How Is Air Ingress Detected And Quantified In Vacuum Condenser Operation?

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Vacuum Condenser Air Ingress Detection Background

Vacuum condensers are critical components in power generation systems, particularly in steam turbine operations where they convert exhaust steam back to water while maintaining a vacuum environment. The integrity of this vacuum is paramount for operational efficiency and system performance. Air ingress—the unintended introduction of atmospheric air into the vacuum system—represents one of the most significant operational challenges faced in condenser management.

The phenomenon of air ingress has been recognized since the early development of steam power systems in the late 19th century. However, systematic approaches to detection and quantification only emerged in the mid-20th century with the advancement of instrumentation technology. Initially, rudimentary methods such as visual inspection for leaks and basic pressure measurements were the primary means of detection.

Air ingress typically occurs through various pathways including valve stem leakages, flange connections, instrument connections, expansion joints, and through degraded condenser tubes. The presence of non-condensable gases, primarily air, in the condenser significantly impairs heat transfer efficiency, increases backpressure on the turbine, and can accelerate corrosion processes within the system.

The economic implications of undetected air ingress are substantial. Studies indicate that for every 1 inch Hg increase in condenser backpressure due to air ingress, there can be approximately 1-2% reduction in turbine efficiency. For a typical 500 MW power plant, this translates to millions of dollars in annual revenue loss, not accounting for increased maintenance costs and reduced equipment lifespan.

Historical approaches to air ingress detection evolved from simple manometric measurements to more sophisticated techniques involving oxygen analyzers, helium leak detection, and ultrasonic testing. The industry standard began to formalize in the 1970s with the introduction of ASME Performance Test Code 19.11, which established methodologies for measuring air leakage rates in steam condensers.

Modern detection methods have increasingly incorporated digital technologies, continuous monitoring systems, and predictive analytics. The integration of these technologies has shifted the paradigm from reactive maintenance to proactive management of condenser systems. Real-time monitoring capabilities now allow operators to detect minute changes in condenser performance that may indicate the onset of air ingress before significant efficiency losses occur.

The regulatory landscape has also evolved, with environmental considerations and energy efficiency standards driving more stringent requirements for system integrity and performance monitoring. This has further accelerated the development and adoption of advanced detection and quantification methodologies across the power generation industry.

The phenomenon of air ingress has been recognized since the early development of steam power systems in the late 19th century. However, systematic approaches to detection and quantification only emerged in the mid-20th century with the advancement of instrumentation technology. Initially, rudimentary methods such as visual inspection for leaks and basic pressure measurements were the primary means of detection.

Air ingress typically occurs through various pathways including valve stem leakages, flange connections, instrument connections, expansion joints, and through degraded condenser tubes. The presence of non-condensable gases, primarily air, in the condenser significantly impairs heat transfer efficiency, increases backpressure on the turbine, and can accelerate corrosion processes within the system.

The economic implications of undetected air ingress are substantial. Studies indicate that for every 1 inch Hg increase in condenser backpressure due to air ingress, there can be approximately 1-2% reduction in turbine efficiency. For a typical 500 MW power plant, this translates to millions of dollars in annual revenue loss, not accounting for increased maintenance costs and reduced equipment lifespan.

Historical approaches to air ingress detection evolved from simple manometric measurements to more sophisticated techniques involving oxygen analyzers, helium leak detection, and ultrasonic testing. The industry standard began to formalize in the 1970s with the introduction of ASME Performance Test Code 19.11, which established methodologies for measuring air leakage rates in steam condensers.

Modern detection methods have increasingly incorporated digital technologies, continuous monitoring systems, and predictive analytics. The integration of these technologies has shifted the paradigm from reactive maintenance to proactive management of condenser systems. Real-time monitoring capabilities now allow operators to detect minute changes in condenser performance that may indicate the onset of air ingress before significant efficiency losses occur.

The regulatory landscape has also evolved, with environmental considerations and energy efficiency standards driving more stringent requirements for system integrity and performance monitoring. This has further accelerated the development and adoption of advanced detection and quantification methodologies across the power generation industry.

Market Demand for Air Ingress Monitoring Solutions

The global market for air ingress monitoring solutions in vacuum condensers is experiencing significant growth, driven by increasing focus on power plant efficiency and operational reliability. Power generation facilities, particularly thermal and nuclear plants, represent the primary demand segment, as these operations rely heavily on vacuum condensers where air ingress can substantially impact performance and energy output.

Industry reports indicate that power plants typically experience 2-5% efficiency losses due to undetected air ingress issues, translating to millions of dollars in annual revenue loss for large facilities. This economic impact has created a strong financial incentive for implementing advanced detection and quantification systems, with the potential return on investment often realized within 12-18 months of deployment.

Environmental regulations and sustainability initiatives have further accelerated market demand, as improved condenser efficiency directly correlates with reduced fuel consumption and lower emissions. Regulatory bodies in North America, Europe, and increasingly in Asia-Pacific regions are implementing stricter efficiency standards that indirectly necessitate better air ingress monitoring capabilities.

The industrial sector represents another significant market segment, with chemical processing, pharmaceutical manufacturing, and food production facilities all utilizing vacuum systems where air ingress detection is critical. These industries prioritize product quality and process consistency, which can be compromised by undetected air leakage.

Market analysis reveals a growing preference for integrated monitoring solutions that provide real-time data and predictive maintenance capabilities. End-users increasingly demand systems that not only detect air ingress but also quantify the extent of the problem and identify specific leak locations, enabling targeted maintenance interventions.

The aftermarket and retrofit segment presents substantial opportunities, as many existing power plants and industrial facilities operate with aging infrastructure that lacks sophisticated monitoring capabilities. This segment is projected to grow at a faster rate than new installations in mature markets.

Geographically, emerging economies in Asia-Pacific, particularly China and India, represent the fastest-growing markets due to rapid industrialization and power sector expansion. However, North America and Europe maintain significant market share driven by modernization initiatives and efficiency upgrades at existing facilities.

Customer pain points consistently identified in market surveys include the need for non-invasive monitoring solutions that don't require system shutdown, improved accuracy in quantification, and integration capabilities with existing plant control systems and digital platforms.

Industry reports indicate that power plants typically experience 2-5% efficiency losses due to undetected air ingress issues, translating to millions of dollars in annual revenue loss for large facilities. This economic impact has created a strong financial incentive for implementing advanced detection and quantification systems, with the potential return on investment often realized within 12-18 months of deployment.

Environmental regulations and sustainability initiatives have further accelerated market demand, as improved condenser efficiency directly correlates with reduced fuel consumption and lower emissions. Regulatory bodies in North America, Europe, and increasingly in Asia-Pacific regions are implementing stricter efficiency standards that indirectly necessitate better air ingress monitoring capabilities.

The industrial sector represents another significant market segment, with chemical processing, pharmaceutical manufacturing, and food production facilities all utilizing vacuum systems where air ingress detection is critical. These industries prioritize product quality and process consistency, which can be compromised by undetected air leakage.

Market analysis reveals a growing preference for integrated monitoring solutions that provide real-time data and predictive maintenance capabilities. End-users increasingly demand systems that not only detect air ingress but also quantify the extent of the problem and identify specific leak locations, enabling targeted maintenance interventions.

The aftermarket and retrofit segment presents substantial opportunities, as many existing power plants and industrial facilities operate with aging infrastructure that lacks sophisticated monitoring capabilities. This segment is projected to grow at a faster rate than new installations in mature markets.

Geographically, emerging economies in Asia-Pacific, particularly China and India, represent the fastest-growing markets due to rapid industrialization and power sector expansion. However, North America and Europe maintain significant market share driven by modernization initiatives and efficiency upgrades at existing facilities.

Customer pain points consistently identified in market surveys include the need for non-invasive monitoring solutions that don't require system shutdown, improved accuracy in quantification, and integration capabilities with existing plant control systems and digital platforms.

Technical Challenges in Vacuum Condenser Leak Detection

Vacuum condensers are critical components in power generation and industrial processes, where maintaining proper vacuum conditions is essential for operational efficiency. The detection and quantification of air ingress present significant technical challenges that impact system performance and reliability. Current detection methods face limitations in sensitivity, response time, and accuracy under varying operational conditions.

Traditional methods such as monitoring condenser pressure and temperature differentials provide basic indicators but often lack precision for early detection of small leaks. These approaches typically detect air ingress only after significant vacuum degradation has occurred, limiting preventative maintenance opportunities and potentially leading to efficiency losses of 1-3% before detection.

Helium leak detection systems, while more sensitive, require system shutdown for implementation, creating operational disruptions and economic losses. The technical complexity of deploying tracer gas methods during continuous operation remains a significant barrier, particularly in large-scale industrial applications where access points may be limited or hazardous.

Mass spectrometry offers high sensitivity but faces challenges in distinguishing between different gas species under complex operational conditions. The instrumentation requires careful calibration and maintenance, with sensitivity to environmental factors potentially causing false readings. Integration of these systems into existing plant infrastructure presents additional engineering challenges related to sampling point locations and data interpretation.

Ultrasonic detection methods show promise but struggle with background noise discrimination in industrial environments. The technology requires sophisticated signal processing algorithms to differentiate between normal operational sounds and the acoustic signatures of air leaks, particularly challenging in environments with variable operational conditions.

Continuous monitoring systems face reliability issues in harsh industrial environments, with sensor degradation affecting long-term measurement accuracy. The development of robust sensors capable of withstanding high temperatures, humidity, and potential chemical exposure represents a significant materials science challenge.

Data interpretation presents another layer of complexity, as distinguishing between normal operational fluctuations and actual air ingress events requires advanced analytical approaches. Current algorithms struggle with the dynamic nature of industrial processes, leading to potential false positives or missed detection events.

Cost-benefit considerations further complicate implementation, as more sophisticated detection systems require significant capital investment and operational expertise. The economic justification for advanced detection systems must balance improved efficiency against implementation costs, creating adoption barriers particularly for smaller facilities or older installations.

Traditional methods such as monitoring condenser pressure and temperature differentials provide basic indicators but often lack precision for early detection of small leaks. These approaches typically detect air ingress only after significant vacuum degradation has occurred, limiting preventative maintenance opportunities and potentially leading to efficiency losses of 1-3% before detection.

Helium leak detection systems, while more sensitive, require system shutdown for implementation, creating operational disruptions and economic losses. The technical complexity of deploying tracer gas methods during continuous operation remains a significant barrier, particularly in large-scale industrial applications where access points may be limited or hazardous.

Mass spectrometry offers high sensitivity but faces challenges in distinguishing between different gas species under complex operational conditions. The instrumentation requires careful calibration and maintenance, with sensitivity to environmental factors potentially causing false readings. Integration of these systems into existing plant infrastructure presents additional engineering challenges related to sampling point locations and data interpretation.

Ultrasonic detection methods show promise but struggle with background noise discrimination in industrial environments. The technology requires sophisticated signal processing algorithms to differentiate between normal operational sounds and the acoustic signatures of air leaks, particularly challenging in environments with variable operational conditions.

Continuous monitoring systems face reliability issues in harsh industrial environments, with sensor degradation affecting long-term measurement accuracy. The development of robust sensors capable of withstanding high temperatures, humidity, and potential chemical exposure represents a significant materials science challenge.

Data interpretation presents another layer of complexity, as distinguishing between normal operational fluctuations and actual air ingress events requires advanced analytical approaches. Current algorithms struggle with the dynamic nature of industrial processes, leading to potential false positives or missed detection events.

Cost-benefit considerations further complicate implementation, as more sophisticated detection systems require significant capital investment and operational expertise. The economic justification for advanced detection systems must balance improved efficiency against implementation costs, creating adoption barriers particularly for smaller facilities or older installations.

Current Air Ingress Detection Methodologies

01 Pressure monitoring systems for air ingress detection

Vacuum condensers can be monitored for air ingress by implementing pressure monitoring systems. These systems typically involve pressure sensors or transducers that continuously measure the pressure within the condenser. Any unexpected increase in pressure can indicate air leakage into the system. Advanced systems may include differential pressure measurements between various points in the condenser to pinpoint the location of air ingress. These monitoring systems often incorporate alarm thresholds to alert operators when pressure values exceed predetermined limits.- Helium leak detection methods: Helium leak detection is a common method for detecting air ingress in vacuum condensers. This technique involves introducing helium gas near potential leak points and using specialized detectors to identify the presence of helium inside the vacuum system. The method provides high sensitivity and can quantify even small leaks by measuring the concentration of helium that penetrates into the system. This approach allows for precise localization of leaks and can be automated for continuous monitoring of vacuum integrity.

- Pressure differential monitoring systems: Vacuum condensers can be monitored for air ingress by implementing pressure differential monitoring systems. These systems continuously measure the pressure inside the condenser and compare it with atmospheric or reference pressure. Any unexpected increase in pressure indicates potential air ingress. Advanced systems incorporate pressure sensors at multiple points throughout the condenser to pinpoint the location of leaks. Some designs include alarm thresholds that trigger when pressure changes exceed predetermined limits, allowing for immediate response to potential air ingress events.

- Gas composition analysis techniques: Air ingress in vacuum condensers can be detected and quantified through gas composition analysis techniques. These methods involve sampling the gas inside the condenser and analyzing its composition using mass spectrometry, gas chromatography, or oxygen analyzers. By detecting atmospheric gases like nitrogen and oxygen that shouldn't be present in a properly sealed vacuum system, these techniques can identify leaks. The concentration of these gases can be measured to quantify the extent of air ingress, helping to determine the severity of the leak and prioritize maintenance actions.

- Acoustic and ultrasonic detection systems: Acoustic and ultrasonic detection systems offer non-invasive methods for identifying air ingress in vacuum condensers. These systems detect the characteristic sounds or ultrasonic signatures produced when air leaks into a vacuum system. Specialized sensors can be placed at strategic locations on the condenser to monitor for these acoustic signatures. Advanced systems use signal processing algorithms to filter out background noise and enhance leak detection sensitivity. This approach allows for real-time monitoring and can detect leaks that might be missed by pressure or composition-based methods.

- Automated monitoring and control systems: Integrated automated systems for continuous monitoring and control of vacuum condensers can effectively detect and quantify air ingress. These systems combine multiple detection methods such as pressure sensors, temperature monitors, and gas analyzers with computerized control systems. The data is processed in real-time to identify patterns indicative of air ingress. Some advanced systems incorporate machine learning algorithms to improve detection accuracy over time by recognizing subtle changes that precede major leaks. These automated systems can also implement immediate corrective actions such as isolating affected sections or adjusting operating parameters to minimize damage.

02 Gas composition analysis techniques

Air ingress in vacuum condensers can be detected and quantified through gas composition analysis. This approach involves sampling the gas within the condenser and analyzing its composition to detect atmospheric components like oxygen and nitrogen. Methods include mass spectrometry, gas chromatography, and oxygen analyzers that can detect even trace amounts of air. Continuous monitoring systems can provide real-time data on gas composition changes, allowing for immediate response to air ingress events. The concentration of detected gases can be used to quantify the amount of air that has entered the system.Expand Specific Solutions03 Thermal performance monitoring for air ingress detection

Changes in thermal performance can indicate air ingress in vacuum condensers. This detection method relies on monitoring heat transfer efficiency, which decreases when non-condensable gases like air accumulate in the system. Temperature sensors placed at strategic locations can detect temperature gradients or unexpected temperature patterns caused by air pockets. Reduced condensation rates or increased condensing pressure at constant cooling water temperature are key indicators of air presence. These thermal monitoring systems can be integrated with automated control systems to maintain optimal condenser performance.Expand Specific Solutions04 Tracer gas methods for leak detection

Tracer gas methods involve introducing a detectable gas outside the vacuum condenser and monitoring for its presence inside the system to identify leak points. Common tracer gases include helium, hydrogen, and specialized refrigerant compounds that can be detected at very low concentrations. Portable or fixed detectors scan the system for the presence of these gases, with helium mass spectrometers being particularly effective for high-sensitivity detection. This approach not only detects air ingress but can precisely locate the source of leaks, allowing for targeted repairs. The rate of tracer gas accumulation can be used to quantify the severity of the leak.Expand Specific Solutions05 Automated monitoring and control systems

Integrated automated systems combine multiple detection methods with advanced control capabilities for comprehensive air ingress management in vacuum condensers. These systems typically incorporate sensors, data acquisition hardware, and specialized software that continuously monitor various parameters including pressure, temperature, and gas composition. Machine learning algorithms can analyze patterns to detect subtle changes indicating air ingress before conventional methods would trigger alarms. Remote monitoring capabilities allow for off-site supervision and rapid response to detected issues. These systems often include automated venting mechanisms to remove accumulated air and maintain optimal condenser performance.Expand Specific Solutions

Leading Manufacturers and Service Providers Analysis

Air ingress detection in vacuum condenser operations is currently in a growth phase, with the market expanding due to increasing focus on energy efficiency and system reliability. The global market for vacuum condenser monitoring technologies is estimated to reach $3.5 billion by 2025, driven by power generation and industrial applications. Technologically, the field is moderately mature with ongoing innovations. Leading players like Siemens AG and Hitachi Ltd. offer advanced detection systems using pressure monitoring and helium leak detection, while Toyota Motor Corp. and Mitsubishi Electric Corp. have developed proprietary sensor technologies. Research institutions such as Forschungszentrum Jülich and Beihang University are advancing non-invasive detection methods, while State Grid Corp. of China and DENSO Corp. focus on integrated monitoring solutions for large-scale industrial applications.

Siemens AG

Technical Solution: Siemens has developed an integrated air ingress detection system for vacuum condensers that combines multiple detection technologies. Their approach utilizes distributed pressure sensors throughout the condenser system that continuously monitor for pressure deviations indicative of air infiltration. These sensors feed into Siemens' SPPA-T3000 automation platform, which employs advanced pattern recognition algorithms to distinguish between normal operational fluctuations and actual air ingress events. The system quantifies air ingress through a combination of mass flow calculations and oxygen concentration measurements, with reported detection thresholds as low as 0.05% air by volume. Siemens' technology also incorporates ejector performance monitoring, as decreased ejector efficiency often correlates with air ingress issues. Their solution features integration with digital twin modeling that can simulate the impact of detected air ingress on overall plant efficiency, allowing operators to make informed decisions about when maintenance interventions are necessary based on economic and performance factors.

Strengths: Seamless integration with existing plant control systems; comprehensive data analytics provide actionable insights; economic impact assessment aids in maintenance prioritization. Weaknesses: Complex implementation requiring significant system integration; higher initial cost compared to standalone solutions; requires regular software updates to maintain optimal performance.

Hitachi-GE Nuclear Energy Ltd.

Technical Solution: Hitachi-GE Nuclear Energy has developed a specialized air ingress detection system for vacuum condensers in nuclear power applications, where system integrity is particularly critical. Their technology employs a combination of radiation-hardened pressure transducers and mass spectrometry to detect and quantify air infiltration. The system features redundant sensor arrays that provide continuous monitoring with fail-safe capabilities, ensuring detection reliability even during component failures. Hitachi-GE's approach includes proprietary algorithms that analyze the ratio of non-condensable gases to steam, allowing for precise quantification of air ingress rates as low as 0.01 kg/hr. Their solution incorporates automated leak location capabilities through sequential isolation testing, where different condenser sections are temporarily isolated while monitoring pressure changes to pinpoint leak sources. The system also features integration with plant safety systems, automatically triggering appropriate responses based on the severity and rate of detected air ingress to prevent potential equipment damage or efficiency losses.

Strengths: Extremely high reliability suitable for nuclear applications; exceptional sensitivity to very small leaks; comprehensive integration with plant safety systems. Weaknesses: Significantly higher cost than conventional systems; complex installation requirements; specialized maintenance procedures necessary.

Key Patents and Research in Leak Quantification

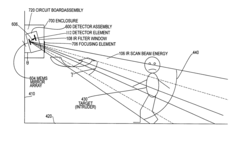

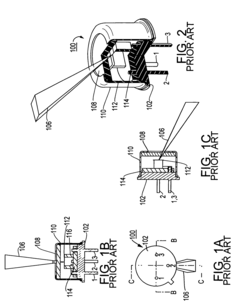

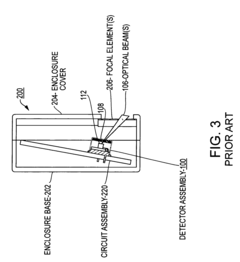

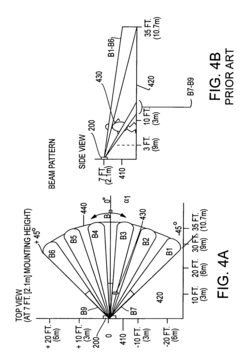

MEMS based space safety infrared sensor apparatus and method for detecting a gas or vapor

PatentActiveUS20060038680A1

Innovation

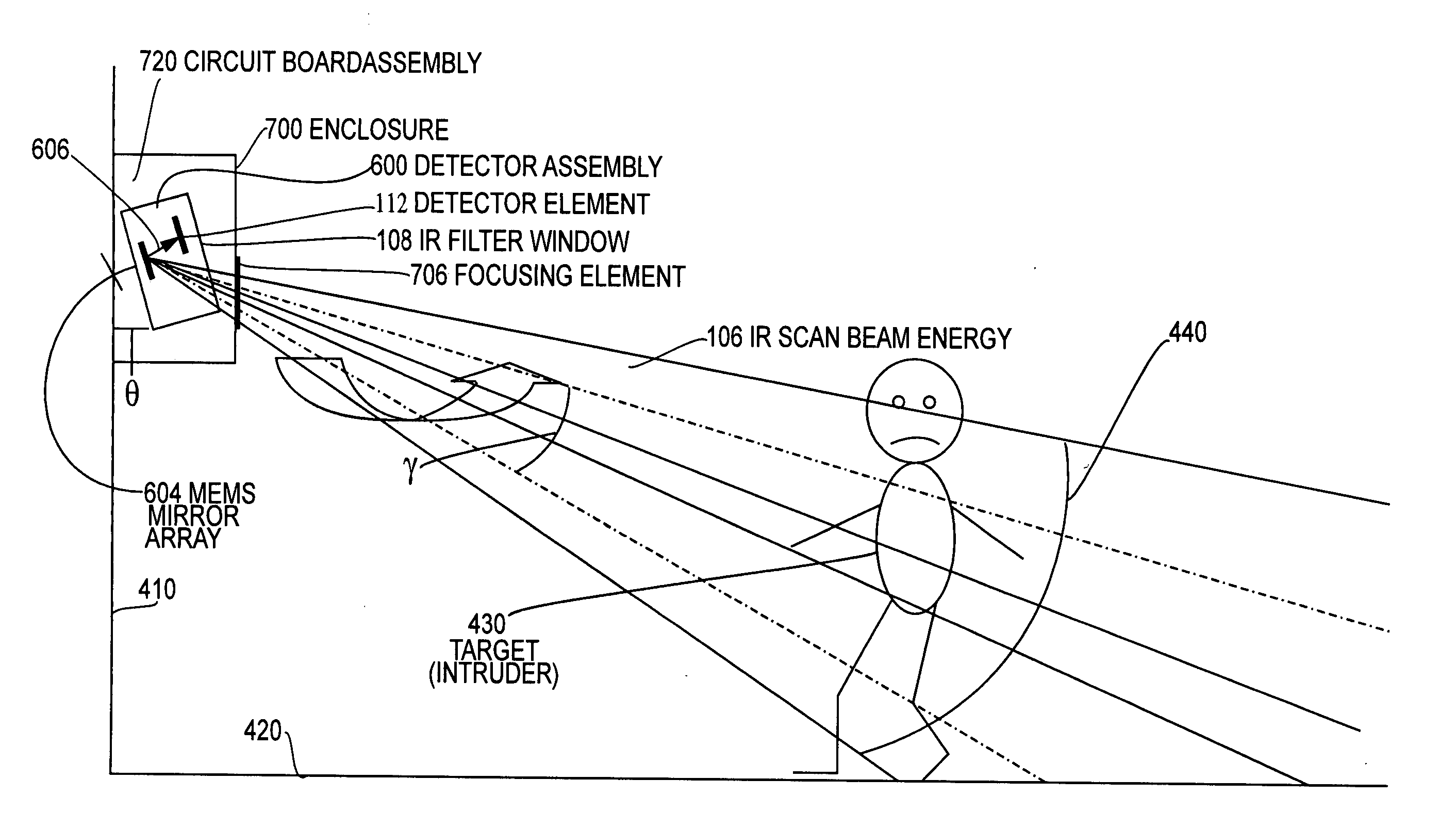

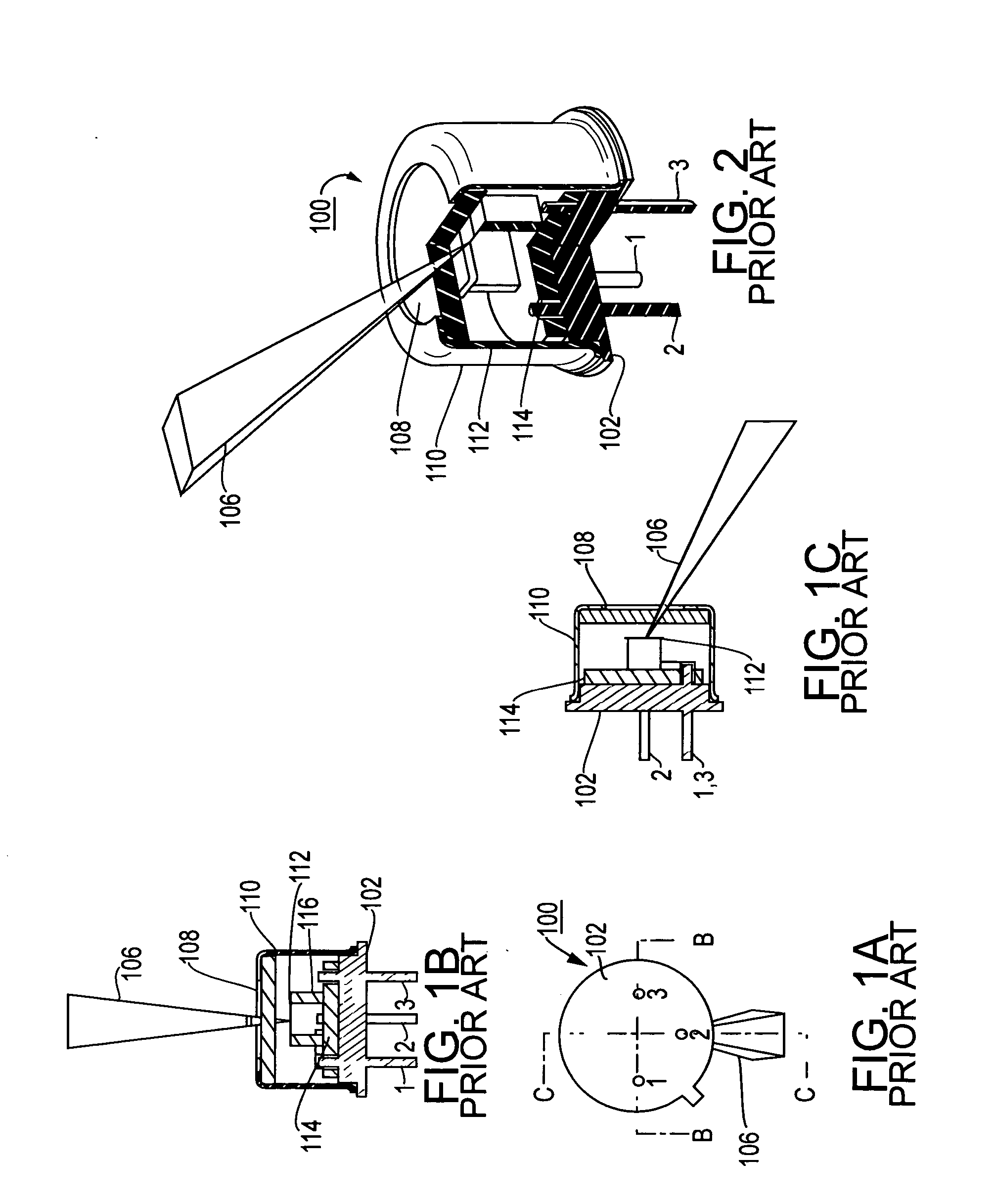

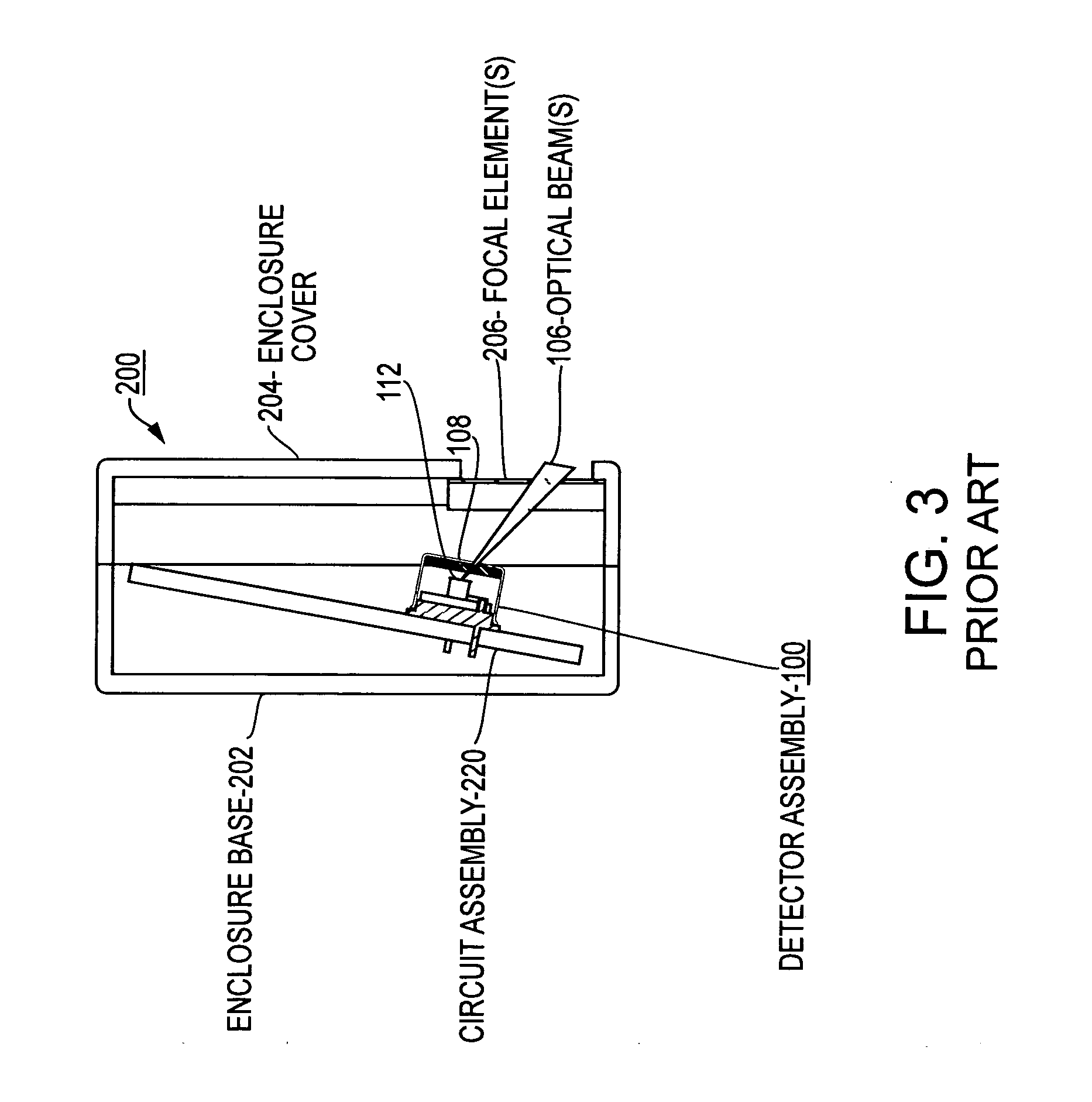

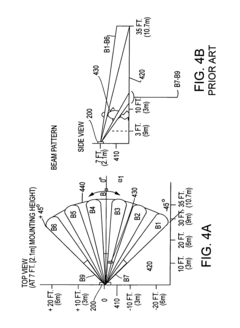

- A space safety apparatus utilizing a multi-axis MEMS mirror array to dynamically scan and focus IR energy within a field of view, allowing for precise detection of intrusions by reflecting IR energy and converting it into output signals for processing, thereby reducing false alarms and ensuring comprehensive coverage.

MEMS based space safety infrared sensor apparatus and method

PatentInactiveUS7145455B2

Innovation

- A space safety apparatus utilizing a micro-electro-mechanical system (MEMS) mirror array to dynamically scan and focus IR energy within a field of view, allowing for precise detection of intrusions by adjusting the angle of mirror elements and switching between different focusing elements, thereby enhancing the accuracy and reducing false alarms.

Energy Efficiency Impact Assessment

Air ingress in vacuum condensers significantly impacts the energy efficiency of power generation systems. When air leaks into a condenser, it creates a thermal barrier that reduces heat transfer efficiency between steam and cooling water. This phenomenon directly increases the backpressure in the turbine, forcing the system to consume more fuel to maintain the same power output. Quantitative assessments indicate that for every 1 inch Hg increase in condenser pressure due to air ingress, there is approximately a 1-2% decrease in overall plant efficiency.

The economic implications of this efficiency loss are substantial. For a typical 500 MW power plant, a 1% reduction in efficiency can translate to approximately $1-2 million in additional fuel costs annually. Furthermore, the increased backpressure requires the turbine to work harder, accelerating component wear and potentially shortening equipment lifespan, which adds to maintenance costs and downtime expenses.

From an environmental perspective, the efficiency losses due to air ingress contribute to increased carbon emissions. A medium-sized coal power plant experiencing condenser inefficiency might emit an additional 10,000-20,000 tons of CO2 annually. This aspect becomes increasingly important as carbon pricing mechanisms and environmental regulations become more stringent globally.

Proper detection and quantification of air ingress enable optimization of vacuum pump operation, which itself consumes energy. Without accurate measurement, vacuum pumps may operate unnecessarily, consuming excess electricity. Studies show that optimized vacuum pump operation based on precise air ingress data can reduce auxiliary power consumption by 5-15%, depending on the system configuration.

The relationship between condenser cleanliness and air ingress effects is also noteworthy. Fouled condensers with air ingress problems compound efficiency losses, with combined effects potentially reducing plant heat rate by up to 5%. This highlights the importance of integrated maintenance approaches that address both issues simultaneously.

Advanced monitoring systems that provide real-time air ingress data allow for dynamic optimization of plant operations, potentially recovering 30-50% of the efficiency losses through operational adjustments alone, without requiring system shutdown for repairs. This represents a significant opportunity for immediate energy savings while more permanent solutions are planned.

The economic implications of this efficiency loss are substantial. For a typical 500 MW power plant, a 1% reduction in efficiency can translate to approximately $1-2 million in additional fuel costs annually. Furthermore, the increased backpressure requires the turbine to work harder, accelerating component wear and potentially shortening equipment lifespan, which adds to maintenance costs and downtime expenses.

From an environmental perspective, the efficiency losses due to air ingress contribute to increased carbon emissions. A medium-sized coal power plant experiencing condenser inefficiency might emit an additional 10,000-20,000 tons of CO2 annually. This aspect becomes increasingly important as carbon pricing mechanisms and environmental regulations become more stringent globally.

Proper detection and quantification of air ingress enable optimization of vacuum pump operation, which itself consumes energy. Without accurate measurement, vacuum pumps may operate unnecessarily, consuming excess electricity. Studies show that optimized vacuum pump operation based on precise air ingress data can reduce auxiliary power consumption by 5-15%, depending on the system configuration.

The relationship between condenser cleanliness and air ingress effects is also noteworthy. Fouled condensers with air ingress problems compound efficiency losses, with combined effects potentially reducing plant heat rate by up to 5%. This highlights the importance of integrated maintenance approaches that address both issues simultaneously.

Advanced monitoring systems that provide real-time air ingress data allow for dynamic optimization of plant operations, potentially recovering 30-50% of the efficiency losses through operational adjustments alone, without requiring system shutdown for repairs. This represents a significant opportunity for immediate energy savings while more permanent solutions are planned.

Maintenance Strategy Optimization

Optimizing maintenance strategies for vacuum condensers requires a systematic approach to air ingress detection and quantification. Implementing a condition-based maintenance (CBM) framework specifically tailored for vacuum systems can significantly reduce unplanned downtime and extend equipment lifespan. This approach shifts from traditional time-based maintenance to a more efficient model that responds to actual system conditions.

The foundation of an effective maintenance strategy lies in continuous monitoring of key parameters that indicate air ingress. Integration of real-time monitoring systems for condenser pressure, dissolved oxygen levels, and non-condensable gas concentration provides the data backbone for predictive maintenance algorithms. These systems should be calibrated to trigger alerts at predetermined thresholds before operational efficiency is significantly compromised.

Risk-based maintenance prioritization represents a critical component of the optimization process. By categorizing potential air ingress points according to their likelihood of occurrence and operational impact, maintenance resources can be allocated more effectively. High-risk components such as shaft seals, valve packings, and instrument connections should receive enhanced monitoring and more frequent inspection schedules.

Implementing a comprehensive data management system enables trend analysis and pattern recognition across operational cycles. Historical data correlation between maintenance activities and subsequent performance improvements can inform future decision-making and validate the effectiveness of specific interventions. Machine learning algorithms can further enhance this capability by identifying subtle precursors to air ingress events.

Standardized response protocols for different levels of air ingress severity ensure consistent and appropriate maintenance actions. These protocols should include clear decision trees for determining whether online repairs are sufficient or if planned outages are necessary. Emergency response procedures for critical air ingress events should be documented and regularly practiced by maintenance teams.

Cost-benefit analysis should guide the selection of maintenance technologies and approaches. Advanced leak detection equipment, such as helium mass spectrometers or ultrasonic detectors, represents significant investment but can deliver substantial returns through early detection capabilities. The financial impact of different maintenance strategies should be quantified, considering both direct costs and the value of avoided downtime.

Personnel training programs focused specifically on vacuum system integrity and air ingress detection techniques form an essential component of the maintenance strategy. Cross-functional teams including operations, maintenance, and engineering personnel should participate in regular knowledge-sharing sessions to maintain institutional expertise in vacuum condenser maintenance.

The foundation of an effective maintenance strategy lies in continuous monitoring of key parameters that indicate air ingress. Integration of real-time monitoring systems for condenser pressure, dissolved oxygen levels, and non-condensable gas concentration provides the data backbone for predictive maintenance algorithms. These systems should be calibrated to trigger alerts at predetermined thresholds before operational efficiency is significantly compromised.

Risk-based maintenance prioritization represents a critical component of the optimization process. By categorizing potential air ingress points according to their likelihood of occurrence and operational impact, maintenance resources can be allocated more effectively. High-risk components such as shaft seals, valve packings, and instrument connections should receive enhanced monitoring and more frequent inspection schedules.

Implementing a comprehensive data management system enables trend analysis and pattern recognition across operational cycles. Historical data correlation between maintenance activities and subsequent performance improvements can inform future decision-making and validate the effectiveness of specific interventions. Machine learning algorithms can further enhance this capability by identifying subtle precursors to air ingress events.

Standardized response protocols for different levels of air ingress severity ensure consistent and appropriate maintenance actions. These protocols should include clear decision trees for determining whether online repairs are sufficient or if planned outages are necessary. Emergency response procedures for critical air ingress events should be documented and regularly practiced by maintenance teams.

Cost-benefit analysis should guide the selection of maintenance technologies and approaches. Advanced leak detection equipment, such as helium mass spectrometers or ultrasonic detectors, represents significant investment but can deliver substantial returns through early detection capabilities. The financial impact of different maintenance strategies should be quantified, considering both direct costs and the value of avoided downtime.

Personnel training programs focused specifically on vacuum system integrity and air ingress detection techniques form an essential component of the maintenance strategy. Cross-functional teams including operations, maintenance, and engineering personnel should participate in regular knowledge-sharing sessions to maintain institutional expertise in vacuum condenser maintenance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!