Borosilicate Glass Contribution to Oceanographic Instruments

JUL 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Borosilicate Glass in Oceanography: Background and Objectives

Borosilicate glass has played a pivotal role in the development and advancement of oceanographic instruments since the early 20th century. This specialized glass, known for its exceptional thermal and chemical resistance, has become an indispensable material in the fabrication of various oceanographic tools and equipment. The evolution of borosilicate glass applications in oceanography closely mirrors the progress of marine science itself, reflecting the growing need for more precise and durable instruments capable of withstanding the harsh conditions of the marine environment.

The primary objective of utilizing borosilicate glass in oceanographic instruments is to enhance the reliability, accuracy, and longevity of measurements in marine research. As oceanographers delve deeper into understanding complex oceanic processes, the demand for instruments that can operate effectively under extreme pressure, temperature variations, and corrosive conditions has intensified. Borosilicate glass, with its unique properties, addresses these challenges by providing a robust and transparent medium for various sensing and sampling devices.

The historical trajectory of borosilicate glass in oceanography began with its use in simple thermometers and water sampling bottles. Over time, its application expanded to more sophisticated instruments such as CTD (Conductivity, Temperature, Depth) sensors, optical sensors for measuring water clarity and chlorophyll concentrations, and specialized housings for underwater cameras and lighting systems. This progression highlights the adaptability of borosilicate glass to meet the evolving needs of oceanographic research.

As we look towards the future, the role of borosilicate glass in oceanographic instruments is expected to grow further. Emerging trends in marine science, such as the increased focus on long-term ocean observatories and autonomous underwater vehicles, present new opportunities and challenges for material science. The ongoing development of borosilicate glass compositions and manufacturing techniques aims to push the boundaries of what is possible in terms of depth ratings, optical clarity, and resistance to biofouling.

Understanding the background and objectives of borosilicate glass use in oceanography is crucial for identifying areas of potential innovation and improvement. By examining the historical context and current applications, researchers and engineers can better anticipate future needs and develop next-generation oceanographic instruments that leverage the unique properties of this versatile material. This forward-looking approach is essential for advancing our understanding of the world's oceans and addressing critical environmental challenges in the coming decades.

The primary objective of utilizing borosilicate glass in oceanographic instruments is to enhance the reliability, accuracy, and longevity of measurements in marine research. As oceanographers delve deeper into understanding complex oceanic processes, the demand for instruments that can operate effectively under extreme pressure, temperature variations, and corrosive conditions has intensified. Borosilicate glass, with its unique properties, addresses these challenges by providing a robust and transparent medium for various sensing and sampling devices.

The historical trajectory of borosilicate glass in oceanography began with its use in simple thermometers and water sampling bottles. Over time, its application expanded to more sophisticated instruments such as CTD (Conductivity, Temperature, Depth) sensors, optical sensors for measuring water clarity and chlorophyll concentrations, and specialized housings for underwater cameras and lighting systems. This progression highlights the adaptability of borosilicate glass to meet the evolving needs of oceanographic research.

As we look towards the future, the role of borosilicate glass in oceanographic instruments is expected to grow further. Emerging trends in marine science, such as the increased focus on long-term ocean observatories and autonomous underwater vehicles, present new opportunities and challenges for material science. The ongoing development of borosilicate glass compositions and manufacturing techniques aims to push the boundaries of what is possible in terms of depth ratings, optical clarity, and resistance to biofouling.

Understanding the background and objectives of borosilicate glass use in oceanography is crucial for identifying areas of potential innovation and improvement. By examining the historical context and current applications, researchers and engineers can better anticipate future needs and develop next-generation oceanographic instruments that leverage the unique properties of this versatile material. This forward-looking approach is essential for advancing our understanding of the world's oceans and addressing critical environmental challenges in the coming decades.

Market Analysis for Oceanographic Instruments

The oceanographic instruments market has been experiencing steady growth, driven by increasing demand for accurate and reliable data collection in marine environments. This market encompasses a wide range of devices, including sensors, probes, buoys, and underwater vehicles, all of which rely on advanced materials such as borosilicate glass for their construction and functionality.

The global oceanographic instruments market was valued at approximately $2.5 billion in 2020 and is projected to reach $3.8 billion by 2026, growing at a CAGR of around 7% during the forecast period. This growth is primarily attributed to the rising need for ocean observation systems, climate change monitoring, and marine resource exploration.

Borosilicate glass plays a crucial role in the development and performance of oceanographic instruments due to its unique properties. Its high chemical resistance, low thermal expansion, and excellent optical clarity make it an ideal material for various applications in marine research and monitoring equipment.

The demand for borosilicate glass in oceanographic instruments is driven by several factors. Firstly, the increasing focus on ocean conservation and environmental monitoring has led to a surge in the deployment of underwater sensors and observation systems. Secondly, the growing interest in deep-sea exploration and offshore energy production has created a need for robust and reliable instruments capable of withstanding extreme pressures and corrosive environments.

Key market segments for borosilicate glass in oceanographic instruments include water quality sensors, pressure housings for underwater cameras and lights, optical windows for submersibles, and protective casings for various marine research equipment. The market is also seeing increased demand for customized borosilicate glass components tailored to specific oceanographic applications.

Geographically, North America and Europe dominate the oceanographic instruments market, accounting for over 60% of the global market share. This is due to the presence of major research institutions, government funding for marine studies, and advanced technological capabilities in these regions. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, driven by increasing investments in marine research and the rapid expansion of offshore industries in countries like China, Japan, and South Korea.

The competitive landscape of the oceanographic instruments market is characterized by a mix of large multinational corporations and specialized niche players. Major companies in this space include Teledyne Technologies, Xylem, and Sea-Bird Scientific, all of which incorporate borosilicate glass components in their product offerings. Additionally, there are numerous smaller firms specializing in the design and manufacture of custom borosilicate glass solutions for specific oceanographic applications.

The global oceanographic instruments market was valued at approximately $2.5 billion in 2020 and is projected to reach $3.8 billion by 2026, growing at a CAGR of around 7% during the forecast period. This growth is primarily attributed to the rising need for ocean observation systems, climate change monitoring, and marine resource exploration.

Borosilicate glass plays a crucial role in the development and performance of oceanographic instruments due to its unique properties. Its high chemical resistance, low thermal expansion, and excellent optical clarity make it an ideal material for various applications in marine research and monitoring equipment.

The demand for borosilicate glass in oceanographic instruments is driven by several factors. Firstly, the increasing focus on ocean conservation and environmental monitoring has led to a surge in the deployment of underwater sensors and observation systems. Secondly, the growing interest in deep-sea exploration and offshore energy production has created a need for robust and reliable instruments capable of withstanding extreme pressures and corrosive environments.

Key market segments for borosilicate glass in oceanographic instruments include water quality sensors, pressure housings for underwater cameras and lights, optical windows for submersibles, and protective casings for various marine research equipment. The market is also seeing increased demand for customized borosilicate glass components tailored to specific oceanographic applications.

Geographically, North America and Europe dominate the oceanographic instruments market, accounting for over 60% of the global market share. This is due to the presence of major research institutions, government funding for marine studies, and advanced technological capabilities in these regions. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, driven by increasing investments in marine research and the rapid expansion of offshore industries in countries like China, Japan, and South Korea.

The competitive landscape of the oceanographic instruments market is characterized by a mix of large multinational corporations and specialized niche players. Major companies in this space include Teledyne Technologies, Xylem, and Sea-Bird Scientific, all of which incorporate borosilicate glass components in their product offerings. Additionally, there are numerous smaller firms specializing in the design and manufacture of custom borosilicate glass solutions for specific oceanographic applications.

Current Challenges in Underwater Instrument Materials

The development of oceanographic instruments faces significant challenges due to the harsh underwater environment. One of the primary concerns is the selection of materials that can withstand high pressure, corrosive saltwater, and extreme temperatures while maintaining their structural integrity and functionality. Traditional materials like metals and plastics often fall short in meeting these demanding requirements.

Borosilicate glass has emerged as a promising material for underwater instruments, offering unique properties that address many of the challenges faced by conventional materials. However, its implementation is not without difficulties. The brittleness of glass poses a risk of fracture under sudden impacts or extreme pressure changes, which could lead to catastrophic failure of the instrument. This vulnerability necessitates careful design considerations and protective measures to ensure the longevity of glass-based components.

Another challenge lies in the integration of borosilicate glass with other materials used in oceanographic instruments. Creating reliable seals between glass and metal or polymer components is crucial to prevent water ingress and maintain instrument integrity. The differences in thermal expansion coefficients between these materials can lead to stress buildup and potential failure points, especially when subjected to temperature fluctuations in deep-sea environments.

The manufacturing process of borosilicate glass components for oceanographic instruments also presents challenges. Achieving the required precision and uniformity in glass fabrication, particularly for complex shapes or large-scale components, can be technically demanding and costly. This can limit the widespread adoption of borosilicate glass in certain applications where cost-effectiveness is a primary concern.

Furthermore, the optical properties of borosilicate glass, while generally advantageous for many applications, can be affected by prolonged exposure to high-pressure environments. Subtle changes in refractive index or transparency over time may impact the accuracy of optical sensors or imaging systems, necessitating regular calibration or replacement of glass components.

The long-term effects of biofouling on borosilicate glass surfaces in marine environments are also a concern. While glass is generally resistant to biological growth, the accumulation of microorganisms and mineral deposits can affect instrument performance over time. Developing effective and environmentally friendly anti-fouling coatings that are compatible with borosilicate glass remains an ongoing challenge for researchers and manufacturers.

Borosilicate glass has emerged as a promising material for underwater instruments, offering unique properties that address many of the challenges faced by conventional materials. However, its implementation is not without difficulties. The brittleness of glass poses a risk of fracture under sudden impacts or extreme pressure changes, which could lead to catastrophic failure of the instrument. This vulnerability necessitates careful design considerations and protective measures to ensure the longevity of glass-based components.

Another challenge lies in the integration of borosilicate glass with other materials used in oceanographic instruments. Creating reliable seals between glass and metal or polymer components is crucial to prevent water ingress and maintain instrument integrity. The differences in thermal expansion coefficients between these materials can lead to stress buildup and potential failure points, especially when subjected to temperature fluctuations in deep-sea environments.

The manufacturing process of borosilicate glass components for oceanographic instruments also presents challenges. Achieving the required precision and uniformity in glass fabrication, particularly for complex shapes or large-scale components, can be technically demanding and costly. This can limit the widespread adoption of borosilicate glass in certain applications where cost-effectiveness is a primary concern.

Furthermore, the optical properties of borosilicate glass, while generally advantageous for many applications, can be affected by prolonged exposure to high-pressure environments. Subtle changes in refractive index or transparency over time may impact the accuracy of optical sensors or imaging systems, necessitating regular calibration or replacement of glass components.

The long-term effects of biofouling on borosilicate glass surfaces in marine environments are also a concern. While glass is generally resistant to biological growth, the accumulation of microorganisms and mineral deposits can affect instrument performance over time. Developing effective and environmentally friendly anti-fouling coatings that are compatible with borosilicate glass remains an ongoing challenge for researchers and manufacturers.

Borosilicate Glass Applications in Underwater Devices

01 Composition and properties of borosilicate glass

Borosilicate glass is a type of glass with silica and boron trioxide as the main glass-forming constituents. It is known for its low thermal expansion coefficient, high chemical resistance, and excellent thermal shock resistance. These properties make it suitable for various applications in laboratory equipment, cookware, and industrial uses.- Composition and properties of borosilicate glass: Borosilicate glass is a type of glass with silica and boron trioxide as the main glass-forming constituents. It is known for its low thermal expansion coefficient, high chemical resistance, and excellent thermal shock resistance. These properties make it suitable for various applications in laboratory equipment, cookware, and industrial uses.

- Manufacturing processes for borosilicate glass: Various manufacturing processes are employed to produce borosilicate glass, including melting, forming, and annealing. Advanced techniques such as float glass production and precision molding are used to create different forms of borosilicate glass products. The manufacturing process often involves careful control of temperature and composition to achieve desired properties.

- Applications of borosilicate glass in laboratory and scientific equipment: Borosilicate glass is widely used in laboratory and scientific equipment due to its chemical inertness and thermal stability. It is commonly used in beakers, test tubes, pipettes, and other laboratory glassware. Its resistance to thermal shock makes it ideal for use in high-temperature applications and in equipment that undergoes rapid temperature changes.

- Use of borosilicate glass in optical and lighting applications: Borosilicate glass finds applications in optical and lighting industries due to its excellent light transmission properties and durability. It is used in the manufacture of lenses, optical fibers, and specialized lighting products. The glass's low expansion coefficient makes it suitable for precision optical components that require dimensional stability under varying temperatures.

- Innovations in borosilicate glass for specialized applications: Ongoing research and development in borosilicate glass technology have led to innovations for specialized applications. These include the development of borosilicate glass with enhanced properties for use in solar panels, high-performance windows, and advanced electronic displays. New formulations and processing techniques are being explored to expand the range of applications for this versatile material.

02 Manufacturing processes for borosilicate glass

Various manufacturing processes are employed to produce borosilicate glass, including melting, forming, and annealing. Advanced techniques such as float glass production and precision molding are used to create high-quality borosilicate glass products with specific shapes and properties. The manufacturing process often involves careful control of temperature and composition to achieve desired characteristics.Expand Specific Solutions03 Applications of borosilicate glass in laboratory and industrial settings

Borosilicate glass is widely used in laboratory glassware, such as beakers, test tubes, and pipettes, due to its chemical resistance and thermal stability. In industrial applications, it is used for sight glasses, process vessels, and piping systems in chemical and pharmaceutical industries. Its durability and transparency make it ideal for these demanding environments.Expand Specific Solutions04 Borosilicate glass in consumer products

Borosilicate glass is increasingly used in consumer products, particularly in kitchenware and home appliances. It is popular for bakeware, storage containers, and coffee makers due to its heat resistance and durability. The glass is also used in lighting fixtures and solar energy applications, taking advantage of its thermal and optical properties.Expand Specific Solutions05 Innovations and modifications in borosilicate glass

Ongoing research focuses on improving the properties of borosilicate glass through composition modifications and novel processing techniques. This includes developing specialized coatings, enhancing strength and impact resistance, and creating composite materials. Recent innovations aim to expand the application range of borosilicate glass in areas such as electronics, aerospace, and medical devices.Expand Specific Solutions

Key Players in Oceanographic Instrument Manufacturing

The borosilicate glass market for oceanographic instruments is in a growth phase, driven by increasing demand for advanced marine research equipment. The global market size is expanding, with key players like SCHOTT AG, Corning, Inc., and AGC, Inc. leading technological advancements. These companies are investing heavily in R&D to improve glass properties for underwater applications. The technology is relatively mature but continues to evolve, with innovations focusing on enhancing durability, optical clarity, and resistance to extreme pressures. Emerging players like Hunan Kibing and Sunshine Lake Pharma are also contributing to market competitiveness, particularly in Asia. Overall, the industry is characterized by ongoing innovation and a focus on high-performance materials for specialized oceanographic applications.

SCHOTT AG

Technical Solution: SCHOTT AG has developed specialized borosilicate glass solutions for oceanographic instruments, leveraging their DURAN® borosilicate glass technology. Their glass components are designed to withstand high pressures and corrosive environments found in deep-sea applications. SCHOTT's borosilicate glass offers excellent thermal shock resistance and chemical durability, making it ideal for use in underwater sensors, pressure housings, and optical windows for oceanographic equipment[1][3]. The company has also developed specialized coating techniques to enhance the glass's performance in marine environments, improving its resistance to biofouling and mineral deposition[2].

Strengths: High pressure resistance, excellent chemical durability, and thermal shock resistance. Weaknesses: Higher cost compared to standard glass, limited flexibility in complex shapes.

Corning, Inc.

Technical Solution: Corning has contributed significantly to oceanographic instruments through its advanced borosilicate glass technologies. Their Pyrex® borosilicate glass, known for its low coefficient of thermal expansion and high chemical resistance, is widely used in underwater research equipment. Corning has developed specialized formulations that enhance the glass's ability to withstand extreme pressures and temperatures encountered in deep-sea environments[4]. The company has also introduced innovative manufacturing processes to create complex shapes and seamless integration with other materials, crucial for designing compact and efficient oceanographic sensors[5]. Corning's borosilicate glass components are utilized in various applications, including water sampling bottles, flow-through systems, and optical sensors for marine research[6].

Strengths: Excellent thermal and chemical properties, versatility in manufacturing complex shapes. Weaknesses: Higher production costs, potential for brittleness in certain applications.

Innovations in Borosilicate Glass for Marine Environments

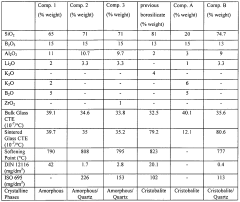

Borosilicate glass compositions and uses thereof

PatentWO2004050575A1

Innovation

- A borosilicate glass composition with silicon dioxide, boric oxide, aluminum oxide, and at least one alkali oxide, which resists devitrification without the addition of inhibitor oxides, maintaining a suitable coefficient of thermal expansion and mechanical strength.

Substrate provided with a coating based on a glass flux, glass flux material, and method for coating a glass or glass ceramic substrate

PatentActiveUS12103890B2

Innovation

- A lead-free glass flux material with a specific composition, including silicon oxide, aluminum oxide, bismuth oxide, and alkali oxides, is developed to create a printable paste that can be fired at temperatures below 750°C, achieving opaque, scratch-resistant, and chemically resistant coatings with a coefficient of linear thermal expansion suitable for low-expansion glass and glass ceramic substrates.

Environmental Impact of Borosilicate Glass in Oceans

The environmental impact of borosilicate glass in oceans is a complex issue that requires careful consideration. Borosilicate glass, widely used in oceanographic instruments due to its durability and chemical resistance, has both positive and negative effects on marine ecosystems.

One of the primary concerns is the potential for glass breakage and subsequent debris in ocean environments. While borosilicate glass is more resistant to thermal shock and chemical corrosion than standard glass, it can still fracture under extreme conditions or due to accidental impacts. When this occurs, the resulting glass fragments can pose risks to marine life through ingestion or physical injury.

However, the chemical composition of borosilicate glass offers some mitigating factors. Unlike many plastics, borosilicate glass does not leach harmful chemicals into the water. Its primary components - silica, boron oxide, and small amounts of alkali and aluminium oxides - are generally inert in marine environments. This reduces the risk of chemical pollution associated with broken instruments.

The long-term persistence of glass in marine environments is another consideration. While this can be viewed negatively in terms of pollution, it also means that borosilicate glass does not break down into microparticles as readily as some other materials. This reduces the risk of microplastic-like pollution, which is a growing concern in ocean ecosystems.

From a lifecycle perspective, the production of borosilicate glass has its own environmental footprint. The manufacturing process requires high temperatures, contributing to energy consumption and associated carbon emissions. However, the durability and reusability of borosilicate glass instruments may offset some of these impacts over time, especially when compared to less durable alternatives that require frequent replacement.

In terms of end-of-life management, borosilicate glass is fully recyclable, which can help mitigate its environmental impact. Proper collection and recycling of decommissioned oceanographic instruments can prevent unnecessary waste and reduce the demand for new raw materials.

The use of borosilicate glass in oceanographic instruments also indirectly contributes to environmental protection. These instruments play a crucial role in monitoring and understanding ocean health, climate change, and marine ecosystems. The data collected using these tools is essential for informing conservation efforts and environmental policies.

In conclusion, while the presence of borosilicate glass in oceans does present some environmental challenges, its overall impact must be weighed against its benefits in oceanographic research and its relatively inert nature compared to other materials. Ongoing research into more environmentally friendly alternatives and improved recycling processes will be crucial in further minimizing the ecological footprint of oceanographic instrumentation.

One of the primary concerns is the potential for glass breakage and subsequent debris in ocean environments. While borosilicate glass is more resistant to thermal shock and chemical corrosion than standard glass, it can still fracture under extreme conditions or due to accidental impacts. When this occurs, the resulting glass fragments can pose risks to marine life through ingestion or physical injury.

However, the chemical composition of borosilicate glass offers some mitigating factors. Unlike many plastics, borosilicate glass does not leach harmful chemicals into the water. Its primary components - silica, boron oxide, and small amounts of alkali and aluminium oxides - are generally inert in marine environments. This reduces the risk of chemical pollution associated with broken instruments.

The long-term persistence of glass in marine environments is another consideration. While this can be viewed negatively in terms of pollution, it also means that borosilicate glass does not break down into microparticles as readily as some other materials. This reduces the risk of microplastic-like pollution, which is a growing concern in ocean ecosystems.

From a lifecycle perspective, the production of borosilicate glass has its own environmental footprint. The manufacturing process requires high temperatures, contributing to energy consumption and associated carbon emissions. However, the durability and reusability of borosilicate glass instruments may offset some of these impacts over time, especially when compared to less durable alternatives that require frequent replacement.

In terms of end-of-life management, borosilicate glass is fully recyclable, which can help mitigate its environmental impact. Proper collection and recycling of decommissioned oceanographic instruments can prevent unnecessary waste and reduce the demand for new raw materials.

The use of borosilicate glass in oceanographic instruments also indirectly contributes to environmental protection. These instruments play a crucial role in monitoring and understanding ocean health, climate change, and marine ecosystems. The data collected using these tools is essential for informing conservation efforts and environmental policies.

In conclusion, while the presence of borosilicate glass in oceans does present some environmental challenges, its overall impact must be weighed against its benefits in oceanographic research and its relatively inert nature compared to other materials. Ongoing research into more environmentally friendly alternatives and improved recycling processes will be crucial in further minimizing the ecological footprint of oceanographic instrumentation.

Standardization and Quality Control in Marine Glassware

Standardization and quality control in marine glassware play a crucial role in ensuring the reliability and accuracy of oceanographic instruments. The use of borosilicate glass in these instruments necessitates stringent measures to maintain consistency and precision across various applications.

One of the primary aspects of standardization in marine glassware is the establishment of uniform specifications for borosilicate glass composition. This includes defining the acceptable ranges for key components such as silica, boron oxide, and alkali oxides. By adhering to these standards, manufacturers can produce glassware with consistent thermal and chemical properties, essential for oceanographic research.

Quality control processes for marine glassware involve rigorous testing protocols. These typically include stress tests to evaluate the glass's resistance to thermal shock and mechanical stress, as well as chemical resistance tests to ensure durability in various marine environments. Optical clarity tests are also conducted to guarantee the glass's suitability for instruments requiring high transparency, such as underwater cameras and sensors.

The implementation of standardized manufacturing processes is another critical aspect of quality control. This involves the use of calibrated equipment, controlled environmental conditions during production, and precise annealing procedures to minimize internal stresses in the glass. Regular audits and inspections of manufacturing facilities help maintain adherence to these standards.

Traceability is a key component of quality control in marine glassware. Each batch of borosilicate glass used in oceanographic instruments should be traceable to its raw materials and manufacturing process. This allows for the identification and resolution of any quality issues that may arise during field use.

Certification programs have been developed to ensure compliance with industry standards. These programs often involve third-party testing and verification, providing users with confidence in the quality and performance of the glassware. Many oceanographic institutions and research vessels require certified glassware to maintain the integrity of their data collection processes.

Continuous improvement in standardization and quality control is driven by ongoing research and collaboration between glassware manufacturers, oceanographers, and regulatory bodies. This collaborative approach leads to the development of new testing methods, updated standards, and innovative quality control techniques that address the evolving needs of oceanographic research.

One of the primary aspects of standardization in marine glassware is the establishment of uniform specifications for borosilicate glass composition. This includes defining the acceptable ranges for key components such as silica, boron oxide, and alkali oxides. By adhering to these standards, manufacturers can produce glassware with consistent thermal and chemical properties, essential for oceanographic research.

Quality control processes for marine glassware involve rigorous testing protocols. These typically include stress tests to evaluate the glass's resistance to thermal shock and mechanical stress, as well as chemical resistance tests to ensure durability in various marine environments. Optical clarity tests are also conducted to guarantee the glass's suitability for instruments requiring high transparency, such as underwater cameras and sensors.

The implementation of standardized manufacturing processes is another critical aspect of quality control. This involves the use of calibrated equipment, controlled environmental conditions during production, and precise annealing procedures to minimize internal stresses in the glass. Regular audits and inspections of manufacturing facilities help maintain adherence to these standards.

Traceability is a key component of quality control in marine glassware. Each batch of borosilicate glass used in oceanographic instruments should be traceable to its raw materials and manufacturing process. This allows for the identification and resolution of any quality issues that may arise during field use.

Certification programs have been developed to ensure compliance with industry standards. These programs often involve third-party testing and verification, providing users with confidence in the quality and performance of the glassware. Many oceanographic institutions and research vessels require certified glassware to maintain the integrity of their data collection processes.

Continuous improvement in standardization and quality control is driven by ongoing research and collaboration between glassware manufacturers, oceanographers, and regulatory bodies. This collaborative approach leads to the development of new testing methods, updated standards, and innovative quality control techniques that address the evolving needs of oceanographic research.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!