creating a uniquely harsh environment for structural materials. The economic impact of such failures is substantial, with the global cement industry alone losing approximately $3-5 billion annually due to kiln-related downtime.

Current technical objectives in this field focus on developing comprehensive failure analysis methodologies that can accurately identify root causes of component degradation. This includes establishing standardized protocols for examining thermal fatigue, mechanical wear, and chemical attack mechanisms. Additionally, there is growing interest in predictive maintenance approaches that leverage advanced monitoring technologies to detect early signs of failure.

The evolution of failure analysis techniques has progressed from basic visual inspection to sophisticated non-destructive testing methods, including thermography, ultrasonic testing, and advanced material characterization. These developments reflect the industry's recognition that component longevity directly impacts operational efficiency and sustainability metrics.

This technical investigation aims to systematically analyze the primary failure modes affecting kiln components, identify their underlying causes, and evaluate potential mitigation strategies. By understanding the complex interplay between operational parameters, material properties, and failure mechanisms, this research seeks to establish a foundation for extending component lifespan, optimizing maintenance schedules, and reducing the environmental footprint associated with premature component replacement.

Market Demand for Reliable Kiln Systems

The global market for reliable kiln systems has experienced significant growth in recent years, driven primarily by expanding industrial sectors such as cement, lime, minerals processing, and waste management. Current market valuations indicate that the industrial kiln equipment sector exceeds $25 billion annually, with a compound annual growth rate of approximately 4.7% projected through 2028. This growth trajectory is particularly pronounced in developing economies where rapid infrastructure development necessitates increased cement and lime production capacity.

Industry stakeholders consistently emphasize the critical importance of kiln reliability, as unplanned downtime can cost operators between $50,000 and $200,000 per day depending on production capacity and market conditions. A recent industry survey revealed that 78% of kiln operators identified component failure as their primary operational concern, with specific emphasis on premature cracking and excessive wear of critical components.

The cement industry, representing the largest market segment for industrial kilns, has demonstrated particular sensitivity to component reliability issues. With global cement production exceeding 4 billion tons annually, even marginal improvements in kiln uptime translate to substantial economic benefits. Market research indicates that cement producers are willing to invest 15-20% premium for kiln components with demonstrably superior durability and predictable service life.

Emerging environmental regulations worldwide have created additional market pressure for more efficient and reliable kiln systems. Regulatory compliance often requires precise temperature control and combustion efficiency, which can only be maintained with properly functioning kiln components. This regulatory landscape has expanded the market for advanced monitoring systems and failure prediction technologies, currently valued at approximately $3.2 billion with double-digit growth rates.

Geographic market analysis reveals significant regional variations in demand patterns. While North American and European markets prioritize technological sophistication and preventive maintenance capabilities, emerging markets in Asia and Africa demonstrate stronger price sensitivity while still requiring acceptable reliability standards. China and India collectively represent over 40% of the global market for industrial kiln components, driven by their extensive cement and steel production capacities.

The aftermarket for kiln components represents another substantial market segment, estimated at $7.8 billion annually. This includes replacement parts, repair services, and retrofitting solutions designed to address common failure modes. Industry data indicates that operators typically allocate 12-18% of their annual operating budgets to maintenance and component replacement, highlighting the economic significance of extending component service life through improved failure analysis and design optimization.

Industry stakeholders consistently emphasize the critical importance of kiln reliability, as unplanned downtime can cost operators between $50,000 and $200,000 per day depending on production capacity and market conditions. A recent industry survey revealed that 78% of kiln operators identified component failure as their primary operational concern, with specific emphasis on premature cracking and excessive wear of critical components.

The cement industry, representing the largest market segment for industrial kilns, has demonstrated particular sensitivity to component reliability issues. With global cement production exceeding 4 billion tons annually, even marginal improvements in kiln uptime translate to substantial economic benefits. Market research indicates that cement producers are willing to invest 15-20% premium for kiln components with demonstrably superior durability and predictable service life.

Emerging environmental regulations worldwide have created additional market pressure for more efficient and reliable kiln systems. Regulatory compliance often requires precise temperature control and combustion efficiency, which can only be maintained with properly functioning kiln components. This regulatory landscape has expanded the market for advanced monitoring systems and failure prediction technologies, currently valued at approximately $3.2 billion with double-digit growth rates.

Geographic market analysis reveals significant regional variations in demand patterns. While North American and European markets prioritize technological sophistication and preventive maintenance capabilities, emerging markets in Asia and Africa demonstrate stronger price sensitivity while still requiring acceptable reliability standards. China and India collectively represent over 40% of the global market for industrial kiln components, driven by their extensive cement and steel production capacities.

The aftermarket for kiln components represents another substantial market segment, estimated at $7.8 billion annually. This includes replacement parts, repair services, and retrofitting solutions designed to address common failure modes. Industry data indicates that operators typically allocate 12-18% of their annual operating budgets to maintenance and component replacement, highlighting the economic significance of extending component service life through improved failure analysis and design optimization.

Current Challenges in Kiln Component Durability

The durability of kiln components represents a significant challenge in industrial operations, particularly in cement, lime, and other high-temperature manufacturing processes. Current kiln systems operate under extreme thermal conditions, with temperatures often exceeding 1400°C, creating an environment where component failure is not merely possible but expected over time. These harsh operating conditions are further exacerbated by thermal cycling, where components expand during heating and contract during cooling, inducing thermal stresses that accelerate material degradation.

Material selection presents a persistent challenge, as no single material perfectly addresses the combined demands of thermal resistance, mechanical strength, and chemical stability. Refractory materials commonly used in kiln construction, such as alumina, magnesia, and silicon carbide, each demonstrate specific vulnerabilities under prolonged exposure to operational stresses. The trade-off between thermal shock resistance and wear resistance continues to challenge engineers and materials scientists.

Mechanical stresses represent another significant challenge, with kiln components subjected to continuous rotational forces, vibration, and material loading. These mechanical factors interact with thermal stresses to create complex failure mechanisms that are difficult to predict using conventional modeling approaches. The interface between different materials, particularly in composite structures, creates weak points where cracks frequently initiate.

Chemical attack further complicates the durability equation. Alkali salts, sulfates, and chlorides present in raw materials can penetrate refractory linings, causing expansive reactions and accelerating deterioration. This chemical infiltration often works synergistically with thermal cycling to exacerbate damage through mechanisms such as spalling and exfoliation of protective layers.

Monitoring and predictive maintenance capabilities remain insufficient despite technological advances. Current non-destructive testing methods struggle to accurately assess internal damage in thick refractory linings while the kiln remains operational. This diagnostic limitation forces operators to rely on external indicators that may only become apparent after significant internal damage has occurred.

Cost constraints further complicate solutions to these challenges. While advanced materials and sophisticated monitoring systems exist, their implementation across entire kiln systems often proves economically prohibitive, particularly for smaller operations. This economic reality forces compromises in material selection and maintenance strategies that ultimately impact component longevity.

The interdisciplinary nature of these challenges requires collaboration between materials science, mechanical engineering, chemical engineering, and process control disciplines. Current approaches often address these factors in isolation rather than developing integrated solutions that consider their complex interactions, limiting the effectiveness of durability improvements in real-world applications.

Material selection presents a persistent challenge, as no single material perfectly addresses the combined demands of thermal resistance, mechanical strength, and chemical stability. Refractory materials commonly used in kiln construction, such as alumina, magnesia, and silicon carbide, each demonstrate specific vulnerabilities under prolonged exposure to operational stresses. The trade-off between thermal shock resistance and wear resistance continues to challenge engineers and materials scientists.

Mechanical stresses represent another significant challenge, with kiln components subjected to continuous rotational forces, vibration, and material loading. These mechanical factors interact with thermal stresses to create complex failure mechanisms that are difficult to predict using conventional modeling approaches. The interface between different materials, particularly in composite structures, creates weak points where cracks frequently initiate.

Chemical attack further complicates the durability equation. Alkali salts, sulfates, and chlorides present in raw materials can penetrate refractory linings, causing expansive reactions and accelerating deterioration. This chemical infiltration often works synergistically with thermal cycling to exacerbate damage through mechanisms such as spalling and exfoliation of protective layers.

Monitoring and predictive maintenance capabilities remain insufficient despite technological advances. Current non-destructive testing methods struggle to accurately assess internal damage in thick refractory linings while the kiln remains operational. This diagnostic limitation forces operators to rely on external indicators that may only become apparent after significant internal damage has occurred.

Cost constraints further complicate solutions to these challenges. While advanced materials and sophisticated monitoring systems exist, their implementation across entire kiln systems often proves economically prohibitive, particularly for smaller operations. This economic reality forces compromises in material selection and maintenance strategies that ultimately impact component longevity.

The interdisciplinary nature of these challenges requires collaboration between materials science, mechanical engineering, chemical engineering, and process control disciplines. Current approaches often address these factors in isolation rather than developing integrated solutions that consider their complex interactions, limiting the effectiveness of durability improvements in real-world applications.

Existing Failure Detection and Prevention Methods

01 Refractory materials for kiln components

Specialized refractory materials can be used in kiln components to prevent cracks and reduce wear. These materials are designed to withstand high temperatures and thermal cycling while maintaining structural integrity. Advanced ceramic composites, heat-resistant alloys, and specialized concrete formulations can significantly extend the service life of kiln components by resisting thermal shock and abrasion that typically lead to cracking and wear.- Refractory materials for kiln components: Specialized refractory materials can be used in kiln components to prevent cracks and reduce wear. These materials are designed to withstand high temperatures and thermal cycling while maintaining structural integrity. Advanced ceramic composites, heat-resistant alloys, and specialized concrete formulations can significantly extend the service life of kiln components by resisting thermal shock and abrasion that typically lead to cracking and wear.

- Structural design improvements for kiln components: Innovative structural designs can help mitigate stress concentrations that lead to cracks in kiln components. These designs include segmented construction, expansion joints, and flexible mounting systems that accommodate thermal expansion and contraction. By distributing thermal and mechanical stresses more evenly throughout the kiln structure, these design improvements can significantly reduce the formation of cracks and minimize wear on critical components.

- Monitoring and early detection systems: Advanced monitoring systems can detect early signs of cracks and wear in kiln components before catastrophic failure occurs. These systems utilize technologies such as thermal imaging, acoustic emission sensors, and vibration analysis to continuously monitor the condition of kiln components during operation. Early detection allows for timely maintenance interventions, preventing minor issues from developing into major failures and extending the operational life of kiln components.

- Protective coatings and surface treatments: Specialized coatings and surface treatments can be applied to kiln components to enhance their resistance to cracking and wear. These include ceramic coatings, thermal barrier coatings, and surface hardening treatments that protect the underlying material from thermal stress, chemical attack, and abrasion. By creating a sacrificial layer or enhancing the surface properties of kiln components, these treatments can significantly extend service life and reduce maintenance requirements.

- Repair and maintenance techniques: Innovative repair and maintenance techniques can address cracks and wear in kiln components without requiring complete replacement. These techniques include in-situ welding, ceramic patching, composite repairs, and specialized grouts that can be applied during scheduled maintenance periods. Preventive maintenance strategies, such as controlled cooling procedures and regular inspections, can also help minimize the development of cracks and reduce wear rates in kiln components.

02 Monitoring systems for crack detection

Implementing monitoring systems can help detect cracks in kiln components at early stages before catastrophic failure occurs. These systems utilize various technologies such as acoustic sensors, thermal imaging, and vibration analysis to continuously monitor the condition of kiln components during operation. Early detection allows for timely maintenance interventions, preventing minor cracks from developing into major structural failures and reducing overall wear.Expand Specific Solutions03 Protective coatings and linings

Applying specialized protective coatings and linings to kiln components can significantly reduce wear and prevent crack formation. These coatings create a barrier against abrasion, chemical attack, and thermal stress. Materials such as ceramic coatings, refractory linings, and composite overlays can be applied to vulnerable areas of the kiln to extend component life and maintain operational efficiency even under extreme conditions.Expand Specific Solutions04 Structural design improvements

Innovative structural designs for kiln components can minimize stress concentration points that typically lead to crack formation. These designs incorporate features such as expansion joints, flexible connections, and optimized geometries that accommodate thermal expansion and contraction. By distributing mechanical and thermal stresses more evenly throughout the components, these design improvements significantly reduce the likelihood of crack formation and propagation.Expand Specific Solutions05 Maintenance and repair techniques

Advanced maintenance and repair techniques can address existing cracks and wear in kiln components, extending their service life. These techniques include specialized welding procedures, composite patching, and in-situ repair methods that can be performed during scheduled downtime. Preventive maintenance schedules based on component wear patterns and operational data can also help identify potential failure points before they develop into critical issues.Expand Specific Solutions

Leading Manufacturers and Service Providers Analysis

The kiln component failure analysis market is in a growth phase, driven by increasing demand for preventive maintenance in industrial sectors. The market size is expanding due to the rising adoption of advanced diagnostic technologies across cement, ceramics, and metallurgical industries. Technologically, the field is moderately mature but evolving rapidly with companies like General Electric, FLSmidth, and Keda Industrial Group leading innovations in predictive analytics and material science. Texas Instruments and IBM are advancing sensor technologies and AI-based monitoring systems, while materials specialists like NGK Insulators and Luyang Energy-Saving Materials are developing more durable refractory solutions. Traditional industrial players such as Tata Steel and ABB Group contribute significant practical expertise in high-temperature applications and automation systems for kiln operations.

General Electric Company

Technical Solution: GE has developed an integrated approach to kiln component failure analysis through their Industrial Internet of Things (IIoT) platform, Predix. This system combines sensor data, historical performance metrics, and advanced analytics to identify patterns leading to component failures. GE's approach includes specialized high-temperature sensors that can withstand the extreme conditions inside industrial kilns while providing continuous monitoring of critical parameters. Their failure analysis methodology incorporates acoustic emission testing to detect crack initiation and propagation in refractory materials before visible damage occurs[1]. GE has also developed proprietary computational fluid dynamics (CFD) models that simulate the thermal and chemical environment inside kilns, allowing engineers to identify zones of accelerated wear and potential failure points. Their materials science division has created advanced ceramic composites with enhanced thermal shock resistance and improved chemical stability for kiln applications. GE's failure analysis protocol includes post-mortem examination using scanning electron microscopy with energy-dispersive X-ray spectroscopy to characterize failure mechanisms at the microstructural level[5]. The company also employs machine learning algorithms that analyze operational data to identify correlations between process parameters and component failures.

Strengths: Comprehensive IIoT platform integration provides holistic view of kiln operations; strong materials science capabilities for developing improved components. Weaknesses: Implementation requires significant digital infrastructure; solutions may be more oriented toward power generation applications than other kiln types.

FLSmidth A/S

Technical Solution: FLSmidth has developed comprehensive failure analysis methodologies specifically for cement and mineral processing kiln components. Their approach combines advanced non-destructive testing techniques with operational data analytics to identify root causes of failures. The company employs thermal imaging systems that can detect temperature anomalies during operation, allowing for early identification of refractory failures before visible cracks appear. Their SmartKiln™ monitoring system integrates multiple sensors to track shell deformation, thermal expansion, and mechanical stress in real-time[1]. FLSmidth's material science division has developed specialized refractory materials with enhanced thermal shock resistance and improved mechanical properties specifically designed to withstand the harsh conditions in rotary kilns. Their failure analysis protocol includes metallurgical examination of failed components using scanning electron microscopy and energy-dispersive X-ray spectroscopy to characterize microstructural changes and chemical degradation mechanisms[3].

Strengths: Integrated approach combining real-time monitoring with advanced materials science; extensive industry experience in cement and minerals processing provides deep application knowledge. Weaknesses: Solutions may be costly to implement fully; primarily focused on cement and minerals industry applications rather than broader industrial kiln applications.

Critical Failure Mechanisms and Metallurgical Analysis

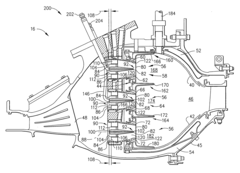

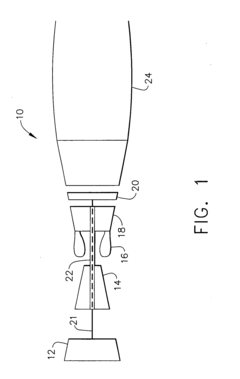

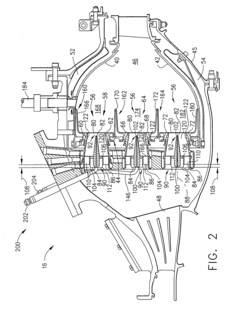

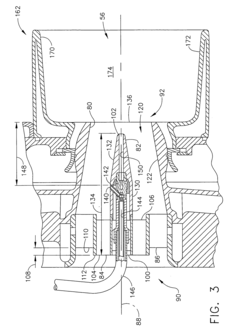

Methods to facilitate extending gas turbine engine useful life

PatentActiveUS20070084049A1

Innovation

- A method involving the identification of distressed combustor and turbine components, followed by the installation of enhancement kits that include redesigned dome assemblies, improved swirler/fuel nozzle interfaces, and upgraded liners with thermal barrier coatings, to extend the engine's operational life and reduce nitrogen oxide emissions.

Thermal Stress Management Strategies

Effective thermal stress management is critical for extending the operational lifespan of kiln components and preventing premature failures. The cyclical heating and cooling processes in kilns create significant thermal gradients that induce stresses capable of initiating and propagating cracks in critical components. These thermal stresses, when combined with mechanical loads, can accelerate wear mechanisms and lead to catastrophic failures if not properly managed.

Material selection represents the first line of defense against thermal stress-induced failures. High-temperature resistant alloys with appropriate coefficients of thermal expansion, such as nickel-chromium alloys and specialized stainless steels, demonstrate superior resistance to thermal fatigue. Recent advancements in ceramic composites and refractory materials have further expanded the options available for extreme temperature applications, offering improved thermal shock resistance and reduced crack propagation rates.

Structural design modifications can significantly mitigate thermal stress concentrations. The implementation of expansion joints and flexible connections allows for controlled thermal expansion without generating excessive stresses. Computational fluid dynamics (CFD) and finite element analysis (FEA) have revolutionized the design process, enabling engineers to identify potential hotspots and optimize component geometries before physical implementation. These simulation tools have proven particularly valuable for redesigning kiln shell supports and tire sections where thermal gradients are most severe.

Operational strategies play an equally important role in thermal stress management. Controlled heating and cooling rates during startup and shutdown phases can prevent the formation of steep thermal gradients. Industry best practices recommend maximum temperature change rates of 50-75°C per hour for large refractory structures, with even more conservative rates for critical transition zones. Automated temperature monitoring systems coupled with adaptive control algorithms have demonstrated up to 40% reduction in thermal stress-related incidents in modern kiln operations.

Protective coatings and surface treatments offer additional thermal stress mitigation options. Thermal barrier coatings (TBCs) consisting of ceramic top layers and metallic bond coats can reduce the temperature gradient across component cross-sections. Advanced plasma-sprayed zirconia coatings have shown particular promise, reducing surface temperatures by 100-200°C in high-heat zones while simultaneously providing protection against chemical attack and erosion.

Preventive maintenance protocols specifically designed to address thermal stress include regular non-destructive testing for early crack detection and strategic component replacement schedules based on thermal cycle counts rather than just operational hours. Infrared thermography has emerged as a valuable predictive maintenance tool, allowing for real-time identification of abnormal thermal patterns that may indicate developing stress concentrations or insulation failures.

Material selection represents the first line of defense against thermal stress-induced failures. High-temperature resistant alloys with appropriate coefficients of thermal expansion, such as nickel-chromium alloys and specialized stainless steels, demonstrate superior resistance to thermal fatigue. Recent advancements in ceramic composites and refractory materials have further expanded the options available for extreme temperature applications, offering improved thermal shock resistance and reduced crack propagation rates.

Structural design modifications can significantly mitigate thermal stress concentrations. The implementation of expansion joints and flexible connections allows for controlled thermal expansion without generating excessive stresses. Computational fluid dynamics (CFD) and finite element analysis (FEA) have revolutionized the design process, enabling engineers to identify potential hotspots and optimize component geometries before physical implementation. These simulation tools have proven particularly valuable for redesigning kiln shell supports and tire sections where thermal gradients are most severe.

Operational strategies play an equally important role in thermal stress management. Controlled heating and cooling rates during startup and shutdown phases can prevent the formation of steep thermal gradients. Industry best practices recommend maximum temperature change rates of 50-75°C per hour for large refractory structures, with even more conservative rates for critical transition zones. Automated temperature monitoring systems coupled with adaptive control algorithms have demonstrated up to 40% reduction in thermal stress-related incidents in modern kiln operations.

Protective coatings and surface treatments offer additional thermal stress mitigation options. Thermal barrier coatings (TBCs) consisting of ceramic top layers and metallic bond coats can reduce the temperature gradient across component cross-sections. Advanced plasma-sprayed zirconia coatings have shown particular promise, reducing surface temperatures by 100-200°C in high-heat zones while simultaneously providing protection against chemical attack and erosion.

Preventive maintenance protocols specifically designed to address thermal stress include regular non-destructive testing for early crack detection and strategic component replacement schedules based on thermal cycle counts rather than just operational hours. Infrared thermography has emerged as a valuable predictive maintenance tool, allowing for real-time identification of abnormal thermal patterns that may indicate developing stress concentrations or insulation failures.

Environmental Impact of Kiln Component Lifecycle

The environmental impact of kiln component lifecycle extends far beyond operational considerations, encompassing raw material extraction, manufacturing, transportation, operation, and end-of-life disposal. The production of kiln components, particularly those made from refractory materials and high-grade alloys, requires extensive mining operations that contribute to habitat destruction, soil erosion, and groundwater contamination. Manufacturing processes involve high-temperature treatments that consume significant energy and release greenhouse gases, particularly CO2.

During operation, kiln components contribute to environmental impact through energy consumption and emissions. Failed components exacerbate these impacts, as cracks and wear lead to thermal inefficiency, increasing fuel consumption by up to 15-20% in severely compromised systems. This translates to higher carbon footprints and operational costs. Additionally, premature component failure necessitates more frequent replacements, multiplying the environmental impacts associated with manufacturing and transportation.

The disposal of worn kiln components presents another environmental challenge. Many refractory materials contain heavy metals and other potentially hazardous substances that can leach into soil and water systems if improperly disposed of. Traditional landfill disposal methods for these materials contribute to long-term environmental degradation and represent a loss of valuable resources.

Recent lifecycle assessments indicate that extending component lifespan through improved failure analysis and preventive maintenance can reduce the environmental impact by 30-40% over the total lifecycle. Advanced materials science has enabled the development of more environmentally friendly refractory materials with reduced heavy metal content while maintaining performance characteristics.

Recycling and reuse strategies are emerging as critical approaches to mitigating environmental impacts. Approximately 60-70% of certain kiln components can be recycled, significantly reducing the demand for virgin materials and associated extraction impacts. Innovative companies are implementing closed-loop systems where worn components are returned to manufacturers for refurbishment or recycling.

The environmental regulatory landscape is increasingly focusing on industrial process efficiency and waste management. Several jurisdictions have implemented extended producer responsibility regulations that hold manufacturers accountable for the entire lifecycle of their products, including kiln components, driving innovation in sustainable design and end-of-life management strategies.

During operation, kiln components contribute to environmental impact through energy consumption and emissions. Failed components exacerbate these impacts, as cracks and wear lead to thermal inefficiency, increasing fuel consumption by up to 15-20% in severely compromised systems. This translates to higher carbon footprints and operational costs. Additionally, premature component failure necessitates more frequent replacements, multiplying the environmental impacts associated with manufacturing and transportation.

The disposal of worn kiln components presents another environmental challenge. Many refractory materials contain heavy metals and other potentially hazardous substances that can leach into soil and water systems if improperly disposed of. Traditional landfill disposal methods for these materials contribute to long-term environmental degradation and represent a loss of valuable resources.

Recent lifecycle assessments indicate that extending component lifespan through improved failure analysis and preventive maintenance can reduce the environmental impact by 30-40% over the total lifecycle. Advanced materials science has enabled the development of more environmentally friendly refractory materials with reduced heavy metal content while maintaining performance characteristics.

Recycling and reuse strategies are emerging as critical approaches to mitigating environmental impacts. Approximately 60-70% of certain kiln components can be recycled, significantly reducing the demand for virgin materials and associated extraction impacts. Innovative companies are implementing closed-loop systems where worn components are returned to manufacturers for refurbishment or recycling.

The environmental regulatory landscape is increasingly focusing on industrial process efficiency and waste management. Several jurisdictions have implemented extended producer responsibility regulations that hold manufacturers accountable for the entire lifecycle of their products, including kiln components, driving innovation in sustainable design and end-of-life management strategies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!