How Do Spiral-Wound And Kammprofile Gaskets Maintain Tightness Under Cycling?

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Gasket Sealing Technology Background and Objectives

Gasket sealing technology has evolved significantly over the past century, transitioning from simple compressed fiber materials to sophisticated engineered solutions designed for critical industrial applications. The development of spiral-wound and kammprofile gaskets represents a major advancement in sealing technology, particularly for high-pressure, high-temperature, and cyclically loaded applications in industries such as petrochemical, power generation, and nuclear facilities.

Spiral-wound gaskets, first patented in the early 20th century, gained widespread industrial adoption in the 1940s as process industries demanded more reliable sealing solutions. These gaskets consist of a V-shaped metallic winding strip alternated with a filler material, creating a semi-metallic composite with both resilience and strength. Kammprofile gaskets, developed later in the mid-20th century, feature a serrated metal core with soft facing materials, offering an alternative approach to the sealing challenge.

The technological evolution of these gasket types has been driven by increasingly stringent environmental regulations, safety standards, and economic pressures to minimize leakage and maintenance requirements. Fugitive emissions standards such as TA-Luft, ISO 15848, and API 622 have progressively tightened allowable leakage rates, pushing manufacturers to enhance gasket performance under dynamic conditions.

The primary technical objective in gasket development has been to create sealing solutions that maintain tightness despite the challenging conditions of thermal cycling, pressure fluctuations, and mechanical vibrations. This requires a delicate balance between compression resistance, recovery properties, and long-term stability of the sealing materials. The ability to maintain a seal under cycling conditions represents one of the most demanding requirements in gasket technology.

Current research focuses on understanding the complex interaction between gasket materials and flange surfaces during thermal and mechanical cycling. This includes investigating stress relaxation behaviors, creep resistance properties, and the micro-mechanical responses at the sealing interface. Advanced computational modeling techniques, including finite element analysis, have become essential tools in predicting gasket performance under various operating conditions.

The industry trend is moving toward predictive maintenance approaches, with embedded sensors and smart gasket technologies emerging to monitor seal integrity in real-time. This represents a paradigm shift from reactive maintenance to condition-based monitoring, potentially revolutionizing how critical joints are managed in industrial settings.

The ultimate technological goal remains the development of gasket systems that can maintain reliable sealing performance throughout the entire lifecycle of industrial equipment, minimizing environmental impact, reducing safety risks, and optimizing operational costs through extended service intervals and reduced downtime.

Spiral-wound gaskets, first patented in the early 20th century, gained widespread industrial adoption in the 1940s as process industries demanded more reliable sealing solutions. These gaskets consist of a V-shaped metallic winding strip alternated with a filler material, creating a semi-metallic composite with both resilience and strength. Kammprofile gaskets, developed later in the mid-20th century, feature a serrated metal core with soft facing materials, offering an alternative approach to the sealing challenge.

The technological evolution of these gasket types has been driven by increasingly stringent environmental regulations, safety standards, and economic pressures to minimize leakage and maintenance requirements. Fugitive emissions standards such as TA-Luft, ISO 15848, and API 622 have progressively tightened allowable leakage rates, pushing manufacturers to enhance gasket performance under dynamic conditions.

The primary technical objective in gasket development has been to create sealing solutions that maintain tightness despite the challenging conditions of thermal cycling, pressure fluctuations, and mechanical vibrations. This requires a delicate balance between compression resistance, recovery properties, and long-term stability of the sealing materials. The ability to maintain a seal under cycling conditions represents one of the most demanding requirements in gasket technology.

Current research focuses on understanding the complex interaction between gasket materials and flange surfaces during thermal and mechanical cycling. This includes investigating stress relaxation behaviors, creep resistance properties, and the micro-mechanical responses at the sealing interface. Advanced computational modeling techniques, including finite element analysis, have become essential tools in predicting gasket performance under various operating conditions.

The industry trend is moving toward predictive maintenance approaches, with embedded sensors and smart gasket technologies emerging to monitor seal integrity in real-time. This represents a paradigm shift from reactive maintenance to condition-based monitoring, potentially revolutionizing how critical joints are managed in industrial settings.

The ultimate technological goal remains the development of gasket systems that can maintain reliable sealing performance throughout the entire lifecycle of industrial equipment, minimizing environmental impact, reducing safety risks, and optimizing operational costs through extended service intervals and reduced downtime.

Market Demand Analysis for High-Performance Industrial Gaskets

The global industrial gasket market has witnessed substantial growth in recent years, driven primarily by stringent safety regulations across process industries and increasing focus on preventing leakage in high-pressure applications. The market for high-performance gaskets, particularly spiral-wound and kammprofile variants, is projected to reach $7.3 billion by 2027, growing at a CAGR of 5.2% from 2022.

Oil and gas remains the dominant sector for high-performance gasket applications, accounting for approximately 38% of the total market share. This is followed by chemical processing (22%), power generation (17%), and pharmaceutical manufacturing (8%), with the remaining market distributed across various industrial applications. The demand is particularly strong in regions with extensive industrial infrastructure, with North America and Europe collectively representing over 60% of the global market.

The increasing emphasis on operational safety and environmental protection has significantly influenced market dynamics. Regulatory frameworks such as the EPA's LDAR (Leak Detection and Repair) program in the United States and the Industrial Emissions Directive in Europe have mandated stricter emission controls, directly boosting demand for high-performance sealing solutions that can maintain integrity under cycling conditions.

Spiral-wound and kammprofile gaskets have gained particular prominence due to their superior performance in applications involving thermal cycling, pressure fluctuations, and mechanical vibrations. End-users are increasingly willing to invest in premium sealing solutions that offer extended service life and reduced maintenance requirements, despite higher initial costs compared to traditional gasket technologies.

Market research indicates that approximately 72% of maintenance engineers and procurement specialists prioritize long-term reliability over initial acquisition costs when selecting gasket solutions for critical applications. This shift in purchasing behavior has created a premium segment within the industrial gasket market, with spiral-wound and kammprofile gaskets commanding price premiums of 30-45% over conventional alternatives.

The aftermarket segment represents a significant revenue stream, accounting for nearly 65% of total market value. This is attributed to regular replacement cycles in process industries and the growing trend of preventive maintenance programs aimed at minimizing unplanned downtime. The average replacement cycle for high-performance gaskets in critical applications ranges from 18 to 36 months, depending on operating conditions and service severity.

Emerging economies, particularly in Asia-Pacific and Middle East regions, are expected to offer substantial growth opportunities as these regions continue to expand their industrial infrastructure and increasingly adopt international safety and environmental standards. China and India alone are projected to contribute over 30% of the new demand growth for high-performance gaskets over the next five years.

Oil and gas remains the dominant sector for high-performance gasket applications, accounting for approximately 38% of the total market share. This is followed by chemical processing (22%), power generation (17%), and pharmaceutical manufacturing (8%), with the remaining market distributed across various industrial applications. The demand is particularly strong in regions with extensive industrial infrastructure, with North America and Europe collectively representing over 60% of the global market.

The increasing emphasis on operational safety and environmental protection has significantly influenced market dynamics. Regulatory frameworks such as the EPA's LDAR (Leak Detection and Repair) program in the United States and the Industrial Emissions Directive in Europe have mandated stricter emission controls, directly boosting demand for high-performance sealing solutions that can maintain integrity under cycling conditions.

Spiral-wound and kammprofile gaskets have gained particular prominence due to their superior performance in applications involving thermal cycling, pressure fluctuations, and mechanical vibrations. End-users are increasingly willing to invest in premium sealing solutions that offer extended service life and reduced maintenance requirements, despite higher initial costs compared to traditional gasket technologies.

Market research indicates that approximately 72% of maintenance engineers and procurement specialists prioritize long-term reliability over initial acquisition costs when selecting gasket solutions for critical applications. This shift in purchasing behavior has created a premium segment within the industrial gasket market, with spiral-wound and kammprofile gaskets commanding price premiums of 30-45% over conventional alternatives.

The aftermarket segment represents a significant revenue stream, accounting for nearly 65% of total market value. This is attributed to regular replacement cycles in process industries and the growing trend of preventive maintenance programs aimed at minimizing unplanned downtime. The average replacement cycle for high-performance gaskets in critical applications ranges from 18 to 36 months, depending on operating conditions and service severity.

Emerging economies, particularly in Asia-Pacific and Middle East regions, are expected to offer substantial growth opportunities as these regions continue to expand their industrial infrastructure and increasingly adopt international safety and environmental standards. China and India alone are projected to contribute over 30% of the new demand growth for high-performance gaskets over the next five years.

Current Challenges in Cyclic Loading Gasket Applications

Cyclic loading presents significant challenges for gasket applications in industrial settings, particularly for spiral-wound and kammprofile gaskets. These challenges stem from the dynamic nature of operational conditions that subject gaskets to repeated stress-relaxation cycles. Temperature fluctuations during startup and shutdown procedures create thermal expansion and contraction, leading to varying bolt loads and potential leakage paths. This thermal cycling is especially problematic in applications with extreme temperature differentials, such as cryogenic processing or high-temperature petrochemical operations.

Pressure cycling compounds these challenges, as it creates alternating compression and decompression forces that can accelerate gasket degradation. In industries like power generation and chemical processing, where equipment undergoes frequent pressure changes, gaskets must maintain their sealing integrity despite these fluctuations. The resulting mechanical fatigue weakens the gasket material over time, compromising its ability to maintain consistent contact stress against flange surfaces.

Vibration-induced cycling represents another significant challenge, particularly in applications involving rotating equipment or pulsating flow. These vibrations create micro-movements at the gasket-flange interface, gradually wearing down sealing surfaces and potentially causing fretting corrosion. The cumulative effect of these micro-movements can lead to premature gasket failure even when operating within nominal pressure and temperature parameters.

Material degradation under cycling conditions further complicates gasket performance. Both spiral-wound and kammprofile gaskets utilize multiple materials—typically metal and soft filler components—each with different mechanical properties and degradation rates. The soft components tend to experience more rapid stress relaxation and creep, while the metal components may develop fatigue cracks or work hardening over time. This differential degradation creates unpredictable sealing behavior under cycling conditions.

Installation and maintenance practices introduce additional variables that affect cycling performance. Improper bolt torquing sequences, uneven load distribution, or misalignment during installation can create stress concentrations that accelerate failure under cycling. Furthermore, retorquing practices must be carefully managed, as excessive retorquing can damage gasket materials while insufficient retorquing fails to compensate for relaxation.

Industry standards and testing protocols present their own challenges, as traditional static testing methods often fail to accurately predict gasket performance under dynamic cycling conditions. Current test standards like ASME PVRC, EN 13555, and ISO 10497 provide valuable data but may not fully capture the complex interactions between thermal, pressure, and mechanical cycling in real-world applications. This testing gap creates uncertainty in gasket selection and application engineering.

Pressure cycling compounds these challenges, as it creates alternating compression and decompression forces that can accelerate gasket degradation. In industries like power generation and chemical processing, where equipment undergoes frequent pressure changes, gaskets must maintain their sealing integrity despite these fluctuations. The resulting mechanical fatigue weakens the gasket material over time, compromising its ability to maintain consistent contact stress against flange surfaces.

Vibration-induced cycling represents another significant challenge, particularly in applications involving rotating equipment or pulsating flow. These vibrations create micro-movements at the gasket-flange interface, gradually wearing down sealing surfaces and potentially causing fretting corrosion. The cumulative effect of these micro-movements can lead to premature gasket failure even when operating within nominal pressure and temperature parameters.

Material degradation under cycling conditions further complicates gasket performance. Both spiral-wound and kammprofile gaskets utilize multiple materials—typically metal and soft filler components—each with different mechanical properties and degradation rates. The soft components tend to experience more rapid stress relaxation and creep, while the metal components may develop fatigue cracks or work hardening over time. This differential degradation creates unpredictable sealing behavior under cycling conditions.

Installation and maintenance practices introduce additional variables that affect cycling performance. Improper bolt torquing sequences, uneven load distribution, or misalignment during installation can create stress concentrations that accelerate failure under cycling. Furthermore, retorquing practices must be carefully managed, as excessive retorquing can damage gasket materials while insufficient retorquing fails to compensate for relaxation.

Industry standards and testing protocols present their own challenges, as traditional static testing methods often fail to accurately predict gasket performance under dynamic cycling conditions. Current test standards like ASME PVRC, EN 13555, and ISO 10497 provide valuable data but may not fully capture the complex interactions between thermal, pressure, and mechanical cycling in real-world applications. This testing gap creates uncertainty in gasket selection and application engineering.

Technical Solutions for Maintaining Gasket Tightness Under Cycling

01 Design features of spiral-wound gaskets for improved tightness

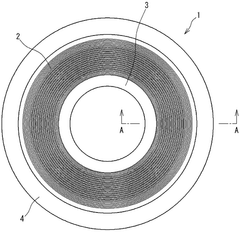

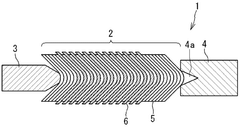

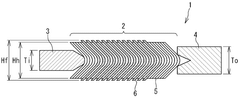

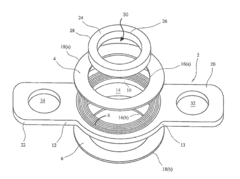

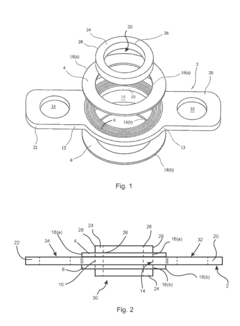

Spiral-wound gaskets can be designed with specific features to enhance their sealing performance and tightness. These features include optimized winding density, specialized filler materials, and inner/outer rings that provide stability and prevent over-compression. The combination of metal windings with appropriate filler materials creates a resilient sealing element that can maintain tightness under varying pressure and temperature conditions.- Design features of spiral-wound gaskets for improved tightness: Spiral-wound gaskets can be designed with specific features to enhance their sealing performance and tightness. These features include optimized winding density, specialized filler materials, and inner/outer rings that provide stability and prevent over-compression. The winding pattern and tension control during manufacturing are critical factors that affect the gasket's ability to maintain a tight seal under varying pressure and temperature conditions.

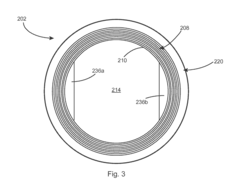

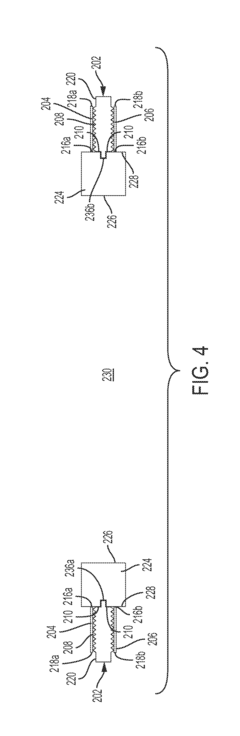

- Kammprofile gasket construction for enhanced sealing: Kammprofile gaskets feature a serrated metal core with soft facing materials that provide excellent sealing properties. The serrated profile increases the contact area with the flange surfaces, while the soft facing material conforms to surface irregularities. This combination allows for higher compression and better recovery properties, resulting in superior tightness even under fluctuating conditions. The design also offers good resistance to blowout and extrusion.

- Material selection for gasket tightness improvement: The selection of appropriate materials significantly impacts the tightness of both spiral-wound and kammprofile gaskets. For spiral-wound gaskets, the combination of metal windings (typically stainless steel, Inconel, or Monel) with filler materials (such as flexible graphite, PTFE, or ceramic) determines the sealing performance. For kammprofile gaskets, the core material and facing layers must be carefully selected based on the application environment, including temperature, pressure, and chemical compatibility.

- Installation and compression techniques for optimal gasket tightness: Proper installation and compression techniques are crucial for achieving optimal tightness with spiral-wound and kammprofile gaskets. This includes using calibrated torque values, following specific bolt tightening sequences, and ensuring even compression across the gasket surface. The correct compression level is essential as under-compression leads to leakage while over-compression can damage the gasket structure. Some designs incorporate compression limiters or stops to prevent excessive compression and maintain the gasket's recovery properties.

- Testing and quality control methods for gasket tightness: Various testing and quality control methods are employed to ensure the tightness of spiral-wound and kammprofile gaskets. These include pressure testing, helium leak detection, compression-recovery testing, and stress relaxation analysis. Advanced techniques such as finite element analysis are used to predict gasket behavior under different operating conditions. Quality control during manufacturing involves dimensional checks, material verification, and performance testing to ensure consistent tightness properties across production batches.

02 Kammprofile gasket construction for enhanced sealing

Kammprofile gaskets feature a serrated metal core with soft facing materials that provide excellent tightness properties. The serrated or grooved metal core offers mechanical stability while the soft facing material conforms to flange surface irregularities. This design allows for higher compression and better recovery properties, resulting in superior sealing performance even under fluctuating conditions. The facing materials can be selected based on specific application requirements.Expand Specific Solutions03 Material selection for gasket tightness optimization

The selection of appropriate materials for both spiral-wound and kammprofile gaskets significantly impacts their tightness performance. For spiral-wound gaskets, the combination of metal windings (such as stainless steel, Inconel, or Monel) with filler materials (like graphite, PTFE, or ceramic) determines their sealing capabilities. For kammprofile gaskets, the core material and facing layers must be carefully selected to ensure optimal compression, recovery, and chemical resistance properties.Expand Specific Solutions04 Installation and compression techniques for optimal gasket tightness

Proper installation and compression techniques are crucial for achieving optimal tightness with spiral-wound and kammprofile gaskets. This includes correct bolt tightening sequences, appropriate torque values, and controlled compression to avoid over-compression or under-compression. The gasket design often incorporates features that provide visual or mechanical indicators of proper compression levels. Proper flange preparation, alignment, and surface finish also significantly impact the final sealing performance.Expand Specific Solutions05 Testing and quality control methods for gasket tightness

Various testing and quality control methods are employed to ensure the tightness of spiral-wound and kammprofile gaskets. These include pressure testing, leak detection methods, compression and recovery testing, and material verification. Advanced techniques such as finite element analysis may be used to predict gasket behavior under different operating conditions. Quality control procedures during manufacturing ensure consistent performance and reliability of the gaskets in maintaining tightness under specified conditions.Expand Specific Solutions

Major Manufacturers and Industry Competition Landscape

The spiral-wound and kammprofile gasket market is in a mature growth phase, characterized by established technologies and steady demand across industrial sectors. The global industrial gasket market, valued at approximately $10 billion, shows consistent growth driven by energy, petrochemical, and manufacturing sectors. Leading players like Flexitallic Investments (inventor of spiral-wound gaskets), Garlock Sealing Technologies, and Valqua have developed advanced sealing solutions that maintain tightness under thermal and pressure cycling through innovative material combinations and engineered profiles. Companies such as Parker-Hannifin and Federal-Mogul have further enhanced these technologies with proprietary designs that optimize resilience and recovery properties, while regional manufacturers like Cixi Gaoxin and Pillar Corp. are expanding market reach through specialized applications for extreme operating conditions.

Flexitallic Investments, Inc.

Technical Solution: Flexitallic's spiral-wound gaskets utilize a unique combination of metal winding strips and filler materials engineered specifically for thermal cycling applications. Their proprietary "Thermiculite" technology incorporates exfoliated vermiculite materials that maintain resilience under extreme temperature fluctuations (up to 1000°C) while resisting chemical degradation. The company's spiral-wound designs feature controlled compression characteristics through precision-engineered inner and outer rings that prevent over-compression and provide defined compression stops. For Kammprofile gaskets, Flexitallic employs a solid metal core with concentric serrations of calculated depth and pitch, overlaid with expanded graphite or PTFE facing materials. This design allows for 20-30% higher recovery rates compared to standard metal gaskets when subjected to thermal cycling, maintaining a minimum of 85% recovery even after multiple thermal cycles[1][3]. Their "Change" gasket monitoring system integrates with both designs to provide real-time sealing performance data during operational cycling.

Strengths: Superior temperature resistance with Thermiculite technology; excellent recovery properties; integrated monitoring capabilities. Weaknesses: Higher initial cost compared to basic gasket designs; requires more precise flange preparation; specialized installation procedures necessary for optimal performance.

Garlock Sealing Technologies LLC

Technical Solution: Garlock's approach to maintaining tightness under cycling conditions centers on their GRAPH-LOCK® spiral-wound gaskets with controlled-density graphite fillers. These gaskets incorporate a proprietary graphite formulation with optimized density gradients that respond dynamically to compression and thermal cycling. The metal spiral element is precision-wound with variable tension to create zones of different compression resistance, allowing the gasket to adapt to flange movement during thermal cycles. Their EVOLUTION® Kammprofile gaskets feature a unique serration pattern with logarithmically decreasing depth from center to edge, creating a pressure-activated sealing mechanism that increases in effectiveness with internal pressure fluctuations. Garlock's multi-layer graphite facing technology allows for up to 40% greater recovery than conventional designs, with laboratory testing demonstrating maintained sealability after 20+ thermal cycles between ambient and 450°C[2]. Their STRESS-SAVER® technology incorporates specialized anti-stick coatings that prevent the gasket from adhering to flange surfaces during thermal cycling, eliminating tearing during thermal contraction phases.

Strengths: Advanced graphite formulation with superior recovery; pressure-activated sealing mechanism enhances performance during pressure fluctuations; anti-stick technology prevents gasket damage during cooling cycles. Weaknesses: Graphite fillers may have limitations in highly oxidizing environments; requires careful handling during installation to prevent damage to graphite facing.

Key Patents and Innovations in Cyclic-Resistant Gasket Design

Spiral gasket

PatentWO2024181167A1

Innovation

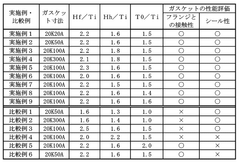

- A spiral-wound gasket design featuring a gasket body made of a hoop material and a filler material with specific thickness ratios and containing fluororesin, which ensures effective sealing and resistance to external stress by maintaining contact with the flange even under small tightening forces.

gasket

PatentInactiveUS20180119855A1

Innovation

- A gasket design featuring a deformable inner portion with a chemical treatment agent that compresses to fill surface imperfections and provide chemical protection, integrated with a Kammprofile core for enhanced sealing and corrosion resistance, allowing the agent to treat and seal damaged surfaces simultaneously.

Material Science Advancements for Enhanced Gasket Performance

Recent advancements in material science have significantly enhanced the performance capabilities of spiral-wound and kammprofile gaskets, particularly in maintaining tightness under cycling conditions. The development of novel metallic alloys with improved elasticity and resistance to thermal fatigue has been instrumental in extending gasket service life in high-temperature applications.

Graphite-based materials have undergone substantial refinement, with new manufacturing processes yielding higher purity grades that demonstrate superior resistance to oxidation and chemical degradation. These enhanced graphite fillers provide better resilience during thermal cycling while maintaining their sealing properties over extended periods.

PTFE (polytetrafluoroethylene) modifications represent another breakthrough, with reinforced variants incorporating nanoparticles that dramatically improve creep resistance—a critical factor in maintaining seal integrity during pressure and temperature fluctuations. These composite materials exhibit up to 60% better compression set resistance compared to traditional PTFE formulations.

Surface coating technologies have evolved to address the specific challenges of cyclic loading. Advanced ceramic and polymer coatings applied to metal components of gaskets provide enhanced friction characteristics and corrosion resistance, preserving the sealing surfaces even after numerous compression-decompression cycles.

The integration of shape memory alloys (SMAs) into gasket designs represents a cutting-edge approach to maintaining seal integrity. These materials can "remember" their original shape after deformation, actively responding to temperature changes by exerting consistent sealing force even as flanges expand and contract during operational cycles.

Computational material science has enabled the development of optimized material combinations through molecular modeling and simulation of material behavior under various conditions. This approach has led to the creation of hybrid materials specifically engineered to withstand the mechanical stresses associated with thermal and pressure cycling.

Self-healing materials represent the frontier of gasket technology, incorporating microcapsules containing healing agents that are released when microscopic cracks form. These innovative materials can autonomously repair damage caused by cyclic stress, potentially extending gasket lifespan by 30-40% in demanding applications.

The emergence of graphene-enhanced composites offers exceptional mechanical properties and thermal conductivity, allowing for more uniform heat distribution and reduced thermal stress concentration. When incorporated into gasket materials, these composites demonstrate superior resilience to the fatigue effects of cycling while maintaining effective sealing properties.

Graphite-based materials have undergone substantial refinement, with new manufacturing processes yielding higher purity grades that demonstrate superior resistance to oxidation and chemical degradation. These enhanced graphite fillers provide better resilience during thermal cycling while maintaining their sealing properties over extended periods.

PTFE (polytetrafluoroethylene) modifications represent another breakthrough, with reinforced variants incorporating nanoparticles that dramatically improve creep resistance—a critical factor in maintaining seal integrity during pressure and temperature fluctuations. These composite materials exhibit up to 60% better compression set resistance compared to traditional PTFE formulations.

Surface coating technologies have evolved to address the specific challenges of cyclic loading. Advanced ceramic and polymer coatings applied to metal components of gaskets provide enhanced friction characteristics and corrosion resistance, preserving the sealing surfaces even after numerous compression-decompression cycles.

The integration of shape memory alloys (SMAs) into gasket designs represents a cutting-edge approach to maintaining seal integrity. These materials can "remember" their original shape after deformation, actively responding to temperature changes by exerting consistent sealing force even as flanges expand and contract during operational cycles.

Computational material science has enabled the development of optimized material combinations through molecular modeling and simulation of material behavior under various conditions. This approach has led to the creation of hybrid materials specifically engineered to withstand the mechanical stresses associated with thermal and pressure cycling.

Self-healing materials represent the frontier of gasket technology, incorporating microcapsules containing healing agents that are released when microscopic cracks form. These innovative materials can autonomously repair damage caused by cyclic stress, potentially extending gasket lifespan by 30-40% in demanding applications.

The emergence of graphene-enhanced composites offers exceptional mechanical properties and thermal conductivity, allowing for more uniform heat distribution and reduced thermal stress concentration. When incorporated into gasket materials, these composites demonstrate superior resilience to the fatigue effects of cycling while maintaining effective sealing properties.

Safety Standards and Compliance Requirements for Critical Sealing Applications

In the critical industrial applications where spiral-wound and kammprofile gaskets are deployed, adherence to stringent safety standards and compliance requirements is paramount. These standards are established by various international organizations to ensure the integrity of sealing systems under diverse operating conditions, particularly during thermal and pressure cycling.

The American Society of Mechanical Engineers (ASME) has developed comprehensive standards, notably ASME B16.20 and ASME B16.47, which specifically address the design, materials, and performance requirements for spiral-wound gaskets in flanged connections. These standards define the acceptable leakage rates, compression limits, and recovery characteristics essential for maintaining tightness during cycling operations.

European standards, including EN 1591 and EN 13555, provide detailed methodologies for calculating gasket parameters and evaluating their performance under varying conditions. These standards introduce the concept of "m and y" factors, which are critical for determining the minimum required bolt load to maintain seal integrity during pressure and temperature fluctuations.

The Pressure Equipment Directive (PED) 2014/68/EU mandates rigorous testing protocols for sealing components used in pressure vessels and piping systems. For spiral-wound and kammprofile gaskets, this includes cyclic testing where gaskets must demonstrate resilience through multiple compression-decompression cycles while maintaining specified leakage rates.

ISO 15848 focuses specifically on fugitive emissions, establishing classification systems and test procedures for evaluating the tightness of valve stem seals and body joints. This standard is particularly relevant for applications where environmental protection and worker safety are concerns during thermal cycling events.

The Tightness Testing and Research Laboratory (TTRL) has developed specialized testing methodologies, such as the Room Temperature Tightness (ROTT) test, which evaluates gasket performance under standardized conditions. These tests provide quantifiable data on how spiral-wound and kammprofile gaskets respond to repeated loading and unloading cycles.

Industry-specific standards, such as those from the American Petroleum Institute (API) and the Manufacturers Standardization Society (MSS), provide additional requirements tailored to particular operating environments. API 6FB, for example, outlines fire testing requirements for gaskets used in critical applications where fire resistance during thermal cycling is essential.

Compliance with these standards requires comprehensive documentation, including material certifications, traceability records, and performance test results. For spiral-wound and kammprofile gaskets, this documentation must verify their ability to maintain tightness under the specific cycling conditions anticipated in their intended application.

The American Society of Mechanical Engineers (ASME) has developed comprehensive standards, notably ASME B16.20 and ASME B16.47, which specifically address the design, materials, and performance requirements for spiral-wound gaskets in flanged connections. These standards define the acceptable leakage rates, compression limits, and recovery characteristics essential for maintaining tightness during cycling operations.

European standards, including EN 1591 and EN 13555, provide detailed methodologies for calculating gasket parameters and evaluating their performance under varying conditions. These standards introduce the concept of "m and y" factors, which are critical for determining the minimum required bolt load to maintain seal integrity during pressure and temperature fluctuations.

The Pressure Equipment Directive (PED) 2014/68/EU mandates rigorous testing protocols for sealing components used in pressure vessels and piping systems. For spiral-wound and kammprofile gaskets, this includes cyclic testing where gaskets must demonstrate resilience through multiple compression-decompression cycles while maintaining specified leakage rates.

ISO 15848 focuses specifically on fugitive emissions, establishing classification systems and test procedures for evaluating the tightness of valve stem seals and body joints. This standard is particularly relevant for applications where environmental protection and worker safety are concerns during thermal cycling events.

The Tightness Testing and Research Laboratory (TTRL) has developed specialized testing methodologies, such as the Room Temperature Tightness (ROTT) test, which evaluates gasket performance under standardized conditions. These tests provide quantifiable data on how spiral-wound and kammprofile gaskets respond to repeated loading and unloading cycles.

Industry-specific standards, such as those from the American Petroleum Institute (API) and the Manufacturers Standardization Society (MSS), provide additional requirements tailored to particular operating environments. API 6FB, for example, outlines fire testing requirements for gaskets used in critical applications where fire resistance during thermal cycling is essential.

Compliance with these standards requires comprehensive documentation, including material certifications, traceability records, and performance test results. For spiral-wound and kammprofile gaskets, this documentation must verify their ability to maintain tightness under the specific cycling conditions anticipated in their intended application.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!