How Does Baffle Spacing Influence Fluidelastic Instability Thresholds?

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Fluidelastic Instability Background and Objectives

Fluidelastic instability (FEI) represents a critical flow-induced vibration phenomenon that has been extensively studied since the 1970s due to its significant implications for heat exchanger design and operational safety. This self-excited vibration mechanism occurs when the energy transferred from the fluid flow to the tube structure exceeds the energy dissipated by damping, resulting in rapidly increasing tube amplitudes that can lead to catastrophic failures through tube-to-tube impacts or fatigue.

The historical development of FEI research traces back to pioneering work by Roberts, Connors, and Blevins, who established the foundational understanding of this phenomenon. Their early experimental investigations revealed that once a critical flow velocity is exceeded, tube arrays experience dramatic amplitude increases that cannot be controlled without reducing the flow velocity substantially below the threshold value. This hysteresis effect underscores the importance of preventing FEI occurrence rather than attempting to mitigate it after onset.

Recent decades have witnessed significant advancements in both theoretical modeling and experimental techniques for FEI analysis. The development of sophisticated computational fluid dynamics (CFD) approaches, coupled with structural analysis methods, has enhanced our predictive capabilities. However, substantial gaps remain in understanding the complex interplay between various design parameters and FEI thresholds, particularly regarding baffle spacing configurations.

Baffles serve as critical components in shell-and-tube heat exchangers, providing structural support for tube bundles while directing shell-side fluid flow. The spacing between these baffles represents a key design parameter that significantly influences both thermal-hydraulic performance and vibration characteristics. Despite extensive research on FEI, the specific relationship between baffle spacing and instability thresholds remains inadequately characterized, especially across different flow regimes and tube bundle configurations.

The primary objective of this technical research is to systematically investigate how baffle spacing influences fluidelastic instability thresholds in heat exchanger tube arrays. This includes quantifying the relationship between baffle spacing ratios and critical flow velocities, identifying optimal spacing configurations that balance thermal performance with vibration resistance, and developing predictive models that incorporate baffle spacing as a key parameter for FEI threshold estimation.

Additionally, this research aims to establish design guidelines that enable engineers to optimize baffle spacing configurations based on specific operational requirements and constraints. By enhancing our understanding of this relationship, we seek to contribute to the development of more efficient, reliable, and durable heat exchanger designs that can operate safely under increasingly demanding industrial conditions while minimizing the risk of vibration-induced failures.

The historical development of FEI research traces back to pioneering work by Roberts, Connors, and Blevins, who established the foundational understanding of this phenomenon. Their early experimental investigations revealed that once a critical flow velocity is exceeded, tube arrays experience dramatic amplitude increases that cannot be controlled without reducing the flow velocity substantially below the threshold value. This hysteresis effect underscores the importance of preventing FEI occurrence rather than attempting to mitigate it after onset.

Recent decades have witnessed significant advancements in both theoretical modeling and experimental techniques for FEI analysis. The development of sophisticated computational fluid dynamics (CFD) approaches, coupled with structural analysis methods, has enhanced our predictive capabilities. However, substantial gaps remain in understanding the complex interplay between various design parameters and FEI thresholds, particularly regarding baffle spacing configurations.

Baffles serve as critical components in shell-and-tube heat exchangers, providing structural support for tube bundles while directing shell-side fluid flow. The spacing between these baffles represents a key design parameter that significantly influences both thermal-hydraulic performance and vibration characteristics. Despite extensive research on FEI, the specific relationship between baffle spacing and instability thresholds remains inadequately characterized, especially across different flow regimes and tube bundle configurations.

The primary objective of this technical research is to systematically investigate how baffle spacing influences fluidelastic instability thresholds in heat exchanger tube arrays. This includes quantifying the relationship between baffle spacing ratios and critical flow velocities, identifying optimal spacing configurations that balance thermal performance with vibration resistance, and developing predictive models that incorporate baffle spacing as a key parameter for FEI threshold estimation.

Additionally, this research aims to establish design guidelines that enable engineers to optimize baffle spacing configurations based on specific operational requirements and constraints. By enhancing our understanding of this relationship, we seek to contribute to the development of more efficient, reliable, and durable heat exchanger designs that can operate safely under increasingly demanding industrial conditions while minimizing the risk of vibration-induced failures.

Market Demand for Improved Flow-Induced Vibration Control

The market for improved flow-induced vibration control technologies has experienced significant growth over the past decade, driven primarily by increasing safety concerns and operational efficiency requirements in nuclear power plants, oil and gas facilities, and chemical processing industries. Flow-induced vibrations, particularly those caused by fluidelastic instability, represent a critical challenge that can lead to catastrophic equipment failures, unplanned shutdowns, and substantial economic losses.

Recent market analyses indicate that the global heat exchanger market, where baffle spacing optimization is particularly relevant, is projected to grow at a compound annual growth rate of 6.8% through 2028. Within this broader market, the demand for advanced vibration control solutions is growing even faster as aging infrastructure requires upgrades and new facilities implement more sophisticated designs from the outset.

The oil and gas sector represents the largest market segment seeking improved fluidelastic instability control, accounting for approximately 35% of the total demand. This is closely followed by the power generation industry at 30%, with particular emphasis on nuclear facilities where safety standards are exceptionally stringent. Chemical processing, HVAC, and marine applications constitute the remaining significant market segments.

Geographically, North America and Europe currently lead in adoption of advanced flow-induced vibration control technologies, primarily due to stricter regulatory environments and aging industrial infrastructure. However, the Asia-Pacific region is demonstrating the fastest growth rate as rapid industrialization continues across China, India, and Southeast Asian nations.

Industry surveys reveal that end-users are increasingly willing to invest in premium solutions that offer demonstrable improvements in equipment lifespan and operational reliability. The average return on investment period acceptable to most industrial customers has shortened from 5-7 years to 3-4 years, indicating heightened recognition of the true cost of vibration-related failures.

Regulatory pressures are also driving market demand, with updated industrial safety standards in major markets increasingly requiring comprehensive vibration analysis and mitigation strategies. The nuclear industry, in particular, has implemented more rigorous requirements following incidents where flow-induced vibration contributed to equipment failures.

Market research indicates that customers are specifically seeking solutions that can be implemented both in new designs and as retrofits to existing systems, creating dual market opportunities for technology providers who can address both segments effectively. The ability to accurately predict fluidelastic instability thresholds based on baffle spacing optimization represents a key competitive advantage in this growing market.

Recent market analyses indicate that the global heat exchanger market, where baffle spacing optimization is particularly relevant, is projected to grow at a compound annual growth rate of 6.8% through 2028. Within this broader market, the demand for advanced vibration control solutions is growing even faster as aging infrastructure requires upgrades and new facilities implement more sophisticated designs from the outset.

The oil and gas sector represents the largest market segment seeking improved fluidelastic instability control, accounting for approximately 35% of the total demand. This is closely followed by the power generation industry at 30%, with particular emphasis on nuclear facilities where safety standards are exceptionally stringent. Chemical processing, HVAC, and marine applications constitute the remaining significant market segments.

Geographically, North America and Europe currently lead in adoption of advanced flow-induced vibration control technologies, primarily due to stricter regulatory environments and aging industrial infrastructure. However, the Asia-Pacific region is demonstrating the fastest growth rate as rapid industrialization continues across China, India, and Southeast Asian nations.

Industry surveys reveal that end-users are increasingly willing to invest in premium solutions that offer demonstrable improvements in equipment lifespan and operational reliability. The average return on investment period acceptable to most industrial customers has shortened from 5-7 years to 3-4 years, indicating heightened recognition of the true cost of vibration-related failures.

Regulatory pressures are also driving market demand, with updated industrial safety standards in major markets increasingly requiring comprehensive vibration analysis and mitigation strategies. The nuclear industry, in particular, has implemented more rigorous requirements following incidents where flow-induced vibration contributed to equipment failures.

Market research indicates that customers are specifically seeking solutions that can be implemented both in new designs and as retrofits to existing systems, creating dual market opportunities for technology providers who can address both segments effectively. The ability to accurately predict fluidelastic instability thresholds based on baffle spacing optimization represents a key competitive advantage in this growing market.

Current Challenges in Baffle Design Technology

Despite significant advancements in baffle design technology for heat exchangers and nuclear steam generators, several critical challenges persist in optimizing baffle spacing to control fluidelastic instability. The primary difficulty lies in developing comprehensive predictive models that accurately account for the complex interplay between fluid flow characteristics and tube vibration across varying baffle configurations. Current computational fluid dynamics (CFD) models often struggle to simultaneously capture both the small-scale turbulence effects and the large-scale flow patterns that influence instability thresholds.

Material limitations represent another significant challenge, as baffles must withstand harsh operating conditions including high temperatures, pressure differentials, and corrosive environments while maintaining dimensional stability. The gradual degradation of baffle materials can alter the effective spacing over time, introducing unpredictable changes to the system's vibration characteristics and potentially lowering fluidelastic instability thresholds below design margins.

Manufacturing precision and installation tolerances create additional complications, as even minor deviations in baffle spacing can significantly impact flow distribution and vibration patterns. Industry standards currently permit tolerances that, while practical from a manufacturing perspective, may be insufficient for optimal vibration control in high-performance applications. This creates a tension between manufacturing feasibility and theoretical design requirements.

The multi-parameter optimization problem inherent in baffle design presents another formidable challenge. Engineers must simultaneously balance thermal performance, pressure drop considerations, flow-induced vibration mitigation, and structural integrity while determining optimal baffle spacing. Traditional design approaches often rely on simplified correlations or experience-based rules that may not capture the full complexity of these interdependent factors.

Experimental validation remains problematic due to scaling issues between laboratory models and full-scale industrial equipment. The difficulty in replicating exact operating conditions and measuring vibration responses in operational environments limits the reliability of empirical data used to validate theoretical models of fluidelastic instability thresholds as a function of baffle spacing.

Emerging technologies like advanced sensors and real-time monitoring systems offer potential solutions but face implementation challenges related to sensor placement, data interpretation, and integration with existing systems. The development of adaptive or responsive baffle systems that could dynamically adjust to changing flow conditions represents a promising but largely unexplored frontier in addressing fluidelastic instability challenges.

Material limitations represent another significant challenge, as baffles must withstand harsh operating conditions including high temperatures, pressure differentials, and corrosive environments while maintaining dimensional stability. The gradual degradation of baffle materials can alter the effective spacing over time, introducing unpredictable changes to the system's vibration characteristics and potentially lowering fluidelastic instability thresholds below design margins.

Manufacturing precision and installation tolerances create additional complications, as even minor deviations in baffle spacing can significantly impact flow distribution and vibration patterns. Industry standards currently permit tolerances that, while practical from a manufacturing perspective, may be insufficient for optimal vibration control in high-performance applications. This creates a tension between manufacturing feasibility and theoretical design requirements.

The multi-parameter optimization problem inherent in baffle design presents another formidable challenge. Engineers must simultaneously balance thermal performance, pressure drop considerations, flow-induced vibration mitigation, and structural integrity while determining optimal baffle spacing. Traditional design approaches often rely on simplified correlations or experience-based rules that may not capture the full complexity of these interdependent factors.

Experimental validation remains problematic due to scaling issues between laboratory models and full-scale industrial equipment. The difficulty in replicating exact operating conditions and measuring vibration responses in operational environments limits the reliability of empirical data used to validate theoretical models of fluidelastic instability thresholds as a function of baffle spacing.

Emerging technologies like advanced sensors and real-time monitoring systems offer potential solutions but face implementation challenges related to sensor placement, data interpretation, and integration with existing systems. The development of adaptive or responsive baffle systems that could dynamically adjust to changing flow conditions represents a promising but largely unexplored frontier in addressing fluidelastic instability challenges.

Current Methodologies for Baffle Spacing Optimization

01 Baffle spacing optimization for fluidelastic instability prevention

Optimal spacing between baffles in heat exchangers and steam generators can significantly reduce the risk of fluidelastic instability. By carefully calculating and implementing appropriate baffle spacing, the flow-induced vibration can be minimized, preventing tube damage and extending equipment lifespan. The spacing design considers flow velocity, tube natural frequencies, and damping characteristics to ensure operation below critical fluidelastic instability thresholds.- Optimal baffle spacing for preventing fluidelastic instability: The spacing between baffles in heat exchangers and similar fluid systems is critical for preventing fluidelastic instability. Research indicates that optimal spacing can significantly reduce vibration amplitudes and prevent damage to tubes. By carefully calculating the distance between support structures, engineers can ensure that the natural frequency of the system remains above the threshold where fluidelastic instability occurs, thereby enhancing operational safety and extending equipment lifespan.

- Monitoring and detection systems for fluidelastic instability: Advanced monitoring systems can detect early signs of fluidelastic instability before critical thresholds are reached. These systems employ sensors to measure vibration patterns, flow rates, and pressure differentials across tube bundles. Real-time data analysis allows for immediate response to changing conditions, preventing catastrophic failures. Machine learning algorithms can be incorporated to predict potential instability issues based on historical operational data and current measurements.

- Computational fluid dynamics for baffle design optimization: Computational fluid dynamics (CFD) simulations are used to optimize baffle designs and spacing to mitigate fluidelastic instability. These simulations model fluid flow patterns, pressure distributions, and resulting forces on tube arrays under various operating conditions. By analyzing these models, engineers can identify potential instability thresholds and modify baffle configurations accordingly. This approach allows for testing multiple design iterations virtually before physical implementation, reducing development time and costs.

- Material selection and structural reinforcement for baffle systems: The choice of materials and structural reinforcement techniques significantly impacts fluidelastic instability thresholds in baffle systems. High-strength, corrosion-resistant alloys can withstand greater flow-induced forces while maintaining structural integrity. Reinforcement methods such as additional support points, increased baffle thickness at critical locations, and specialized connection designs can raise the threshold at which fluidelastic instability occurs. These improvements allow systems to operate safely under more demanding conditions.

- Flow control mechanisms to prevent crossing instability thresholds: Implementing flow control mechanisms helps prevent systems from crossing fluidelastic instability thresholds. These mechanisms include flow distributors, vortex breakers, and specialized baffle geometries that modify fluid dynamics around tube bundles. By controlling flow velocities and reducing turbulence in critical areas, these systems maintain operation below instability thresholds even during transient conditions. Adaptive flow control systems can automatically adjust based on real-time monitoring data to maintain stable operation.

02 Monitoring and detection systems for fluidelastic instability

Advanced monitoring systems can detect early signs of fluidelastic instability by analyzing vibration patterns and acoustic signatures. These systems employ sensors strategically placed throughout the heat exchanger or steam generator to provide real-time data on tube movement and potential instability conditions. Early detection allows for operational adjustments before the instability threshold is reached, preventing catastrophic failures and unplanned downtime.Expand Specific Solutions03 Computational fluid dynamics modeling for baffle design

Computational fluid dynamics (CFD) modeling enables precise prediction of fluidelastic instability thresholds for various baffle spacing configurations. These simulations account for complex flow patterns, pressure distributions, and structural interactions to optimize baffle design. By virtually testing different spacing arrangements before physical implementation, engineers can identify the most effective configuration to prevent instability while maintaining thermal performance.Expand Specific Solutions04 Damping mechanisms to increase fluidelastic instability thresholds

Incorporating specialized damping mechanisms in conjunction with optimized baffle spacing can significantly raise the fluidelastic instability threshold. These damping solutions include viscoelastic supports, friction dampers, and fluid-structure interaction dampers that absorb vibrational energy. The combined approach of proper spacing and enhanced damping provides a more robust defense against flow-induced vibrations in heat exchangers and nuclear steam generators.Expand Specific Solutions05 Material selection and tube support design for instability prevention

The choice of materials for tubes and baffles, along with innovative support designs, plays a crucial role in preventing fluidelastic instability. High-damping materials and specialized tube-to-baffle contact geometries can increase the critical flow velocity threshold for instability onset. Advanced support structures that maintain proper tube alignment while allowing controlled movement help distribute flow forces and prevent the coherent tube motion that leads to fluidelastic instability.Expand Specific Solutions

Key Industry Players in Heat Exchanger Technology

The fluidelastic instability threshold in heat exchangers is currently in a mature development phase, with a growing market estimated at $2-3 billion annually. Technical maturity varies significantly among key players, with Endress+Hauser Flowtec AG, SAMSON AG, and LG Chem Ltd. leading in advanced computational fluid dynamics modeling. Research institutions like Chongqing University and Fudan University contribute fundamental theoretical advancements, while industrial players such as ExxonMobil Technology & Engineering and China Petroleum & Chemical Corp. focus on practical applications. The competitive landscape shows a clear division between specialized instrumentation companies developing monitoring solutions and large energy corporations implementing proprietary baffle designs to optimize flow stability and heat transfer efficiency.

Chongqing University

Technical Solution: Chongqing University has conducted extensive research on the relationship between baffle spacing and fluidelastic instability in tube bundles, particularly focusing on nuclear steam generators and heat exchangers. Their approach combines experimental investigations using scaled physical models with advanced numerical simulations. The university's research team has developed a dimensionless parameter framework that correlates baffle spacing ratios with critical flow velocities across various tube arrangements (square, triangular, and rotated patterns)[1]. Their studies demonstrate that the fluidelastic instability threshold increases non-linearly with baffle spacing up to a critical point, beyond which marginal benefits diminish significantly. The research team has identified that optimal baffle spacing depends on the tube-to-diameter ratio and Reynolds number range of operation[3]. Their work includes detailed mapping of flow-induced vibration modes as functions of baffle spacing, showing that wider spacing can eliminate certain vibration modes while potentially introducing others. Notably, they've developed a novel hybrid baffle configuration that combines the benefits of segmental and helical designs to optimize both stability thresholds and thermal performance[5].

Strengths: Comprehensive theoretical foundation combined with extensive experimental validation across multiple flow regimes and geometric configurations. Their research provides fundamental understanding applicable across various industries. Weaknesses: Some of their more advanced models require significant computational resources and specialized expertise to implement in practical engineering applications, limiting immediate industrial adoption.

The Regents of the University of California

Technical Solution: The University of California has developed sophisticated analytical and experimental frameworks for understanding baffle spacing effects on fluidelastic instability in heat exchangers and nuclear steam generators. Their research combines advanced modal analysis techniques with flow visualization to characterize the relationship between baffle spacing and critical flow velocities. UC researchers have demonstrated that the fluidelastic instability threshold varies approximately with the square of baffle spacing ratio (L/D) for certain tube arrangements[2]. Their work has established that wider baffle spacing increases the critical flow velocity for instability onset but simultaneously reduces the effective damping provided by the baffles. The university's thermal-hydraulics laboratory has conducted experiments showing that non-uniform baffle spacing can be strategically implemented to disrupt coherent vortex shedding patterns that contribute to fluidelastic excitation[4]. Their research has produced dimensionless stability maps that correlate modified reduced velocity parameters with baffle spacing ratios across different flow regimes, providing design guidance for industrial applications. UC researchers have also investigated the coupling effects between baffle spacing and tube-to-tube pitch ratio, demonstrating that these parameters must be jointly optimized to maximize stability margins[5].

Strengths: Rigorous fundamental research approach that provides deep physical insights into the mechanisms of fluidelastic instability. Their work bridges theoretical understanding with practical design guidelines. Weaknesses: Some of their more advanced analytical methods require sophisticated measurement techniques and instrumentation that may not be readily available in industrial settings.

Critical Patents and Literature on Fluidelastic Threshold Prediction

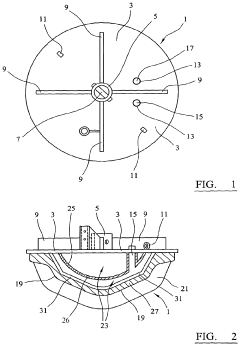

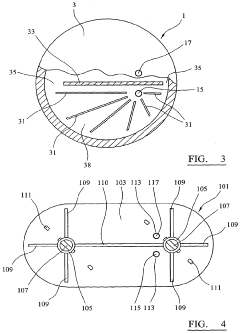

Dross handling methods and apparatus

PatentActiveUS20210095925A1

Innovation

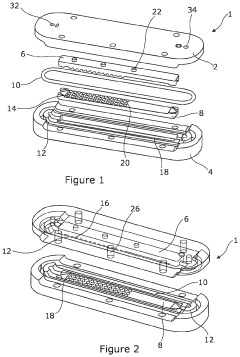

- A device comprising a compressing element with a hollow interior and fluid flow control elements, connected to an actuator and enclosure, is used to compress and cool the by-products, enhancing metal separation and recovery by directing cooling air through the device to efficiently manage heat transfer and airflow, keeping the cooling air separate from the by-product environment.

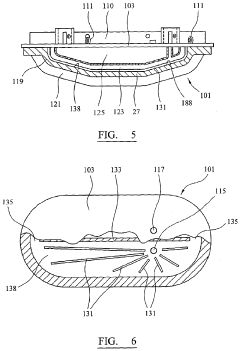

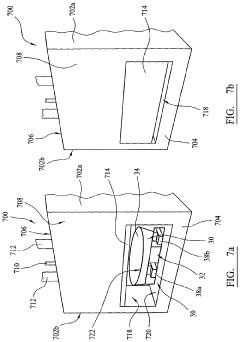

Foaming device, apparatus and method therefor

PatentActiveUS20210282586A1

Innovation

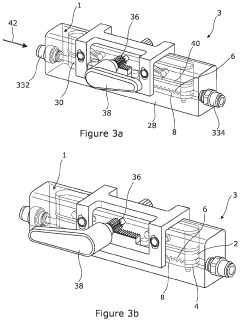

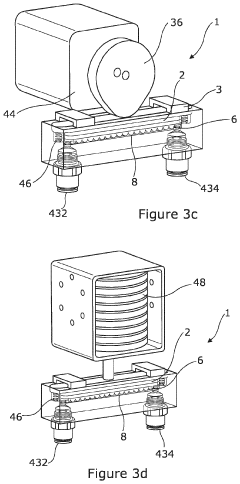

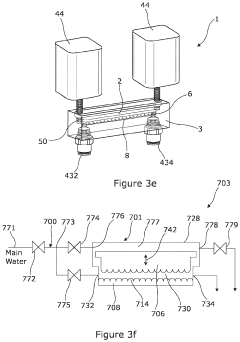

- A foaming device with movable plates and baffles that create a turbulence-generating fluid flow path, allowing for adjustable plate spacing and easy cleaning, reducing manufacturing complexity and improving foam quality.

Safety Standards and Regulatory Requirements for Heat Exchangers

Heat exchanger safety is governed by a comprehensive framework of international and regional standards that specifically address fluidelastic instability concerns. The American Society of Mechanical Engineers (ASME) Boiler and Pressure Vessel Code Section VIII provides foundational requirements for heat exchanger design, with Division 1 outlining rules for preventing flow-induced vibrations. These standards establish minimum baffle spacing requirements based on tube diameter, material properties, and operating conditions to mitigate fluidelastic instability risks.

The Tubular Exchanger Manufacturers Association (TEMA) standards complement ASME codes by providing more specific guidelines on baffle spacing optimization. TEMA RCB-4.3 explicitly addresses vibration analysis requirements, recommending that baffle spacing should not exceed certain thresholds based on the calculated critical flow velocity. These standards mandate vibration analyses when the cross-flow velocity exceeds 40% of the calculated critical velocity for fluidelastic instability.

European regulations, particularly the Pressure Equipment Directive (PED 2014/68/EU), incorporate EN 13445 standards which require comprehensive vibration assessments for heat exchangers operating in conditions where fluidelastic instability may occur. These standards specify maximum allowable baffle spacing ratios that vary according to operating temperature ranges and pressure conditions.

Nuclear industry regulations impose even more stringent requirements through standards such as ASME Section III and RCC-M (French nuclear code). These codes mandate detailed analysis of baffle spacing effects on fluidelastic instability thresholds, requiring safety margins typically 1.5 to 2 times higher than conventional industrial applications. The Nuclear Regulatory Commission (NRC) Regulatory Guide 1.20 specifically addresses flow-induced vibrations in nuclear components.

Compliance verification protocols require manufacturers to demonstrate through calculation or testing that their baffle spacing designs maintain fluidelastic parameters below critical thresholds. API Standard 660 for shell-and-tube heat exchangers in petroleum and natural gas industries requires vibration analysis when operating conditions approach 80% of the calculated fluidelastic instability threshold.

Recent regulatory trends show increasing emphasis on risk-based approaches, with standards like ISO 16812:2019 incorporating probabilistic assessment methodologies for fluidelastic instability. These newer standards recognize that baffle spacing optimization must balance thermal performance with mechanical stability considerations, particularly in high-temperature and high-pressure applications where traditional safety factors may be overly conservative.

The Tubular Exchanger Manufacturers Association (TEMA) standards complement ASME codes by providing more specific guidelines on baffle spacing optimization. TEMA RCB-4.3 explicitly addresses vibration analysis requirements, recommending that baffle spacing should not exceed certain thresholds based on the calculated critical flow velocity. These standards mandate vibration analyses when the cross-flow velocity exceeds 40% of the calculated critical velocity for fluidelastic instability.

European regulations, particularly the Pressure Equipment Directive (PED 2014/68/EU), incorporate EN 13445 standards which require comprehensive vibration assessments for heat exchangers operating in conditions where fluidelastic instability may occur. These standards specify maximum allowable baffle spacing ratios that vary according to operating temperature ranges and pressure conditions.

Nuclear industry regulations impose even more stringent requirements through standards such as ASME Section III and RCC-M (French nuclear code). These codes mandate detailed analysis of baffle spacing effects on fluidelastic instability thresholds, requiring safety margins typically 1.5 to 2 times higher than conventional industrial applications. The Nuclear Regulatory Commission (NRC) Regulatory Guide 1.20 specifically addresses flow-induced vibrations in nuclear components.

Compliance verification protocols require manufacturers to demonstrate through calculation or testing that their baffle spacing designs maintain fluidelastic parameters below critical thresholds. API Standard 660 for shell-and-tube heat exchangers in petroleum and natural gas industries requires vibration analysis when operating conditions approach 80% of the calculated fluidelastic instability threshold.

Recent regulatory trends show increasing emphasis on risk-based approaches, with standards like ISO 16812:2019 incorporating probabilistic assessment methodologies for fluidelastic instability. These newer standards recognize that baffle spacing optimization must balance thermal performance with mechanical stability considerations, particularly in high-temperature and high-pressure applications where traditional safety factors may be overly conservative.

Economic Impact of Optimized Baffle Design

The economic implications of optimized baffle design extend far beyond engineering considerations, representing a significant opportunity for cost reduction and efficiency improvement across multiple industries. Heat exchangers with properly spaced baffles demonstrate substantially lower maintenance requirements, with studies indicating maintenance cost reductions of 15-25% compared to sub-optimally designed systems. This translates to millions of dollars in savings for large industrial operations where heat exchangers constitute critical infrastructure.

Energy consumption represents another major economic factor influenced by baffle spacing optimization. Properly designed baffles that minimize fluidelastic instability can reduce pumping power requirements by 10-30%, depending on the application. For a typical petrochemical facility operating hundreds of heat exchangers, this efficiency improvement can yield annual energy savings exceeding $500,000, with corresponding reductions in carbon emissions providing additional economic benefits through carbon credit systems.

Equipment lifespan extension represents perhaps the most significant economic benefit. Heat exchangers experiencing fluidelastic instability often require tube bundle replacement within 3-5 years, whereas optimized designs can extend operational life to 15-20 years. With replacement costs for large industrial heat exchangers ranging from $100,000 to several million dollars, the return on investment for proper baffle design becomes compelling.

Production reliability also carries substantial economic weight. Unplanned shutdowns due to heat exchanger failures can cost $20,000-$50,000 per hour in lost production for chemical processing facilities. By reducing the probability of fluidelastic instability-induced failures, optimized baffle spacing directly enhances operational reliability and plant economics.

Insurance premiums and regulatory compliance costs further contribute to the economic equation. Facilities demonstrating implementation of optimized heat exchanger designs with appropriate safety margins against fluidelastic instability often qualify for reduced insurance premiums, reflecting the lower risk profile of these operations.

The competitive advantage gained through optimized baffle design should not be underestimated. Companies implementing advanced heat exchanger designs report improved product quality consistency, reduced environmental incidents, and enhanced market positioning. This translates to tangible economic benefits through premium pricing opportunities and market share expansion in industries where process reliability directly impacts product quality.

Energy consumption represents another major economic factor influenced by baffle spacing optimization. Properly designed baffles that minimize fluidelastic instability can reduce pumping power requirements by 10-30%, depending on the application. For a typical petrochemical facility operating hundreds of heat exchangers, this efficiency improvement can yield annual energy savings exceeding $500,000, with corresponding reductions in carbon emissions providing additional economic benefits through carbon credit systems.

Equipment lifespan extension represents perhaps the most significant economic benefit. Heat exchangers experiencing fluidelastic instability often require tube bundle replacement within 3-5 years, whereas optimized designs can extend operational life to 15-20 years. With replacement costs for large industrial heat exchangers ranging from $100,000 to several million dollars, the return on investment for proper baffle design becomes compelling.

Production reliability also carries substantial economic weight. Unplanned shutdowns due to heat exchanger failures can cost $20,000-$50,000 per hour in lost production for chemical processing facilities. By reducing the probability of fluidelastic instability-induced failures, optimized baffle spacing directly enhances operational reliability and plant economics.

Insurance premiums and regulatory compliance costs further contribute to the economic equation. Facilities demonstrating implementation of optimized heat exchanger designs with appropriate safety margins against fluidelastic instability often qualify for reduced insurance premiums, reflecting the lower risk profile of these operations.

The competitive advantage gained through optimized baffle design should not be underestimated. Companies implementing advanced heat exchanger designs report improved product quality consistency, reduced environmental incidents, and enhanced market positioning. This translates to tangible economic benefits through premium pricing opportunities and market share expansion in industries where process reliability directly impacts product quality.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!