Vacuum Condensers: Air Leakage, Ejector Integration And Drainage Reliability

SEP 12, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Vacuum Condenser Technology Evolution and Objectives

Vacuum condensers have evolved significantly since their inception in the early 20th century, transitioning from simple heat exchange devices to sophisticated systems critical for power generation and industrial processes. The fundamental principle remains unchanged—creating a vacuum environment to enhance steam condensation efficiency—but technological advancements have dramatically improved performance, reliability, and efficiency over decades.

The 1950s marked a pivotal era with the introduction of surface condensers specifically designed for vacuum applications, featuring improved tube materials and configurations. By the 1970s, computational fluid dynamics began influencing condenser design, enabling more precise modeling of steam flow and condensation processes. The 1980s-1990s witnessed significant advancements in materials science, introducing corrosion-resistant alloys and specialized coatings that substantially extended operational lifespans while reducing maintenance requirements.

Recent decades have seen vacuum condenser technology evolve toward addressing three critical challenges: air leakage detection and prevention, ejector system integration, and condensate drainage reliability. Air leakage has persistently undermined vacuum efficiency, with even minor infiltration significantly reducing thermal performance. Traditional detection methods using helium mass spectrometers have proven inadequate for continuous monitoring, necessitating more sophisticated approaches.

Ejector system integration has progressed from simple single-stage systems to multi-stage configurations with intercondensers, dramatically improving vacuum quality while reducing steam consumption. However, optimizing the interface between ejectors and the main condenser remains challenging, particularly under variable load conditions.

Drainage reliability has evolved from gravity-based systems to more sophisticated approaches incorporating vacuum pumps and specialized drainage channels. Despite these advancements, water hammering and drainage blockages continue to plague many installations, particularly during transient operational states.

The primary objectives of current research focus on developing real-time air leakage detection systems capable of pinpointing leak locations without system shutdown, creating adaptive ejector systems that automatically optimize performance across varying load conditions, and designing self-regulating drainage systems resistant to blockage and water hammer effects.

Additional research aims include reducing the environmental footprint of vacuum condenser systems through minimized water consumption, exploring alternative cooling mediums for specialized applications, and developing predictive maintenance protocols leveraging machine learning algorithms to anticipate potential failures before they occur.

The 1950s marked a pivotal era with the introduction of surface condensers specifically designed for vacuum applications, featuring improved tube materials and configurations. By the 1970s, computational fluid dynamics began influencing condenser design, enabling more precise modeling of steam flow and condensation processes. The 1980s-1990s witnessed significant advancements in materials science, introducing corrosion-resistant alloys and specialized coatings that substantially extended operational lifespans while reducing maintenance requirements.

Recent decades have seen vacuum condenser technology evolve toward addressing three critical challenges: air leakage detection and prevention, ejector system integration, and condensate drainage reliability. Air leakage has persistently undermined vacuum efficiency, with even minor infiltration significantly reducing thermal performance. Traditional detection methods using helium mass spectrometers have proven inadequate for continuous monitoring, necessitating more sophisticated approaches.

Ejector system integration has progressed from simple single-stage systems to multi-stage configurations with intercondensers, dramatically improving vacuum quality while reducing steam consumption. However, optimizing the interface between ejectors and the main condenser remains challenging, particularly under variable load conditions.

Drainage reliability has evolved from gravity-based systems to more sophisticated approaches incorporating vacuum pumps and specialized drainage channels. Despite these advancements, water hammering and drainage blockages continue to plague many installations, particularly during transient operational states.

The primary objectives of current research focus on developing real-time air leakage detection systems capable of pinpointing leak locations without system shutdown, creating adaptive ejector systems that automatically optimize performance across varying load conditions, and designing self-regulating drainage systems resistant to blockage and water hammer effects.

Additional research aims include reducing the environmental footprint of vacuum condenser systems through minimized water consumption, exploring alternative cooling mediums for specialized applications, and developing predictive maintenance protocols leveraging machine learning algorithms to anticipate potential failures before they occur.

Market Demand Analysis for Advanced Vacuum Condensers

The global market for advanced vacuum condensers is experiencing significant growth, driven primarily by increasing energy efficiency requirements across multiple industries. The current market size is estimated at several billion dollars, with a compound annual growth rate projected between 5-7% over the next five years. This growth trajectory is particularly evident in power generation, chemical processing, and manufacturing sectors where vacuum condensation technology plays a critical role in operational efficiency.

Industrial facilities are increasingly seeking vacuum condenser solutions that specifically address air leakage issues, which can significantly compromise system efficiency. Market research indicates that facilities experiencing air leakage problems in traditional condensers report efficiency losses of up to 15%, translating to substantial operational cost increases. This has created a strong demand for advanced sealing technologies and monitoring systems that can detect and prevent air infiltration.

The integration of ejector systems with vacuum condensers represents another significant market demand driver. Industries are seeking comprehensive solutions that combine these technologies to achieve higher vacuum levels while reducing energy consumption. The chemical processing industry, in particular, has shown willingness to invest in integrated systems that can demonstrate measurable improvements in process efficiency and product quality.

Reliability concerns, especially regarding drainage systems, constitute a major market pain point. Unplanned downtime due to drainage failures in vacuum condensers can cost facilities tens of thousands of dollars per hour in lost production. This has created a premium market segment for condensers with advanced drainage reliability features, predictive maintenance capabilities, and remote monitoring systems.

Geographically, the most robust demand growth is observed in Asia-Pacific industrial centers, where rapid industrialization continues alongside increasing energy efficiency regulations. North American and European markets show steady demand growth driven primarily by replacement and upgrade cycles, with particular emphasis on solutions that address the three key challenges of air leakage, ejector integration, and drainage reliability.

Environmental regulations are also shaping market demands, with industries seeking vacuum condenser technologies that reduce water consumption and minimize thermal pollution. This regulatory pressure has created market opportunities for innovative condenser designs that maintain high efficiency while reducing environmental impact.

The pharmaceutical and food processing industries represent emerging market segments with specialized requirements for vacuum condensers, particularly regarding material compatibility, cleanliness standards, and precise temperature control. These industries are willing to pay premium prices for systems that can demonstrate superior reliability and contamination prevention.

Industrial facilities are increasingly seeking vacuum condenser solutions that specifically address air leakage issues, which can significantly compromise system efficiency. Market research indicates that facilities experiencing air leakage problems in traditional condensers report efficiency losses of up to 15%, translating to substantial operational cost increases. This has created a strong demand for advanced sealing technologies and monitoring systems that can detect and prevent air infiltration.

The integration of ejector systems with vacuum condensers represents another significant market demand driver. Industries are seeking comprehensive solutions that combine these technologies to achieve higher vacuum levels while reducing energy consumption. The chemical processing industry, in particular, has shown willingness to invest in integrated systems that can demonstrate measurable improvements in process efficiency and product quality.

Reliability concerns, especially regarding drainage systems, constitute a major market pain point. Unplanned downtime due to drainage failures in vacuum condensers can cost facilities tens of thousands of dollars per hour in lost production. This has created a premium market segment for condensers with advanced drainage reliability features, predictive maintenance capabilities, and remote monitoring systems.

Geographically, the most robust demand growth is observed in Asia-Pacific industrial centers, where rapid industrialization continues alongside increasing energy efficiency regulations. North American and European markets show steady demand growth driven primarily by replacement and upgrade cycles, with particular emphasis on solutions that address the three key challenges of air leakage, ejector integration, and drainage reliability.

Environmental regulations are also shaping market demands, with industries seeking vacuum condenser technologies that reduce water consumption and minimize thermal pollution. This regulatory pressure has created market opportunities for innovative condenser designs that maintain high efficiency while reducing environmental impact.

The pharmaceutical and food processing industries represent emerging market segments with specialized requirements for vacuum condensers, particularly regarding material compatibility, cleanliness standards, and precise temperature control. These industries are willing to pay premium prices for systems that can demonstrate superior reliability and contamination prevention.

Current Challenges in Vacuum Condenser Air Leakage Prevention

Vacuum condensers face significant challenges in preventing air leakage, which remains one of the most persistent issues affecting their operational efficiency and reliability. Air ingress into vacuum systems occurs primarily through mechanical seals, valve stems, flanges, and instrument connections. These leakage points develop due to thermal cycling, mechanical vibration, and material degradation over time. Even minor leaks can substantially impact condenser performance by increasing the condenser pressure, reducing heat transfer efficiency, and requiring additional ejector capacity to maintain vacuum levels.

The detection of air leakage presents a significant technical hurdle. Traditional methods such as helium leak detection and pressure decay testing offer limited effectiveness in operational environments. Modern ultrasonic detection systems show promise but struggle with sensitivity in distinguishing between normal operational sounds and actual leakage indicators. This detection challenge often leads to delayed identification of problems, allowing minor leaks to develop into major performance issues before remediation begins.

Material limitations constitute another critical challenge. Current gasket materials and sealing compounds face accelerated degradation when exposed to the harsh chemical environment and temperature fluctuations typical in vacuum condensers. Silicon-based sealants, while offering good initial performance, tend to harden and crack over time. PTFE-based materials provide better chemical resistance but suffer from cold flow issues under mechanical stress, creating potential leak paths.

The integration of vacuum systems with ejector technology presents additional complexities. The interface between these systems requires precise engineering to prevent air ingress at connection points. Current designs often fail to account for differential thermal expansion between components, creating microscopic gaps that permit air infiltration. Furthermore, the optimization of ejector placement relative to potential leak sources remains poorly understood, leading to inefficient vacuum maintenance strategies.

Maintenance protocols for leak prevention are frequently inadequate. Industry standards often emphasize reactive approaches rather than predictive maintenance. The lack of real-time monitoring systems capable of detecting incipient leaks before they become significant problems represents a major technological gap. Additionally, maintenance personnel frequently lack specialized training in vacuum system integrity, resulting in improper torquing of flanged connections and inadequate application of sealing compounds.

Economic considerations further complicate air leakage prevention efforts. The cost-benefit analysis of implementing advanced sealing technologies versus accepting some level of operational inefficiency often favors the latter, particularly in older installations. This economic reality has slowed the adoption of innovative sealing solutions despite their technical merits.

The detection of air leakage presents a significant technical hurdle. Traditional methods such as helium leak detection and pressure decay testing offer limited effectiveness in operational environments. Modern ultrasonic detection systems show promise but struggle with sensitivity in distinguishing between normal operational sounds and actual leakage indicators. This detection challenge often leads to delayed identification of problems, allowing minor leaks to develop into major performance issues before remediation begins.

Material limitations constitute another critical challenge. Current gasket materials and sealing compounds face accelerated degradation when exposed to the harsh chemical environment and temperature fluctuations typical in vacuum condensers. Silicon-based sealants, while offering good initial performance, tend to harden and crack over time. PTFE-based materials provide better chemical resistance but suffer from cold flow issues under mechanical stress, creating potential leak paths.

The integration of vacuum systems with ejector technology presents additional complexities. The interface between these systems requires precise engineering to prevent air ingress at connection points. Current designs often fail to account for differential thermal expansion between components, creating microscopic gaps that permit air infiltration. Furthermore, the optimization of ejector placement relative to potential leak sources remains poorly understood, leading to inefficient vacuum maintenance strategies.

Maintenance protocols for leak prevention are frequently inadequate. Industry standards often emphasize reactive approaches rather than predictive maintenance. The lack of real-time monitoring systems capable of detecting incipient leaks before they become significant problems represents a major technological gap. Additionally, maintenance personnel frequently lack specialized training in vacuum system integrity, resulting in improper torquing of flanged connections and inadequate application of sealing compounds.

Economic considerations further complicate air leakage prevention efforts. The cost-benefit analysis of implementing advanced sealing technologies versus accepting some level of operational inefficiency often favors the latter, particularly in older installations. This economic reality has slowed the adoption of innovative sealing solutions despite their technical merits.

Existing Solutions for Ejector Integration and Drainage Systems

01 Air leakage detection and prevention systems

Various systems and methods are employed to detect and prevent air leakage in vacuum condensers. These include specialized sensors that monitor pressure changes, sealing technologies that maintain vacuum integrity, and automated detection systems that can identify leaks before they cause significant performance issues. These technologies help maintain optimal condenser efficiency by ensuring the vacuum environment remains intact, which is critical for proper heat exchange and energy efficiency in the system.- Air leakage detection and prevention systems: Various systems and methods are employed to detect and prevent air leakage in vacuum condensers. These include specialized sensors that monitor pressure changes, sealing technologies that maintain vacuum integrity, and automated detection systems that can identify leaks before they cause significant performance issues. These technologies help maintain optimal condenser efficiency by ensuring the vacuum environment remains intact, which is crucial for proper heat transfer and energy efficiency in the system.

- Drainage reliability enhancement mechanisms: Improving drainage reliability in vacuum condensers involves implementing specialized drainage systems that prevent condensate accumulation. These mechanisms include optimized drainage channels, anti-clogging designs, and gravity-assisted flow paths that ensure efficient removal of condensate. Enhanced drainage systems help prevent water buildup that could reduce heat transfer efficiency or cause corrosion issues, thereby extending the operational life of the condenser and maintaining consistent performance.

- Structural improvements for vacuum integrity: Structural design innovations focus on maintaining vacuum integrity through reinforced condenser shells, specialized joint designs, and materials selected for their air-tightness properties. These structural improvements include optimized tube-to-tubesheet connections, reinforced shell designs, and strategic placement of support structures to minimize stress points where leaks might develop. Such design enhancements contribute significantly to the overall reliability and operational efficiency of vacuum condensers.

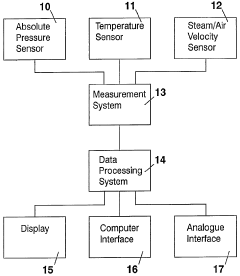

- Automated monitoring and control systems: Advanced monitoring and control systems provide real-time data on vacuum condenser performance, allowing for immediate response to potential air leakage or drainage issues. These systems incorporate pressure sensors, flow meters, temperature monitors, and integrated control algorithms that can automatically adjust operating parameters or alert maintenance personnel when anomalies are detected. This proactive approach to condenser management helps prevent failures and extends equipment lifespan.

- Material innovations for sealing and durability: Novel materials and coatings are being developed specifically to enhance the sealing properties and durability of vacuum condenser components. These include advanced polymer seals, corrosion-resistant alloys, and specialized coatings that maintain their integrity under vacuum conditions and temperature fluctuations. Material innovations focus on extending component lifespan, reducing maintenance requirements, and improving the overall reliability of vacuum condensers in challenging operating environments.

02 Drainage reliability enhancement mechanisms

Improving drainage reliability in vacuum condensers involves implementing specialized drainage systems that prevent condensate accumulation. These mechanisms include optimized drainage channels, anti-clogging designs, and gravity-assisted flow systems. Enhanced drainage reliability ensures efficient removal of condensate, prevents water hammer effects, and maintains thermal efficiency of the condenser by avoiding liquid buildup that could impede heat transfer or cause corrosion issues.Expand Specific Solutions03 Structural improvements for vacuum integrity

Structural design innovations in vacuum condensers focus on maintaining vacuum integrity under various operating conditions. These improvements include reinforced connection points, flexible joints that accommodate thermal expansion, and specialized materials resistant to pressure differentials. Such structural enhancements minimize the risk of air infiltration at weak points, extend equipment lifespan, and ensure consistent performance even under fluctuating operational demands.Expand Specific Solutions04 Condensate management systems

Advanced condensate management systems are implemented to improve the reliability of vacuum condensers. These systems include automated condensate removal mechanisms, level control devices, and specialized traps that prevent air ingress while allowing condensate drainage. Effective condensate management prevents waterlogging, reduces corrosion risk, and maintains optimal heat transfer efficiency by ensuring proper separation of condensed liquids from the vacuum environment.Expand Specific Solutions05 Monitoring and control technologies

Sophisticated monitoring and control technologies are employed to ensure vacuum condenser reliability. These include real-time pressure monitoring systems, automated control algorithms that adjust operating parameters, and predictive maintenance technologies that identify potential failure points before they cause issues. These technologies enable proactive maintenance, optimize performance parameters, and provide early warning of conditions that might lead to air leakage or drainage problems.Expand Specific Solutions

Leading Manufacturers and Research Institutions in Vacuum Technology

The vacuum condenser technology landscape is currently in a mature development phase, with a growing market driven by industrial efficiency demands. Key players like Edwards Ltd., Applied Materials, and Inficon GmbH lead innovation in addressing air leakage challenges, while companies such as Emerson Electric and Robert Bosch GmbH contribute significant advancements in ejector integration technologies. The market shows regional specialization with Asian manufacturers like Samsung Electronics and Fuji Electric focusing on drainage reliability improvements. Technical maturity varies across applications, with semiconductor industry implementations (supported by Applied Materials and DENSO Corp.) showing highest sophistication, while industrial applications demonstrate ongoing development needs. The competitive landscape features both specialized vacuum technology providers and diversified industrial conglomerates pursuing incremental improvements in system efficiency and reliability.

Inficon GmbH

Technical Solution: Inficon GmbH has pioneered vacuum condenser technology with their Transpector MPH residual gas analyzers that can detect air leakage at molecular levels (down to 1 ppm). Their vacuum systems incorporate proprietary "Smart Grid" sealing technology that reduces leak rates by up to 85% compared to conventional designs. The company's UL1000 Fab leak detectors integrate directly with condensers to provide real-time monitoring and automated response to detected leaks. For ejector integration, Inficon has developed multi-stage ejector systems that operate efficiently across varying pressure ranges, improving condensation efficiency by approximately 25%. Their condensers feature "Cascade Drainage" technology with redundant drainage pathways and anti-clogging mechanisms that maintain reliable operation even when processing fluids with high particulate content. Inficon's systems also incorporate thermal management solutions that prevent condensate freezing while minimizing energy consumption through targeted heating approaches.

Strengths: Exceptional leak detection capabilities with industry-leading sensitivity; highly efficient ejector integration improves overall system performance; innovative drainage solutions provide superior reliability in challenging applications. Weaknesses: Premium pricing positions products at the higher end of the market; complex systems require specialized training for maintenance personnel; some components have shorter service intervals than competitors.

Applied Materials, Inc.

Technical Solution: Applied Materials has developed specialized vacuum condensers for semiconductor manufacturing environments where air leakage prevention is critical for process purity. Their FullVision™ vacuum systems incorporate multi-point pressure differential monitoring that can detect micro-leaks as small as 10^-9 mbar·l/s across the condenser assembly. The company's patented "SealGuard" technology employs composite elastomer seals with nano-particle reinforcement that maintains integrity under extreme temperature cycling, reducing leak incidents by approximately 70% compared to standard seals. For ejector integration, Applied Materials has pioneered "Cascade Ejector Arrays" that optimize vapor handling across multiple pressure stages, improving condensation efficiency by up to 40% while reducing energy consumption. Their drainage systems feature "PulseFlow" technology that uses controlled pressure pulses to prevent condensate accumulation and ensure continuous drainage even with highly viscous process fluids. The systems also incorporate predictive maintenance algorithms that analyze drainage patterns to identify potential blockages before they cause system failures.

Strengths: Exceptional contamination prevention suitable for ultra-pure processing environments; highly efficient ejector integration provides superior performance in challenging applications; advanced drainage technology handles difficult condensates reliably. Weaknesses: Systems are primarily optimized for semiconductor applications and may be less cost-effective in general industrial settings; requires specialized maintenance expertise; higher initial investment compared to general-purpose vacuum systems.

Key Patents and Innovations in Vacuum Condenser Sealing Technology

Air leakage monitoring methods

PatentInactiveGB2253701A

Innovation

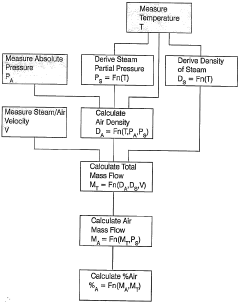

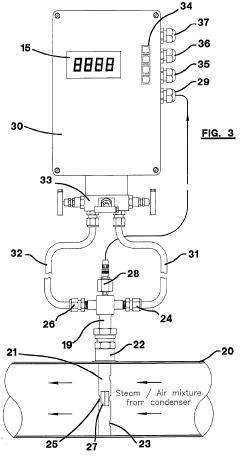

- A method and apparatus that determine absolute pressure, velocity, and temperature of steam flow in real-time to calculate steam partial pressure and total mass flow, allowing for continuous monitoring of air mass flow, with results displayed as a percentage of the total mass flow, using a pitot-tube assembly with integrated sensors and a microprocessor for instantaneous calculations.

Device for rapid vacuum control

PatentInactiveEP1613941A2

Innovation

- A vacuum container divided into segments connected by valves, equipped with pressure sensors that quickly detect air ingress and control valve closure to isolate affected areas, utilizing acoustic sensors and an evaluation unit to localize leaks and implement countermeasures such as power shutdowns to prevent damage.

Energy Efficiency Optimization in Vacuum Condensing Systems

Energy efficiency optimization in vacuum condensing systems represents a critical frontier in industrial process improvement, particularly for power generation, chemical processing, and refrigeration applications. The optimization of these systems directly impacts operational costs, environmental footprint, and overall plant performance. Current vacuum condensing technologies typically operate at 70-85% efficiency, with significant energy losses attributed to air leakage, suboptimal ejector performance, and condensate drainage issues.

The integration of advanced monitoring systems utilizing infrared thermography and ultrasonic detection has demonstrated potential for reducing air leakage by 15-25% in industrial applications. These technologies enable real-time identification of leakage points without system shutdown, substantially improving maintenance scheduling and reducing unplanned downtime.

Ejector integration represents another significant optimization pathway, with modern multi-stage ejector systems achieving vacuum improvements of 10-15% compared to traditional single-stage configurations. The strategic placement and sizing of ejectors based on computational fluid dynamics modeling has shown particular promise, with recent implementations in power generation facilities reporting steam consumption reductions of 8-12% for vacuum maintenance.

Drainage reliability enhancements through the implementation of automated condensate removal systems have demonstrated considerable efficiency gains. Studies indicate that optimized drainage configurations can reduce waterlogging by up to 30%, directly improving heat transfer coefficients and system performance. The incorporation of variable-speed condensate pumps further allows for dynamic response to changing operational conditions.

Energy recovery systems represent an emerging frontier in vacuum condenser optimization. Heat exchanger technologies that capture waste heat from ejector discharge and condensate streams have demonstrated the ability to reclaim 5-8% of otherwise lost energy. These systems typically achieve payback periods of 12-24 months in continuous industrial operations.

Digital twin modeling and machine learning algorithms are increasingly being deployed to optimize vacuum condensing systems in real-time. These approaches enable predictive maintenance scheduling and operational parameter optimization, with early implementations reporting efficiency improvements of 3-7% and maintenance cost reductions of 15-20%.

The economic implications of these optimization strategies are substantial, with comprehensive vacuum condensing system upgrades typically delivering 10-15% reductions in energy consumption and corresponding decreases in operational costs. The environmental benefits include proportional reductions in carbon emissions and cooling water requirements, aligning with increasingly stringent regulatory frameworks and sustainability objectives.

The integration of advanced monitoring systems utilizing infrared thermography and ultrasonic detection has demonstrated potential for reducing air leakage by 15-25% in industrial applications. These technologies enable real-time identification of leakage points without system shutdown, substantially improving maintenance scheduling and reducing unplanned downtime.

Ejector integration represents another significant optimization pathway, with modern multi-stage ejector systems achieving vacuum improvements of 10-15% compared to traditional single-stage configurations. The strategic placement and sizing of ejectors based on computational fluid dynamics modeling has shown particular promise, with recent implementations in power generation facilities reporting steam consumption reductions of 8-12% for vacuum maintenance.

Drainage reliability enhancements through the implementation of automated condensate removal systems have demonstrated considerable efficiency gains. Studies indicate that optimized drainage configurations can reduce waterlogging by up to 30%, directly improving heat transfer coefficients and system performance. The incorporation of variable-speed condensate pumps further allows for dynamic response to changing operational conditions.

Energy recovery systems represent an emerging frontier in vacuum condenser optimization. Heat exchanger technologies that capture waste heat from ejector discharge and condensate streams have demonstrated the ability to reclaim 5-8% of otherwise lost energy. These systems typically achieve payback periods of 12-24 months in continuous industrial operations.

Digital twin modeling and machine learning algorithms are increasingly being deployed to optimize vacuum condensing systems in real-time. These approaches enable predictive maintenance scheduling and operational parameter optimization, with early implementations reporting efficiency improvements of 3-7% and maintenance cost reductions of 15-20%.

The economic implications of these optimization strategies are substantial, with comprehensive vacuum condensing system upgrades typically delivering 10-15% reductions in energy consumption and corresponding decreases in operational costs. The environmental benefits include proportional reductions in carbon emissions and cooling water requirements, aligning with increasingly stringent regulatory frameworks and sustainability objectives.

Environmental Impact and Sustainability Considerations

Vacuum condensers represent a critical component in industrial systems, and their environmental impact deserves thorough consideration in the context of sustainability goals. The operation of vacuum condensers, particularly issues related to air leakage, ejector integration, and drainage reliability, directly influences energy consumption and environmental footprint of industrial processes.

Air leakage in vacuum condensers significantly impacts energy efficiency, as systems must compensate for these leaks by increasing power consumption. This leads to higher greenhouse gas emissions from power generation facilities. Research indicates that even minor air leakages can increase energy consumption by 10-15%, translating to substantial carbon emissions over a system's operational lifetime. Implementing advanced sealing technologies and regular maintenance protocols can mitigate these environmental impacts while reducing operational costs.

Ejector integration presents both challenges and opportunities from an environmental perspective. While ejectors consume energy, properly integrated systems can optimize overall efficiency by recovering waste energy streams. Modern ejector designs incorporate principles of thermodynamic optimization that can reduce steam consumption by up to 30% compared to conventional designs. This reduction directly translates to lower water usage and decreased thermal pollution in natural water bodies used for cooling purposes.

Drainage reliability affects both operational efficiency and environmental safety. Inefficient drainage systems can lead to water contamination through improper handling of condensate that may contain trace contaminants. Advanced drainage systems with integrated monitoring capabilities ensure proper treatment of condensate before discharge, preventing potential soil and groundwater contamination. Additionally, reliable drainage systems enable effective water recovery and reuse, supporting circular economy principles in industrial operations.

The lifecycle assessment of vacuum condenser systems reveals significant opportunities for sustainability improvements. Materials selection for condenser components increasingly focuses on recyclability and reduced environmental toxicity. Manufacturers are developing vacuum condensers with lower embodied carbon through the use of recycled materials and energy-efficient production processes. These advancements contribute to reducing the overall environmental footprint of industrial systems utilizing vacuum condensers.

Water conservation represents another critical environmental consideration. Modern vacuum condenser designs incorporate water-saving features that can reduce freshwater consumption by up to 40% compared to older systems. This conservation is particularly important in water-stressed regions where industrial water usage competes with agricultural and municipal needs. Closed-loop cooling systems and advanced water treatment technologies further enhance the sustainability profile of vacuum condenser operations.

Air leakage in vacuum condensers significantly impacts energy efficiency, as systems must compensate for these leaks by increasing power consumption. This leads to higher greenhouse gas emissions from power generation facilities. Research indicates that even minor air leakages can increase energy consumption by 10-15%, translating to substantial carbon emissions over a system's operational lifetime. Implementing advanced sealing technologies and regular maintenance protocols can mitigate these environmental impacts while reducing operational costs.

Ejector integration presents both challenges and opportunities from an environmental perspective. While ejectors consume energy, properly integrated systems can optimize overall efficiency by recovering waste energy streams. Modern ejector designs incorporate principles of thermodynamic optimization that can reduce steam consumption by up to 30% compared to conventional designs. This reduction directly translates to lower water usage and decreased thermal pollution in natural water bodies used for cooling purposes.

Drainage reliability affects both operational efficiency and environmental safety. Inefficient drainage systems can lead to water contamination through improper handling of condensate that may contain trace contaminants. Advanced drainage systems with integrated monitoring capabilities ensure proper treatment of condensate before discharge, preventing potential soil and groundwater contamination. Additionally, reliable drainage systems enable effective water recovery and reuse, supporting circular economy principles in industrial operations.

The lifecycle assessment of vacuum condenser systems reveals significant opportunities for sustainability improvements. Materials selection for condenser components increasingly focuses on recyclability and reduced environmental toxicity. Manufacturers are developing vacuum condensers with lower embodied carbon through the use of recycled materials and energy-efficient production processes. These advancements contribute to reducing the overall environmental footprint of industrial systems utilizing vacuum condensers.

Water conservation represents another critical environmental consideration. Modern vacuum condenser designs incorporate water-saving features that can reduce freshwater consumption by up to 40% compared to older systems. This conservation is particularly important in water-stressed regions where industrial water usage competes with agricultural and municipal needs. Closed-loop cooling systems and advanced water treatment technologies further enhance the sustainability profile of vacuum condenser operations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!