Chloramine And Biofouling In Cooling Water: Countermeasures And Material Impacts

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Chloramine Treatment Evolution and Objectives

Chloramine treatment for cooling water systems has evolved significantly over the past several decades, transitioning from simple chlorination methods to more sophisticated approaches. In the 1950s and 1960s, free chlorine was the predominant biocide used in industrial cooling systems. However, environmental concerns regarding chlorinated discharge and the formation of harmful disinfection by-products led to regulatory restrictions in the 1970s, prompting the industry to seek alternative solutions.

The 1980s marked a pivotal shift with the introduction of chloramines as a viable alternative to free chlorine. Chloramines, formed by the reaction between ammonia and chlorine, offered extended persistence in water systems while producing fewer harmful by-products. This characteristic made them particularly valuable for large-scale cooling systems where maintaining consistent biocidal activity throughout extensive distribution networks was challenging.

The 1990s witnessed significant advancements in chloramine chemistry understanding, with researchers identifying optimal chlorine-to-ammonia ratios for different system conditions. Monochloramine emerged as the preferred species due to its superior stability and efficacy against biofilm formation compared to dichloramine and trichloramine. This period also saw the development of more precise dosing and monitoring technologies, enabling better control of chloramine levels.

By the early 2000s, integrated approaches combining chloramines with other treatment chemicals gained prominence. These synergistic treatments addressed multiple water quality issues simultaneously, including corrosion control, scale inhibition, and biofouling prevention. The industry also began adopting pulsed chloramine dosing strategies, which proved more effective at penetrating established biofilms while using lower overall chemical quantities.

Recent developments have focused on optimizing chloramine treatment to minimize environmental impact while maximizing biofouling control. Advanced monitoring systems utilizing real-time sensors and predictive analytics now allow for precise chloramine dosing based on actual system conditions rather than fixed schedules. Additionally, research into the specific mechanisms of chloramine action against different microbial communities has enabled more targeted treatment approaches.

The primary objectives of modern chloramine treatment include: achieving consistent microbial control throughout cooling systems; minimizing the formation of disinfection by-products; reducing the environmental footprint of water treatment programs; extending equipment service life by preventing microbiologically influenced corrosion; and ensuring regulatory compliance across increasingly stringent global standards. These objectives reflect the industry's movement toward more sustainable, efficient, and environmentally responsible cooling water management practices.

The 1980s marked a pivotal shift with the introduction of chloramines as a viable alternative to free chlorine. Chloramines, formed by the reaction between ammonia and chlorine, offered extended persistence in water systems while producing fewer harmful by-products. This characteristic made them particularly valuable for large-scale cooling systems where maintaining consistent biocidal activity throughout extensive distribution networks was challenging.

The 1990s witnessed significant advancements in chloramine chemistry understanding, with researchers identifying optimal chlorine-to-ammonia ratios for different system conditions. Monochloramine emerged as the preferred species due to its superior stability and efficacy against biofilm formation compared to dichloramine and trichloramine. This period also saw the development of more precise dosing and monitoring technologies, enabling better control of chloramine levels.

By the early 2000s, integrated approaches combining chloramines with other treatment chemicals gained prominence. These synergistic treatments addressed multiple water quality issues simultaneously, including corrosion control, scale inhibition, and biofouling prevention. The industry also began adopting pulsed chloramine dosing strategies, which proved more effective at penetrating established biofilms while using lower overall chemical quantities.

Recent developments have focused on optimizing chloramine treatment to minimize environmental impact while maximizing biofouling control. Advanced monitoring systems utilizing real-time sensors and predictive analytics now allow for precise chloramine dosing based on actual system conditions rather than fixed schedules. Additionally, research into the specific mechanisms of chloramine action against different microbial communities has enabled more targeted treatment approaches.

The primary objectives of modern chloramine treatment include: achieving consistent microbial control throughout cooling systems; minimizing the formation of disinfection by-products; reducing the environmental footprint of water treatment programs; extending equipment service life by preventing microbiologically influenced corrosion; and ensuring regulatory compliance across increasingly stringent global standards. These objectives reflect the industry's movement toward more sustainable, efficient, and environmentally responsible cooling water management practices.

Market Analysis of Cooling Water Treatment Solutions

The global cooling water treatment solutions market is experiencing robust growth, valued at approximately 18.2 billion USD in 2022 with projections to reach 26.5 billion USD by 2028, representing a compound annual growth rate of 6.4%. This growth is primarily driven by increasing industrialization, stringent environmental regulations, and growing awareness about water conservation and efficiency.

The industrial sector constitutes the largest market segment, with power generation, oil and gas, manufacturing, and chemical processing being the primary consumers. Power plants alone account for nearly 40% of the cooling water treatment market due to their extensive water requirements and the critical nature of preventing equipment damage.

Geographically, North America and Europe currently dominate the market with mature industrial bases and strict regulatory frameworks. However, the Asia-Pacific region is witnessing the fastest growth rate at 8.2% annually, fueled by rapid industrialization in China, India, and Southeast Asian countries. The Middle East is also emerging as a significant market due to water scarcity concerns and heavy investments in industrial infrastructure.

The market is characterized by a shift toward environmentally friendly and sustainable treatment solutions. Traditional chlorine-based treatments are gradually being replaced by advanced oxidation processes, non-oxidizing biocides, and chloramine-based solutions that offer reduced environmental impact while maintaining efficacy against biofouling.

Customer demand is increasingly focused on integrated water management solutions rather than standalone products. End-users are seeking comprehensive packages that include monitoring systems, automated dosing equipment, and technical support services. This trend has prompted many suppliers to transition from product-centric to service-oriented business models.

Cost considerations remain paramount in purchasing decisions, with operational expenditure often outweighing initial capital investment. Solutions that demonstrate clear return on investment through extended equipment life, reduced downtime, and lower maintenance costs gain competitive advantage. The average payback period expected by customers has decreased from 3-4 years to 1.5-2 years.

Digital transformation is creating new market opportunities, with smart water treatment systems incorporating sensors, data analytics, and automation gaining traction. These systems offer real-time monitoring, predictive maintenance capabilities, and optimization of chemical usage, addressing both economic and environmental concerns simultaneously.

The industrial sector constitutes the largest market segment, with power generation, oil and gas, manufacturing, and chemical processing being the primary consumers. Power plants alone account for nearly 40% of the cooling water treatment market due to their extensive water requirements and the critical nature of preventing equipment damage.

Geographically, North America and Europe currently dominate the market with mature industrial bases and strict regulatory frameworks. However, the Asia-Pacific region is witnessing the fastest growth rate at 8.2% annually, fueled by rapid industrialization in China, India, and Southeast Asian countries. The Middle East is also emerging as a significant market due to water scarcity concerns and heavy investments in industrial infrastructure.

The market is characterized by a shift toward environmentally friendly and sustainable treatment solutions. Traditional chlorine-based treatments are gradually being replaced by advanced oxidation processes, non-oxidizing biocides, and chloramine-based solutions that offer reduced environmental impact while maintaining efficacy against biofouling.

Customer demand is increasingly focused on integrated water management solutions rather than standalone products. End-users are seeking comprehensive packages that include monitoring systems, automated dosing equipment, and technical support services. This trend has prompted many suppliers to transition from product-centric to service-oriented business models.

Cost considerations remain paramount in purchasing decisions, with operational expenditure often outweighing initial capital investment. Solutions that demonstrate clear return on investment through extended equipment life, reduced downtime, and lower maintenance costs gain competitive advantage. The average payback period expected by customers has decreased from 3-4 years to 1.5-2 years.

Digital transformation is creating new market opportunities, with smart water treatment systems incorporating sensors, data analytics, and automation gaining traction. These systems offer real-time monitoring, predictive maintenance capabilities, and optimization of chemical usage, addressing both economic and environmental concerns simultaneously.

Current Challenges in Biofouling Control Technologies

Despite significant advancements in biofouling control technologies for cooling water systems, several persistent challenges continue to impede optimal performance and efficiency. The traditional chlorine-based treatments face increasing regulatory scrutiny due to environmental concerns and the formation of disinfection by-products (DBPs), particularly trihalomethanes and haloacetic acids, which pose potential health risks and are subject to stringent discharge limitations.

Chloramine, while offering extended residual protection compared to free chlorine, presents its own set of challenges. The stability of chloramine varies significantly with pH, temperature, and water chemistry, making consistent dosing difficult across diverse operational conditions. Additionally, certain microorganisms have demonstrated resistance to chloramine treatments, requiring higher concentrations or complementary biocides to achieve effective control.

Biofilm formation represents another formidable challenge, as established biofilms can reduce treatment efficacy by up to 1000-fold compared to planktonic microorganisms. Once formed, these protective matrices shield microorganisms from biocides and create microenvironments conducive to microbial proliferation and accelerated corrosion processes through microbiologically influenced corrosion (MIC).

The increasing prevalence of extremophilic microorganisms in industrial cooling systems further complicates control strategies. These organisms can withstand extreme pH conditions, elevated temperatures, and high concentrations of traditional biocides, necessitating more aggressive treatment approaches that may accelerate material degradation in system components.

Material compatibility issues represent a significant operational constraint, as many effective biocides demonstrate corrosive properties toward common cooling system materials. Chloramine specifically can accelerate degradation of copper alloys, elastomers, and certain polymeric components through oxidative mechanisms, creating a difficult balance between effective microbial control and system longevity.

Monitoring and control technologies present additional challenges, as real-time assessment of biofilm development and treatment efficacy remains difficult in operational systems. Current monitoring approaches often rely on indirect measurements or periodic sampling, which may fail to detect early-stage biofilm formation or provide timely feedback on treatment effectiveness.

Emerging regulatory frameworks increasingly restrict the use of traditional biocides, driving the need for alternative approaches that maintain efficacy while reducing environmental impact. This regulatory landscape varies significantly across regions, creating compliance challenges for organizations operating globally and necessitating customized treatment strategies based on local requirements.

Chloramine, while offering extended residual protection compared to free chlorine, presents its own set of challenges. The stability of chloramine varies significantly with pH, temperature, and water chemistry, making consistent dosing difficult across diverse operational conditions. Additionally, certain microorganisms have demonstrated resistance to chloramine treatments, requiring higher concentrations or complementary biocides to achieve effective control.

Biofilm formation represents another formidable challenge, as established biofilms can reduce treatment efficacy by up to 1000-fold compared to planktonic microorganisms. Once formed, these protective matrices shield microorganisms from biocides and create microenvironments conducive to microbial proliferation and accelerated corrosion processes through microbiologically influenced corrosion (MIC).

The increasing prevalence of extremophilic microorganisms in industrial cooling systems further complicates control strategies. These organisms can withstand extreme pH conditions, elevated temperatures, and high concentrations of traditional biocides, necessitating more aggressive treatment approaches that may accelerate material degradation in system components.

Material compatibility issues represent a significant operational constraint, as many effective biocides demonstrate corrosive properties toward common cooling system materials. Chloramine specifically can accelerate degradation of copper alloys, elastomers, and certain polymeric components through oxidative mechanisms, creating a difficult balance between effective microbial control and system longevity.

Monitoring and control technologies present additional challenges, as real-time assessment of biofilm development and treatment efficacy remains difficult in operational systems. Current monitoring approaches often rely on indirect measurements or periodic sampling, which may fail to detect early-stage biofilm formation or provide timely feedback on treatment effectiveness.

Emerging regulatory frameworks increasingly restrict the use of traditional biocides, driving the need for alternative approaches that maintain efficacy while reducing environmental impact. This regulatory landscape varies significantly across regions, creating compliance challenges for organizations operating globally and necessitating customized treatment strategies based on local requirements.

Existing Chloramine-Based Biofouling Control Methods

01 Chloramine treatment methods for biofouling prevention

Chloramine compounds can be used as effective biocides to prevent biofouling in water systems. These compounds work by disrupting microbial cell functions and preventing biofilm formation. Various chloramine formulations and application methods have been developed to optimize their effectiveness against biofouling while minimizing environmental impact and system corrosion.- Chloramine treatment methods for biofouling prevention: Chloramine compounds can be used as effective biocides to prevent biofouling in water systems. These compounds work by disrupting the cellular processes of microorganisms that cause biofouling. The controlled application of chloramines can inhibit biofilm formation on surfaces in contact with water, providing a preventive approach to biofouling management in various water treatment systems.

- Membrane filtration systems with chloramine resistance: Specialized membrane filtration systems have been developed with enhanced resistance to chloramine degradation. These membranes maintain their structural integrity and filtration efficiency even when exposed to chloramine-treated water. The design incorporates materials that can withstand the oxidative effects of chloramines while preventing biofouling accumulation on the membrane surface, extending the operational lifespan of filtration systems.

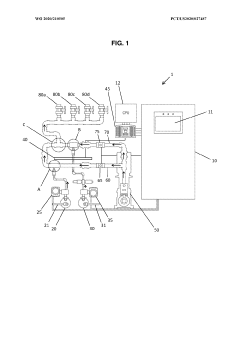

- Monitoring and control systems for chloramine levels: Advanced monitoring and control systems have been developed to maintain optimal chloramine concentrations for biofouling prevention while minimizing adverse effects. These systems utilize sensors and automated dosing equipment to continuously measure and adjust chloramine levels in water treatment facilities. Real-time monitoring ensures effective biofouling control while preventing excessive chloramine concentrations that could damage equipment or affect water quality.

- Chloramine-resistant biofilm removal techniques: Specialized techniques have been developed to remove biofilms that have developed resistance to conventional chloramine treatments. These methods often combine mechanical cleaning with enhanced chemical formulations that can penetrate and disrupt established biofilms. The techniques may include pulsed chloramine treatments, combination with other biocides, or the use of enzymes that break down the extracellular polymeric substances that protect biofilms from chloramine exposure.

- Environmental impact mitigation of chloramine biofouling treatments: Methods to reduce the environmental impact of chloramine-based biofouling control have been developed. These approaches focus on minimizing chloramine discharge into natural water bodies while maintaining effective biofouling prevention. Techniques include chloramine neutralization systems, closed-loop water treatment designs, and biodegradable chloramine alternatives that provide similar biofouling control with reduced environmental persistence and toxicity to aquatic organisms.

02 Monitoring and control systems for chloramine treatment

Advanced monitoring and control systems have been developed to optimize chloramine dosing for biofouling prevention. These systems include sensors that measure chloramine levels, biofilm formation, and water quality parameters in real-time. Automated control mechanisms adjust chloramine dosage based on these measurements to maintain effective biofouling prevention while minimizing chemical usage and environmental impact.Expand Specific Solutions03 Membrane and filtration technologies for chloramine management

Specialized membrane and filtration technologies have been developed to manage chloramine levels in water treatment systems. These technologies help remove excess chloramines after biofouling treatment or selectively control chloramine distribution within systems. Advanced filtration materials and designs enhance the efficiency of chloramine-based biofouling prevention while protecting sensitive system components.Expand Specific Solutions04 Chloramine-resistant materials and coatings

Materials and coatings resistant to chloramine degradation have been developed for use in water treatment systems. These innovations help extend the lifespan of system components exposed to chloramine treatments while maintaining biofouling prevention efficacy. Specialized polymers, metal alloys, and protective coatings minimize system damage while allowing effective chloramine-based biofouling control.Expand Specific Solutions05 Combined treatment approaches with chloramines

Synergistic treatment approaches combining chloramines with other biofouling prevention methods have been developed. These combined treatments may include additional chemical agents, physical cleaning methods, or biological controls that enhance the effectiveness of chloramine treatments. Such integrated approaches provide more comprehensive biofouling prevention while potentially reducing the required chloramine dosage and associated impacts.Expand Specific Solutions

Leading Companies in Water Treatment Industry

The chloramine and biofouling control market in cooling water systems is in a mature growth phase, with an estimated global market size of $4-5 billion annually. Leading water treatment specialists like Ecolab, Kurita Water Industries, ChemTreat, and Solenis dominate the competitive landscape, offering comprehensive solutions that combine chemicals, equipment, and monitoring services. The technology has reached high maturity levels, with companies like Buckman Laboratories and Aquatech International focusing on environmentally sustainable approaches that minimize material corrosion. Academic-industry partnerships, particularly involving institutions like MIT and KAUST, are driving innovation in advanced materials and smart monitoring systems that can withstand chloramine exposure while effectively preventing biofouling in industrial cooling applications.

Kurita Water Industries Ltd.

Technical Solution: Kurita has developed a comprehensive chloramine management system called "KURITA ACF Technology" (Advanced Chloramine Formulation) that combines optimized chloramine chemistry with real-time monitoring. Their approach utilizes stabilized monochloramine formulations that maintain effective biocidal properties while minimizing corrosion risks. The system incorporates proprietary chemical formulations that enhance chloramine stability in high-temperature cooling water environments, preventing rapid decomposition that typically occurs above 40°C. Kurita's technology includes automated dosing systems that adjust chloramine levels based on continuous monitoring of microbiological activity, oxidation-reduction potential, and chloramine residuals, ensuring optimal biofouling control while minimizing chemical usage.

Strengths: Superior chloramine stability at elevated temperatures; integrated monitoring systems reduce chemical consumption by up to 30%; demonstrated reduction in biofilm formation even in challenging industrial environments. Weaknesses: Higher initial implementation costs compared to traditional chlorination; requires more sophisticated monitoring equipment; may necessitate specialized operator training.

ChemTreat, Inc.

Technical Solution: ChemTreat has pioneered the "FlexPro" chloramine management technology specifically designed for industrial cooling systems. This technology employs a dual-approach methodology combining pre-formed monochloramine with proprietary biodispersants that penetrate existing biofilms while preventing new formation. Their system features patented stabilization chemistry that extends chloramine half-life in cooling water by up to 300% compared to conventional treatments. ChemTreat's approach includes specialized corrosion inhibitor packages designed to work synergistically with chloramine, addressing the specific corrosion mechanisms associated with chloramine use in various metallurgies including copper alloys, stainless steel, and carbon steel components. The company has also developed specialized monitoring protocols that track not only chloramine levels but also biofilm development using ATP (Adenosine Triphosphate) analysis to verify treatment efficacy.

Strengths: Exceptional biofilm penetration capabilities; comprehensive corrosion inhibition specifically designed for chloramine systems; extended chloramine stability reduces chemical consumption. Weaknesses: Higher chemical costs compared to simple chlorination; requires more complex implementation strategy; may require system modifications for optimal performance in older cooling systems.

Critical Patents in Chloramine Application Technologies

Process for the disinfection of waters

PatentInactiveEP1734008A2

Innovation

- A process involving the controlled mixing of an oxidant, such as sodium hypochlorite (NaOCl), with an ammonium salt, like ammonium bromide (NH4Br), to form a biocidal mixture that maintains a high biocidal effect and rapid kill rate, even in high chlorine demand waters, by adjusting the mole ratio, pH, and treatment frequency.

Systems and methods for controlling a chloramine synthesis reaction in industrial water systems

PatentWO2020210505A1

Innovation

- A system and method that includes real-time monitoring of sodium hypochlorite concentration using an optical measurement device to adjust the flow of precursor chemicals, allowing for a wider range of chemical feed rates and using various ammonium salts, ensuring the correct molar ratio and enhancing reaction kinetics to produce the desired chloramine products.

Material Compatibility and Corrosion Mitigation Strategies

The selection of materials for cooling water systems exposed to chloramine treatment requires careful consideration of compatibility factors. Various metals and alloys exhibit different responses to chloramine exposure, with copper alloys showing particular vulnerability to ammonia-based compounds that can cause stress corrosion cracking. Stainless steel generally offers better resistance but may still experience localized corrosion under certain conditions. Non-metallic materials like certain polymers and elastomers demonstrate superior chemical resistance but may have limitations in mechanical properties or temperature tolerance.

Material selection should be based on comprehensive testing under actual operating conditions, as laboratory results may not fully predict field performance. The concentration of chloramine, pH levels, temperature fluctuations, and water chemistry all influence corrosion rates and material degradation patterns. System designers must consider these variables when specifying materials for components such as heat exchangers, piping, valves, and gaskets.

Corrosion mitigation strategies for chloramine-treated cooling systems include the implementation of sacrificial anodes in critical areas to provide cathodic protection. These anodes, typically made of zinc, aluminum, or magnesium alloys, corrode preferentially to protect the primary system components. Regular inspection and replacement of these anodes is essential to maintain protection effectiveness.

Chemical inhibitors represent another important mitigation approach, with phosphate-based, silicate-based, and film-forming inhibitors being commonly employed. These chemicals form protective layers on metal surfaces, reducing direct contact between chloramine and the substrate material. Dosing must be carefully controlled to prevent under or over-treatment, which could lead to ineffective protection or secondary issues like scale formation.

Coating and lining systems provide an additional barrier against chloramine attack. Epoxy, polyurethane, and fluoropolymer coatings have demonstrated good resistance to chloramine degradation when properly applied. However, coating integrity must be maintained through regular inspection and maintenance, as any breach can lead to accelerated localized corrosion beneath the coating.

Monitoring and control systems play a crucial role in material protection strategies. Online monitoring of key parameters such as chloramine levels, pH, conductivity, and corrosion rates allows for timely adjustments to treatment programs. Corrosion coupons and electrical resistance probes installed at strategic locations provide valuable data on system performance and material degradation rates, enabling proactive maintenance before critical failures occur.

Material selection should be based on comprehensive testing under actual operating conditions, as laboratory results may not fully predict field performance. The concentration of chloramine, pH levels, temperature fluctuations, and water chemistry all influence corrosion rates and material degradation patterns. System designers must consider these variables when specifying materials for components such as heat exchangers, piping, valves, and gaskets.

Corrosion mitigation strategies for chloramine-treated cooling systems include the implementation of sacrificial anodes in critical areas to provide cathodic protection. These anodes, typically made of zinc, aluminum, or magnesium alloys, corrode preferentially to protect the primary system components. Regular inspection and replacement of these anodes is essential to maintain protection effectiveness.

Chemical inhibitors represent another important mitigation approach, with phosphate-based, silicate-based, and film-forming inhibitors being commonly employed. These chemicals form protective layers on metal surfaces, reducing direct contact between chloramine and the substrate material. Dosing must be carefully controlled to prevent under or over-treatment, which could lead to ineffective protection or secondary issues like scale formation.

Coating and lining systems provide an additional barrier against chloramine attack. Epoxy, polyurethane, and fluoropolymer coatings have demonstrated good resistance to chloramine degradation when properly applied. However, coating integrity must be maintained through regular inspection and maintenance, as any breach can lead to accelerated localized corrosion beneath the coating.

Monitoring and control systems play a crucial role in material protection strategies. Online monitoring of key parameters such as chloramine levels, pH, conductivity, and corrosion rates allows for timely adjustments to treatment programs. Corrosion coupons and electrical resistance probes installed at strategic locations provide valuable data on system performance and material degradation rates, enabling proactive maintenance before critical failures occur.

Environmental Regulations Impact on Chloramine Usage

Environmental regulations governing water treatment and discharge have significantly evolved over the past decades, directly impacting chloramine usage in cooling water systems across industries. The United States Environmental Protection Agency (EPA) has established increasingly stringent guidelines under the Clean Water Act, particularly focusing on chloramine discharge limits due to their potential environmental toxicity. These regulations have set maximum contaminant levels (MCLs) for disinfection byproducts, including various chloramine compounds, compelling industries to reconsider their biofouling control strategies.

The European Union's Water Framework Directive similarly imposes strict limitations on chloramine discharge, with particular emphasis on protecting aquatic ecosystems from chemical contamination. These regulations have established environmental quality standards (EQS) that industrial facilities must adhere to, often requiring advanced monitoring systems and treatment technologies to ensure compliance.

In Asia-Pacific regions, regulatory frameworks vary significantly, with countries like Japan and Australia implementing comprehensive water quality standards, while developing economies are gradually strengthening their environmental protection measures. This regulatory diversity creates challenges for multinational corporations operating cooling systems across different jurisdictions.

The regulatory landscape has driven significant innovation in chloramine management technologies. Industries must now implement sophisticated dosing control systems that maintain effective biofouling prevention while staying within regulatory limits. This has led to the development of smart monitoring systems that continuously analyze chloramine levels and adjust dosing accordingly, ensuring both operational efficiency and regulatory compliance.

Compliance costs have become a major consideration for industries utilizing cooling water systems. These expenses include implementation of advanced treatment technologies, monitoring equipment, staff training, and reporting systems. Studies indicate that regulatory compliance can represent 15-25% of total cooling water management costs, depending on facility size and local regulatory requirements.

Future regulatory trends suggest even tighter restrictions on chloramine usage, with increasing focus on total environmental impact assessment rather than single-parameter limits. This shift is driving research into alternative biofouling control methods that minimize environmental footprint while maintaining system efficiency. The regulatory push toward "green chemistry" solutions is accelerating development of biodegradable alternatives and non-chemical treatment approaches.

Cross-border regulatory harmonization efforts are emerging, particularly in regions with shared water resources. These initiatives aim to standardize monitoring methodologies and discharge limits, potentially simplifying compliance for international operations while raising the overall standard of environmental protection.

The European Union's Water Framework Directive similarly imposes strict limitations on chloramine discharge, with particular emphasis on protecting aquatic ecosystems from chemical contamination. These regulations have established environmental quality standards (EQS) that industrial facilities must adhere to, often requiring advanced monitoring systems and treatment technologies to ensure compliance.

In Asia-Pacific regions, regulatory frameworks vary significantly, with countries like Japan and Australia implementing comprehensive water quality standards, while developing economies are gradually strengthening their environmental protection measures. This regulatory diversity creates challenges for multinational corporations operating cooling systems across different jurisdictions.

The regulatory landscape has driven significant innovation in chloramine management technologies. Industries must now implement sophisticated dosing control systems that maintain effective biofouling prevention while staying within regulatory limits. This has led to the development of smart monitoring systems that continuously analyze chloramine levels and adjust dosing accordingly, ensuring both operational efficiency and regulatory compliance.

Compliance costs have become a major consideration for industries utilizing cooling water systems. These expenses include implementation of advanced treatment technologies, monitoring equipment, staff training, and reporting systems. Studies indicate that regulatory compliance can represent 15-25% of total cooling water management costs, depending on facility size and local regulatory requirements.

Future regulatory trends suggest even tighter restrictions on chloramine usage, with increasing focus on total environmental impact assessment rather than single-parameter limits. This shift is driving research into alternative biofouling control methods that minimize environmental footprint while maintaining system efficiency. The regulatory push toward "green chemistry" solutions is accelerating development of biodegradable alternatives and non-chemical treatment approaches.

Cross-border regulatory harmonization efforts are emerging, particularly in regions with shared water resources. These initiatives aim to standardize monitoring methodologies and discharge limits, potentially simplifying compliance for international operations while raising the overall standard of environmental protection.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!