Rotary Kiln Operation For Calcination: Key Parameters And Controls

AUG 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Rotary Kiln Calcination Technology Background and Objectives

Rotary kiln calcination technology has evolved significantly since its inception in the late 19th century, initially developed for cement production before expanding to various industrial applications. The technology's evolution has been marked by continuous improvements in design efficiency, material handling capabilities, and process control systems. Modern rotary kilns represent a culmination of over a century of engineering refinements, addressing challenges in thermal efficiency, material throughput, and environmental impact.

The fundamental principle of rotary kiln operation involves the controlled heating of materials as they progress through a rotating cylindrical vessel. This process facilitates crucial chemical and physical transformations including dehydration, decarbonation, phase transitions, and solid-state reactions. These transformations are essential in industries ranging from cement and lime production to mineral processing, waste treatment, and specialty chemical manufacturing.

Current technological trends in rotary kiln calcination focus on enhancing energy efficiency, reducing emissions, improving process automation, and developing advanced refractory materials. The integration of digital technologies, including IoT sensors, real-time monitoring systems, and predictive maintenance algorithms, represents a significant advancement in operational control and optimization. These innovations aim to address the persistent challenges of thermal efficiency, product quality consistency, and environmental compliance.

The primary technical objectives in rotary kiln calcination research include optimizing heat transfer mechanisms, developing precise temperature profile control methodologies, and establishing robust correlations between operational parameters and product quality attributes. Additionally, there is growing emphasis on reducing the carbon footprint of calcination processes through alternative fuel utilization, heat recovery systems, and process intensification techniques.

Emerging research directions include the development of hybrid heating systems combining conventional and alternative energy sources, advanced computational fluid dynamics modeling for process optimization, and novel refractory materials with enhanced durability and thermal properties. The integration of artificial intelligence and machine learning algorithms for adaptive process control represents a promising frontier in addressing the inherent complexities of rotary kiln operations.

The technological trajectory suggests a future where rotary kiln calcination processes will become increasingly precise, energy-efficient, and environmentally sustainable. This evolution will likely be characterized by greater process integration, closed-loop control systems, and the ability to handle more diverse and challenging feed materials while maintaining strict quality standards and minimizing environmental impact.

The fundamental principle of rotary kiln operation involves the controlled heating of materials as they progress through a rotating cylindrical vessel. This process facilitates crucial chemical and physical transformations including dehydration, decarbonation, phase transitions, and solid-state reactions. These transformations are essential in industries ranging from cement and lime production to mineral processing, waste treatment, and specialty chemical manufacturing.

Current technological trends in rotary kiln calcination focus on enhancing energy efficiency, reducing emissions, improving process automation, and developing advanced refractory materials. The integration of digital technologies, including IoT sensors, real-time monitoring systems, and predictive maintenance algorithms, represents a significant advancement in operational control and optimization. These innovations aim to address the persistent challenges of thermal efficiency, product quality consistency, and environmental compliance.

The primary technical objectives in rotary kiln calcination research include optimizing heat transfer mechanisms, developing precise temperature profile control methodologies, and establishing robust correlations between operational parameters and product quality attributes. Additionally, there is growing emphasis on reducing the carbon footprint of calcination processes through alternative fuel utilization, heat recovery systems, and process intensification techniques.

Emerging research directions include the development of hybrid heating systems combining conventional and alternative energy sources, advanced computational fluid dynamics modeling for process optimization, and novel refractory materials with enhanced durability and thermal properties. The integration of artificial intelligence and machine learning algorithms for adaptive process control represents a promising frontier in addressing the inherent complexities of rotary kiln operations.

The technological trajectory suggests a future where rotary kiln calcination processes will become increasingly precise, energy-efficient, and environmentally sustainable. This evolution will likely be characterized by greater process integration, closed-loop control systems, and the ability to handle more diverse and challenging feed materials while maintaining strict quality standards and minimizing environmental impact.

Market Demand Analysis for Calcination Processes

The global calcination market has been experiencing steady growth, driven primarily by increasing demand across multiple industries including cement, mining, metallurgy, and chemical processing. The market size for industrial calcination equipment was valued at approximately 7.2 billion USD in 2022, with projections indicating a compound annual growth rate of 4.8% through 2030. Rotary kilns represent the largest segment within this market, accounting for over 60% of all calcination equipment installations worldwide.

The cement industry remains the dominant consumer of calcination technology, representing roughly 45% of the total market demand. With global construction activities expanding, particularly in developing regions across Asia-Pacific and Africa, the need for efficient calcination processes continues to rise. China, India, and Southeast Asian countries collectively account for over 50% of new rotary kiln installations, reflecting the rapid industrialization and infrastructure development in these regions.

Environmental regulations have emerged as a significant market driver, with stringent emission control requirements forcing industries to upgrade their calcination technologies. This has created a substantial retrofit market estimated at 1.3 billion USD annually, focused on improving energy efficiency and reducing carbon footprints of existing rotary kiln operations. The European Union's carbon neutrality goals have particularly accelerated demand for advanced control systems that optimize fuel consumption and minimize emissions.

The mining and metallurgical sectors represent the fastest-growing segment for calcination technologies, with a 6.2% annual growth rate. This is primarily driven by increasing mineral processing activities and the expanding need for high-purity materials in electronics and battery manufacturing. The lithium processing industry alone has increased its demand for specialized calcination equipment by over 200% in the past five years, corresponding with the electric vehicle market expansion.

Energy efficiency has become a critical factor influencing purchasing decisions, with industries prioritizing rotary kiln systems that offer at least 15-20% reduction in energy consumption compared to conventional designs. This trend is particularly pronounced in regions with high energy costs, such as Europe and Japan, where the return on investment for energy-efficient calcination systems can be realized within 3-4 years of operation.

Digital transformation is reshaping market demands, with increasing preference for rotary kilns equipped with advanced monitoring and control systems. The market for smart calcination solutions incorporating IoT sensors, real-time analytics, and automated parameter adjustment capabilities has grown by approximately 22% annually since 2020, reflecting industry's shift toward data-driven operational optimization and predictive maintenance approaches.

The cement industry remains the dominant consumer of calcination technology, representing roughly 45% of the total market demand. With global construction activities expanding, particularly in developing regions across Asia-Pacific and Africa, the need for efficient calcination processes continues to rise. China, India, and Southeast Asian countries collectively account for over 50% of new rotary kiln installations, reflecting the rapid industrialization and infrastructure development in these regions.

Environmental regulations have emerged as a significant market driver, with stringent emission control requirements forcing industries to upgrade their calcination technologies. This has created a substantial retrofit market estimated at 1.3 billion USD annually, focused on improving energy efficiency and reducing carbon footprints of existing rotary kiln operations. The European Union's carbon neutrality goals have particularly accelerated demand for advanced control systems that optimize fuel consumption and minimize emissions.

The mining and metallurgical sectors represent the fastest-growing segment for calcination technologies, with a 6.2% annual growth rate. This is primarily driven by increasing mineral processing activities and the expanding need for high-purity materials in electronics and battery manufacturing. The lithium processing industry alone has increased its demand for specialized calcination equipment by over 200% in the past five years, corresponding with the electric vehicle market expansion.

Energy efficiency has become a critical factor influencing purchasing decisions, with industries prioritizing rotary kiln systems that offer at least 15-20% reduction in energy consumption compared to conventional designs. This trend is particularly pronounced in regions with high energy costs, such as Europe and Japan, where the return on investment for energy-efficient calcination systems can be realized within 3-4 years of operation.

Digital transformation is reshaping market demands, with increasing preference for rotary kilns equipped with advanced monitoring and control systems. The market for smart calcination solutions incorporating IoT sensors, real-time analytics, and automated parameter adjustment capabilities has grown by approximately 22% annually since 2020, reflecting industry's shift toward data-driven operational optimization and predictive maintenance approaches.

Current Technical Challenges in Rotary Kiln Operations

Rotary kilns used in calcination processes face several significant technical challenges that impact operational efficiency, product quality, and environmental compliance. The complexity of thermal processes within these systems creates difficulties in maintaining optimal conditions consistently across various operational scenarios.

Temperature control remains one of the most critical challenges, as temperature gradients along the kiln length can lead to uneven calcination, affecting product quality and energy efficiency. Current monitoring systems often provide limited real-time data on internal temperature profiles, making precise control difficult, especially during process transitions or when processing materials with varying properties.

Material flow dynamics present another substantial challenge. The behavior of particulate materials within the rotating drum is influenced by numerous factors including rotation speed, kiln inclination, material properties, and feed rate. Achieving consistent residence time distribution is particularly problematic when processing materials with different physical characteristics or when production requirements change.

Heat transfer efficiency issues significantly impact energy consumption and operational costs. The thermal efficiency of many industrial kilns remains suboptimal, with considerable heat losses occurring through the kiln shell, exit gases, and clinker discharge. Modern refractory materials and insulation technologies have improved this situation, but implementation challenges persist, particularly in retrofitting existing systems.

Emissions control has become increasingly important due to stricter environmental regulations worldwide. Controlling NOx, SOx, particulate matter, and CO2 emissions requires sophisticated abatement technologies that must be integrated with kiln operations without compromising process stability or product quality. The balance between environmental compliance and operational efficiency represents a significant technical challenge.

Mechanical reliability issues continue to affect kiln operations. Thermal cycling, material buildup, and mechanical stresses lead to refractory damage, shell deformation, and drive system wear. These problems result in unplanned downtime and costly maintenance, with current predictive maintenance approaches still limited in their ability to anticipate failures accurately.

Process automation and control systems face integration challenges, particularly in older facilities. While advanced control algorithms and artificial intelligence offer potential solutions for optimizing kiln operations, implementing these technologies requires significant investment and expertise. Many existing control systems lack the necessary flexibility to incorporate these advanced approaches without major upgrades.

Material coating and buildup within the kiln represent persistent operational problems that reduce heat transfer efficiency and can lead to production bottlenecks. Current cleaning technologies often require kiln shutdown, and online cleaning methods have limited effectiveness for certain material types.

Temperature control remains one of the most critical challenges, as temperature gradients along the kiln length can lead to uneven calcination, affecting product quality and energy efficiency. Current monitoring systems often provide limited real-time data on internal temperature profiles, making precise control difficult, especially during process transitions or when processing materials with varying properties.

Material flow dynamics present another substantial challenge. The behavior of particulate materials within the rotating drum is influenced by numerous factors including rotation speed, kiln inclination, material properties, and feed rate. Achieving consistent residence time distribution is particularly problematic when processing materials with different physical characteristics or when production requirements change.

Heat transfer efficiency issues significantly impact energy consumption and operational costs. The thermal efficiency of many industrial kilns remains suboptimal, with considerable heat losses occurring through the kiln shell, exit gases, and clinker discharge. Modern refractory materials and insulation technologies have improved this situation, but implementation challenges persist, particularly in retrofitting existing systems.

Emissions control has become increasingly important due to stricter environmental regulations worldwide. Controlling NOx, SOx, particulate matter, and CO2 emissions requires sophisticated abatement technologies that must be integrated with kiln operations without compromising process stability or product quality. The balance between environmental compliance and operational efficiency represents a significant technical challenge.

Mechanical reliability issues continue to affect kiln operations. Thermal cycling, material buildup, and mechanical stresses lead to refractory damage, shell deformation, and drive system wear. These problems result in unplanned downtime and costly maintenance, with current predictive maintenance approaches still limited in their ability to anticipate failures accurately.

Process automation and control systems face integration challenges, particularly in older facilities. While advanced control algorithms and artificial intelligence offer potential solutions for optimizing kiln operations, implementing these technologies requires significant investment and expertise. Many existing control systems lack the necessary flexibility to incorporate these advanced approaches without major upgrades.

Material coating and buildup within the kiln represent persistent operational problems that reduce heat transfer efficiency and can lead to production bottlenecks. Current cleaning technologies often require kiln shutdown, and online cleaning methods have limited effectiveness for certain material types.

Current Parameter Control Solutions for Rotary Kilns

01 Temperature control and monitoring systems

Temperature control is a critical parameter in rotary kiln operations. Advanced monitoring systems are employed to maintain optimal temperature profiles throughout the kiln length. These systems include thermocouples, infrared sensors, and thermal imaging cameras that provide real-time data for process control. Maintaining precise temperature zones is essential for product quality and energy efficiency. Control algorithms adjust fuel input and airflow to ensure consistent temperature distribution and prevent thermal shock to the kiln shell.- Temperature Control Systems: Temperature control is a critical parameter in rotary kiln operations. Advanced systems monitor and regulate the temperature profile throughout the kiln to ensure optimal thermal processing. These systems typically include thermocouples, infrared sensors, and automated control algorithms that adjust fuel input and airflow to maintain desired temperature zones. Proper temperature control ensures product quality, reduces energy consumption, and extends the service life of the kiln lining.

- Rotational Speed and Material Flow Management: The rotational speed of a kiln directly affects material residence time and processing efficiency. Control systems regulate the rotation speed based on material characteristics, feed rate, and desired output quality. Material flow management includes monitoring the bed depth, material distribution, and cascading patterns within the kiln. Optimizing these parameters ensures uniform heat transfer, prevents material buildup, and maintains consistent product quality while maximizing throughput.

- Combustion and Fuel Efficiency Systems: Combustion control is essential for energy efficiency and emission management in rotary kilns. Advanced systems monitor oxygen levels, flame characteristics, and fuel-air ratios to optimize combustion. These systems may include automated burner adjustments, alternative fuel integration capabilities, and exhaust gas recirculation. Efficient combustion control reduces fuel consumption, minimizes harmful emissions, and ensures consistent heat distribution throughout the kiln.

- Kiln Shell Monitoring and Structural Integrity: Monitoring the kiln shell condition is crucial for operational safety and equipment longevity. Systems track shell temperature profiles, ovality, alignment, and mechanical stress indicators. Advanced monitoring includes thermal imaging cameras, laser-based alignment systems, and vibration sensors to detect potential issues before failure occurs. Proper shell monitoring prevents catastrophic failures, optimizes maintenance scheduling, and extends the operational life of the rotary kiln.

- Automation and Integrated Control Systems: Modern rotary kilns employ integrated automation systems that coordinate multiple control parameters simultaneously. These systems utilize predictive modeling, artificial intelligence, and real-time data analytics to optimize kiln performance. Comprehensive control platforms integrate temperature, rotation, material flow, and combustion parameters into a unified system with remote monitoring capabilities. Advanced automation improves operational efficiency, reduces human error, ensures consistent product quality, and enables adaptive control strategies based on changing process conditions.

02 Rotational speed and material flow control

The rotational speed of a kiln is a key parameter that affects material residence time and heat transfer efficiency. Control systems regulate the kiln's rotation speed based on material properties and desired processing outcomes. Material flow control mechanisms ensure proper feed rate and distribution within the kiln. These systems include variable speed drives, load sensors, and automated feed systems that optimize the material bed depth and movement pattern. Proper control of these parameters prevents material buildup and ensures uniform processing.Expand Specific Solutions03 Combustion efficiency and fuel management

Combustion control systems are essential for optimizing fuel efficiency and maintaining consistent heat generation in rotary kilns. These systems monitor oxygen levels, fuel-air ratios, and flame characteristics to ensure complete combustion. Advanced burner designs with precise control capabilities allow for adjustments based on process requirements. Fuel management systems incorporate multiple fuel options and automated switching mechanisms to optimize energy costs while maintaining process stability. Proper combustion control reduces emissions and improves the overall thermal efficiency of the kiln operation.Expand Specific Solutions04 Pressure and airflow regulation

Pressure control within a rotary kiln affects the movement of gases and particulates through the system. Negative pressure is typically maintained to prevent dust emissions and ensure proper gas flow direction. Airflow regulation systems control the volume and distribution of combustion air, cooling air, and exhaust gases. These systems include dampers, fans, and pressure sensors that work together to maintain optimal operating conditions. Proper pressure and airflow management prevents material entrainment in exhaust gases and ensures efficient heat transfer throughout the kiln.Expand Specific Solutions05 Kiln alignment and mechanical integrity monitoring

Maintaining proper kiln alignment is crucial for operational efficiency and equipment longevity. Advanced monitoring systems track shell ovality, tire and roller conditions, and axial thrust to prevent mechanical failures. These systems employ laser alignment tools, vibration sensors, and thermal expansion monitoring to detect potential issues before they cause damage. Automated adjustment mechanisms can correct minor misalignments during operation. Regular monitoring of mechanical parameters extends kiln life, reduces maintenance costs, and prevents catastrophic failures that could result in production downtime.Expand Specific Solutions

Major Industry Players in Calcination Equipment Manufacturing

The rotary kiln calcination market is currently in a growth phase, driven by increasing demand across metallurgical, cement, and chemical industries. The global market size is estimated to exceed $3.5 billion, with projected annual growth of 4-6% through 2028. Technology maturity varies across applications, with established players like Lhoist Recherche et Développement and thyssenkrupp Polysius offering advanced control systems, while newer entrants like Beijing Kehuide Automation Technology focus on innovative monitoring solutions. Leading companies including Air Products & Chemicals and Sumitomo Metal Mining are investing in process optimization technologies to improve energy efficiency and reduce emissions. Academic institutions such as South China University of Technology and Northeastern University are collaborating with industry partners to develop next-generation calcination technologies addressing sustainability challenges.

Lhoist Recherche et Développement SA

Technical Solution: Lhoist has developed a comprehensive rotary kiln control system specifically optimized for limestone calcination. Their technology features a multi-zone temperature management approach that precisely controls the preheating, calcination, and cooling phases within the kiln. The system incorporates proprietary computational fluid dynamics modeling to optimize burner positioning and flame characteristics based on specific limestone compositions and desired product properties. Lhoist's approach includes advanced material tracking algorithms that monitor the progression of limestone through the kiln using a combination of weight sensors and thermal imaging. Their technology features adaptive control algorithms that automatically adjust kiln parameters based on feed material variations, maintaining consistent product quality despite raw material heterogeneity. The system also incorporates sophisticated refractory management protocols with thermal mapping to extend kiln lining life while maintaining optimal heat transfer characteristics. Lhoist has integrated energy recovery systems that capture waste heat from the cooling zone and hot exhaust gases, significantly improving overall thermal efficiency. Their control system also includes predictive maintenance capabilities that identify potential equipment issues before they impact production, reducing unplanned downtime.

Strengths: Their specialized focus on limestone calcination has resulted in highly optimized processes specifically tailored to calcium oxide production requirements. The adaptive control algorithms effectively handle variations in limestone composition, ensuring consistent product quality. Weaknesses: The system's specialization for limestone calcination limits its applicability to other calcination processes without significant modifications. The sophisticated control systems require specialized technical expertise for maintenance and optimization.

thyssenkrupp Polysius GmbH

Technical Solution: thyssenkrupp Polysius has developed advanced rotary kiln technology for calcination processes with their POLCAL system. This technology incorporates sophisticated thermal profiling throughout the kiln length, utilizing multiple temperature measurement points to create precise temperature gradients essential for optimal calcination. Their system features a proprietary burner design that allows for precise flame shape control and fuel distribution, enabling operators to adjust the heat transfer characteristics based on material properties. The POLCAL system integrates automated feed rate controls that dynamically adjust based on real-time thermal measurements, ensuring consistent material residence time. Their digital twin modeling approach creates virtual representations of the kiln operation, allowing for predictive maintenance and process optimization without disrupting production. The system also incorporates advanced refractory management with thermal imaging to detect hotspots and potential refractory failures before they cause operational issues.

Strengths: Superior thermal profiling capabilities allow for precise temperature control throughout the calcination process, resulting in consistent product quality. Their digital twin technology enables predictive maintenance and process optimization without production disruption. Weaknesses: The sophisticated control systems require highly trained operators and maintenance personnel, potentially increasing operational costs. The initial capital investment for their advanced systems is significantly higher than conventional rotary kiln technologies.

Critical Technical Innovations in Kiln Operation Parameters

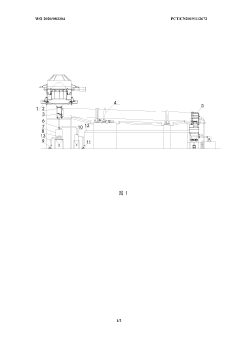

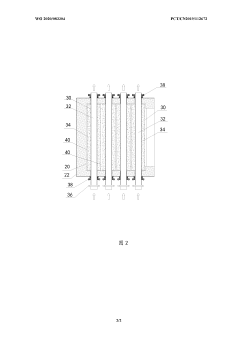

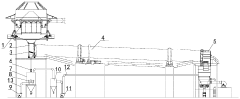

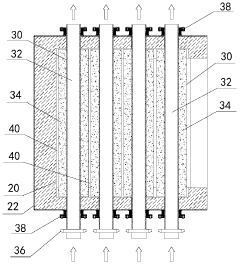

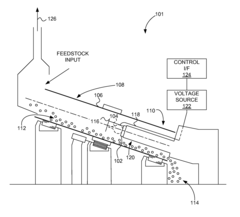

Fine material synergetic calcination type rotary kiln graded calcination system

PatentWO2020083304A1

Innovation

- Design a rotary kiln graded calcining system for coordinated calcination of fine materials, including a preheater, transfer chute, rotary kiln, kiln head vertical cooler, fly ash cooling ash silo and graded discharge device, allowing fine limestone with a particle size less than 10mm. The materials are completely decomposed in the preheater and screened by the classification discharge device before entering the fly ash cooling ash silo to prevent fine materials from entering the rotary kiln for over-burning.

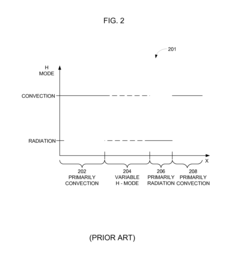

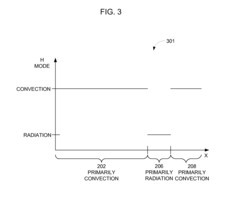

Flame enhancement for a rotary kiln

PatentInactiveUS20130333279A1

Innovation

- A rotary kiln system with a stationary burner and electrodes that apply a high voltage to the flame, controlling its characteristics to maintain a consistent temperature profile and confine the flame to minimize variable heating modes, thereby optimizing the calcination process.

Energy Efficiency and Sustainability Considerations

Energy efficiency in rotary kiln operations represents a critical factor in modern calcination processes, with significant implications for both operational costs and environmental impact. The energy consumption of rotary kilns typically accounts for 30-40% of total production costs in industries such as cement, lime, and minerals processing. Recent technological advancements have enabled efficiency improvements of up to 15-20% compared to conventional systems from the previous decade.

Heat recovery systems have emerged as a primary focus area, with waste heat recovery units capable of capturing thermal energy from kiln exhaust gases. These systems can generate up to 30% of a plant's electricity requirements when properly implemented. Advanced refractory materials with improved thermal insulation properties have demonstrated the ability to reduce heat losses through kiln shells by 8-12%, directly translating to fuel savings.

Process optimization through digital control systems represents another significant advancement in energy efficiency. Artificial intelligence and machine learning algorithms can continuously adjust firing conditions based on real-time monitoring of material properties and thermal profiles, reducing energy consumption by 5-8% while maintaining product quality standards.

Alternative fuel utilization has become increasingly prevalent, with many operations achieving 40-60% substitution rates of conventional fossil fuels with biomass, waste-derived fuels, or hydrogen blends. This transition not only reduces carbon emissions but often provides economic benefits through lower fuel costs and potential carbon credit opportunities.

Carbon capture technologies specifically designed for rotary kiln applications are advancing rapidly, with pilot projects demonstrating capture rates of 80-90% of CO2 emissions. While implementation costs remain high, regulatory pressures and carbon pricing mechanisms are accelerating adoption timelines across major industrial markets.

Water conservation measures integrated with kiln operations have shown potential for reducing freshwater consumption by 25-35% through closed-loop cooling systems and process water recycling. This aspect of sustainability is gaining importance as water scarcity concerns increase globally.

Life cycle assessment studies indicate that modernization of rotary kiln operations with state-of-the-art efficiency technologies can reduce the overall environmental footprint by 30-45% when considering combined impacts of greenhouse gas emissions, resource consumption, and waste generation across the entire production chain.

Heat recovery systems have emerged as a primary focus area, with waste heat recovery units capable of capturing thermal energy from kiln exhaust gases. These systems can generate up to 30% of a plant's electricity requirements when properly implemented. Advanced refractory materials with improved thermal insulation properties have demonstrated the ability to reduce heat losses through kiln shells by 8-12%, directly translating to fuel savings.

Process optimization through digital control systems represents another significant advancement in energy efficiency. Artificial intelligence and machine learning algorithms can continuously adjust firing conditions based on real-time monitoring of material properties and thermal profiles, reducing energy consumption by 5-8% while maintaining product quality standards.

Alternative fuel utilization has become increasingly prevalent, with many operations achieving 40-60% substitution rates of conventional fossil fuels with biomass, waste-derived fuels, or hydrogen blends. This transition not only reduces carbon emissions but often provides economic benefits through lower fuel costs and potential carbon credit opportunities.

Carbon capture technologies specifically designed for rotary kiln applications are advancing rapidly, with pilot projects demonstrating capture rates of 80-90% of CO2 emissions. While implementation costs remain high, regulatory pressures and carbon pricing mechanisms are accelerating adoption timelines across major industrial markets.

Water conservation measures integrated with kiln operations have shown potential for reducing freshwater consumption by 25-35% through closed-loop cooling systems and process water recycling. This aspect of sustainability is gaining importance as water scarcity concerns increase globally.

Life cycle assessment studies indicate that modernization of rotary kiln operations with state-of-the-art efficiency technologies can reduce the overall environmental footprint by 30-45% when considering combined impacts of greenhouse gas emissions, resource consumption, and waste generation across the entire production chain.

Material Quality Control and Product Consistency

Material quality control in rotary kiln calcination processes represents a critical operational dimension that directly impacts product consistency and overall process efficiency. The inherent variability in raw material characteristics—including chemical composition, particle size distribution, and moisture content—necessitates robust monitoring and control systems to ensure final product specifications are consistently met. Advanced online analyzers utilizing X-ray fluorescence (XRF) and near-infrared (NIR) spectroscopy technologies enable real-time assessment of material composition throughout the calcination process, allowing for immediate corrective actions when deviations occur.

Feed rate consistency emerges as a fundamental parameter affecting product quality, with automated weighing systems and computerized feed controllers maintaining precise material flow into the kiln. These systems typically achieve accuracy within ±1% of target values, significantly reducing quality variations compared to manual control methods. Equally important is the homogenization of raw materials prior to kiln entry, with blending systems and pre-processing techniques ensuring uniform composition and reducing thermal shock during calcination.

Temperature profile management across different kiln zones directly correlates with product consistency, particularly in applications such as limestone calcination where CaCO₃ to CaO conversion requires precise thermal conditions. Modern kilns incorporate multiple temperature measurement points with automated control systems maintaining zone temperatures within ±5°C of setpoints, dramatically improving consistency compared to earlier systems with ±20°C variations.

Residence time control, achieved through kiln rotation speed adjustments and material flow management, ensures consistent exposure to thermal treatment. Statistical process control (SPC) methodologies applied to calcination operations have demonstrated up to 40% reduction in product quality variations by systematically analyzing process data and implementing corrective measures before significant deviations occur.

Quality assurance protocols typically include regular sampling regimes with laboratory analysis of physical properties (bulk density, porosity) and chemical composition. Advanced operations implement closed-loop quality control systems where analytical results automatically trigger process adjustments. Industry benchmarks indicate that effective material quality control systems can reduce product rejections by 60-80% while simultaneously decreasing energy consumption by 5-15% through optimized operation parameters.

The economic impact of improved material quality control extends beyond direct production costs, with downstream benefits including enhanced customer satisfaction, reduced warranty claims, and strengthened market position. Recent technological innovations in artificial intelligence and machine learning algorithms are enabling predictive quality control systems that anticipate potential quality issues before they manifest, representing the next frontier in rotary kiln calcination process optimization.

Feed rate consistency emerges as a fundamental parameter affecting product quality, with automated weighing systems and computerized feed controllers maintaining precise material flow into the kiln. These systems typically achieve accuracy within ±1% of target values, significantly reducing quality variations compared to manual control methods. Equally important is the homogenization of raw materials prior to kiln entry, with blending systems and pre-processing techniques ensuring uniform composition and reducing thermal shock during calcination.

Temperature profile management across different kiln zones directly correlates with product consistency, particularly in applications such as limestone calcination where CaCO₃ to CaO conversion requires precise thermal conditions. Modern kilns incorporate multiple temperature measurement points with automated control systems maintaining zone temperatures within ±5°C of setpoints, dramatically improving consistency compared to earlier systems with ±20°C variations.

Residence time control, achieved through kiln rotation speed adjustments and material flow management, ensures consistent exposure to thermal treatment. Statistical process control (SPC) methodologies applied to calcination operations have demonstrated up to 40% reduction in product quality variations by systematically analyzing process data and implementing corrective measures before significant deviations occur.

Quality assurance protocols typically include regular sampling regimes with laboratory analysis of physical properties (bulk density, porosity) and chemical composition. Advanced operations implement closed-loop quality control systems where analytical results automatically trigger process adjustments. Industry benchmarks indicate that effective material quality control systems can reduce product rejections by 60-80% while simultaneously decreasing energy consumption by 5-15% through optimized operation parameters.

The economic impact of improved material quality control extends beyond direct production costs, with downstream benefits including enhanced customer satisfaction, reduced warranty claims, and strengthened market position. Recent technological innovations in artificial intelligence and machine learning algorithms are enabling predictive quality control systems that anticipate potential quality issues before they manifest, representing the next frontier in rotary kiln calcination process optimization.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!