Borosilicate Glass-Rubber Composite Impact Studies

JUL 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Background and Objectives

Borosilicate glass-rubber composites have emerged as a promising material for impact-resistant applications, combining the strength and transparency of glass with the flexibility and shock-absorbing properties of rubber. The development of these composites stems from the need for materials that can withstand high-impact forces while maintaining optical clarity and structural integrity. This technology has its roots in the early 20th century with the invention of borosilicate glass, known for its low thermal expansion coefficient and high resistance to thermal shock.

The evolution of glass-rubber composites has been driven by increasing demands in various industries, including automotive, aerospace, and construction. The primary objective of impact studies on these composites is to understand and enhance their performance under dynamic loading conditions. Researchers aim to optimize the composition, structure, and manufacturing processes to achieve superior impact resistance without compromising other desirable properties such as transparency and weight.

Recent advancements in materials science and engineering have led to significant improvements in the design and fabrication of borosilicate glass-rubber composites. The integration of nanotechnology and advanced polymer science has opened new avenues for enhancing the interfacial bonding between glass and rubber components, a critical factor in determining the overall impact resistance of the composite.

The global trend towards sustainable and energy-efficient materials has also influenced the development of these composites. Researchers are exploring bio-based rubbers and environmentally friendly manufacturing processes to reduce the carbon footprint of these materials while maintaining their high-performance characteristics.

One of the key technical goals in this field is to develop predictive models that can accurately simulate the behavior of glass-rubber composites under various impact scenarios. This involves complex multi-physics simulations that account for the non-linear behavior of rubber, the brittle nature of glass, and the intricate interactions at the interface between these materials.

Another important objective is to expand the application range of these composites by tailoring their properties for specific use cases. This includes developing composites that can withstand extreme temperatures, resist chemical degradation, or provide additional functionalities such as self-healing or energy absorption.

As the technology continues to evolve, researchers are also focusing on scaling up production processes to enable cost-effective manufacturing of large-scale glass-rubber composite structures. This is crucial for widespread adoption in industries such as construction and transportation, where size and cost are significant factors.

The evolution of glass-rubber composites has been driven by increasing demands in various industries, including automotive, aerospace, and construction. The primary objective of impact studies on these composites is to understand and enhance their performance under dynamic loading conditions. Researchers aim to optimize the composition, structure, and manufacturing processes to achieve superior impact resistance without compromising other desirable properties such as transparency and weight.

Recent advancements in materials science and engineering have led to significant improvements in the design and fabrication of borosilicate glass-rubber composites. The integration of nanotechnology and advanced polymer science has opened new avenues for enhancing the interfacial bonding between glass and rubber components, a critical factor in determining the overall impact resistance of the composite.

The global trend towards sustainable and energy-efficient materials has also influenced the development of these composites. Researchers are exploring bio-based rubbers and environmentally friendly manufacturing processes to reduce the carbon footprint of these materials while maintaining their high-performance characteristics.

One of the key technical goals in this field is to develop predictive models that can accurately simulate the behavior of glass-rubber composites under various impact scenarios. This involves complex multi-physics simulations that account for the non-linear behavior of rubber, the brittle nature of glass, and the intricate interactions at the interface between these materials.

Another important objective is to expand the application range of these composites by tailoring their properties for specific use cases. This includes developing composites that can withstand extreme temperatures, resist chemical degradation, or provide additional functionalities such as self-healing or energy absorption.

As the technology continues to evolve, researchers are also focusing on scaling up production processes to enable cost-effective manufacturing of large-scale glass-rubber composite structures. This is crucial for widespread adoption in industries such as construction and transportation, where size and cost are significant factors.

Market Analysis

The market for borosilicate glass-rubber composites is experiencing significant growth, driven by the increasing demand for impact-resistant materials in various industries. These composites offer a unique combination of properties, including high thermal resistance, chemical stability, and enhanced impact resistance, making them attractive for applications in automotive, aerospace, construction, and consumer electronics sectors.

In the automotive industry, there is a growing need for lightweight yet durable materials to improve fuel efficiency and safety. Borosilicate glass-rubber composites are being explored for use in windshields, side windows, and other automotive components that require high impact resistance. The global automotive glass market is expected to grow steadily, with a particular focus on advanced materials that can enhance vehicle safety and performance.

The aerospace sector is another key market for these composites, as they offer potential weight savings and improved durability for aircraft windows and other structural components. With the increasing emphasis on fuel efficiency and passenger safety in the aviation industry, the demand for advanced materials like borosilicate glass-rubber composites is likely to rise.

In the construction industry, there is a growing interest in impact-resistant glazing solutions for buildings in areas prone to extreme weather conditions or security threats. Borosilicate glass-rubber composites could provide an effective solution for hurricane-resistant windows, blast-resistant facades, and other high-performance building materials.

The consumer electronics market is also showing potential for these composites, particularly in the development of more durable smartphone screens and tablet displays. As consumers demand more robust and scratch-resistant devices, manufacturers are exploring new materials that can withstand daily wear and tear while maintaining optical clarity.

Market trends indicate a shift towards sustainable and eco-friendly materials, which could present both opportunities and challenges for borosilicate glass-rubber composites. While these materials offer durability and potential for extended product lifecycles, their recyclability and end-of-life disposal may need to be addressed to align with growing environmental concerns.

The global market for advanced glass materials, including composites, is projected to grow steadily in the coming years. Factors such as urbanization, infrastructure development, and technological advancements in manufacturing processes are expected to drive this growth. However, the market penetration of borosilicate glass-rubber composites will depend on their cost-effectiveness compared to traditional materials and their ability to meet increasingly stringent performance standards across different industries.

In the automotive industry, there is a growing need for lightweight yet durable materials to improve fuel efficiency and safety. Borosilicate glass-rubber composites are being explored for use in windshields, side windows, and other automotive components that require high impact resistance. The global automotive glass market is expected to grow steadily, with a particular focus on advanced materials that can enhance vehicle safety and performance.

The aerospace sector is another key market for these composites, as they offer potential weight savings and improved durability for aircraft windows and other structural components. With the increasing emphasis on fuel efficiency and passenger safety in the aviation industry, the demand for advanced materials like borosilicate glass-rubber composites is likely to rise.

In the construction industry, there is a growing interest in impact-resistant glazing solutions for buildings in areas prone to extreme weather conditions or security threats. Borosilicate glass-rubber composites could provide an effective solution for hurricane-resistant windows, blast-resistant facades, and other high-performance building materials.

The consumer electronics market is also showing potential for these composites, particularly in the development of more durable smartphone screens and tablet displays. As consumers demand more robust and scratch-resistant devices, manufacturers are exploring new materials that can withstand daily wear and tear while maintaining optical clarity.

Market trends indicate a shift towards sustainable and eco-friendly materials, which could present both opportunities and challenges for borosilicate glass-rubber composites. While these materials offer durability and potential for extended product lifecycles, their recyclability and end-of-life disposal may need to be addressed to align with growing environmental concerns.

The global market for advanced glass materials, including composites, is projected to grow steadily in the coming years. Factors such as urbanization, infrastructure development, and technological advancements in manufacturing processes are expected to drive this growth. However, the market penetration of borosilicate glass-rubber composites will depend on their cost-effectiveness compared to traditional materials and their ability to meet increasingly stringent performance standards across different industries.

Technical Challenges

The development of borosilicate glass-rubber composites for impact resistance faces several significant technical challenges. One of the primary obstacles is achieving optimal adhesion between the glass and rubber components. The vastly different chemical and physical properties of these materials make it difficult to create a strong, durable bond that can withstand high-impact forces without delamination or separation.

Another major challenge lies in balancing the conflicting properties of rigidity and flexibility. Borosilicate glass provides excellent hardness and scratch resistance but is inherently brittle. Rubber, on the other hand, offers elasticity and impact absorption but lacks structural integrity. Finding the right composition and structural design to leverage the strengths of both materials while mitigating their weaknesses remains a complex engineering problem.

The manufacturing process for these composites presents its own set of challenges. Integrating rubber with glass during production without compromising the optical clarity or structural integrity of the glass is technically demanding. Additionally, ensuring uniform distribution of rubber within the composite and controlling the interface between the two materials at a microscopic level requires advanced manufacturing techniques and precise process control.

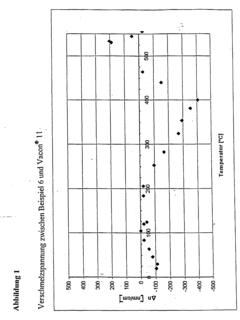

Thermal management is another critical issue in borosilicate glass-rubber composites. The significant difference in thermal expansion coefficients between glass and rubber can lead to internal stresses and potential failure under temperature fluctuations. Developing composites that maintain their structural integrity and impact resistance across a wide range of temperatures is essential for many applications but technically challenging.

Durability and long-term performance of these composites under various environmental conditions pose further challenges. Exposure to UV radiation, moisture, and chemical agents can degrade the rubber component over time, potentially compromising the composite's impact resistance. Developing formulations and protective measures to ensure long-lasting performance in diverse environments is an ongoing area of research and development.

Lastly, the characterization and testing of borosilicate glass-rubber composites present unique challenges. Developing standardized methods to accurately assess impact resistance, adhesion strength, and long-term durability of these heterogeneous materials is crucial. This requires innovative testing protocols and sophisticated analytical techniques to understand the complex failure mechanisms and predict real-world performance.

Another major challenge lies in balancing the conflicting properties of rigidity and flexibility. Borosilicate glass provides excellent hardness and scratch resistance but is inherently brittle. Rubber, on the other hand, offers elasticity and impact absorption but lacks structural integrity. Finding the right composition and structural design to leverage the strengths of both materials while mitigating their weaknesses remains a complex engineering problem.

The manufacturing process for these composites presents its own set of challenges. Integrating rubber with glass during production without compromising the optical clarity or structural integrity of the glass is technically demanding. Additionally, ensuring uniform distribution of rubber within the composite and controlling the interface between the two materials at a microscopic level requires advanced manufacturing techniques and precise process control.

Thermal management is another critical issue in borosilicate glass-rubber composites. The significant difference in thermal expansion coefficients between glass and rubber can lead to internal stresses and potential failure under temperature fluctuations. Developing composites that maintain their structural integrity and impact resistance across a wide range of temperatures is essential for many applications but technically challenging.

Durability and long-term performance of these composites under various environmental conditions pose further challenges. Exposure to UV radiation, moisture, and chemical agents can degrade the rubber component over time, potentially compromising the composite's impact resistance. Developing formulations and protective measures to ensure long-lasting performance in diverse environments is an ongoing area of research and development.

Lastly, the characterization and testing of borosilicate glass-rubber composites present unique challenges. Developing standardized methods to accurately assess impact resistance, adhesion strength, and long-term durability of these heterogeneous materials is crucial. This requires innovative testing protocols and sophisticated analytical techniques to understand the complex failure mechanisms and predict real-world performance.

Current Solutions

01 Composition of borosilicate glass-rubber composite

The composite material is typically composed of borosilicate glass and rubber components. The specific composition and ratio of these materials can be adjusted to optimize impact resistance. The rubber component may include various types of elastomers or synthetic rubbers, while the borosilicate glass provides strength and durability.- Composition of borosilicate glass-rubber composite: The composite material is typically composed of borosilicate glass and rubber components. The specific composition and ratio of these materials can be adjusted to optimize impact resistance. The rubber component may include various types of elastomers or synthetic rubbers, while the borosilicate glass provides strength and durability.

- Manufacturing process for improved impact resistance: The manufacturing process plays a crucial role in enhancing the impact resistance of borosilicate glass-rubber composites. This may involve specialized techniques such as hot pressing, injection molding, or lamination. The process often includes careful control of temperature, pressure, and curing conditions to ensure optimal bonding between the glass and rubber components.

- Surface treatment and interface modification: Surface treatments and interface modifications can significantly improve the impact resistance of borosilicate glass-rubber composites. This may include chemical treatments of the glass surface, application of coupling agents, or the use of intermediate layers to enhance adhesion between the glass and rubber components. These modifications aim to strengthen the interface and improve stress transfer between the materials.

- Reinforcement strategies for enhanced impact resistance: Various reinforcement strategies can be employed to further enhance the impact resistance of borosilicate glass-rubber composites. These may include the incorporation of fibers, nanoparticles, or other reinforcing agents into the composite structure. The reinforcements can help distribute impact forces and prevent crack propagation, thereby improving overall impact resistance.

- Testing and characterization methods: Specific testing and characterization methods are crucial for evaluating and optimizing the impact resistance of borosilicate glass-rubber composites. These may include standardized impact tests, fracture toughness measurements, and microscopic analysis of failure modes. Advanced techniques such as high-speed imaging or acoustic emission analysis may also be employed to understand the dynamic behavior of these composites under impact conditions.

02 Manufacturing process for improved impact resistance

The manufacturing process plays a crucial role in enhancing the impact resistance of borosilicate glass-rubber composites. This may involve specialized techniques for bonding the glass and rubber components, such as heat treatment, pressure application, or the use of specific adhesives. The process may also include surface treatments or the incorporation of additional layers to improve overall performance.Expand Specific Solutions03 Structural design for enhanced impact resistance

The structural design of the composite material can significantly influence its impact resistance. This may involve creating layered structures, incorporating reinforcing elements, or designing specific geometries that distribute impact forces effectively. The arrangement and interaction between the glass and rubber components are carefully engineered to maximize energy absorption and minimize damage.Expand Specific Solutions04 Additives and fillers for improved performance

Various additives and fillers can be incorporated into the borosilicate glass-rubber composite to enhance its impact resistance. These may include nanoparticles, fibers, or other reinforcing materials that improve the overall strength and toughness of the composite. The selection and distribution of these additives are optimized to achieve the desired impact resistance properties.Expand Specific Solutions05 Testing and evaluation methods for impact resistance

Specialized testing and evaluation methods are employed to assess the impact resistance of borosilicate glass-rubber composites. These may include standardized impact tests, drop tests, or ballistic tests to simulate various impact scenarios. Advanced analysis techniques, such as high-speed imaging or computer simulations, may be used to understand the behavior of the composite under impact and optimize its performance.Expand Specific Solutions

Industry Leaders

The competitive landscape for Borosilicate Glass-Rubber Composite Impact Studies is characterized by a mature market with established players and ongoing innovation. The industry is in a growth phase, driven by increasing demand for impact-resistant materials in various sectors. Key players like Corning, Inc. and SCHOTT AG dominate the market, leveraging their extensive experience in specialty glass manufacturing. The technology's maturity is evident in the diverse applications across industries, from consumer electronics to automotive. However, emerging companies such as Sunshine Lake Pharma Co., Ltd. and Hunan Kibing Pharmaceutical Material Technology Co., Ltd. are also making strides in specialized applications, particularly in the pharmaceutical sector, indicating potential for further market expansion and technological advancements.

Corning, Inc.

Technical Solution: Corning has developed a proprietary borosilicate glass-rubber composite technology called Gorilla Glass Victus. This composite material combines the strength and scratch resistance of borosilicate glass with the impact absorption properties of rubber. The glass layer is chemically strengthened through ion exchange, while a thin rubber interlayer is bonded to the glass surface. This structure allows the composite to withstand drops from heights up to 2 meters onto hard surfaces[1]. The rubber layer helps dissipate impact energy and prevent crack propagation. Corning has also implemented nanostructuring of the glass surface to enhance flexibility[2].

Strengths: Superior impact resistance, maintains optical clarity, thin form factor. Weaknesses: Higher production costs, potential for delamination over time, limited flexibility compared to pure polymers.

SCHOTT AG

Technical Solution: SCHOTT has developed a borosilicate glass-rubber composite called SCHOTT RealFeel. This composite utilizes a chemically strengthened borosilicate glass core with a proprietary rubber-based polymer coating. The glass core provides excellent scratch resistance and optical clarity, while the rubber coating absorbs impact energy. SCHOTT's manufacturing process involves a specialized bonding technique that creates strong adhesion between the glass and rubber layers[3]. The composite can withstand repeated impacts without compromising structural integrity. SCHOTT has also incorporated anti-reflective and oleophobic coatings to enhance usability[4].

Strengths: High impact resistance, maintains optical properties, resistant to environmental factors. Weaknesses: Thicker profile compared to pure glass, potential for coating wear over time, higher cost than standard glass.

Key Innovations

Borosilicate glass of high chemical resistance and its application

PatentInactiveEP0992462A1

Innovation

- A borosilicate glass composition with a low SiO2 content (71-73% by weight), high Al2O3 content (5.5-9% by weight), moderate B2O3 content (7-10% by weight), and controlled Li2O and ZrO2 content, which balances chemical resistance, thermal expansion, and processing temperature, ensuring a thermal expansion coefficient between 5.2 and 5.7 x 10^-6/K, thereby preventing tensile stresses and promoting compressive stresses for a hermetic seal.

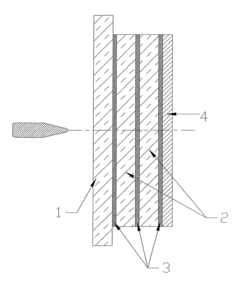

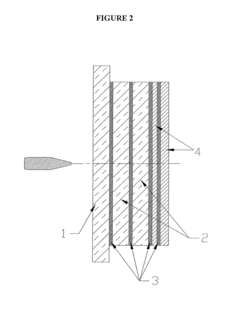

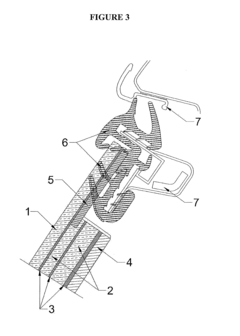

Curved bullet proof glass made of glass, glass-ceramic or ceramic mechanically curved on the strike-face layer

PatentActiveUS20160023938A1

Innovation

- The process involves mechanically curving glass, glass-ceramic, or ceramic layers during a low-heat and pressure lamination process, utilizing an ion exchange process to enhance flexibility and mechanical resistance, allowing for individual bending of intermediate layers with different softening temperatures without simultaneous bending-annealing, and using organic paints to maintain mechanical resistance.

Material Properties

Borosilicate glass-rubber composites represent a unique class of materials that combine the properties of two distinct components: borosilicate glass and rubber. These composites are designed to leverage the strengths of both materials while mitigating their individual weaknesses. Borosilicate glass, known for its excellent thermal shock resistance and chemical durability, contributes to the composite's overall strength and stability. On the other hand, rubber provides flexibility, impact resistance, and energy absorption capabilities.

The material properties of borosilicate glass-rubber composites are highly dependent on the ratio of glass to rubber, the specific types of rubber used, and the manufacturing process. Generally, these composites exhibit a combination of high strength, toughness, and impact resistance. The glass component typically maintains its characteristic hardness and scratch resistance, while the rubber phase enhances the material's ability to absorb and dissipate energy upon impact.

One of the key properties of these composites is their improved impact resistance compared to pure borosilicate glass. The rubber phase acts as a shock absorber, distributing the force of an impact over a larger area and reducing the likelihood of catastrophic failure. This property makes borosilicate glass-rubber composites particularly suitable for applications requiring both transparency and impact resistance, such as protective screens or safety glasses.

The thermal properties of these composites are also noteworthy. While borosilicate glass is known for its low coefficient of thermal expansion, the addition of rubber can modify this characteristic. Depending on the rubber content, the composite may exhibit a range of thermal expansion behaviors, which can be tailored for specific applications. This adaptability allows for the creation of materials that can withstand thermal cycling without compromising their structural integrity.

Optically, borosilicate glass-rubber composites can maintain a high degree of transparency, especially when the rubber content is kept low. However, increasing the rubber content may lead to some light scattering, potentially reducing overall transparency. This trade-off between impact resistance and optical clarity is a crucial consideration in the design and application of these materials.

The chemical resistance of borosilicate glass-rubber composites is generally good, inherited from the borosilicate glass component. However, the rubber phase may introduce some limitations in terms of chemical compatibility, particularly with organic solvents or certain aggressive chemicals. The specific chemical resistance profile will depend on the type of rubber used in the composite.

In terms of mechanical properties, these composites often display non-linear stress-strain behavior, combining the initial stiffness of glass with the elasticity of rubber. This results in materials that can withstand high loads while also exhibiting some degree of flexibility, a combination that is particularly valuable in impact-resistant applications.

The material properties of borosilicate glass-rubber composites are highly dependent on the ratio of glass to rubber, the specific types of rubber used, and the manufacturing process. Generally, these composites exhibit a combination of high strength, toughness, and impact resistance. The glass component typically maintains its characteristic hardness and scratch resistance, while the rubber phase enhances the material's ability to absorb and dissipate energy upon impact.

One of the key properties of these composites is their improved impact resistance compared to pure borosilicate glass. The rubber phase acts as a shock absorber, distributing the force of an impact over a larger area and reducing the likelihood of catastrophic failure. This property makes borosilicate glass-rubber composites particularly suitable for applications requiring both transparency and impact resistance, such as protective screens or safety glasses.

The thermal properties of these composites are also noteworthy. While borosilicate glass is known for its low coefficient of thermal expansion, the addition of rubber can modify this characteristic. Depending on the rubber content, the composite may exhibit a range of thermal expansion behaviors, which can be tailored for specific applications. This adaptability allows for the creation of materials that can withstand thermal cycling without compromising their structural integrity.

Optically, borosilicate glass-rubber composites can maintain a high degree of transparency, especially when the rubber content is kept low. However, increasing the rubber content may lead to some light scattering, potentially reducing overall transparency. This trade-off between impact resistance and optical clarity is a crucial consideration in the design and application of these materials.

The chemical resistance of borosilicate glass-rubber composites is generally good, inherited from the borosilicate glass component. However, the rubber phase may introduce some limitations in terms of chemical compatibility, particularly with organic solvents or certain aggressive chemicals. The specific chemical resistance profile will depend on the type of rubber used in the composite.

In terms of mechanical properties, these composites often display non-linear stress-strain behavior, combining the initial stiffness of glass with the elasticity of rubber. This results in materials that can withstand high loads while also exhibiting some degree of flexibility, a combination that is particularly valuable in impact-resistant applications.

Safety Standards

Safety standards play a crucial role in the development and implementation of borosilicate glass-rubber composite materials for impact-resistant applications. These standards ensure that the composite materials meet specific requirements for safety, reliability, and performance under various impact conditions.

The primary safety standards governing borosilicate glass-rubber composites are typically established by international organizations such as the International Organization for Standardization (ISO) and the American Society for Testing and Materials (ASTM). These standards outline specific testing methodologies, performance criteria, and quality control measures that manufacturers must adhere to when producing and evaluating these composite materials.

One of the key safety standards applicable to borosilicate glass-rubber composites is the impact resistance test. This test evaluates the material's ability to withstand sudden forces without shattering or compromising its structural integrity. The standard typically specifies the impact energy levels, projectile types, and testing conditions that the composite must endure to meet safety requirements.

Additionally, safety standards often address the durability and long-term performance of the composite materials. These standards may include accelerated aging tests, environmental exposure simulations, and cyclic loading tests to ensure that the composites maintain their impact resistance properties over time and under various environmental conditions.

Transparency and optical clarity are also important considerations in safety standards for borosilicate glass-rubber composites, particularly in applications where visibility is critical. Standards may specify minimum levels of light transmission and maximum allowable distortion to ensure that the composite materials do not compromise visual acuity or safety in their intended applications.

Furthermore, safety standards often encompass requirements for chemical resistance and compatibility. This is particularly important for borosilicate glass-rubber composites used in environments where they may be exposed to various chemicals or solvents. Standards may outline specific testing procedures to evaluate the material's resistance to degradation or changes in mechanical properties when exposed to different chemical agents.

Compliance with these safety standards is typically verified through rigorous testing and certification processes. Manufacturers must demonstrate that their borosilicate glass-rubber composites meet or exceed the specified performance criteria through standardized testing procedures conducted by accredited laboratories. This ensures that the materials used in safety-critical applications, such as protective equipment or transportation systems, consistently meet the required safety standards.

As research in borosilicate glass-rubber composites advances, safety standards are continually evolving to address new challenges and incorporate improved testing methodologies. This ongoing development of standards helps drive innovation in composite materials while maintaining a high level of safety and reliability in their applications.

The primary safety standards governing borosilicate glass-rubber composites are typically established by international organizations such as the International Organization for Standardization (ISO) and the American Society for Testing and Materials (ASTM). These standards outline specific testing methodologies, performance criteria, and quality control measures that manufacturers must adhere to when producing and evaluating these composite materials.

One of the key safety standards applicable to borosilicate glass-rubber composites is the impact resistance test. This test evaluates the material's ability to withstand sudden forces without shattering or compromising its structural integrity. The standard typically specifies the impact energy levels, projectile types, and testing conditions that the composite must endure to meet safety requirements.

Additionally, safety standards often address the durability and long-term performance of the composite materials. These standards may include accelerated aging tests, environmental exposure simulations, and cyclic loading tests to ensure that the composites maintain their impact resistance properties over time and under various environmental conditions.

Transparency and optical clarity are also important considerations in safety standards for borosilicate glass-rubber composites, particularly in applications where visibility is critical. Standards may specify minimum levels of light transmission and maximum allowable distortion to ensure that the composite materials do not compromise visual acuity or safety in their intended applications.

Furthermore, safety standards often encompass requirements for chemical resistance and compatibility. This is particularly important for borosilicate glass-rubber composites used in environments where they may be exposed to various chemicals or solvents. Standards may outline specific testing procedures to evaluate the material's resistance to degradation or changes in mechanical properties when exposed to different chemical agents.

Compliance with these safety standards is typically verified through rigorous testing and certification processes. Manufacturers must demonstrate that their borosilicate glass-rubber composites meet or exceed the specified performance criteria through standardized testing procedures conducted by accredited laboratories. This ensures that the materials used in safety-critical applications, such as protective equipment or transportation systems, consistently meet the required safety standards.

As research in borosilicate glass-rubber composites advances, safety standards are continually evolving to address new challenges and incorporate improved testing methodologies. This ongoing development of standards helps drive innovation in composite materials while maintaining a high level of safety and reliability in their applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!