Tube Failure Forensics: Pit Morphology, SCC Features And Root Cause Links

SEP 12, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Tube Failure Forensics Background and Objectives

Tube failure forensics has emerged as a critical field in industrial engineering, particularly in sectors such as power generation, petrochemical processing, and manufacturing where tube integrity directly impacts operational safety and efficiency. The evolution of this technical domain spans several decades, with significant advancements occurring in analytical methodologies, diagnostic tools, and preventive strategies. Recent technological developments have enabled more precise identification of failure mechanisms, particularly in relation to pit morphology and stress corrosion cracking (SCC) features.

The historical progression of tube failure analysis reveals a transition from primarily reactive investigations to proactive monitoring systems. Early approaches focused on visual inspection and basic metallurgical testing, while contemporary methods incorporate advanced spectroscopic techniques, electron microscopy, and computational modeling to establish definitive links between observed damage patterns and root causes.

Current industry challenges necessitate a comprehensive understanding of the relationship between pit morphology characteristics and the underlying mechanisms of tube degradation. The morphological features of pitting—including depth profiles, geometric patterns, and spatial distribution—provide crucial forensic evidence that, when properly interpreted, can reveal specific environmental conditions and operational factors contributing to failure.

Stress corrosion cracking represents a particularly insidious failure mode that combines mechanical stress with corrosive environmental factors. The distinctive features of SCC, such as branching crack patterns, transgranular or intergranular propagation paths, and crack orientation relative to applied stresses, constitute a forensic signature that demands sophisticated analytical approaches for accurate interpretation.

The primary objective of this technical research is to establish reliable correlations between observable forensic indicators (pit morphology and SCC features) and their root causes. This includes developing systematic classification frameworks for damage patterns, identifying distinctive markers associated with specific failure mechanisms, and creating diagnostic protocols that enable rapid and accurate determination of failure origins.

Additionally, this research aims to enhance predictive capabilities by identifying early-stage indicators of potential tube failure, thereby enabling timely intervention before catastrophic failure occurs. The development of standardized forensic methodologies will facilitate more consistent analysis across the industry, improving both the accuracy of failure investigations and the effectiveness of preventive maintenance strategies.

The ultimate goal is to translate forensic insights into practical engineering solutions, including material selection guidelines, operational parameter recommendations, and monitoring protocols that effectively mitigate the risk of tube failures in critical industrial applications. This research will contribute to extending equipment service life, reducing unplanned downtime, and enhancing overall system reliability and safety.

The historical progression of tube failure analysis reveals a transition from primarily reactive investigations to proactive monitoring systems. Early approaches focused on visual inspection and basic metallurgical testing, while contemporary methods incorporate advanced spectroscopic techniques, electron microscopy, and computational modeling to establish definitive links between observed damage patterns and root causes.

Current industry challenges necessitate a comprehensive understanding of the relationship between pit morphology characteristics and the underlying mechanisms of tube degradation. The morphological features of pitting—including depth profiles, geometric patterns, and spatial distribution—provide crucial forensic evidence that, when properly interpreted, can reveal specific environmental conditions and operational factors contributing to failure.

Stress corrosion cracking represents a particularly insidious failure mode that combines mechanical stress with corrosive environmental factors. The distinctive features of SCC, such as branching crack patterns, transgranular or intergranular propagation paths, and crack orientation relative to applied stresses, constitute a forensic signature that demands sophisticated analytical approaches for accurate interpretation.

The primary objective of this technical research is to establish reliable correlations between observable forensic indicators (pit morphology and SCC features) and their root causes. This includes developing systematic classification frameworks for damage patterns, identifying distinctive markers associated with specific failure mechanisms, and creating diagnostic protocols that enable rapid and accurate determination of failure origins.

Additionally, this research aims to enhance predictive capabilities by identifying early-stage indicators of potential tube failure, thereby enabling timely intervention before catastrophic failure occurs. The development of standardized forensic methodologies will facilitate more consistent analysis across the industry, improving both the accuracy of failure investigations and the effectiveness of preventive maintenance strategies.

The ultimate goal is to translate forensic insights into practical engineering solutions, including material selection guidelines, operational parameter recommendations, and monitoring protocols that effectively mitigate the risk of tube failures in critical industrial applications. This research will contribute to extending equipment service life, reducing unplanned downtime, and enhancing overall system reliability and safety.

Industry Demand for Tube Failure Analysis

The tube failure analysis market has experienced significant growth over the past decade, driven primarily by aging infrastructure in critical industries such as power generation, oil and gas, chemical processing, and manufacturing. According to recent industry reports, the global non-destructive testing market, which includes tube failure analysis, is valued at approximately $21 billion and projected to grow at a compound annual rate of 7.3% through 2028.

Power generation facilities, particularly those utilizing steam generators and heat exchangers, represent the largest segment demanding tube failure forensics. These facilities typically operate under extreme conditions of temperature, pressure, and corrosive environments, making tubes susceptible to various failure mechanisms including stress corrosion cracking (SCC) and pitting. The average cost of unplanned downtime in power plants can exceed $500,000 per day, creating substantial economic incentive for preventive analysis and maintenance.

The oil and gas sector presents another significant market for tube failure analysis, with refineries and processing plants requiring regular inspection of critical heat exchanger tubes. Industry data indicates that approximately 40% of equipment failures in refineries are related to corrosion issues, with tube failures accounting for a substantial portion of these incidents. The financial impact extends beyond immediate repair costs to include production losses, environmental remediation, and potential regulatory penalties.

Chemical processing industries face similar challenges, with an estimated 70% of facilities operating equipment beyond its designed service life. This aging infrastructure creates heightened demand for sophisticated failure analysis techniques that can identify early indicators of tube degradation, particularly pit morphology and stress corrosion cracking features that precede catastrophic failures.

Nuclear power generation represents a specialized segment with stringent requirements for tube integrity analysis. The consequences of tube failures in nuclear steam generators extend beyond economic considerations to safety and regulatory compliance. Recent incidents have highlighted the critical importance of advanced forensic techniques that can link observed failure patterns to root causes.

Market research indicates growing demand for integrated analysis approaches that combine traditional metallurgical examination with advanced non-destructive testing methods. Customers increasingly seek comprehensive solutions that not only identify failure mechanisms but establish definitive links between observed damage patterns and specific operational or environmental factors.

The competitive landscape includes specialized engineering firms, equipment manufacturers offering aftermarket services, and independent testing laboratories. Recent market consolidation reflects the trend toward providing end-to-end solutions that span inspection, analysis, remediation recommendations, and preventive strategies.

Power generation facilities, particularly those utilizing steam generators and heat exchangers, represent the largest segment demanding tube failure forensics. These facilities typically operate under extreme conditions of temperature, pressure, and corrosive environments, making tubes susceptible to various failure mechanisms including stress corrosion cracking (SCC) and pitting. The average cost of unplanned downtime in power plants can exceed $500,000 per day, creating substantial economic incentive for preventive analysis and maintenance.

The oil and gas sector presents another significant market for tube failure analysis, with refineries and processing plants requiring regular inspection of critical heat exchanger tubes. Industry data indicates that approximately 40% of equipment failures in refineries are related to corrosion issues, with tube failures accounting for a substantial portion of these incidents. The financial impact extends beyond immediate repair costs to include production losses, environmental remediation, and potential regulatory penalties.

Chemical processing industries face similar challenges, with an estimated 70% of facilities operating equipment beyond its designed service life. This aging infrastructure creates heightened demand for sophisticated failure analysis techniques that can identify early indicators of tube degradation, particularly pit morphology and stress corrosion cracking features that precede catastrophic failures.

Nuclear power generation represents a specialized segment with stringent requirements for tube integrity analysis. The consequences of tube failures in nuclear steam generators extend beyond economic considerations to safety and regulatory compliance. Recent incidents have highlighted the critical importance of advanced forensic techniques that can link observed failure patterns to root causes.

Market research indicates growing demand for integrated analysis approaches that combine traditional metallurgical examination with advanced non-destructive testing methods. Customers increasingly seek comprehensive solutions that not only identify failure mechanisms but establish definitive links between observed damage patterns and specific operational or environmental factors.

The competitive landscape includes specialized engineering firms, equipment manufacturers offering aftermarket services, and independent testing laboratories. Recent market consolidation reflects the trend toward providing end-to-end solutions that span inspection, analysis, remediation recommendations, and preventive strategies.

Current Challenges in Pit Morphology Assessment

Despite significant advancements in tube failure analysis techniques, the assessment of pit morphology continues to present substantial challenges for researchers and industry professionals. Current methodologies often struggle with accurately characterizing the three-dimensional nature of corrosion pits, which are critical precursors to stress corrosion cracking (SCC) in various industrial applications, particularly in heat exchangers, boilers, and pipeline systems.

One of the primary challenges lies in the non-standardized approaches to pit measurement and classification. Different industries and research groups employ varying metrics for pit depth, width, aspect ratio, and density measurements, making cross-study comparisons difficult and hindering the development of universal predictive models for pit-to-crack transitions.

The resolution limitations of conventional imaging techniques present another significant obstacle. While scanning electron microscopy (SEM) provides detailed surface characterization, it often fails to adequately capture the subsurface morphology of pits without destructive cross-sectioning. This limitation creates a significant blind spot in understanding how pit geometry evolves beneath the surface and subsequently influences crack initiation.

Environmental factors further complicate pit morphology assessment. The dynamic nature of corrosive environments means that pit characteristics observed in laboratory settings may not accurately reflect those developing under actual operating conditions. Temperature fluctuations, flow dynamics, and chemical composition variations can dramatically alter pit formation mechanisms, creating challenges for developing reliable assessment protocols.

Data integration represents another substantial hurdle. Current analytical frameworks struggle to effectively combine information from multiple characterization techniques such as optical profilometry, X-ray computed tomography, and electrochemical measurements. This fragmentation of data impedes the development of comprehensive pit morphology models that could better predict failure mechanisms.

The relationship between pit morphology and subsequent SCC initiation remains incompletely understood. While certain pit characteristics (such as sharp, angular features) are generally associated with higher crack initiation probability, quantitative correlations between specific morphological features and crack nucleation thresholds are not well established across different material-environment systems.

Automation of pit analysis presents both an opportunity and a challenge. Machine learning approaches show promise for rapid, consistent pit characterization but require extensive training datasets that are currently lacking in diversity and comprehensiveness. The development of robust algorithms capable of accurately identifying and characterizing pits across various materials and corrosion conditions remains an active area of research with significant technical barriers.

One of the primary challenges lies in the non-standardized approaches to pit measurement and classification. Different industries and research groups employ varying metrics for pit depth, width, aspect ratio, and density measurements, making cross-study comparisons difficult and hindering the development of universal predictive models for pit-to-crack transitions.

The resolution limitations of conventional imaging techniques present another significant obstacle. While scanning electron microscopy (SEM) provides detailed surface characterization, it often fails to adequately capture the subsurface morphology of pits without destructive cross-sectioning. This limitation creates a significant blind spot in understanding how pit geometry evolves beneath the surface and subsequently influences crack initiation.

Environmental factors further complicate pit morphology assessment. The dynamic nature of corrosive environments means that pit characteristics observed in laboratory settings may not accurately reflect those developing under actual operating conditions. Temperature fluctuations, flow dynamics, and chemical composition variations can dramatically alter pit formation mechanisms, creating challenges for developing reliable assessment protocols.

Data integration represents another substantial hurdle. Current analytical frameworks struggle to effectively combine information from multiple characterization techniques such as optical profilometry, X-ray computed tomography, and electrochemical measurements. This fragmentation of data impedes the development of comprehensive pit morphology models that could better predict failure mechanisms.

The relationship between pit morphology and subsequent SCC initiation remains incompletely understood. While certain pit characteristics (such as sharp, angular features) are generally associated with higher crack initiation probability, quantitative correlations between specific morphological features and crack nucleation thresholds are not well established across different material-environment systems.

Automation of pit analysis presents both an opportunity and a challenge. Machine learning approaches show promise for rapid, consistent pit characterization but require extensive training datasets that are currently lacking in diversity and comprehensiveness. The development of robust algorithms capable of accurately identifying and characterizing pits across various materials and corrosion conditions remains an active area of research with significant technical barriers.

Established Methodologies for SCC Feature Identification

01 Stress Corrosion Cracking (SCC) Analysis Techniques

Various techniques are employed to analyze stress corrosion cracking in tubes, including microscopic examination of crack morphology, propagation patterns, and branching characteristics. These methods help identify the specific type of SCC (intergranular, transgranular) and determine environmental factors contributing to failure. Advanced imaging techniques allow for detailed characterization of crack features, helping to distinguish SCC from other failure mechanisms and establish root causes in tube failure forensics.- Stress Corrosion Cracking (SCC) Analysis Techniques: Advanced techniques for analyzing stress corrosion cracking in tubes, including microscopic examination of crack morphology, propagation patterns, and branching characteristics. These methods help identify the root causes of tube failures by examining the distinctive features of SCC such as intergranular or transgranular cracking patterns, crack orientation relative to stress direction, and the presence of corrosion products within cracks.

- Pit Morphology Characterization Systems: Systems and methods for characterizing pit morphology in failed tubes using 3D imaging, surface profiling, and dimensional analysis. These technologies enable detailed examination of pit features including depth, width, shape, and distribution patterns. The characterization helps determine whether pitting is due to general corrosion, microbiologically influenced corrosion, or localized chemical attack, which is crucial for preventing future failures.

- AI-Based Failure Analysis Systems: Artificial intelligence and machine learning approaches for tube failure forensics that can automatically identify and classify pit morphology and SCC features. These systems analyze large datasets of failure images to recognize patterns, predict failure mechanisms, and recommend preventive measures. The AI models are trained on historical failure data to improve accuracy in identifying specific corrosion and cracking mechanisms.

- Non-Destructive Testing for Tube Integrity Assessment: Non-destructive testing methods specifically designed to detect and characterize early-stage pit formation and stress corrosion cracking in tubes. These techniques include advanced ultrasonic testing, eddy current analysis, and radiographic examination that can identify subsurface defects before catastrophic failure occurs. The methods provide detailed information about defect morphology without requiring destructive sectioning of the tubes.

- Environmental Factors in Tube Failure Analysis: Analysis of environmental factors contributing to specific pit morphologies and SCC features in tubes. This includes examination of chemical composition of process fluids, temperature cycling effects, flow conditions, and contaminant presence. Understanding these environmental influences helps in determining the specific corrosion mechanisms at work and developing appropriate mitigation strategies for extending tube service life.

02 Pit Morphology Classification and Analysis

Pit morphology analysis involves classifying corrosion pits based on their shape, size, depth, and distribution patterns. This classification helps determine the corrosion mechanism and environmental conditions that led to tube failure. Techniques such as 3D surface profiling and cross-sectional analysis are used to characterize pit features, including undercut regions, lacy covers, and subsurface networks. Understanding pit morphology is crucial for identifying specific corrosion types and predicting potential failure progression.Expand Specific Solutions03 AI and Machine Learning for Failure Analysis

Artificial intelligence and machine learning algorithms are increasingly used to analyze tube failure patterns, including pit morphology and SCC features. These technologies can process large datasets of failure characteristics to identify patterns that might be missed by human analysts. Computer vision techniques automatically classify pit types and crack propagation patterns, while predictive models estimate remaining useful life based on detected features. This approach enhances the accuracy and efficiency of tube failure forensics.Expand Specific Solutions04 Environmental Factors in Tube Failure Mechanisms

Environmental conditions significantly influence tube failure mechanisms, affecting both pit formation and stress corrosion cracking. Factors such as temperature, pH, chemical composition of surrounding media, and cyclic loading contribute to specific failure patterns. Analysis of these environmental factors in relation to observed pit morphology and SCC features helps establish the root cause of tube failures. Understanding these correlations is essential for developing preventive measures and improving material selection for specific operating environments.Expand Specific Solutions05 Non-Destructive Testing for Tube Integrity Assessment

Non-destructive testing methods are employed to assess tube integrity and characterize failure features without further damaging the specimens. Techniques such as ultrasonic testing, eddy current analysis, radiography, and acoustic emission monitoring help identify and measure pit dimensions and SCC features in tubes. These methods allow for in-situ monitoring of developing failure mechanisms and provide valuable data for forensic analysis of tube failures, enabling early detection of potential issues before catastrophic failure occurs.Expand Specific Solutions

Leading Organizations in Tube Forensic Analysis

The tube failure forensics field, focusing on pit morphology, stress corrosion cracking (SCC) features, and root cause analysis, is currently in a growth phase with an estimated global market size of $2-3 billion. The technology maturity varies across sectors, with nuclear and petrochemical industries leading adoption. Key players demonstrate different specialization levels: China Nuclear Power Operation Management and Third Qinshan Nuclear Power have advanced nuclear-specific forensic capabilities; CNPC, Sinopec, and PetroChina dominate in oil and gas applications; while research institutions like Southwest Petroleum University and Dalian University of Technology drive innovation through academic-industrial partnerships. International corporations including GE and IBM contribute sophisticated analytical tools, creating a competitive landscape balanced between specialized regional expertise and global technology solutions.

China Nuclear Power Operation Management Co., Ltd.

Technical Solution: China Nuclear Power Operation Management Co., Ltd. has developed specialized tube failure forensics methodologies focused on the unique challenges of nuclear power plant environments. Their technical approach centers on correlating specific pit morphologies and SCC features with water chemistry parameters in primary and secondary cooling circuits. The company employs high-resolution metallography combined with electron backscatter diffraction (EBSD) to characterize the crystallographic orientation relationships in SCC crack paths, establishing correlations between grain boundary characteristics and crack susceptibility. Their methodology includes specialized hot cell facilities for examining radioactive components, enabling detailed analysis of irradiation effects on SCC mechanisms. The company has developed proprietary algorithms that analyze pit initiation sites to distinguish between different corrosion mechanisms (microbiologically influenced corrosion, flow-accelerated corrosion, and various forms of SCC). Their approach incorporates operational history analysis that correlates water chemistry excursions with specific damage morphologies, enabling identification of critical parameters that trigger failure initiation. Additionally, they employ advanced residual stress measurement techniques, including neutron diffraction, to quantify stress distributions around welds and other high-risk locations, correlating these with observed crack patterns to establish causal relationships.

Strengths: Their specialized focus on nuclear applications provides deep expertise in high-temperature, high-pressure water environments. Their methodologies excel at distinguishing between radiation-influenced and conventional corrosion mechanisms. Weaknesses: The highly specialized nature of their approach limits applicability to non-nuclear industries. The necessary radiation safety protocols increase analysis time and cost compared to conventional forensic approaches.

China National Petroleum Corp.

Technical Solution: China National Petroleum Corp. (CNPC) has developed a systematic tube failure forensics methodology focused on correlating pit morphology with specific corrosion mechanisms in oil and gas transportation systems. Their approach integrates field monitoring with laboratory analysis, utilizing advanced characterization techniques including 3D optical profilometry to quantify pit geometry parameters (depth-to-width ratio, undercut features, and surface topography). CNPC's technical solution incorporates electrochemical impedance spectroscopy (EIS) to identify SCC initiation sites before visible cracking occurs. Their forensic protocol includes specialized metallographic preparation techniques that preserve corrosion products for analysis, allowing identification of critical environmental contaminants that catalyze failure. CNPC has established a comprehensive classification system for pit morphologies that correlates specific geometric features with environmental factors and operational conditions. Their research has identified distinctive crystallographic orientation effects in SCC propagation, demonstrating how grain boundary characteristics influence crack path selection and propagation rates in various pipeline materials. Additionally, CNPC employs residual stress mapping using X-ray diffraction to correlate stress distributions with SCC susceptibility.

Strengths: Their methodology excels at distinguishing between mechanically-induced and corrosion-induced failures through detailed surface analysis. The integration of operational data with metallurgical findings enables practical corrective actions. Weaknesses: Their approach requires extensive specialized equipment and expertise, limiting deployment in remote locations. The time-intensive nature of their comprehensive analysis can delay implementation of mitigation measures in critical situations.

Critical Patents in Tube Failure Root Cause Analysis

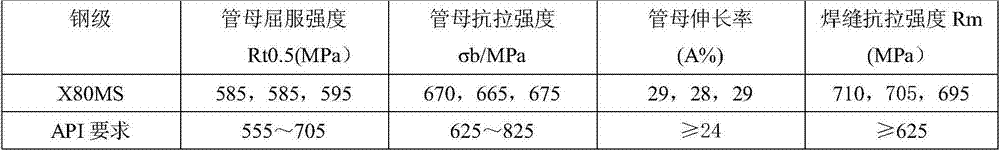

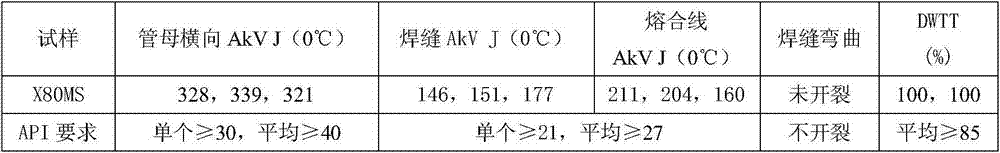

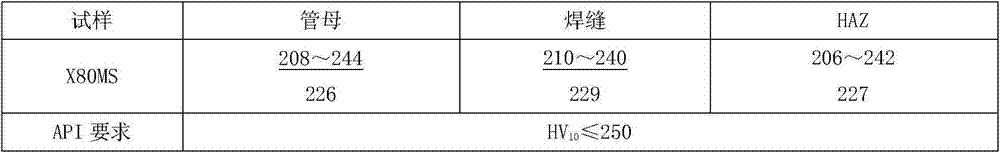

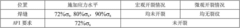

X80-level straight seam submerged-arc welded pipe with hydrogen sulfide stress corrosion resistance as well as manufacturing method thereof

PatentActiveCN103540867A

Innovation

- By optimizing the steel plate composition and welding process, using ultra-low C and low Mn composition design, adding alloy elements such as Cr and Mo, controlling the uniformity of the plate structure and weld composition, using three-wire submerged arc automatic welding technology, combined with JCO forming and expansion diameter process to reduce welding residual stress, select high-purity flux and welding wire, and conduct multiple inspections and treatments to ensure the strength and corrosion resistance of the welded joints.

X80-level straight seam submerged-arc welded pipe with hydrogen sulfide stress corrosion resistance as well as manufacturing method thereof

PatentActiveCN103540867A

Innovation

- By optimizing the steel plate composition and welding process, using ultra-low C and low Mn composition design, adding alloy elements such as Cr and Mo, controlling the uniformity of the plate structure and weld composition, using three-wire submerged arc automatic welding technology, combined with JCO forming and expansion diameter process to reduce welding residual stress, select high-purity flux and welding wire, and conduct multiple inspections and treatments to ensure the strength and corrosion resistance of the welded joints.

Material Science Implications for Tube Integrity

The material science aspects of tube failure forensics reveal critical relationships between microstructural properties and failure mechanisms. Understanding these relationships is essential for predicting and preventing tube failures in industrial applications. Material composition, processing history, and service conditions collectively influence how tubes respond to stress, corrosion, and other degradation mechanisms.

Pit morphology analysis provides significant insights into material behavior under corrosive conditions. The shape, depth, and distribution patterns of pits correlate strongly with specific material properties such as grain boundary characteristics, inclusion content, and phase distribution. For instance, elongated pits often indicate directional material properties resulting from manufacturing processes, while crystallographically-oriented pits may reveal susceptibility to specific corrosion mechanisms related to material composition.

Stress corrosion cracking (SCC) features observed in failed tubes demonstrate the complex interplay between mechanical stress and electrochemical reactions at the microstructural level. The branching patterns, crack propagation paths, and fracture surface characteristics directly reflect material response to combined environmental and mechanical factors. Materials with larger grain sizes typically exhibit more susceptible grain boundary networks for SCC propagation, while certain precipitate distributions can either enhance or inhibit crack growth depending on their coherency with the matrix.

The root cause links between material properties and tube failures often trace back to manufacturing variables and material selection decisions. Heat treatment protocols significantly impact precipitate formation and distribution, which in turn affects corrosion resistance. Similarly, minor variations in alloying elements can dramatically alter susceptibility to localized corrosion and SCC. The presence of residual stresses from forming operations creates preferential sites for failure initiation, particularly when combined with aggressive service environments.

Advanced material characterization techniques have revealed that seemingly minor microstructural features can have profound implications for tube integrity. For example, the orientation relationship between precipitates and the matrix can determine whether they serve as effective barriers to crack propagation or as initiation sites for failure. Similarly, the coherency of phase boundaries influences how effectively they can accommodate strain without creating void nucleation sites.

Understanding these material science implications enables more effective failure prevention strategies, including optimized material specifications, improved manufacturing processes, and more accurate lifetime prediction models. By correlating specific microstructural features with observed failure mechanisms, engineers can develop targeted approaches to enhance tube integrity in critical applications.

Pit morphology analysis provides significant insights into material behavior under corrosive conditions. The shape, depth, and distribution patterns of pits correlate strongly with specific material properties such as grain boundary characteristics, inclusion content, and phase distribution. For instance, elongated pits often indicate directional material properties resulting from manufacturing processes, while crystallographically-oriented pits may reveal susceptibility to specific corrosion mechanisms related to material composition.

Stress corrosion cracking (SCC) features observed in failed tubes demonstrate the complex interplay between mechanical stress and electrochemical reactions at the microstructural level. The branching patterns, crack propagation paths, and fracture surface characteristics directly reflect material response to combined environmental and mechanical factors. Materials with larger grain sizes typically exhibit more susceptible grain boundary networks for SCC propagation, while certain precipitate distributions can either enhance or inhibit crack growth depending on their coherency with the matrix.

The root cause links between material properties and tube failures often trace back to manufacturing variables and material selection decisions. Heat treatment protocols significantly impact precipitate formation and distribution, which in turn affects corrosion resistance. Similarly, minor variations in alloying elements can dramatically alter susceptibility to localized corrosion and SCC. The presence of residual stresses from forming operations creates preferential sites for failure initiation, particularly when combined with aggressive service environments.

Advanced material characterization techniques have revealed that seemingly minor microstructural features can have profound implications for tube integrity. For example, the orientation relationship between precipitates and the matrix can determine whether they serve as effective barriers to crack propagation or as initiation sites for failure. Similarly, the coherency of phase boundaries influences how effectively they can accommodate strain without creating void nucleation sites.

Understanding these material science implications enables more effective failure prevention strategies, including optimized material specifications, improved manufacturing processes, and more accurate lifetime prediction models. By correlating specific microstructural features with observed failure mechanisms, engineers can develop targeted approaches to enhance tube integrity in critical applications.

Environmental Factors Affecting Tube Degradation Mechanisms

The environmental conditions surrounding industrial tubes play a critical role in determining the nature and progression of degradation mechanisms. Temperature variations represent one of the most significant factors, with elevated temperatures accelerating corrosion rates exponentially according to the Arrhenius equation. In high-temperature environments (>500°C), tubes experience accelerated oxidation and potential microstructural changes that can compromise mechanical integrity and create favorable conditions for stress corrosion cracking (SCC).

Chemical composition of the surrounding medium directly influences pit formation and SCC propagation. Chloride ions are particularly aggressive, penetrating protective oxide layers and initiating localized corrosion sites that evolve into distinctive pit morphologies. Studies have shown that chloride concentrations as low as 10 ppm can initiate pitting in susceptible materials under certain conditions, with pit geometry often reflecting the specific environmental chemistry.

pH levels demonstrate a complex relationship with tube degradation mechanisms. Acidic environments (pH<4) typically accelerate general corrosion and pit initiation, while alkaline conditions may promote specific forms of SCC, particularly in austenitic stainless steels. The morphological characteristics of pits formed in acidic versus alkaline environments often display distinctive features that can serve as forensic indicators of the corrosive medium.

Flow dynamics significantly impact degradation patterns through erosion-corrosion mechanisms. Turbulent flow can remove protective films and accelerate material loss in specific regions, creating characteristic "horseshoe" or directional pit formations. Stagnant conditions, conversely, allow concentration cells to develop, promoting deep, narrow pitting with distinctive undercut morphologies.

Cyclic operating conditions introduce additional complexity through thermal and mechanical fatigue mechanisms. Temperature fluctuations create expansion and contraction stresses that can initiate or propagate cracks, particularly at metallurgical discontinuities. These cyclic stresses, when combined with corrosive environments, often produce transgranular cracking patterns with distinctive beach marks that reflect operational cycles.

Microbiologically influenced corrosion (MIC) represents another significant environmental factor, with bacterial colonies creating localized chemical environments that can accelerate pit formation. MIC-induced pits typically display characteristic hemispherical morphologies with subsurface tunneling and often contain biological residues that can be identified through specialized forensic techniques.

Understanding these environmental influences provides critical context for interpreting pit morphology and SCC features, establishing clear links between observed degradation patterns and their root causes. This knowledge enables more accurate failure analysis and informs preventive measures for similar systems.

Chemical composition of the surrounding medium directly influences pit formation and SCC propagation. Chloride ions are particularly aggressive, penetrating protective oxide layers and initiating localized corrosion sites that evolve into distinctive pit morphologies. Studies have shown that chloride concentrations as low as 10 ppm can initiate pitting in susceptible materials under certain conditions, with pit geometry often reflecting the specific environmental chemistry.

pH levels demonstrate a complex relationship with tube degradation mechanisms. Acidic environments (pH<4) typically accelerate general corrosion and pit initiation, while alkaline conditions may promote specific forms of SCC, particularly in austenitic stainless steels. The morphological characteristics of pits formed in acidic versus alkaline environments often display distinctive features that can serve as forensic indicators of the corrosive medium.

Flow dynamics significantly impact degradation patterns through erosion-corrosion mechanisms. Turbulent flow can remove protective films and accelerate material loss in specific regions, creating characteristic "horseshoe" or directional pit formations. Stagnant conditions, conversely, allow concentration cells to develop, promoting deep, narrow pitting with distinctive undercut morphologies.

Cyclic operating conditions introduce additional complexity through thermal and mechanical fatigue mechanisms. Temperature fluctuations create expansion and contraction stresses that can initiate or propagate cracks, particularly at metallurgical discontinuities. These cyclic stresses, when combined with corrosive environments, often produce transgranular cracking patterns with distinctive beach marks that reflect operational cycles.

Microbiologically influenced corrosion (MIC) represents another significant environmental factor, with bacterial colonies creating localized chemical environments that can accelerate pit formation. MIC-induced pits typically display characteristic hemispherical morphologies with subsurface tunneling and often contain biological residues that can be identified through specialized forensic techniques.

Understanding these environmental influences provides critical context for interpreting pit morphology and SCC features, establishing clear links between observed degradation patterns and their root causes. This knowledge enables more accurate failure analysis and informs preventive measures for similar systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!