How Do Duplex And Titanium Tubes Resist MIC And Pitting In Seawater Duties?

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Seawater Corrosion Resistance Background and Objectives

Seawater corrosion represents one of the most challenging environments for materials in marine applications, with microbiologically influenced corrosion (MIC) and pitting corrosion being particularly destructive phenomena. The historical development of corrosion-resistant alloys for seawater applications has evolved significantly over the past century, from basic carbon steels to sophisticated duplex stainless steels and titanium alloys.

The evolution of these materials has been driven by increasing demands for reliability in critical marine infrastructure, offshore oil and gas installations, desalination plants, and naval applications. Early failures in conventional materials led to substantial economic losses and safety concerns, prompting intensive research into more resilient alternatives.

Duplex stainless steels emerged in the 1930s but gained significant traction in the 1970s with the development of modern duplex grades. These materials combine the strength of ferritic steels with the corrosion resistance of austenitic grades through their characteristic dual-phase microstructure. Titanium alloys, meanwhile, have been increasingly adopted since the 1950s for the most demanding seawater applications due to their exceptional corrosion resistance.

The technical objective of utilizing duplex stainless steels and titanium tubes in seawater environments centers on achieving long-term operational reliability while minimizing maintenance requirements and lifecycle costs. These materials must withstand not only general corrosion but specifically resist localized attacks such as pitting and MIC, which can cause rapid and unpredictable failures.

Current industry trends indicate growing adoption of these advanced materials as operational lifespans extend and as installations move into more aggressive environments, including deeper waters and higher temperature applications. The economic justification for premium materials has strengthened as the cost of failures and downtime increases in critical infrastructure.

The technical goals for these materials include maintaining structural integrity under combined stresses (mechanical, thermal, and chemical), providing predictable service life of 25+ years in seawater environments, and offering resistance to biofilm formation that typically precedes MIC. Additionally, these materials must maintain their protective properties despite variations in seawater chemistry, temperature, flow rates, and biological activity.

Understanding the fundamental mechanisms by which duplex stainless steels and titanium resist MIC and pitting corrosion is essential for optimizing material selection, predicting service life, and developing next-generation alloys with enhanced performance characteristics. This technical investigation aims to elucidate these mechanisms and provide guidance for engineering applications in seawater environments.

The evolution of these materials has been driven by increasing demands for reliability in critical marine infrastructure, offshore oil and gas installations, desalination plants, and naval applications. Early failures in conventional materials led to substantial economic losses and safety concerns, prompting intensive research into more resilient alternatives.

Duplex stainless steels emerged in the 1930s but gained significant traction in the 1970s with the development of modern duplex grades. These materials combine the strength of ferritic steels with the corrosion resistance of austenitic grades through their characteristic dual-phase microstructure. Titanium alloys, meanwhile, have been increasingly adopted since the 1950s for the most demanding seawater applications due to their exceptional corrosion resistance.

The technical objective of utilizing duplex stainless steels and titanium tubes in seawater environments centers on achieving long-term operational reliability while minimizing maintenance requirements and lifecycle costs. These materials must withstand not only general corrosion but specifically resist localized attacks such as pitting and MIC, which can cause rapid and unpredictable failures.

Current industry trends indicate growing adoption of these advanced materials as operational lifespans extend and as installations move into more aggressive environments, including deeper waters and higher temperature applications. The economic justification for premium materials has strengthened as the cost of failures and downtime increases in critical infrastructure.

The technical goals for these materials include maintaining structural integrity under combined stresses (mechanical, thermal, and chemical), providing predictable service life of 25+ years in seawater environments, and offering resistance to biofilm formation that typically precedes MIC. Additionally, these materials must maintain their protective properties despite variations in seawater chemistry, temperature, flow rates, and biological activity.

Understanding the fundamental mechanisms by which duplex stainless steels and titanium resist MIC and pitting corrosion is essential for optimizing material selection, predicting service life, and developing next-generation alloys with enhanced performance characteristics. This technical investigation aims to elucidate these mechanisms and provide guidance for engineering applications in seawater environments.

Market Demand for Corrosion-Resistant Marine Materials

The global market for corrosion-resistant marine materials has experienced significant growth in recent years, driven primarily by expanding offshore oil and gas operations, increasing naval defense budgets, and the rapid development of marine renewable energy installations. The demand for specialized materials like duplex stainless steel and titanium tubes has seen a compound annual growth rate of approximately 6.8% between 2018 and 2023, with projections indicating continued strong performance through 2030.

Seawater applications present one of the most challenging environments for metallic components, with microbiologically influenced corrosion (MIC) and pitting corrosion representing critical failure mechanisms that can compromise structural integrity and operational safety. This has created a substantial market need for advanced materials that can withstand these specific corrosion types while maintaining mechanical properties in harsh marine conditions.

The offshore oil and gas sector remains the largest consumer of corrosion-resistant marine materials, accounting for roughly 42% of market share. This sector's demand is particularly focused on materials for heat exchangers, pumping systems, and subsea equipment where exposure to seawater is constant and failure costs are exceptionally high. The average replacement cost for a failed heat exchanger tube bundle can exceed $500,000, not including production downtime losses.

Desalination plants represent another rapidly growing market segment, with global capacity additions increasing by nearly 30% over the past five years. These facilities require extensive use of corrosion-resistant tubing materials for heat exchangers and water transport systems, with material failure potentially resulting in complete plant shutdown. The Middle East and North Africa region leads this market segment, followed by Asia-Pacific.

Naval defense applications constitute a premium segment within this market, where performance requirements often supersede cost considerations. Naval vessels typically utilize titanium alloys for critical seawater cooling systems, particularly in submarines and specialized surface vessels. This segment has shown steady growth aligned with increasing defense budgets globally.

The marine renewable energy sector, particularly offshore wind and emerging tidal energy installations, represents the fastest-growing market segment with annual growth rates exceeding 15%. These installations face unique challenges with both atmospheric and immersed corrosion conditions, driving demand for specialized duplex stainless steel components.

Market analysis indicates a growing preference for lifecycle cost assessment rather than initial acquisition cost when selecting materials for marine applications. This trend favors premium materials like super duplex stainless steels and titanium alloys, which despite higher upfront costs, deliver superior total cost of ownership through extended service life and reduced maintenance requirements.

Seawater applications present one of the most challenging environments for metallic components, with microbiologically influenced corrosion (MIC) and pitting corrosion representing critical failure mechanisms that can compromise structural integrity and operational safety. This has created a substantial market need for advanced materials that can withstand these specific corrosion types while maintaining mechanical properties in harsh marine conditions.

The offshore oil and gas sector remains the largest consumer of corrosion-resistant marine materials, accounting for roughly 42% of market share. This sector's demand is particularly focused on materials for heat exchangers, pumping systems, and subsea equipment where exposure to seawater is constant and failure costs are exceptionally high. The average replacement cost for a failed heat exchanger tube bundle can exceed $500,000, not including production downtime losses.

Desalination plants represent another rapidly growing market segment, with global capacity additions increasing by nearly 30% over the past five years. These facilities require extensive use of corrosion-resistant tubing materials for heat exchangers and water transport systems, with material failure potentially resulting in complete plant shutdown. The Middle East and North Africa region leads this market segment, followed by Asia-Pacific.

Naval defense applications constitute a premium segment within this market, where performance requirements often supersede cost considerations. Naval vessels typically utilize titanium alloys for critical seawater cooling systems, particularly in submarines and specialized surface vessels. This segment has shown steady growth aligned with increasing defense budgets globally.

The marine renewable energy sector, particularly offshore wind and emerging tidal energy installations, represents the fastest-growing market segment with annual growth rates exceeding 15%. These installations face unique challenges with both atmospheric and immersed corrosion conditions, driving demand for specialized duplex stainless steel components.

Market analysis indicates a growing preference for lifecycle cost assessment rather than initial acquisition cost when selecting materials for marine applications. This trend favors premium materials like super duplex stainless steels and titanium alloys, which despite higher upfront costs, deliver superior total cost of ownership through extended service life and reduced maintenance requirements.

Current Challenges in Seawater Corrosion Protection

Seawater environments present significant challenges for materials used in marine applications, with corrosion being the primary concern that impacts structural integrity, operational efficiency, and maintenance costs. Despite advances in materials science, several persistent challenges continue to plague seawater corrosion protection systems, particularly for critical components like heat exchanger tubes in desalination plants, offshore platforms, and naval vessels.

Microbiologically Influenced Corrosion (MIC) remains one of the most insidious forms of corrosion in seawater applications. The complex microbial communities in marine environments can accelerate corrosion rates by up to 10 times compared to sterile conditions. These microorganisms form biofilms that create localized chemistry changes, leading to differential aeration cells and subsequent accelerated corrosion.

Pitting corrosion presents another significant challenge, particularly in chloride-rich seawater environments. The unpredictable nature of pitting initiation and propagation makes it difficult to model and predict failure rates accurately. Current monitoring technologies often detect pitting damage only after significant material degradation has occurred, limiting preventive maintenance opportunities.

The variability of seawater conditions across different geographical locations compounds these challenges. Factors such as temperature, salinity, dissolved oxygen content, and biological activity vary significantly between tropical and arctic waters, requiring different protection strategies. This environmental variability makes universal protection solutions nearly impossible to implement.

Traditional cathodic protection systems face limitations in complex geometries and crevice areas, where achieving uniform current distribution remains problematic. Additionally, impressed current systems require continuous power supply and monitoring, presenting logistical challenges for remote offshore installations.

Coating technologies, while continuously improving, still struggle with long-term adhesion in submerged conditions. Mechanical damage during installation or operation often compromises coating integrity, creating vulnerable points for corrosion initiation. The environmental regulations restricting the use of certain effective but toxic anti-fouling compounds have further complicated protection strategies.

The economic impact of these challenges is substantial, with the global cost of corrosion in marine environments estimated at hundreds of billions annually. Industries face difficult trade-offs between initial material costs and long-term maintenance expenses. While advanced materials like duplex stainless steels and titanium alloys offer superior resistance, their higher procurement costs often lead to suboptimal material selections based on short-term budget constraints rather than lifecycle cost analysis.

Emerging technologies like advanced sensors for real-time corrosion monitoring and machine learning algorithms for predictive maintenance show promise but remain in early adoption phases. The integration of these technologies into comprehensive corrosion management systems represents the next frontier in addressing seawater corrosion challenges.

Microbiologically Influenced Corrosion (MIC) remains one of the most insidious forms of corrosion in seawater applications. The complex microbial communities in marine environments can accelerate corrosion rates by up to 10 times compared to sterile conditions. These microorganisms form biofilms that create localized chemistry changes, leading to differential aeration cells and subsequent accelerated corrosion.

Pitting corrosion presents another significant challenge, particularly in chloride-rich seawater environments. The unpredictable nature of pitting initiation and propagation makes it difficult to model and predict failure rates accurately. Current monitoring technologies often detect pitting damage only after significant material degradation has occurred, limiting preventive maintenance opportunities.

The variability of seawater conditions across different geographical locations compounds these challenges. Factors such as temperature, salinity, dissolved oxygen content, and biological activity vary significantly between tropical and arctic waters, requiring different protection strategies. This environmental variability makes universal protection solutions nearly impossible to implement.

Traditional cathodic protection systems face limitations in complex geometries and crevice areas, where achieving uniform current distribution remains problematic. Additionally, impressed current systems require continuous power supply and monitoring, presenting logistical challenges for remote offshore installations.

Coating technologies, while continuously improving, still struggle with long-term adhesion in submerged conditions. Mechanical damage during installation or operation often compromises coating integrity, creating vulnerable points for corrosion initiation. The environmental regulations restricting the use of certain effective but toxic anti-fouling compounds have further complicated protection strategies.

The economic impact of these challenges is substantial, with the global cost of corrosion in marine environments estimated at hundreds of billions annually. Industries face difficult trade-offs between initial material costs and long-term maintenance expenses. While advanced materials like duplex stainless steels and titanium alloys offer superior resistance, their higher procurement costs often lead to suboptimal material selections based on short-term budget constraints rather than lifecycle cost analysis.

Emerging technologies like advanced sensors for real-time corrosion monitoring and machine learning algorithms for predictive maintenance show promise but remain in early adoption phases. The integration of these technologies into comprehensive corrosion management systems represents the next frontier in addressing seawater corrosion challenges.

Existing MIC and Pitting Prevention Solutions

01 Duplex stainless steel composition for corrosion resistance

Duplex stainless steels with specific compositions offer enhanced resistance to microbiologically influenced corrosion (MIC) and pitting. These steels typically contain balanced amounts of austenite and ferrite phases with optimized levels of chromium, nickel, molybdenum, and nitrogen. The dual-phase microstructure provides superior corrosion resistance in aggressive environments compared to conventional stainless steels, making them suitable for tube applications in marine and chemical processing environments.- Duplex stainless steel composition for MIC and pitting resistance: Duplex stainless steels with specific compositions offer enhanced resistance to microbiologically influenced corrosion (MIC) and pitting. These alloys typically contain balanced amounts of chromium, nickel, molybdenum, and nitrogen that work synergistically to create a stable passive layer. The dual-phase microstructure of ferrite and austenite contributes to superior corrosion resistance in aggressive environments where both MIC and pitting are concerns.

- Titanium alloy tubes with enhanced corrosion resistance: Titanium alloy tubes demonstrate exceptional resistance to microbiologically influenced corrosion and pitting due to their naturally forming stable oxide layer. Specific titanium alloys can be formulated with elements such as molybdenum, nickel, and palladium to further enhance their resistance to localized corrosion in harsh environments. These titanium tubes are particularly valuable in marine applications and chemical processing where both MIC and pitting corrosion are significant concerns.

- Surface treatment methods for improving corrosion resistance: Various surface treatment methods can significantly enhance the resistance of both duplex stainless steel and titanium tubes to MIC and pitting corrosion. These treatments include passivation processes, electropolishing, and the application of specialized coatings. Surface modifications create more uniform and stable passive layers that prevent the initiation of localized corrosion. Additionally, certain treatments can reduce surface roughness, which minimizes sites where microorganisms can attach and initiate MIC.

- Heat treatment processes for optimizing corrosion resistance: Specific heat treatment processes can optimize the microstructure of duplex stainless steel and titanium tubes to maximize their resistance to MIC and pitting. Controlled heating and cooling cycles help achieve the ideal phase balance in duplex steels and the optimal crystal structure in titanium alloys. These heat treatments can dissolve detrimental precipitates, homogenize the material composition, and create a more uniform passive layer, all contributing to enhanced resistance against localized corrosion phenomena.

- Alloying elements and their impact on corrosion resistance: The addition of specific alloying elements plays a crucial role in enhancing the resistance of both duplex stainless steel and titanium tubes to MIC and pitting corrosion. Elements such as chromium, molybdenum, and nitrogen in duplex steels, and palladium, ruthenium, or nickel in titanium alloys, significantly improve corrosion resistance. These elements contribute to the formation of more stable passive films, increase the pitting resistance equivalent number (PREN), and create environments less favorable for microbiological activity on the metal surface.

02 Titanium alloy formulations for improved corrosion resistance

Titanium tubes can be formulated with specific alloying elements to enhance their resistance to MIC and pitting corrosion. These alloys typically incorporate elements such as molybdenum, nickel, and palladium that stabilize the passive oxide layer on titanium surfaces. The resulting tubes exhibit exceptional resistance to localized corrosion in chloride-containing environments and biologically active media, making them ideal for applications in seawater systems and chemical processing where conventional materials would fail.Expand Specific Solutions03 Surface treatment methods for enhanced corrosion resistance

Various surface treatment methods can be applied to duplex and titanium tubes to further enhance their resistance to MIC and pitting. These include passivation treatments, electropolishing, and the application of specialized coatings. Such treatments modify the surface properties by removing free iron, enhancing the passive layer formation, or creating a protective barrier. The treated surfaces show improved resistance to bacterial attachment and initiation of localized corrosion, extending the service life of tubes in corrosive environments.Expand Specific Solutions04 Manufacturing processes for corrosion-resistant tubes

Specialized manufacturing processes can significantly improve the MIC and pitting resistance of duplex and titanium tubes. These processes include controlled heat treatment, cold working, and precise welding techniques that maintain the material's microstructure and corrosion resistance. The manufacturing methods focus on achieving uniform properties throughout the tube, eliminating weak points that could become sites for corrosion initiation, and ensuring consistent performance in aggressive environments.Expand Specific Solutions05 Testing and qualification methods for corrosion resistance

Specific testing and qualification methods have been developed to evaluate the resistance of duplex and titanium tubes to MIC and pitting corrosion. These include accelerated corrosion tests, electrochemical measurements, and microbiological exposure tests that simulate real-world conditions. The testing protocols help in selecting appropriate materials for specific applications and predicting long-term performance. Advanced analytical techniques are also used to investigate corrosion mechanisms and develop improved alloys and treatments for enhanced resistance.Expand Specific Solutions

Leading Manufacturers in Corrosion-Resistant Tube Industry

The seawater corrosion resistance market for duplex and titanium tubes is in a mature growth phase, with an estimated global market size exceeding $2 billion annually. Technologically, titanium offers superior resistance to microbiologically influenced corrosion (MIC) and pitting in aggressive seawater environments, while duplex stainless steels provide a cost-effective alternative with good performance. Key players demonstrate varying technological maturity: POSCO Holdings, Nippon Steel, and JFE Steel lead in advanced duplex steel development; Titanium specialists include Sumitomo and Hitachi; while Technip Energies provides engineering expertise for marine applications. Companies like Brunswick Corp. and National Oilwell Varco represent end-users driving innovation in marine equipment requiring superior corrosion resistance, particularly for offshore and naval applications.

Institute of Metal Research Chinese Academy of Sciences

Technical Solution: The Institute of Metal Research (IMR) at the Chinese Academy of Sciences has conducted extensive research on advanced duplex stainless steel and titanium tube materials for seawater applications. Their research team has developed modified duplex stainless steel compositions containing optimized levels of chromium (24-26%), molybdenum (3-4%), and nitrogen (0.25-0.30%) to achieve Pitting Resistance Equivalent Numbers (PREN) exceeding 40. IMR's innovative approach includes controlled additions of rare earth elements (0.03-0.05% cerium) that modify the morphology and distribution of inclusions, significantly improving pitting resistance. Their manufacturing process incorporates precise thermomechanical treatments including solution annealing at 1080°C followed by controlled cooling rates to maintain ideal phase balance. For titanium tubes, IMR has developed novel surface modification techniques including plasma electrolytic oxidation treatments that create a 10-15μm thick ceramic-like TiO2 layer with enhanced resistance to biofilm attachment. Their research has demonstrated that these modified surfaces reduce bacterial adhesion by over 85% compared to untreated titanium, significantly mitigating MIC risk. IMR's comparative studies have shown their optimized duplex stainless steel tubes maintain corrosion rates below 0.01mm/year in accelerated testing with artificial seawater containing sulfate-reducing bacteria, while their surface-modified titanium tubes show virtually no measurable weight loss under identical conditions.

Strengths: Cutting-edge research combining metallurgical optimization and surface engineering approaches; development of cost-effective solutions through microstructural control rather than solely relying on expensive alloying elements; comprehensive testing protocols that accurately simulate real-world marine conditions. Weaknesses: Some advanced technologies remain at laboratory or pilot scale rather than full commercial implementation; certain surface treatments may have limited long-term stability in dynamic seawater environments; economic viability of some approaches not fully established for mass production.

NIPPON STEEL CORP.

Technical Solution: Nippon Steel has developed advanced duplex stainless steel (DSS) tubes specifically engineered for seawater applications. Their proprietary Super Duplex Stainless Steel (SDSS) contains approximately 25% chromium, 7% nickel, 3.5% molybdenum, and controlled nitrogen additions, creating a balanced microstructure of approximately 50% austenite and 50% ferrite phases. This balanced structure provides superior resistance to microbiologically influenced corrosion (MIC) and pitting in aggressive seawater environments. Nippon Steel's manufacturing process includes solution annealing at precisely controlled temperatures (1050-1100°C) followed by rapid quenching to prevent detrimental intermetallic phase formation. Their tubes undergo specialized surface treatments including pickling and passivation to enhance the protective chromium oxide layer. For extreme conditions, they've developed specialized grades with increased pitting resistance equivalent numbers (PREN > 40) through optimized molybdenum and nitrogen content, significantly outperforming conventional materials in accelerated corrosion testing.

Strengths: Superior resistance to both localized corrosion and stress corrosion cracking due to the balanced microstructure; excellent mechanical properties including high yield strength (>550 MPa) and good toughness; cost-effective alternative to more expensive titanium in many applications. Weaknesses: Susceptibility to embrittlement if improperly heat treated; more difficult to weld than conventional stainless steels; higher initial cost compared to standard austenitic grades.

Key Metallurgical Innovations for Seawater Applications

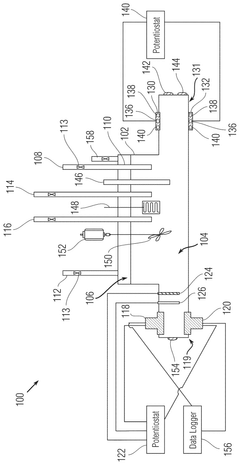

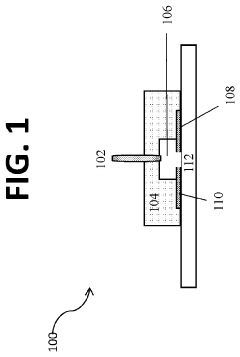

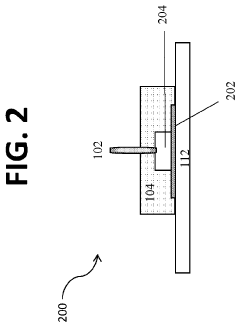

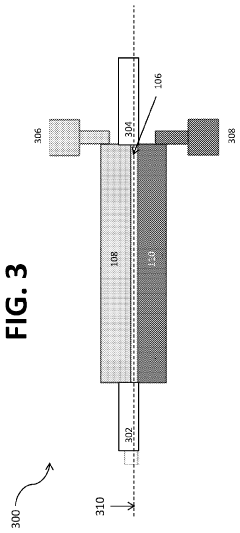

Apparatus for in-situ monitoring of general corrosion and localized microbiologically influenced corrosion (MIC)

PatentActiveUS12098996B2

Innovation

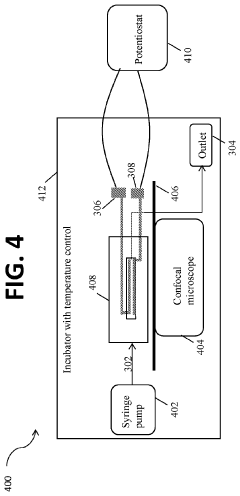

- An apparatus comprising electrical resistance (ER) and electrochemical noise (EN) probes within a chamber, connected to potentiostats, allows for simultaneous measurement of general and localized corrosion rates without surface polarization, enabling real-time monitoring in a simulated environment, with adjustable probe alignment and chemical injection capabilities to assess the effects of biocides and corrosion inhibitors.

M-MIC: Microfluidic Microbiologically Influenced Corrosion Model

PatentPendingUS20200217778A1

Innovation

- A microfluidic MIC flow cell system (M-MIC) that generates a laminar flow of microorganisms to form biofilms on electrodes, allowing for real-time electrochemical measurements to monitor corrosion and biofilm development, enabling the identification of microorganisms and effectiveness of biocide treatments.

Environmental Impact of Corrosion-Resistant Materials

The environmental implications of corrosion-resistant materials like duplex stainless steel and titanium tubes extend far beyond their immediate industrial applications. When considering the lifecycle environmental impact of these materials in seawater applications, their superior resistance to microbiologically influenced corrosion (MIC) and pitting significantly reduces the frequency of replacement and maintenance operations, thereby minimizing waste generation and resource consumption.

The manufacturing processes for these corrosion-resistant alloys, particularly titanium, require substantial energy inputs, contributing to their initial carbon footprint. However, this environmental cost is often offset by their extended service life in harsh marine environments. Studies indicate that titanium tubes can last up to five times longer than conventional materials in seawater applications, resulting in a net reduction of lifecycle environmental impact despite higher initial production emissions.

Reduced leaching of metal ions into marine ecosystems represents another critical environmental benefit. Unlike less resistant materials that gradually release potentially harmful metal compounds into seawater, properly specified duplex stainless steels and titanium alloys maintain their structural integrity with minimal material loss to the surrounding environment, protecting sensitive marine biota from metal contamination.

The recyclability of these materials further enhances their environmental profile. Both duplex stainless steel and titanium maintain their valuable properties through multiple recycling cycles, with recovery rates exceeding 90% in modern recycling facilities. This circular economy aspect significantly reduces the need for virgin material extraction and associated environmental disruptions.

From a chemical perspective, the passive oxide films that form on these materials' surfaces not only protect against corrosion but also minimize the need for environmentally problematic protective coatings and treatments. Traditional corrosion prevention methods often involve toxic compounds that can leach into marine environments, whereas these advanced alloys rely primarily on their inherent properties.

Energy efficiency in operational systems also improves with these materials. The smooth, corrosion-free surfaces of properly maintained titanium and duplex steel heat exchangers and piping systems maintain optimal thermal transfer efficiency throughout their service life, reducing energy consumption in marine applications such as desalination plants and offshore energy facilities.

The manufacturing processes for these corrosion-resistant alloys, particularly titanium, require substantial energy inputs, contributing to their initial carbon footprint. However, this environmental cost is often offset by their extended service life in harsh marine environments. Studies indicate that titanium tubes can last up to five times longer than conventional materials in seawater applications, resulting in a net reduction of lifecycle environmental impact despite higher initial production emissions.

Reduced leaching of metal ions into marine ecosystems represents another critical environmental benefit. Unlike less resistant materials that gradually release potentially harmful metal compounds into seawater, properly specified duplex stainless steels and titanium alloys maintain their structural integrity with minimal material loss to the surrounding environment, protecting sensitive marine biota from metal contamination.

The recyclability of these materials further enhances their environmental profile. Both duplex stainless steel and titanium maintain their valuable properties through multiple recycling cycles, with recovery rates exceeding 90% in modern recycling facilities. This circular economy aspect significantly reduces the need for virgin material extraction and associated environmental disruptions.

From a chemical perspective, the passive oxide films that form on these materials' surfaces not only protect against corrosion but also minimize the need for environmentally problematic protective coatings and treatments. Traditional corrosion prevention methods often involve toxic compounds that can leach into marine environments, whereas these advanced alloys rely primarily on their inherent properties.

Energy efficiency in operational systems also improves with these materials. The smooth, corrosion-free surfaces of properly maintained titanium and duplex steel heat exchangers and piping systems maintain optimal thermal transfer efficiency throughout their service life, reducing energy consumption in marine applications such as desalination plants and offshore energy facilities.

Lifecycle Cost Analysis of Duplex and Titanium Solutions

When evaluating the lifecycle costs of duplex stainless steel and titanium solutions for seawater applications, it is essential to consider both initial investment and long-term operational expenses. The acquisition cost of titanium tubes typically ranges from 3 to 5 times higher than duplex stainless steel alternatives, representing a significant upfront investment difference. However, this initial cost disparity must be balanced against the extended service life that titanium offers.

Titanium solutions generally provide a service life of 25+ years in aggressive seawater environments, compared to 10-15 years for duplex stainless steel under similar conditions. This extended operational lifespan significantly reduces replacement frequency and associated downtime costs, which can be substantial in critical marine applications such as offshore platforms, desalination plants, and naval vessels.

Maintenance expenses represent another crucial factor in the total cost equation. Titanium's superior resistance to microbiologically influenced corrosion (MIC) and pitting virtually eliminates the need for chemical treatments and frequent inspections that are necessary with duplex stainless steel systems. Annual maintenance costs for titanium systems typically run 60-70% lower than comparable duplex installations, creating substantial operational savings over time.

Energy efficiency considerations also favor titanium in long-term cost analyses. The smooth surface that titanium maintains throughout its service life (due to minimal corrosion product buildup) results in reduced pumping energy requirements of approximately 8-12% compared to duplex systems after several years of operation. This energy saving compounds annually and becomes increasingly significant as energy costs rise.

Risk assessment calculations further strengthen titanium's economic case. The probability of catastrophic failure in critical seawater systems is estimated at less than 0.5% for titanium versus 3-5% for duplex stainless steel over a 20-year period. When factoring in the potential costs of system failure—including environmental damage, production losses, and safety incidents—the risk-adjusted lifecycle cost comparison often favors titanium despite its higher initial investment.

Break-even analysis typically shows that titanium solutions become economically advantageous over duplex alternatives within 7-9 years of installation in highly corrosive seawater environments. This timeframe shortens in applications where reliability is paramount or where replacement costs are exceptionally high due to accessibility challenges or system criticality.

Titanium solutions generally provide a service life of 25+ years in aggressive seawater environments, compared to 10-15 years for duplex stainless steel under similar conditions. This extended operational lifespan significantly reduces replacement frequency and associated downtime costs, which can be substantial in critical marine applications such as offshore platforms, desalination plants, and naval vessels.

Maintenance expenses represent another crucial factor in the total cost equation. Titanium's superior resistance to microbiologically influenced corrosion (MIC) and pitting virtually eliminates the need for chemical treatments and frequent inspections that are necessary with duplex stainless steel systems. Annual maintenance costs for titanium systems typically run 60-70% lower than comparable duplex installations, creating substantial operational savings over time.

Energy efficiency considerations also favor titanium in long-term cost analyses. The smooth surface that titanium maintains throughout its service life (due to minimal corrosion product buildup) results in reduced pumping energy requirements of approximately 8-12% compared to duplex systems after several years of operation. This energy saving compounds annually and becomes increasingly significant as energy costs rise.

Risk assessment calculations further strengthen titanium's economic case. The probability of catastrophic failure in critical seawater systems is estimated at less than 0.5% for titanium versus 3-5% for duplex stainless steel over a 20-year period. When factoring in the potential costs of system failure—including environmental damage, production losses, and safety incidents—the risk-adjusted lifecycle cost comparison often favors titanium despite its higher initial investment.

Break-even analysis typically shows that titanium solutions become economically advantageous over duplex alternatives within 7-9 years of installation in highly corrosive seawater environments. This timeframe shortens in applications where reliability is paramount or where replacement costs are exceptionally high due to accessibility challenges or system criticality.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!