Bundle Fouling Mapping: DP Trends, Thermal Signals And Inspection Targeting

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Bundle Fouling Background and Objectives

Bundle fouling represents a critical challenge in the petrochemical industry, particularly in heat exchanger operations where it significantly impacts thermal efficiency and operational costs. The phenomenon occurs when unwanted deposits accumulate on heat transfer surfaces, creating barriers to efficient heat exchange and increasing pressure drops across the system. Historically, bundle fouling has been addressed through reactive maintenance approaches, often resulting in unplanned downtime and substantial economic losses.

The evolution of bundle fouling detection and management has progressed from basic visual inspections to more sophisticated monitoring techniques. Early detection methods relied primarily on indirect indicators such as decreased heat transfer efficiency or increased pressure drops, without providing detailed insights into the fouling distribution or severity across the bundle.

Recent technological advancements have enabled more proactive approaches to fouling management, incorporating real-time monitoring systems and predictive analytics. These developments align with the industry's shift toward condition-based maintenance strategies, aiming to optimize cleaning schedules and minimize operational disruptions.

The primary objective of Bundle Fouling Mapping technology is to develop comprehensive methodologies for accurately identifying, characterizing, and visualizing fouling patterns within heat exchanger bundles. By integrating differential pressure (DP) trend analysis with thermal signal processing, this technology seeks to create detailed fouling maps that can guide targeted inspection and maintenance activities.

Specifically, the technology aims to establish correlations between measurable parameters (pressure differentials and temperature distributions) and the actual fouling conditions within the bundle. This approach enables operators to move beyond binary "fouled/clean" determinations toward nuanced understanding of fouling progression and distribution.

Additionally, the technology seeks to develop predictive capabilities that can anticipate fouling behavior based on operational parameters and historical data, allowing for proactive intervention before critical thresholds are reached. This predictive element represents a significant advancement over traditional reactive approaches to fouling management.

The ultimate goal is to transform bundle maintenance from a periodic, often disruptive process into a targeted, data-driven activity that maximizes operational efficiency while minimizing downtime. By precisely mapping fouling patterns, maintenance resources can be directed to specific areas requiring attention rather than applying blanket cleaning procedures to entire systems.

Furthermore, this technology aims to establish standardized methodologies for fouling assessment that can be implemented across various heat exchanger designs and operational environments, creating a unified approach to what has traditionally been a highly specialized and equipment-specific challenge.

The evolution of bundle fouling detection and management has progressed from basic visual inspections to more sophisticated monitoring techniques. Early detection methods relied primarily on indirect indicators such as decreased heat transfer efficiency or increased pressure drops, without providing detailed insights into the fouling distribution or severity across the bundle.

Recent technological advancements have enabled more proactive approaches to fouling management, incorporating real-time monitoring systems and predictive analytics. These developments align with the industry's shift toward condition-based maintenance strategies, aiming to optimize cleaning schedules and minimize operational disruptions.

The primary objective of Bundle Fouling Mapping technology is to develop comprehensive methodologies for accurately identifying, characterizing, and visualizing fouling patterns within heat exchanger bundles. By integrating differential pressure (DP) trend analysis with thermal signal processing, this technology seeks to create detailed fouling maps that can guide targeted inspection and maintenance activities.

Specifically, the technology aims to establish correlations between measurable parameters (pressure differentials and temperature distributions) and the actual fouling conditions within the bundle. This approach enables operators to move beyond binary "fouled/clean" determinations toward nuanced understanding of fouling progression and distribution.

Additionally, the technology seeks to develop predictive capabilities that can anticipate fouling behavior based on operational parameters and historical data, allowing for proactive intervention before critical thresholds are reached. This predictive element represents a significant advancement over traditional reactive approaches to fouling management.

The ultimate goal is to transform bundle maintenance from a periodic, often disruptive process into a targeted, data-driven activity that maximizes operational efficiency while minimizing downtime. By precisely mapping fouling patterns, maintenance resources can be directed to specific areas requiring attention rather than applying blanket cleaning procedures to entire systems.

Furthermore, this technology aims to establish standardized methodologies for fouling assessment that can be implemented across various heat exchanger designs and operational environments, creating a unified approach to what has traditionally been a highly specialized and equipment-specific challenge.

Market Needs Analysis

The global market for bundle fouling mapping technologies is experiencing significant growth, driven primarily by the increasing operational challenges in refineries and petrochemical plants. As facilities age and process more complex feedstocks, the incidence of heat exchanger fouling has risen dramatically, creating substantial demand for advanced detection and monitoring solutions. Industry reports indicate that fouling-related issues cost the refining industry billions of dollars annually through reduced thermal efficiency, increased energy consumption, and unplanned downtime.

Differential pressure (DP) monitoring systems represent the largest segment of this market, with adoption rates increasing by approximately 15% annually over the past five years. This growth reflects the industry's recognition that early fouling detection can significantly reduce maintenance costs and extend equipment life cycles. Refineries operating in regions with strict environmental regulations show particularly strong demand for these technologies, as they face additional pressure to optimize energy efficiency and reduce emissions.

Thermal signal analysis technologies are gaining market traction as complementary solutions to traditional DP monitoring. The market for advanced thermal mapping systems has doubled in size since 2018, reflecting the industry's growing appreciation for multi-parameter monitoring approaches. End-users increasingly demand integrated solutions that combine pressure differential data with thermal profiling to provide more comprehensive fouling assessments.

The inspection targeting segment shows the highest growth potential within this market, with demand for predictive maintenance solutions rising sharply. Plant operators seek technologies that can not only detect fouling but also predict optimal cleaning schedules and identify specific bundles requiring intervention. This shift from reactive to predictive maintenance represents a fundamental change in market requirements, with customers willing to pay premium prices for solutions that minimize downtime and optimize maintenance resources.

Regional analysis reveals that North America and the Middle East currently represent the largest markets for bundle fouling mapping technologies, accounting for approximately 60% of global demand. However, the Asia-Pacific region is expected to show the fastest growth rate over the next five years as refineries in China and India upgrade their monitoring capabilities to improve operational efficiency.

Customer feedback indicates increasing demand for cloud-based monitoring solutions and integration with existing plant management systems. The ability to access real-time fouling data remotely and incorporate this information into broader operational decision-making processes has become a key purchasing criterion for many end-users.

Differential pressure (DP) monitoring systems represent the largest segment of this market, with adoption rates increasing by approximately 15% annually over the past five years. This growth reflects the industry's recognition that early fouling detection can significantly reduce maintenance costs and extend equipment life cycles. Refineries operating in regions with strict environmental regulations show particularly strong demand for these technologies, as they face additional pressure to optimize energy efficiency and reduce emissions.

Thermal signal analysis technologies are gaining market traction as complementary solutions to traditional DP monitoring. The market for advanced thermal mapping systems has doubled in size since 2018, reflecting the industry's growing appreciation for multi-parameter monitoring approaches. End-users increasingly demand integrated solutions that combine pressure differential data with thermal profiling to provide more comprehensive fouling assessments.

The inspection targeting segment shows the highest growth potential within this market, with demand for predictive maintenance solutions rising sharply. Plant operators seek technologies that can not only detect fouling but also predict optimal cleaning schedules and identify specific bundles requiring intervention. This shift from reactive to predictive maintenance represents a fundamental change in market requirements, with customers willing to pay premium prices for solutions that minimize downtime and optimize maintenance resources.

Regional analysis reveals that North America and the Middle East currently represent the largest markets for bundle fouling mapping technologies, accounting for approximately 60% of global demand. However, the Asia-Pacific region is expected to show the fastest growth rate over the next five years as refineries in China and India upgrade their monitoring capabilities to improve operational efficiency.

Customer feedback indicates increasing demand for cloud-based monitoring solutions and integration with existing plant management systems. The ability to access real-time fouling data remotely and incorporate this information into broader operational decision-making processes has become a key purchasing criterion for many end-users.

Technical Challenges

Bundle fouling in heat exchangers presents significant technical challenges that impact operational efficiency and maintenance strategies across various industries. The primary challenge lies in accurately detecting and mapping fouling distribution within complex bundle geometries, as traditional methods often provide only partial or delayed insights into the fouling condition.

Differential pressure (DP) measurement techniques, while widely implemented, face substantial limitations in providing spatial resolution of fouling patterns. Current DP sensors typically offer only aggregate measurements across entire bundles, making it difficult to pinpoint specific fouling locations. Additionally, pressure drop signals can be influenced by multiple factors beyond fouling, including flow rate variations and fluid property changes, creating signal interpretation complexities.

Thermal signal analysis presents its own set of technical hurdles. Temperature measurements at bundle surfaces often fail to accurately represent internal fouling conditions due to thermal gradients and heat transfer complexities. The time lag between fouling formation and detectable thermal signatures further complicates real-time monitoring efforts. Current thermal imaging technologies also struggle with penetrating multiple tube layers to provide comprehensive bundle assessment.

Integration of multiple data streams (DP, thermal, flow) into coherent fouling maps remains technically challenging. Existing correlation models between these parameters and actual fouling conditions contain significant uncertainties, particularly in variable operating conditions. The industry lacks standardized algorithms for translating these diverse signals into actionable fouling intelligence.

Inspection targeting faces practical constraints related to bundle accessibility and inspection technology limitations. Many heat exchanger designs restrict physical access to critical areas, while non-destructive testing methods often cannot penetrate multiple tube layers effectively. The trade-off between inspection coverage and operational downtime creates additional complications for maintenance planning.

Data processing challenges are equally significant. The volume of sensor data generated during continuous monitoring requires sophisticated filtering and analysis capabilities. Distinguishing between normal operational variations and actual fouling signals demands advanced pattern recognition algorithms that are still evolving. Furthermore, historical data integration for predictive modeling remains underdeveloped in many industrial applications.

Cost-effective implementation of comprehensive fouling mapping systems represents perhaps the most practical challenge. The economic justification for advanced monitoring systems must balance installation and maintenance costs against potential efficiency gains and downtime reduction. This economic equation varies significantly across different industries and operational contexts.

Differential pressure (DP) measurement techniques, while widely implemented, face substantial limitations in providing spatial resolution of fouling patterns. Current DP sensors typically offer only aggregate measurements across entire bundles, making it difficult to pinpoint specific fouling locations. Additionally, pressure drop signals can be influenced by multiple factors beyond fouling, including flow rate variations and fluid property changes, creating signal interpretation complexities.

Thermal signal analysis presents its own set of technical hurdles. Temperature measurements at bundle surfaces often fail to accurately represent internal fouling conditions due to thermal gradients and heat transfer complexities. The time lag between fouling formation and detectable thermal signatures further complicates real-time monitoring efforts. Current thermal imaging technologies also struggle with penetrating multiple tube layers to provide comprehensive bundle assessment.

Integration of multiple data streams (DP, thermal, flow) into coherent fouling maps remains technically challenging. Existing correlation models between these parameters and actual fouling conditions contain significant uncertainties, particularly in variable operating conditions. The industry lacks standardized algorithms for translating these diverse signals into actionable fouling intelligence.

Inspection targeting faces practical constraints related to bundle accessibility and inspection technology limitations. Many heat exchanger designs restrict physical access to critical areas, while non-destructive testing methods often cannot penetrate multiple tube layers effectively. The trade-off between inspection coverage and operational downtime creates additional complications for maintenance planning.

Data processing challenges are equally significant. The volume of sensor data generated during continuous monitoring requires sophisticated filtering and analysis capabilities. Distinguishing between normal operational variations and actual fouling signals demands advanced pattern recognition algorithms that are still evolving. Furthermore, historical data integration for predictive modeling remains underdeveloped in many industrial applications.

Cost-effective implementation of comprehensive fouling mapping systems represents perhaps the most practical challenge. The economic justification for advanced monitoring systems must balance installation and maintenance costs against potential efficiency gains and downtime reduction. This economic equation varies significantly across different industries and operational contexts.

Current DP Monitoring Solutions

01 Monitoring bundle fouling using differential pressure trends

Systems for monitoring bundle fouling in heat exchangers by analyzing differential pressure (DP) trends. These systems track changes in pressure across heat exchanger bundles to detect fouling buildup. By establishing baseline measurements and monitoring deviations, operators can identify when fouling reaches critical levels requiring maintenance. This approach enables predictive maintenance scheduling based on actual fouling conditions rather than fixed time intervals.- Monitoring bundle fouling through differential pressure (DP) trends: Systems for monitoring bundle fouling in heat exchangers by analyzing differential pressure trends. These systems track changes in pressure across heat exchanger bundles to detect fouling buildup. By establishing baseline measurements and monitoring deviations, operators can identify when fouling reaches critical levels requiring intervention. This approach enables predictive maintenance and helps prevent efficiency losses in thermal systems.

- Thermal signal analysis for fouling detection: Methods for detecting fouling in heat exchange equipment through thermal signal analysis. These techniques involve monitoring temperature distributions and thermal patterns across bundle surfaces to identify anomalies indicative of fouling. Advanced sensors and thermal imaging technologies capture temperature variations that reveal fouling hotspots. This approach provides early detection of fouling issues before they significantly impact system performance.

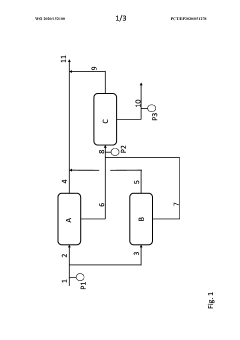

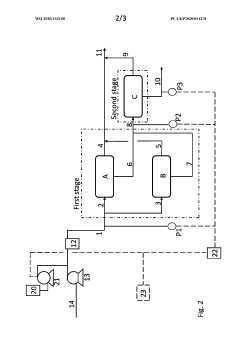

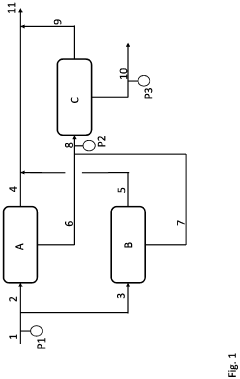

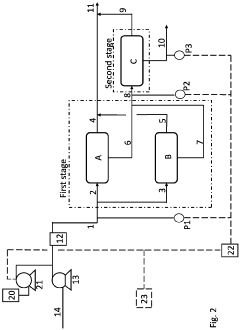

- Integrated fouling mapping systems combining multiple signals: Comprehensive fouling mapping systems that integrate multiple signal types including differential pressure, thermal readings, and flow measurements. These systems create detailed fouling distribution maps across heat exchanger bundles by correlating data from various sensors. The integrated approach provides more accurate fouling characterization than single-parameter monitoring, enabling targeted cleaning and maintenance strategies for affected areas.

- Real-time monitoring and trend analysis for fouling prediction: Real-time monitoring systems that analyze fouling trends to predict future fouling behavior in heat exchanger bundles. These systems employ algorithms that process historical and current data to forecast fouling progression. By identifying patterns in differential pressure and thermal signal changes over time, operators can anticipate maintenance needs and optimize cleaning schedules, reducing unexpected downtime and extending equipment life.

- Automated fouling detection and alert systems: Automated systems that detect bundle fouling conditions and generate alerts when predefined thresholds are exceeded. These systems continuously monitor differential pressure trends and thermal signals, automatically identifying abnormal patterns indicative of fouling. When critical conditions are detected, the systems trigger notifications to maintenance personnel, enabling prompt intervention before equipment performance is significantly compromised.

02 Thermal signal analysis for fouling detection

Methods for detecting fouling in heat exchange equipment through thermal signal analysis. These techniques involve monitoring temperature distributions and thermal patterns across bundle surfaces to identify anomalies indicating fouling deposits. Advanced thermal imaging and temperature sensors provide data that can be analyzed to create thermal maps of equipment, highlighting areas where heat transfer efficiency is compromised due to fouling buildup.Expand Specific Solutions03 Integrated monitoring systems combining DP and thermal data

Comprehensive monitoring solutions that integrate both differential pressure trends and thermal signals to provide more accurate fouling assessments. These systems correlate multiple data streams to create detailed fouling maps of heat exchanger bundles. By combining pressure and temperature measurements, these solutions can distinguish between different types of fouling and provide more precise location information, enabling targeted cleaning and maintenance procedures.Expand Specific Solutions04 Data visualization and mapping techniques for fouling analysis

Advanced visualization tools and mapping techniques that transform raw fouling data into actionable insights. These solutions create visual representations of fouling distribution across heat exchanger bundles, enabling operators to quickly identify problem areas. The mapping technologies include color-coded heat maps, 3D visualizations, and trend analysis displays that show fouling progression over time, facilitating better decision-making for maintenance scheduling.Expand Specific Solutions05 Predictive analytics for fouling trend forecasting

Predictive analytics systems that use historical DP trends and thermal signal data to forecast future fouling development. These solutions employ machine learning algorithms and statistical models to predict when fouling will reach critical thresholds. By analyzing patterns in pressure drops and temperature distributions, these systems can estimate remaining operational time before maintenance is required, allowing for optimal scheduling of cleaning procedures and minimizing unexpected downtime.Expand Specific Solutions

Industry Leaders

Bundle fouling mapping technology is currently in an early growth phase, with increasing adoption across the petrochemical industry. The market size is expanding as refineries seek to optimize operations and reduce maintenance costs, estimated to reach significant scale within the next five years. Technologically, the field shows moderate maturity with advanced players like PetroChina, Sinopec, and China Petroleum & Chemical Corp leading development through integration of thermal imaging, pressure differential monitoring, and predictive analytics. Companies including Noria Water Technologies and BL Technology are advancing the field through AI/ML applications, while research institutions like King Fahd University of Petroleum & Minerals and IFP Energies Nouvelles contribute fundamental innovations in fouling detection methodologies and signal processing techniques.

PetroChina Co., Ltd.

Technical Solution: PetroChina has developed a comprehensive bundle fouling mapping system that combines traditional differential pressure monitoring with advanced thermal imaging and machine learning algorithms. Their solution employs a distributed sensor network that captures both macro and micro-level fouling patterns across heat exchanger bundles. The system utilizes infrared thermography coupled with proprietary image processing techniques to create detailed thermal maps that identify fouling hotspots with high spatial resolution. PetroChina's approach incorporates real-time data analytics that correlate process variables with fouling patterns, enabling operators to understand root causes and optimize operating conditions accordingly. Their technology includes an intelligent inspection targeting module that uses historical fouling data and current measurements to recommend optimal cleaning schedules and methods for specific bundle sections, maximizing maintenance efficiency while minimizing production disruptions.

Strengths: Comprehensive integration of multiple data sources provides detailed fouling characterization. The root cause analysis capabilities help prevent recurrence of fouling issues. Weaknesses: System complexity requires significant operator training and ongoing technical support to maintain optimal performance.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed an advanced bundle fouling mapping system that integrates differential pressure (DP) monitoring with thermal imaging technology. Their solution employs a network of strategically placed sensors throughout heat exchanger bundles to create real-time fouling distribution maps. The system utilizes machine learning algorithms to analyze historical DP trends against thermal signal patterns, enabling predictive maintenance scheduling. Sinopec's approach incorporates multi-point temperature measurement using fiber optic sensors that can withstand harsh refinery conditions, providing high-resolution thermal mapping of fouling deposits. Their technology includes automated inspection targeting that directs maintenance crews to specific bundle sections requiring cleaning, significantly reducing downtime and improving operational efficiency.

Strengths: Comprehensive integration of DP and thermal data provides more accurate fouling detection than single-parameter systems. The predictive maintenance capabilities reduce unplanned shutdowns. Weaknesses: System requires significant initial investment and integration with existing infrastructure can be challenging in older refineries.

Thermal Mapping Technologies

Fouling type detection

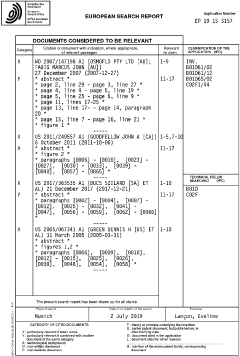

PatentWO2020152100A1

Innovation

- A system with pressure sensors and a data processor that estimates differential pressure slopes to differentiate between types of fouling (mineral scaling, colloidal/algae, biofouling, and low permeability) and recommends specific cleaning actions, such as acid or alkaline soaks, to tailor cleaning procedures based on the identified fouling type.

Fouling type detection

PatentPendingEP3685908A1

Innovation

- A system with pressure sensors and a data processor that estimates differential pressure slopes to differentiate between types of fouling (mineral scaling, colloidal/algae, biological, and low permeability) and automatically recommends or initiates targeted cleaning actions, reducing unnecessary chemical use and downtime.

Regulatory Compliance

Regulatory compliance in the context of bundle fouling mapping represents a critical dimension for industrial operations, particularly in sectors such as petrochemical processing, power generation, and refining. The monitoring and management of heat exchanger fouling must adhere to increasingly stringent environmental and safety regulations across global jurisdictions.

The Environmental Protection Agency (EPA) in the United States has established specific guidelines under the Clean Air Act and Clean Water Act that directly impact fouling management practices. These regulations mandate regular monitoring and reporting of thermal efficiency in industrial heat exchange systems, with penalties for operations that fail to maintain minimum efficiency standards due to excessive fouling.

In the European Union, the Industrial Emissions Directive (IED) imposes strict requirements for energy efficiency and emissions control, necessitating advanced fouling detection and management systems. Companies must demonstrate continuous monitoring capabilities and implement best available techniques (BAT) for fouling prevention and remediation.

The Occupational Safety and Health Administration (OSHA) regulations further complicate compliance requirements by establishing standards for worker safety during inspection and cleaning operations. These standards necessitate the development of non-invasive fouling mapping techniques that minimize human exposure to hazardous environments.

Recent regulatory trends show increasing focus on predictive maintenance approaches rather than reactive measures. Regulatory bodies are beginning to recognize differential pressure (DP) trending and thermal signal analysis as acceptable compliance methodologies when properly documented and validated. This shift presents both opportunities and challenges for organizations implementing bundle fouling mapping technologies.

Insurance requirements represent another compliance dimension, with many underwriters now requiring documented fouling monitoring programs as conditions for coverage of industrial equipment. The financial implications of non-compliance extend beyond regulatory fines to include increased insurance premiums and potential coverage limitations.

International standards organizations, including ISO and ASME, have developed technical standards specifically addressing heat exchanger performance monitoring and fouling assessment methodologies. Compliance with these standards often serves as a proxy for regulatory compliance and represents industry best practices for fouling management.

The integration of digital monitoring systems for fouling mapping introduces additional compliance considerations related to data integrity, cybersecurity, and record retention. Regulatory frameworks increasingly require verifiable data trails demonstrating consistent monitoring and timely intervention when fouling thresholds are exceeded.

The Environmental Protection Agency (EPA) in the United States has established specific guidelines under the Clean Air Act and Clean Water Act that directly impact fouling management practices. These regulations mandate regular monitoring and reporting of thermal efficiency in industrial heat exchange systems, with penalties for operations that fail to maintain minimum efficiency standards due to excessive fouling.

In the European Union, the Industrial Emissions Directive (IED) imposes strict requirements for energy efficiency and emissions control, necessitating advanced fouling detection and management systems. Companies must demonstrate continuous monitoring capabilities and implement best available techniques (BAT) for fouling prevention and remediation.

The Occupational Safety and Health Administration (OSHA) regulations further complicate compliance requirements by establishing standards for worker safety during inspection and cleaning operations. These standards necessitate the development of non-invasive fouling mapping techniques that minimize human exposure to hazardous environments.

Recent regulatory trends show increasing focus on predictive maintenance approaches rather than reactive measures. Regulatory bodies are beginning to recognize differential pressure (DP) trending and thermal signal analysis as acceptable compliance methodologies when properly documented and validated. This shift presents both opportunities and challenges for organizations implementing bundle fouling mapping technologies.

Insurance requirements represent another compliance dimension, with many underwriters now requiring documented fouling monitoring programs as conditions for coverage of industrial equipment. The financial implications of non-compliance extend beyond regulatory fines to include increased insurance premiums and potential coverage limitations.

International standards organizations, including ISO and ASME, have developed technical standards specifically addressing heat exchanger performance monitoring and fouling assessment methodologies. Compliance with these standards often serves as a proxy for regulatory compliance and represents industry best practices for fouling management.

The integration of digital monitoring systems for fouling mapping introduces additional compliance considerations related to data integrity, cybersecurity, and record retention. Regulatory frameworks increasingly require verifiable data trails demonstrating consistent monitoring and timely intervention when fouling thresholds are exceeded.

Economic Impact Assessment

The economic impact of bundle fouling in heat exchangers and similar equipment extends far beyond immediate operational concerns, affecting the entire value chain of process industries. Fouling-related inefficiencies cost the global process industry an estimated $4.5-5.7 billion annually, with petroleum refining bearing approximately 40% of these costs.

When examining direct financial impacts, bundle fouling significantly increases energy consumption due to reduced heat transfer efficiency. Studies indicate that a moderate fouling layer can decrease thermal efficiency by 20-30%, translating to proportional increases in energy costs. For a medium-sized refinery processing 100,000 barrels per day, this inefficiency can represent additional energy expenditures of $2-3 million annually.

Maintenance costs constitute another substantial economic burden. The cleaning and inspection of fouled bundles typically requires planned shutdowns, with each day of downtime potentially costing $500,000-$1,000,000 in lost production for larger facilities. Advanced mapping technologies that accurately target fouling can reduce cleaning time by 30-40%, representing significant cost savings.

Equipment lifecycle considerations reveal further economic implications. Accelerated corrosion and mechanical stress from fouling can reduce the operational lifespan of heat exchangers by 15-25%. Premature replacement of these components represents a major capital expenditure, with a single large heat exchanger potentially costing $1-2 million.

The implementation of effective bundle fouling mapping technologies demonstrates compelling return on investment metrics. Facilities employing advanced DP trend analysis and thermal signal monitoring report payback periods of 6-18 months on their monitoring investments. One case study from a European petrochemical facility documented annual savings of $1.7 million after implementing targeted inspection systems based on these technologies.

From a broader economic perspective, improved fouling management contributes to sustainability goals that increasingly carry financial implications. Reduced energy consumption translates directly to lower carbon emissions, potentially saving facilities millions in carbon taxes or credits depending on regulatory frameworks. Additionally, more efficient operations reduce water consumption and waste generation, factors increasingly subject to environmental compliance costs.

The competitive advantage gained through superior fouling management should not be underestimated. Companies implementing advanced bundle fouling mapping technologies report 5-8% improvements in overall equipment effectiveness (OEE), translating to enhanced market position and profitability in highly competitive process industries.

When examining direct financial impacts, bundle fouling significantly increases energy consumption due to reduced heat transfer efficiency. Studies indicate that a moderate fouling layer can decrease thermal efficiency by 20-30%, translating to proportional increases in energy costs. For a medium-sized refinery processing 100,000 barrels per day, this inefficiency can represent additional energy expenditures of $2-3 million annually.

Maintenance costs constitute another substantial economic burden. The cleaning and inspection of fouled bundles typically requires planned shutdowns, with each day of downtime potentially costing $500,000-$1,000,000 in lost production for larger facilities. Advanced mapping technologies that accurately target fouling can reduce cleaning time by 30-40%, representing significant cost savings.

Equipment lifecycle considerations reveal further economic implications. Accelerated corrosion and mechanical stress from fouling can reduce the operational lifespan of heat exchangers by 15-25%. Premature replacement of these components represents a major capital expenditure, with a single large heat exchanger potentially costing $1-2 million.

The implementation of effective bundle fouling mapping technologies demonstrates compelling return on investment metrics. Facilities employing advanced DP trend analysis and thermal signal monitoring report payback periods of 6-18 months on their monitoring investments. One case study from a European petrochemical facility documented annual savings of $1.7 million after implementing targeted inspection systems based on these technologies.

From a broader economic perspective, improved fouling management contributes to sustainability goals that increasingly carry financial implications. Reduced energy consumption translates directly to lower carbon emissions, potentially saving facilities millions in carbon taxes or credits depending on regulatory frameworks. Additionally, more efficient operations reduce water consumption and waste generation, factors increasingly subject to environmental compliance costs.

The competitive advantage gained through superior fouling management should not be underestimated. Companies implementing advanced bundle fouling mapping technologies report 5-8% improvements in overall equipment effectiveness (OEE), translating to enhanced market position and profitability in highly competitive process industries.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!