Borosilicate Glass Structural Role in Plasma Confinement Systems

JUL 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Plasma Confinement Glass Evolution

The evolution of plasma confinement glass has been a critical aspect in the development of fusion energy systems. Borosilicate glass, known for its exceptional thermal and chemical resistance, has played a pivotal role in this progression. Initially, the use of glass in plasma confinement was limited due to concerns about its ability to withstand extreme conditions.

In the early stages of plasma confinement research, glass components were primarily used in diagnostic windows and viewports. These applications required materials that could maintain transparency while resisting high temperatures and radiation exposure. Borosilicate glass emerged as a suitable candidate due to its low thermal expansion coefficient and high resistance to thermal shock.

As fusion research advanced, the demands on materials increased significantly. The need for improved plasma-facing components led to the exploration of more advanced glass compositions. Researchers began investigating the potential of borosilicate glass as a structural material in certain areas of plasma confinement systems. This shift was driven by the glass's unique properties, including its ability to maintain structural integrity under high heat flux and its resistance to plasma erosion.

The 1980s and 1990s saw significant advancements in glass manufacturing techniques, enabling the production of more robust and specialized borosilicate glass formulations. These improvements allowed for the integration of glass components in more critical areas of plasma confinement devices. For instance, specially designed borosilicate glass insulators were developed to provide electrical isolation in high-voltage regions of tokamaks.

In recent years, the role of borosilicate glass in plasma confinement has expanded further. Advanced coating technologies have been developed to enhance the glass's performance in fusion environments. These coatings can improve the glass's resistance to sputtering, reduce secondary electron emission, and enhance its overall durability in the presence of plasma.

The latest developments in plasma confinement glass technology focus on nanostructured borosilicate composites. These materials combine the beneficial properties of borosilicate glass with those of other advanced materials, creating hybrid structures with enhanced performance characteristics. Such innovations are pushing the boundaries of what is possible in terms of material performance in fusion reactors.

Looking ahead, the evolution of borosilicate glass in plasma confinement systems continues to be an active area of research. Scientists are exploring new glass compositions and manufacturing techniques to further improve the material's capabilities in extreme fusion environments. The ongoing advancements in this field are crucial for the development of more efficient and durable fusion energy systems.

In the early stages of plasma confinement research, glass components were primarily used in diagnostic windows and viewports. These applications required materials that could maintain transparency while resisting high temperatures and radiation exposure. Borosilicate glass emerged as a suitable candidate due to its low thermal expansion coefficient and high resistance to thermal shock.

As fusion research advanced, the demands on materials increased significantly. The need for improved plasma-facing components led to the exploration of more advanced glass compositions. Researchers began investigating the potential of borosilicate glass as a structural material in certain areas of plasma confinement systems. This shift was driven by the glass's unique properties, including its ability to maintain structural integrity under high heat flux and its resistance to plasma erosion.

The 1980s and 1990s saw significant advancements in glass manufacturing techniques, enabling the production of more robust and specialized borosilicate glass formulations. These improvements allowed for the integration of glass components in more critical areas of plasma confinement devices. For instance, specially designed borosilicate glass insulators were developed to provide electrical isolation in high-voltage regions of tokamaks.

In recent years, the role of borosilicate glass in plasma confinement has expanded further. Advanced coating technologies have been developed to enhance the glass's performance in fusion environments. These coatings can improve the glass's resistance to sputtering, reduce secondary electron emission, and enhance its overall durability in the presence of plasma.

The latest developments in plasma confinement glass technology focus on nanostructured borosilicate composites. These materials combine the beneficial properties of borosilicate glass with those of other advanced materials, creating hybrid structures with enhanced performance characteristics. Such innovations are pushing the boundaries of what is possible in terms of material performance in fusion reactors.

Looking ahead, the evolution of borosilicate glass in plasma confinement systems continues to be an active area of research. Scientists are exploring new glass compositions and manufacturing techniques to further improve the material's capabilities in extreme fusion environments. The ongoing advancements in this field are crucial for the development of more efficient and durable fusion energy systems.

Market Analysis for Fusion Reactors

The market for fusion reactors is currently in its nascent stage, with significant potential for growth as the technology matures. The global energy landscape is shifting towards cleaner, more sustainable sources, and fusion energy represents a promising solution to meet long-term energy demands. While commercial fusion reactors are not yet operational, the market for fusion-related technologies and components is expanding.

Borosilicate glass, known for its thermal and chemical resistance, plays a crucial role in plasma confinement systems within fusion reactors. As research and development in fusion technology progress, the demand for specialized materials like borosilicate glass is expected to increase. The market for these materials is closely tied to the overall fusion reactor market, which is projected to grow substantially in the coming decades.

Several factors are driving the market potential for fusion reactors and associated technologies. Climate change concerns and the push for decarbonization are accelerating investments in clean energy solutions. Governments and private entities worldwide are allocating substantial funds to fusion research and development, creating a robust ecosystem for innovation and commercialization.

The market for fusion reactor components, including those utilizing borosilicate glass, is characterized by high barriers to entry due to the specialized nature of the technology. This creates opportunities for companies with expertise in advanced materials and plasma physics to establish strong market positions. As the technology advances, we anticipate increased competition and potential for market consolidation.

Key market segments for fusion reactor technologies include national laboratories, research institutions, and private fusion companies. These entities are driving demand for specialized materials and components, including those incorporating borosilicate glass for plasma confinement. The market is global, with significant activities in North America, Europe, and Asia.

While the immediate market size for fusion reactor components is relatively small compared to established energy technologies, the long-term potential is substantial. Industry analysts project that the fusion energy market could reach hundreds of billions of dollars by mid-century, assuming successful commercialization of the technology. This growth trajectory presents significant opportunities for companies involved in the development and production of critical components like borosilicate glass-based plasma confinement systems.

Borosilicate glass, known for its thermal and chemical resistance, plays a crucial role in plasma confinement systems within fusion reactors. As research and development in fusion technology progress, the demand for specialized materials like borosilicate glass is expected to increase. The market for these materials is closely tied to the overall fusion reactor market, which is projected to grow substantially in the coming decades.

Several factors are driving the market potential for fusion reactors and associated technologies. Climate change concerns and the push for decarbonization are accelerating investments in clean energy solutions. Governments and private entities worldwide are allocating substantial funds to fusion research and development, creating a robust ecosystem for innovation and commercialization.

The market for fusion reactor components, including those utilizing borosilicate glass, is characterized by high barriers to entry due to the specialized nature of the technology. This creates opportunities for companies with expertise in advanced materials and plasma physics to establish strong market positions. As the technology advances, we anticipate increased competition and potential for market consolidation.

Key market segments for fusion reactor technologies include national laboratories, research institutions, and private fusion companies. These entities are driving demand for specialized materials and components, including those incorporating borosilicate glass for plasma confinement. The market is global, with significant activities in North America, Europe, and Asia.

While the immediate market size for fusion reactor components is relatively small compared to established energy technologies, the long-term potential is substantial. Industry analysts project that the fusion energy market could reach hundreds of billions of dollars by mid-century, assuming successful commercialization of the technology. This growth trajectory presents significant opportunities for companies involved in the development and production of critical components like borosilicate glass-based plasma confinement systems.

Borosilicate Glass Properties and Challenges

Borosilicate glass plays a crucial role in plasma confinement systems, offering unique properties that make it suitable for this demanding application. However, its use also presents several challenges that must be addressed to ensure optimal performance and longevity of the confinement systems.

One of the primary advantages of borosilicate glass is its excellent thermal shock resistance. This property allows it to withstand rapid temperature changes without cracking or shattering, which is essential in plasma environments where temperature fluctuations are common. Additionally, borosilicate glass exhibits low thermal expansion, further enhancing its ability to maintain structural integrity under varying thermal conditions.

The high chemical resistance of borosilicate glass is another key attribute that makes it valuable in plasma confinement systems. It can withstand exposure to various corrosive substances and maintain its properties over extended periods, ensuring the longevity of the confinement structure. This resistance also helps prevent contamination of the plasma, which is crucial for maintaining the purity of the confined material.

Borosilicate glass also offers good electrical insulation properties, which is important in plasma confinement systems where electrical fields play a significant role. Its ability to withstand high voltages without breakdown contributes to the overall stability and safety of the system.

Despite these advantages, the use of borosilicate glass in plasma confinement systems presents several challenges. One of the primary concerns is its brittleness, which makes it susceptible to mechanical stress and impact. This vulnerability necessitates careful handling and design considerations to prevent fractures or cracks that could compromise the integrity of the confinement system.

Another challenge is the potential for surface degradation over time due to prolonged exposure to high-energy plasma. This can lead to changes in the glass's optical and mechanical properties, potentially affecting the performance of the confinement system. Researchers are actively exploring ways to mitigate this issue, such as developing protective coatings or surface treatments.

The limited maximum operating temperature of borosilicate glass compared to some other materials used in plasma confinement systems is also a constraint. While it can withstand higher temperatures than many other types of glass, extreme plasma conditions may push it beyond its operational limits, necessitating careful thermal management strategies.

Lastly, the fabrication of complex shapes and large-scale structures from borosilicate glass can be challenging and costly. This limitation can impact the design flexibility and scalability of plasma confinement systems, requiring innovative manufacturing techniques and design approaches to overcome these constraints.

One of the primary advantages of borosilicate glass is its excellent thermal shock resistance. This property allows it to withstand rapid temperature changes without cracking or shattering, which is essential in plasma environments where temperature fluctuations are common. Additionally, borosilicate glass exhibits low thermal expansion, further enhancing its ability to maintain structural integrity under varying thermal conditions.

The high chemical resistance of borosilicate glass is another key attribute that makes it valuable in plasma confinement systems. It can withstand exposure to various corrosive substances and maintain its properties over extended periods, ensuring the longevity of the confinement structure. This resistance also helps prevent contamination of the plasma, which is crucial for maintaining the purity of the confined material.

Borosilicate glass also offers good electrical insulation properties, which is important in plasma confinement systems where electrical fields play a significant role. Its ability to withstand high voltages without breakdown contributes to the overall stability and safety of the system.

Despite these advantages, the use of borosilicate glass in plasma confinement systems presents several challenges. One of the primary concerns is its brittleness, which makes it susceptible to mechanical stress and impact. This vulnerability necessitates careful handling and design considerations to prevent fractures or cracks that could compromise the integrity of the confinement system.

Another challenge is the potential for surface degradation over time due to prolonged exposure to high-energy plasma. This can lead to changes in the glass's optical and mechanical properties, potentially affecting the performance of the confinement system. Researchers are actively exploring ways to mitigate this issue, such as developing protective coatings or surface treatments.

The limited maximum operating temperature of borosilicate glass compared to some other materials used in plasma confinement systems is also a constraint. While it can withstand higher temperatures than many other types of glass, extreme plasma conditions may push it beyond its operational limits, necessitating careful thermal management strategies.

Lastly, the fabrication of complex shapes and large-scale structures from borosilicate glass can be challenging and costly. This limitation can impact the design flexibility and scalability of plasma confinement systems, requiring innovative manufacturing techniques and design approaches to overcome these constraints.

Current Borosilicate Glass Applications

01 Thermal and chemical resistance

Borosilicate glass plays a crucial structural role due to its excellent thermal and chemical resistance properties. Its low coefficient of thermal expansion makes it resistant to thermal shock, while its chemical composition provides resistance to various corrosive substances. These properties make it ideal for use in laboratory equipment, cookware, and industrial applications where exposure to extreme temperatures and chemicals is common.- Thermal and chemical resistance: Borosilicate glass plays a crucial structural role due to its excellent thermal and chemical resistance properties. Its low coefficient of thermal expansion makes it resistant to thermal shock, while its chemical composition provides resistance to various corrosive substances. These properties make it ideal for use in laboratory equipment, cookware, and industrial applications where exposure to extreme temperatures and chemicals is common.

- Optical and electronic applications: Borosilicate glass serves a structural role in optical and electronic devices due to its high transparency and low refractive index. It is used in the production of lenses, optical fibers, and display screens. Its electrical insulating properties also make it suitable for use in electronic components and semiconductor manufacturing processes.

- Architectural and construction applications: In architecture and construction, borosilicate glass is used for its structural integrity and safety features. Its strength and durability make it suitable for use in windows, doors, and facades of buildings. It is also used in fire-resistant glass applications due to its low thermal expansion coefficient, providing enhanced safety in case of fires.

- Aerospace and automotive industries: Borosilicate glass plays a structural role in aerospace and automotive applications due to its lightweight nature and high strength-to-weight ratio. It is used in aircraft windows, spacecraft components, and automotive lighting systems. Its ability to withstand high pressures and temperatures makes it ideal for these demanding environments.

- Medical and pharmaceutical applications: In the medical and pharmaceutical industries, borosilicate glass serves a critical structural role due to its biocompatibility and chemical inertness. It is used in the manufacture of laboratory glassware, syringes, vials, and ampules for drug storage and delivery. Its resistance to sterilization processes and ability to maintain the integrity of stored substances make it essential in these fields.

02 Optical and electronic applications

Borosilicate glass serves a structural role in optical and electronic devices due to its high transparency and electrical insulation properties. It is used in the manufacturing of lenses, optical fibers, and display screens. Its low dielectric constant and high resistivity make it suitable for electronic components and substrates in semiconductor manufacturing.Expand Specific Solutions03 Architectural and construction applications

In architecture and construction, borosilicate glass provides structural integrity due to its strength and durability. It is used in fire-resistant glass, skylights, and building facades. Its low thermal expansion coefficient makes it resistant to cracking under temperature changes, enhancing the safety and longevity of structures.Expand Specific Solutions04 Aerospace and automotive industries

Borosilicate glass plays a structural role in aerospace and automotive applications due to its lightweight nature and high strength-to-weight ratio. It is used in aircraft windows, spacecraft components, and automotive lighting systems. Its ability to withstand high pressures and extreme temperatures makes it suitable for these demanding environments.Expand Specific Solutions05 Medical and pharmaceutical applications

In the medical and pharmaceutical fields, borosilicate glass serves a critical structural role due to its biocompatibility and chemical inertness. It is used in the manufacturing of medical devices, laboratory glassware, and pharmaceutical packaging. Its resistance to leaching and ability to maintain the integrity of stored substances make it ideal for these sensitive applications.Expand Specific Solutions

Key Players in Fusion Reactor Development

The competitive landscape for borosilicate glass in plasma confinement systems is characterized by a mature market with established players and ongoing technological advancements. Key companies like SCHOTT AG, Corning, Inc., and Nippon Electric Glass Co., Ltd. dominate the field, leveraging their extensive experience in specialty glass manufacturing. The market size is moderate but growing, driven by increasing demand in fusion research and plasma-based technologies. While the core technology is well-established, ongoing research by institutions like Forschungszentrum Jülich GmbH and universities aims to enhance glass properties for improved plasma confinement performance. The industry is in a phase of incremental innovation, focusing on optimizing glass compositions and manufacturing processes to meet the stringent requirements of advanced plasma systems.

SCHOTT AG

Technical Solution: SCHOTT AG has developed advanced borosilicate glass compositions specifically tailored for plasma confinement systems in fusion reactors. Their DURAN® borosilicate glass offers exceptional thermal shock resistance and low thermal expansion, crucial for withstanding the extreme temperature fluctuations in plasma environments[1]. SCHOTT's glass formulations incorporate precise amounts of boron oxide to enhance neutron absorption capabilities, reducing radiation leakage. The company has also implemented innovative surface treatment techniques to improve the glass's resistance to plasma erosion and minimize impurity release, which is critical for maintaining plasma purity[2]. SCHOTT's borosilicate glass components are manufactured using advanced forming processes that ensure high dimensional accuracy and structural integrity, essential for creating vacuum-tight seals in plasma confinement vessels[3].

Strengths: Superior thermal and mechanical properties, excellent neutron absorption, and high purity maintenance. Weaknesses: Higher cost compared to standard glass, limited flexibility in large-scale forming.

Corning, Inc.

Technical Solution: Corning has pioneered the development of ultra-low expansion (ULE®) borosilicate glass for plasma confinement systems. Their proprietary glass composition exhibits near-zero thermal expansion over a wide temperature range, making it ideal for maintaining structural stability in fusion reactor environments[4]. Corning's borosilicate glass incorporates advanced dopants that enhance its electrical insulation properties, crucial for isolating plasma from external electromagnetic fields. The company has also developed specialized coating technologies that improve the glass's resistance to ion bombardment and reduce secondary electron emission, which is essential for maintaining plasma stability[5]. Corning's manufacturing process includes precision annealing techniques that minimize internal stresses, ensuring long-term structural integrity under the intense conditions of plasma confinement[6].

Strengths: Exceptional dimensional stability, superior electrical insulation, and advanced surface treatments. Weaknesses: High production costs and limited availability in large quantities.

Innovations in Glass-Based Plasma Confinement

Test cell for a noble gas polarizer

PatentInactiveEP1192476A2

Innovation

- A glass sample cell design featuring flat, plane windows fused into a cylindrical borosilicate glass body, capable of withstanding high pressures, with non-magnetic and alkali-resistant sealing, and ethylene propylene sealing rings to minimize polarization loss, ensuring a parallel light path and reduced lens effects.

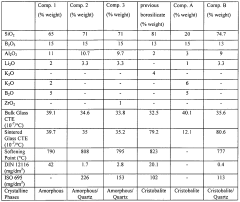

Borosilicate glass compositions and uses thereof

PatentWO2004050575A1

Innovation

- A borosilicate glass composition with silicon dioxide, boric oxide, aluminum oxide, and at least one alkali oxide, which resists devitrification without the addition of inhibitor oxides, maintaining a suitable coefficient of thermal expansion and mechanical strength.

Safety and Radiation Shielding Aspects

Borosilicate glass plays a crucial role in plasma confinement systems, not only for its structural properties but also for its significant contributions to safety and radiation shielding. The unique composition of borosilicate glass, particularly its high boron content, makes it an excellent material for neutron absorption, a critical aspect of radiation shielding in fusion reactors.

In plasma confinement systems, the primary safety concern is the containment of high-energy particles and radiation produced during the fusion process. Borosilicate glass, when incorporated into the reactor design, serves as an effective barrier against these potentially harmful emissions. The glass's ability to absorb neutrons without becoming highly radioactive itself is a key advantage, reducing the overall radioactive inventory of the system.

The radiation shielding properties of borosilicate glass are further enhanced by its resistance to radiation-induced degradation. Unlike many other materials, borosilicate glass maintains its structural integrity and optical properties even under prolonged exposure to high-energy particles. This durability ensures that the shielding effectiveness remains consistent over the operational lifetime of the plasma confinement system.

Moreover, the transparency of borosilicate glass allows for visual inspection of the plasma chamber without compromising the shielding integrity. This feature is invaluable for monitoring the condition of internal components and the plasma itself, contributing to both safety and operational efficiency.

In terms of safety during maintenance and decommissioning, the use of borosilicate glass components can significantly reduce personnel exposure to radiation. The glass's ability to trap activated particles within its matrix means that contamination is less likely to spread, simplifying cleanup procedures and reducing the risk to workers.

The integration of borosilicate glass in plasma confinement systems also addresses concerns related to waste management. The relatively low activation of borosilicate glass compared to other structural materials means that it produces less radioactive waste at the end of its lifecycle. This characteristic aligns with the broader goal of minimizing the environmental impact of fusion energy production.

Research into advanced borosilicate glass compositions continues, with efforts focused on optimizing the balance between neutron absorption, structural strength, and transparency. These developments aim to further enhance the safety and shielding capabilities of plasma confinement systems, paving the way for more efficient and secure fusion energy production in the future.

In plasma confinement systems, the primary safety concern is the containment of high-energy particles and radiation produced during the fusion process. Borosilicate glass, when incorporated into the reactor design, serves as an effective barrier against these potentially harmful emissions. The glass's ability to absorb neutrons without becoming highly radioactive itself is a key advantage, reducing the overall radioactive inventory of the system.

The radiation shielding properties of borosilicate glass are further enhanced by its resistance to radiation-induced degradation. Unlike many other materials, borosilicate glass maintains its structural integrity and optical properties even under prolonged exposure to high-energy particles. This durability ensures that the shielding effectiveness remains consistent over the operational lifetime of the plasma confinement system.

Moreover, the transparency of borosilicate glass allows for visual inspection of the plasma chamber without compromising the shielding integrity. This feature is invaluable for monitoring the condition of internal components and the plasma itself, contributing to both safety and operational efficiency.

In terms of safety during maintenance and decommissioning, the use of borosilicate glass components can significantly reduce personnel exposure to radiation. The glass's ability to trap activated particles within its matrix means that contamination is less likely to spread, simplifying cleanup procedures and reducing the risk to workers.

The integration of borosilicate glass in plasma confinement systems also addresses concerns related to waste management. The relatively low activation of borosilicate glass compared to other structural materials means that it produces less radioactive waste at the end of its lifecycle. This characteristic aligns with the broader goal of minimizing the environmental impact of fusion energy production.

Research into advanced borosilicate glass compositions continues, with efforts focused on optimizing the balance between neutron absorption, structural strength, and transparency. These developments aim to further enhance the safety and shielding capabilities of plasma confinement systems, paving the way for more efficient and secure fusion energy production in the future.

Environmental Impact of Fusion Technology

The environmental impact of fusion technology, particularly in relation to borosilicate glass used in plasma confinement systems, is a critical aspect to consider in the development of fusion energy. Borosilicate glass, while playing a crucial structural role in these systems, also presents unique environmental challenges and benefits.

One of the primary environmental advantages of fusion technology is its potential to provide clean, safe, and virtually limitless energy. Unlike traditional nuclear fission, fusion reactions produce no long-lived radioactive waste, significantly reducing the environmental burden associated with nuclear power generation. The use of borosilicate glass in plasma confinement systems contributes to this environmental benefit by enhancing the efficiency and stability of fusion reactions.

However, the production and disposal of borosilicate glass components used in fusion reactors do have environmental implications. The manufacturing process of borosilicate glass requires high temperatures and energy inputs, contributing to carbon emissions if not powered by renewable sources. Additionally, the mining and processing of raw materials for borosilicate glass production can have localized environmental impacts, including habitat disruption and potential water pollution.

On the positive side, borosilicate glass is highly durable and resistant to thermal shock, reducing the frequency of replacement and minimizing waste generation during the operational lifetime of fusion reactors. Its chemical stability also means that it is less likely to leach harmful substances into the environment if disposed of properly.

The end-of-life management of borosilicate glass components from fusion reactors presents both challenges and opportunities. While the glass itself is not radioactive, it may become activated through exposure to neutron radiation during reactor operation. This necessitates careful handling and specialized disposal techniques to prevent environmental contamination. However, advanced recycling technologies are being developed to reprocess and reuse these materials, potentially creating a closed-loop system that minimizes environmental impact.

In terms of resource consumption, the use of borosilicate glass in fusion technology represents a relatively small environmental footprint compared to the materials required for other energy generation methods. The abundance of the primary raw materials (silica and boron) used in borosilicate glass production ensures a sustainable supply chain with less environmental stress compared to rare earth elements or fossil fuels.

Looking ahead, ongoing research aims to further optimize the environmental profile of borosilicate glass in fusion applications. This includes developing more energy-efficient production methods, exploring bio-based alternatives for certain components, and improving the recyclability of used materials. These advancements will be crucial in ensuring that fusion technology, supported by borosilicate glass structures, remains at the forefront of environmentally sustainable energy solutions.

One of the primary environmental advantages of fusion technology is its potential to provide clean, safe, and virtually limitless energy. Unlike traditional nuclear fission, fusion reactions produce no long-lived radioactive waste, significantly reducing the environmental burden associated with nuclear power generation. The use of borosilicate glass in plasma confinement systems contributes to this environmental benefit by enhancing the efficiency and stability of fusion reactions.

However, the production and disposal of borosilicate glass components used in fusion reactors do have environmental implications. The manufacturing process of borosilicate glass requires high temperatures and energy inputs, contributing to carbon emissions if not powered by renewable sources. Additionally, the mining and processing of raw materials for borosilicate glass production can have localized environmental impacts, including habitat disruption and potential water pollution.

On the positive side, borosilicate glass is highly durable and resistant to thermal shock, reducing the frequency of replacement and minimizing waste generation during the operational lifetime of fusion reactors. Its chemical stability also means that it is less likely to leach harmful substances into the environment if disposed of properly.

The end-of-life management of borosilicate glass components from fusion reactors presents both challenges and opportunities. While the glass itself is not radioactive, it may become activated through exposure to neutron radiation during reactor operation. This necessitates careful handling and specialized disposal techniques to prevent environmental contamination. However, advanced recycling technologies are being developed to reprocess and reuse these materials, potentially creating a closed-loop system that minimizes environmental impact.

In terms of resource consumption, the use of borosilicate glass in fusion technology represents a relatively small environmental footprint compared to the materials required for other energy generation methods. The abundance of the primary raw materials (silica and boron) used in borosilicate glass production ensures a sustainable supply chain with less environmental stress compared to rare earth elements or fossil fuels.

Looking ahead, ongoing research aims to further optimize the environmental profile of borosilicate glass in fusion applications. This includes developing more energy-efficient production methods, exploring bio-based alternatives for certain components, and improving the recyclability of used materials. These advancements will be crucial in ensuring that fusion technology, supported by borosilicate glass structures, remains at the forefront of environmentally sustainable energy solutions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!