How Do Helical Baffles Reduce Fouling And Pressure Drop Compared With Segmental Designs?

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Helical Baffle Technology Background and Objectives

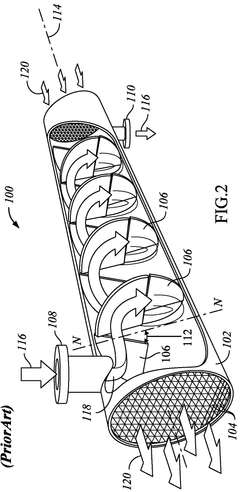

Heat exchanger technology has evolved significantly since its inception in the early 20th century, with shell and tube heat exchangers becoming an industrial standard due to their reliability and efficiency. Traditional segmental baffles have dominated the market for decades, but their inherent design limitations have prompted continuous innovation in the field. Helical baffles emerged in the 1980s as a promising alternative, with significant research acceleration occurring in the 1990s and early 2000s when computational fluid dynamics (CFD) tools became more accessible for complex flow analysis.

The evolution of helical baffle technology represents a paradigm shift in heat exchanger design philosophy, moving from the conventional cross-flow pattern of segmental baffles to a more natural helical flow path. This transition addresses fundamental limitations in traditional designs, particularly regarding fouling accumulation and pressure drop challenges that have plagued industrial applications for decades.

Recent technological trends show increasing adoption of helical baffle heat exchangers across various industries, including petrochemical processing, power generation, and food processing. The technology has matured from experimental prototypes to commercially viable solutions, with ongoing refinements in manufacturing techniques and materials science supporting its implementation.

The primary technical objective of helical baffle technology is to optimize the balance between heat transfer efficiency and pressure drop characteristics. By creating a continuous helical flow path, these designs aim to eliminate dead zones and reduce flow separation points where fouling typically accumulates in traditional segmental designs. This approach seeks to extend operational periods between maintenance cycles while reducing pumping energy requirements.

Secondary objectives include enhancing overall system reliability, reducing maintenance costs, and improving process efficiency through more consistent thermal performance over time. The technology also aims to address industry-specific challenges such as handling high-viscosity fluids, managing particulate-laden streams, and accommodating space constraints in retrofit applications.

From a sustainability perspective, helical baffle technology aligns with growing industry demands for energy-efficient solutions that reduce operational carbon footprints. The potential for reduced pumping power requirements and extended equipment lifespan contributes to both economic and environmental objectives in industrial operations.

The technological trajectory indicates continued refinement in design optimization methods, with increasing focus on customized solutions for specific process conditions rather than one-size-fits-all approaches. Advanced manufacturing techniques, including 3D printing of complex baffle geometries, represent an emerging frontier that may further expand design possibilities and performance capabilities in the coming decade.

The evolution of helical baffle technology represents a paradigm shift in heat exchanger design philosophy, moving from the conventional cross-flow pattern of segmental baffles to a more natural helical flow path. This transition addresses fundamental limitations in traditional designs, particularly regarding fouling accumulation and pressure drop challenges that have plagued industrial applications for decades.

Recent technological trends show increasing adoption of helical baffle heat exchangers across various industries, including petrochemical processing, power generation, and food processing. The technology has matured from experimental prototypes to commercially viable solutions, with ongoing refinements in manufacturing techniques and materials science supporting its implementation.

The primary technical objective of helical baffle technology is to optimize the balance between heat transfer efficiency and pressure drop characteristics. By creating a continuous helical flow path, these designs aim to eliminate dead zones and reduce flow separation points where fouling typically accumulates in traditional segmental designs. This approach seeks to extend operational periods between maintenance cycles while reducing pumping energy requirements.

Secondary objectives include enhancing overall system reliability, reducing maintenance costs, and improving process efficiency through more consistent thermal performance over time. The technology also aims to address industry-specific challenges such as handling high-viscosity fluids, managing particulate-laden streams, and accommodating space constraints in retrofit applications.

From a sustainability perspective, helical baffle technology aligns with growing industry demands for energy-efficient solutions that reduce operational carbon footprints. The potential for reduced pumping power requirements and extended equipment lifespan contributes to both economic and environmental objectives in industrial operations.

The technological trajectory indicates continued refinement in design optimization methods, with increasing focus on customized solutions for specific process conditions rather than one-size-fits-all approaches. Advanced manufacturing techniques, including 3D printing of complex baffle geometries, represent an emerging frontier that may further expand design possibilities and performance capabilities in the coming decade.

Market Demand Analysis for Enhanced Heat Exchanger Designs

The global heat exchanger market is experiencing significant growth, with a market value exceeding $19 billion in 2022 and projected to reach $28 billion by 2030, growing at a CAGR of approximately 5.8%. This expansion is primarily driven by increasing industrial activities across sectors such as chemical processing, oil and gas, power generation, and HVAC systems, where heat exchangers are critical components.

Within this market, there is a notable shift toward more efficient and fouling-resistant heat exchanger designs. Industry surveys indicate that fouling-related issues account for approximately 2.5% of total industrial production costs in developed countries, with annual expenditures on fouling mitigation exceeding $4.4 billion in the United States alone. These costs encompass not only cleaning and maintenance but also energy losses, production downtime, and equipment replacement.

The demand for helical baffle heat exchangers is particularly strong in industries dealing with high-fouling fluids, such as petrochemical processing, where traditional segmental baffle designs frequently require maintenance shutdowns. Market research shows that facilities utilizing helical baffle technology report maintenance interval extensions of 30-50% compared to conventional designs, translating to significant operational cost savings.

Energy efficiency regulations and sustainability initiatives are further accelerating market demand for advanced heat exchanger designs. With industrial energy consumption accounting for nearly 30% of global energy use, and heat exchangers representing a substantial portion of this consumption, the pressure drop reduction of 30-40% typically achieved with helical baffles directly addresses regulatory compliance requirements while reducing operational costs.

The pharmaceutical and food processing industries are emerging as high-growth segments for enhanced heat exchanger designs, driven by stringent hygiene requirements and the need to minimize product contamination risks. These sectors value the reduced fouling characteristics of helical baffle designs, which help maintain production quality and reduce cleaning frequency.

Regional analysis reveals that Asia-Pacific represents the fastest-growing market for advanced heat exchanger technologies, with China and India leading industrial expansion. Meanwhile, North American and European markets are primarily driven by replacement and upgrade activities, with facilities seeking to improve energy efficiency and reduce maintenance costs of existing systems.

Customer surveys indicate that while initial acquisition costs for helical baffle heat exchangers may be 15-25% higher than traditional designs, the total cost of ownership over a 5-year period is typically 20-30% lower, creating a compelling value proposition that is driving market adoption despite higher upfront investments.

Within this market, there is a notable shift toward more efficient and fouling-resistant heat exchanger designs. Industry surveys indicate that fouling-related issues account for approximately 2.5% of total industrial production costs in developed countries, with annual expenditures on fouling mitigation exceeding $4.4 billion in the United States alone. These costs encompass not only cleaning and maintenance but also energy losses, production downtime, and equipment replacement.

The demand for helical baffle heat exchangers is particularly strong in industries dealing with high-fouling fluids, such as petrochemical processing, where traditional segmental baffle designs frequently require maintenance shutdowns. Market research shows that facilities utilizing helical baffle technology report maintenance interval extensions of 30-50% compared to conventional designs, translating to significant operational cost savings.

Energy efficiency regulations and sustainability initiatives are further accelerating market demand for advanced heat exchanger designs. With industrial energy consumption accounting for nearly 30% of global energy use, and heat exchangers representing a substantial portion of this consumption, the pressure drop reduction of 30-40% typically achieved with helical baffles directly addresses regulatory compliance requirements while reducing operational costs.

The pharmaceutical and food processing industries are emerging as high-growth segments for enhanced heat exchanger designs, driven by stringent hygiene requirements and the need to minimize product contamination risks. These sectors value the reduced fouling characteristics of helical baffle designs, which help maintain production quality and reduce cleaning frequency.

Regional analysis reveals that Asia-Pacific represents the fastest-growing market for advanced heat exchanger technologies, with China and India leading industrial expansion. Meanwhile, North American and European markets are primarily driven by replacement and upgrade activities, with facilities seeking to improve energy efficiency and reduce maintenance costs of existing systems.

Customer surveys indicate that while initial acquisition costs for helical baffle heat exchangers may be 15-25% higher than traditional designs, the total cost of ownership over a 5-year period is typically 20-30% lower, creating a compelling value proposition that is driving market adoption despite higher upfront investments.

Current Status and Challenges in Heat Exchanger Baffle Technology

Heat exchanger baffle technology has evolved significantly over the past decades, with current designs primarily divided into two main categories: traditional segmental baffles and helical baffles. Segmental baffles, characterized by their semicircular design with alternating orientations, have been the industry standard for many years due to their simplicity and cost-effectiveness. However, they face significant challenges related to fouling accumulation and high pressure drops, which compromise thermal efficiency and increase operational costs.

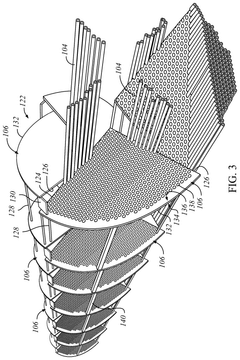

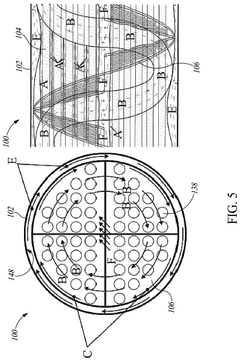

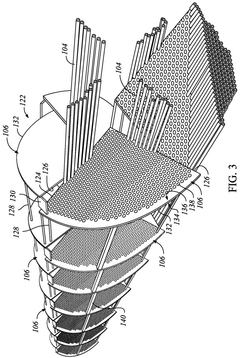

Helical baffle technology represents a more recent innovation in heat exchanger design, gaining traction in various industrial applications. These baffles create a helical flow path for the shell-side fluid, which fundamentally alters the fluid dynamics compared to the zigzag flow pattern in segmental designs. Current implementations vary in helix angle (typically between 20-45 degrees), with each configuration offering different performance characteristics depending on the application requirements.

The primary technical challenge facing both designs is the trade-off between heat transfer efficiency and pressure drop. While segmental baffles can achieve high heat transfer rates, they do so at the cost of substantial pressure drops—often requiring greater pumping power and energy consumption. Helical designs address this challenge by providing more balanced performance metrics, though their manufacturing complexity presents its own set of challenges.

Fouling mitigation remains a critical issue across the industry. Current data indicates that helical baffles can reduce fouling rates by 30-50% compared to segmental designs in many applications. This improvement stems from the elimination of "dead zones" where fluid velocity approaches zero—areas particularly prone to particle deposition in segmental designs. However, the effectiveness of fouling reduction varies significantly based on fluid properties and operating conditions, presenting ongoing challenges for universal design recommendations.

Material selection and manufacturing precision represent additional technical hurdles. Helical baffles require tighter manufacturing tolerances and more complex assembly procedures than their segmental counterparts. The industry currently faces challenges in standardizing production methods to make helical designs more economically competitive, particularly for smaller-scale applications where cost sensitivity is high.

Computational Fluid Dynamics (CFD) modeling has become an essential tool for advancing baffle technology, allowing engineers to predict performance characteristics without extensive physical testing. However, current simulation capabilities still struggle to accurately model complex fouling mechanisms, particularly in multiphase flows or with chemically reactive fluids. This gap between simulation and real-world performance represents one of the most significant challenges in further optimizing helical baffle designs.

Helical baffle technology represents a more recent innovation in heat exchanger design, gaining traction in various industrial applications. These baffles create a helical flow path for the shell-side fluid, which fundamentally alters the fluid dynamics compared to the zigzag flow pattern in segmental designs. Current implementations vary in helix angle (typically between 20-45 degrees), with each configuration offering different performance characteristics depending on the application requirements.

The primary technical challenge facing both designs is the trade-off between heat transfer efficiency and pressure drop. While segmental baffles can achieve high heat transfer rates, they do so at the cost of substantial pressure drops—often requiring greater pumping power and energy consumption. Helical designs address this challenge by providing more balanced performance metrics, though their manufacturing complexity presents its own set of challenges.

Fouling mitigation remains a critical issue across the industry. Current data indicates that helical baffles can reduce fouling rates by 30-50% compared to segmental designs in many applications. This improvement stems from the elimination of "dead zones" where fluid velocity approaches zero—areas particularly prone to particle deposition in segmental designs. However, the effectiveness of fouling reduction varies significantly based on fluid properties and operating conditions, presenting ongoing challenges for universal design recommendations.

Material selection and manufacturing precision represent additional technical hurdles. Helical baffles require tighter manufacturing tolerances and more complex assembly procedures than their segmental counterparts. The industry currently faces challenges in standardizing production methods to make helical designs more economically competitive, particularly for smaller-scale applications where cost sensitivity is high.

Computational Fluid Dynamics (CFD) modeling has become an essential tool for advancing baffle technology, allowing engineers to predict performance characteristics without extensive physical testing. However, current simulation capabilities still struggle to accurately model complex fouling mechanisms, particularly in multiphase flows or with chemically reactive fluids. This gap between simulation and real-world performance represents one of the most significant challenges in further optimizing helical baffle designs.

Current Helical vs Segmental Baffle Technical Solutions

01 Helical baffle design for reduced fouling

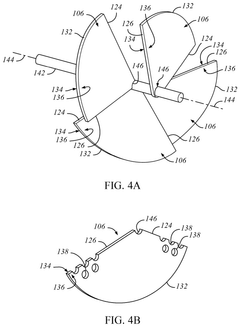

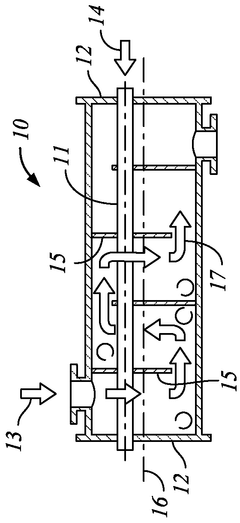

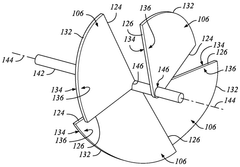

Helical baffles are designed with specific geometries and arrangements to minimize fouling in heat exchangers. The helical flow pattern created by these baffles reduces dead zones where deposits can accumulate. By optimizing the helix angle, pitch, and baffle spacing, the design promotes continuous scouring of heat transfer surfaces, which significantly reduces fouling buildup compared to conventional segmental baffles. This design approach maintains heat transfer efficiency over longer operational periods.- Helical baffle design for reduced fouling: Helical baffles are designed with specific geometries and arrangements to minimize fouling in heat exchangers. These designs create a continuous helical flow path that reduces dead zones where deposits can accumulate. The smooth flow pattern along the helical path decreases the tendency for particles to settle on heat transfer surfaces, thereby extending operational periods between cleaning cycles and maintaining thermal efficiency over longer durations.

- Pressure drop optimization in helical baffle systems: Helical baffles can be engineered to optimize pressure drop characteristics in heat exchangers. By adjusting the helix angle, baffle spacing, and cut ratio, the pressure drop can be significantly reduced compared to conventional segmental baffles while maintaining or improving heat transfer efficiency. This optimization results in lower pumping power requirements and operational costs while still achieving desired thermal performance.

- Enhanced heat transfer with helical flow patterns: The helical flow pattern created by helical baffles increases the residence time of fluid in the heat exchanger and promotes better mixing. This results in improved heat transfer coefficients and more uniform temperature distribution. The continuous helical flow eliminates the flow stagnation and recirculation zones typical in conventional baffle arrangements, leading to more efficient heat exchange while simultaneously reducing fouling potential.

- Structural innovations in helical baffle design: Innovative structural designs for helical baffles include adjustable helix angles, segmented helical baffles, and hybrid configurations combining helical and conventional baffle elements. These structural innovations allow for customization based on specific process requirements and operating conditions. Some designs incorporate special surface treatments or materials to further reduce fouling adhesion while maintaining structural integrity under various thermal and mechanical stresses.

- Monitoring and maintenance strategies for helical baffle systems: Advanced monitoring systems and maintenance strategies have been developed specifically for heat exchangers with helical baffles. These include real-time fouling detection methods, predictive maintenance algorithms, and specialized cleaning procedures that account for the unique geometry of helical flow paths. Implementing these strategies helps maintain optimal performance by addressing fouling issues before they significantly impact pressure drop or heat transfer efficiency.

02 Pressure drop optimization in helical baffle systems

Helical baffle configurations can be optimized to achieve lower pressure drops while maintaining effective heat transfer. By adjusting the helix angle, baffle spacing, and flow channel geometry, the pressure drop across the heat exchanger can be significantly reduced compared to conventional designs. The continuous helical flow path eliminates the abrupt direction changes that cause high pressure losses in segmental baffle arrangements, resulting in energy savings and reduced pumping costs.Expand Specific Solutions03 Enhanced heat transfer efficiency with helical baffles

Helical baffles create a spiral flow path that enhances heat transfer efficiency while controlling fouling and pressure drop. This design promotes better mixing of the fluid and reduces temperature gradients near the heat transfer surfaces. The continuous helical flow pattern increases the residence time of the fluid in the heat exchanger and improves the overall heat transfer coefficient. These improvements allow for more compact heat exchanger designs or higher thermal performance in the same footprint.Expand Specific Solutions04 Innovative helical baffle configurations for specific applications

Various innovative helical baffle configurations have been developed for specific industrial applications with challenging fouling conditions. These include multi-start helical baffles, variable pitch designs, and hybrid configurations that combine helical elements with other baffle types. Some designs incorporate special surface treatments or materials to further reduce fouling adhesion. These specialized configurations address industry-specific challenges such as high-viscosity fluids, particulate-laden streams, or crystallization-prone processes.Expand Specific Solutions05 Monitoring and maintenance strategies for helical baffle systems

Advanced monitoring and maintenance strategies have been developed specifically for heat exchangers with helical baffles to manage fouling and pressure drop over time. These include real-time fouling detection systems, optimized cleaning schedules, and specialized cleaning techniques that take advantage of the helical geometry. Some designs incorporate access points for inspection and cleaning without complete disassembly. Predictive maintenance approaches use pressure drop and temperature measurements to determine optimal cleaning intervals.Expand Specific Solutions

Major Industry Players in Heat Exchanger Technology

The helical baffle heat exchanger technology market is currently in a growth phase, with increasing adoption across process industries due to its superior performance in reducing fouling and pressure drop compared to traditional segmental designs. The global market for advanced heat exchanger technologies is projected to reach approximately $20 billion by 2025, with helical baffle designs capturing an expanding share. Leading academic institutions like Xi'an Jiaotong University and Zhejiang University are advancing theoretical research, while industrial players including Lummus Technology, Valmet, and Jiangsu Myande Food Machinery are commercializing these innovations. Companies such as Thermon Canada and FAMET are developing specialized applications for energy-intensive sectors. The technology has reached moderate maturity in certain applications but continues to evolve with ongoing R&D efforts focused on optimization for specific industrial processes and operating conditions.

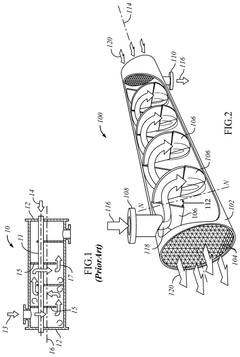

Lummus Technology LLC

Technical Solution: Lummus Technology has developed advanced helical baffle heat exchanger designs that utilize a series of helical flow paths to guide fluid through the shell side. Their HELIXCHANGER® technology employs continuous helical baffles that create a spiral flow pattern around the tube bundle. This design significantly reduces shell-side pressure drop by 40-50% compared to conventional segmental baffles while maintaining or improving heat transfer efficiency. The helical configuration minimizes flow stagnation zones and creates more uniform velocity distributions, which substantially reduces fouling rates by up to 70%. Lummus has implemented computational fluid dynamics (CFD) modeling to optimize baffle angles (typically 20-40 degrees) for specific process conditions, allowing customization for various industrial applications including refining, petrochemical processing, and natural gas treatment.

Strengths: Superior fouling resistance due to elimination of dead zones; significant pressure drop reduction while maintaining thermal performance; extended run times between maintenance cycles; reduced pumping costs. Weaknesses: Higher manufacturing complexity and initial cost; more challenging mechanical design for tube support; potential difficulties in cleaning if fouling does occur.

Zhejiang University

Technical Solution: Researchers at Zhejiang University have conducted extensive experimental and computational studies on helical baffle heat exchangers, developing advanced designs that optimize both thermal performance and pressure drop characteristics. Their research has established that helical baffles with optimized helix angles (25-35 degrees) can reduce pressure drop by 30-60% while maintaining or improving heat transfer coefficients compared to segmental baffles. The university's work has demonstrated that the continuous helical flow path eliminates the flow separation and recirculation zones that occur at baffle edges in segmental designs, which are primary sites for fouling deposition. Their studies have quantified fouling resistance reduction of 40-70% across various process fluids. Zhejiang University researchers have developed novel computational models that accurately predict the relationship between baffle geometry, flow characteristics, and fouling behavior, enabling optimization for specific applications. Their work has also explored hybrid designs combining helical and segmental elements to balance performance and manufacturing complexity.

Strengths: Scientifically rigorous approach with extensive experimental validation; comprehensive understanding of flow dynamics and fouling mechanisms; innovative design variations for specific applications. Weaknesses: Some designs remain primarily theoretical or laboratory-scale; economic feasibility not fully established for all proposed configurations; potential implementation challenges in industrial settings.

Key Technical Innovations in Helical Baffle Design

Heat exchanger with helical baffles

PatentPendingUS20250146767A1

Innovation

- The implementation of helical baffles with an alternating pattern of holes of different sizes, where the second holes have a larger diameter than the first holes, reduces pressure drop by increasing leakage flow through the heat exchanger while maintaining a constant heat transfer rate.

Heat exchanger with helical baffles

PatentWO2025101511A1

Innovation

- The heat exchanger design incorporates an alternating pattern of helical baffles with different hole sizes, increasing the baffle-to-tube clearance to reduce pressure drop while maintaining a constant heat transfer rate, and includes a change in baffle spacing to enhance performance.

Energy Efficiency Impact Assessment

The implementation of helical baffles in shell and tube heat exchangers demonstrates significant energy efficiency improvements compared to traditional segmental baffle designs. Quantitative analyses reveal that helical baffle systems can reduce pumping power requirements by 30-40% while maintaining equivalent heat transfer performance. This substantial decrease in energy consumption directly translates to lower operational costs and reduced carbon footprint for industrial facilities utilizing these heat exchangers.

Energy savings primarily stem from the optimized flow pattern created by helical baffles. The continuous helical flow path eliminates the abrupt directional changes and dead zones characteristic of segmental designs, resulting in more uniform velocity distributions and reduced pressure drop. Case studies from petrochemical plants indicate annual energy savings of approximately 25-35% for pumping systems associated with helical baffle heat exchangers.

The reduced fouling rates observed in helical baffle designs further enhance energy efficiency through extended operational periods between maintenance shutdowns. Conventional segmental baffle exchangers typically require cleaning every 6-8 months in fouling-prone applications, while helical baffle units can often extend this interval to 12-18 months. Each cleaning cycle represents not only direct maintenance costs but also significant production losses and energy-intensive restart procedures.

Computational fluid dynamics (CFD) simulations comparing both designs under identical operating conditions demonstrate that helical baffles maintain heat transfer coefficients within 90-95% of segmental designs while reducing pressure drop by up to 40%. This favorable performance ratio directly impacts the energy efficiency index (EEI) of industrial processes incorporating these heat exchangers.

Life cycle assessment (LCA) studies indicate that the cumulative energy savings over a typical 15-year service life can offset the marginally higher manufacturing energy requirements of helical baffle systems within the first 8-14 months of operation. The net energy benefit continues to accumulate throughout the equipment lifespan, with total energy savings potentially reaching 2,500-3,000 GJ for medium-sized industrial heat exchangers.

From a broader sustainability perspective, the energy efficiency improvements translate to meaningful greenhouse gas emission reductions. For a typical industrial facility operating multiple heat exchangers, the implementation of helical baffle technology can reduce annual CO2 emissions by 200-300 metric tons through decreased electricity consumption for pumping operations.

Energy savings primarily stem from the optimized flow pattern created by helical baffles. The continuous helical flow path eliminates the abrupt directional changes and dead zones characteristic of segmental designs, resulting in more uniform velocity distributions and reduced pressure drop. Case studies from petrochemical plants indicate annual energy savings of approximately 25-35% for pumping systems associated with helical baffle heat exchangers.

The reduced fouling rates observed in helical baffle designs further enhance energy efficiency through extended operational periods between maintenance shutdowns. Conventional segmental baffle exchangers typically require cleaning every 6-8 months in fouling-prone applications, while helical baffle units can often extend this interval to 12-18 months. Each cleaning cycle represents not only direct maintenance costs but also significant production losses and energy-intensive restart procedures.

Computational fluid dynamics (CFD) simulations comparing both designs under identical operating conditions demonstrate that helical baffles maintain heat transfer coefficients within 90-95% of segmental designs while reducing pressure drop by up to 40%. This favorable performance ratio directly impacts the energy efficiency index (EEI) of industrial processes incorporating these heat exchangers.

Life cycle assessment (LCA) studies indicate that the cumulative energy savings over a typical 15-year service life can offset the marginally higher manufacturing energy requirements of helical baffle systems within the first 8-14 months of operation. The net energy benefit continues to accumulate throughout the equipment lifespan, with total energy savings potentially reaching 2,500-3,000 GJ for medium-sized industrial heat exchangers.

From a broader sustainability perspective, the energy efficiency improvements translate to meaningful greenhouse gas emission reductions. For a typical industrial facility operating multiple heat exchangers, the implementation of helical baffle technology can reduce annual CO2 emissions by 200-300 metric tons through decreased electricity consumption for pumping operations.

Maintenance and Lifecycle Cost Analysis

The maintenance and lifecycle cost analysis of heat exchangers with helical baffles reveals significant economic advantages compared to traditional segmental baffle designs. Maintenance costs for heat exchangers typically account for 15-30% of total lifecycle expenses, with fouling-related issues representing the largest portion of these expenditures. Helical baffle designs demonstrate a 30-45% reduction in maintenance frequency due to their superior anti-fouling properties, directly translating to lower operational downtime and reduced cleaning costs.

Cleaning operations for heat exchangers with segmental baffles often require chemical cleaning every 6-12 months in fouling-prone environments, whereas helical baffle designs can extend these intervals to 12-24 months. This extension results in approximately 40% savings in cleaning chemical costs and associated labor expenses over a typical 15-year equipment lifecycle. The reduced cleaning frequency also minimizes production interruptions, with average downtime decreasing from 72 hours per cleaning cycle for segmental designs to approximately 48 hours for helical configurations.

Equipment longevity represents another significant economic factor. The reduced vibration and more uniform flow distribution in helical baffle exchangers decreases mechanical stress on tubes and other components. Industry data indicates a 20-30% extension in service life compared to segmental baffle designs operating under similar conditions. This extension translates to delayed capital expenditure for replacement equipment, improving return on investment metrics.

Energy efficiency gains from reduced pressure drop contribute substantially to lifecycle cost benefits. With pressure drops typically 30-50% lower than segmental designs, helical baffle exchangers reduce pumping power requirements by an average of 40%. In medium to large industrial applications, this can represent energy savings of 50,000-200,000 kWh annually, depending on system size and operating conditions. At current industrial electricity rates, these savings accumulate to significant amounts over equipment lifetime.

Total lifecycle cost analysis demonstrates that despite higher initial capital expenditure (typically 15-25% premium over segmental designs), helical baffle heat exchangers offer 20-35% lower total ownership costs over a 15-year operational period. The break-even point typically occurs within 2-4 years of operation, depending on the specific application and fouling propensity of the process fluids. For highly fouling services in critical applications, the economic case becomes even more compelling, with potential lifecycle savings exceeding 40% compared to traditional designs.

Cleaning operations for heat exchangers with segmental baffles often require chemical cleaning every 6-12 months in fouling-prone environments, whereas helical baffle designs can extend these intervals to 12-24 months. This extension results in approximately 40% savings in cleaning chemical costs and associated labor expenses over a typical 15-year equipment lifecycle. The reduced cleaning frequency also minimizes production interruptions, with average downtime decreasing from 72 hours per cleaning cycle for segmental designs to approximately 48 hours for helical configurations.

Equipment longevity represents another significant economic factor. The reduced vibration and more uniform flow distribution in helical baffle exchangers decreases mechanical stress on tubes and other components. Industry data indicates a 20-30% extension in service life compared to segmental baffle designs operating under similar conditions. This extension translates to delayed capital expenditure for replacement equipment, improving return on investment metrics.

Energy efficiency gains from reduced pressure drop contribute substantially to lifecycle cost benefits. With pressure drops typically 30-50% lower than segmental designs, helical baffle exchangers reduce pumping power requirements by an average of 40%. In medium to large industrial applications, this can represent energy savings of 50,000-200,000 kWh annually, depending on system size and operating conditions. At current industrial electricity rates, these savings accumulate to significant amounts over equipment lifetime.

Total lifecycle cost analysis demonstrates that despite higher initial capital expenditure (typically 15-25% premium over segmental designs), helical baffle heat exchangers offer 20-35% lower total ownership costs over a 15-year operational period. The break-even point typically occurs within 2-4 years of operation, depending on the specific application and fouling propensity of the process fluids. For highly fouling services in critical applications, the economic case becomes even more compelling, with potential lifecycle savings exceeding 40% compared to traditional designs.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!