Shell-Side Nozzle Erosion: Velocity Control, Flow Turning And Material Choices

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Shell-Side Nozzle Erosion Background and Objectives

Shell-side nozzle erosion represents a significant challenge in heat exchanger design and operation, particularly in industries such as petrochemical processing, power generation, and oil refining. The phenomenon has been observed since the early development of shell and tube heat exchangers in the 1920s, but became a documented engineering concern in the 1950s as industrial processes intensified and operating conditions became more severe.

The erosion process occurs when high-velocity fluid enters the shell side of a heat exchanger through inlet nozzles, creating localized regions of turbulence and impingement. This fluid-structure interaction leads to material degradation over time, compromising the structural integrity of the equipment and potentially resulting in costly failures and unplanned downtime.

Historical approaches to mitigating this issue have evolved from simple geometric modifications to sophisticated computational fluid dynamics (CFD) modeling. Early solutions focused primarily on empirical design rules, while contemporary approaches incorporate multiphysics simulations that account for flow characteristics, material properties, and erosion mechanisms simultaneously.

The technical evolution in this field has been driven by three primary factors: increasing process intensification requiring higher throughput rates, economic pressures to extend equipment service life, and regulatory requirements for safer industrial operations. These drivers have pushed the technical boundaries from basic mechanical solutions toward integrated approaches that combine velocity control strategies, optimized flow path designs, and advanced material science.

Current research indicates that effective management of shell-side nozzle erosion requires a multidisciplinary approach addressing fluid dynamics, materials engineering, and mechanical design principles. The interplay between these disciplines creates both challenges and opportunities for innovative solutions.

The primary objectives of this technical investigation are threefold: first, to comprehensively analyze velocity control methodologies that can effectively distribute flow energy and reduce localized erosion; second, to evaluate flow turning techniques that minimize impingement angles and redirect high-velocity streams away from vulnerable surfaces; and third, to assess advanced material options that offer superior erosion resistance while maintaining thermal efficiency and cost-effectiveness.

Additionally, this research aims to establish quantifiable performance metrics for erosion resistance, develop predictive models for erosion rates under various operating conditions, and formulate design guidelines that can be readily implemented by engineering teams across relevant industries. The ultimate goal is to extend equipment service life by at least 30% while maintaining or improving thermal performance characteristics.

The erosion process occurs when high-velocity fluid enters the shell side of a heat exchanger through inlet nozzles, creating localized regions of turbulence and impingement. This fluid-structure interaction leads to material degradation over time, compromising the structural integrity of the equipment and potentially resulting in costly failures and unplanned downtime.

Historical approaches to mitigating this issue have evolved from simple geometric modifications to sophisticated computational fluid dynamics (CFD) modeling. Early solutions focused primarily on empirical design rules, while contemporary approaches incorporate multiphysics simulations that account for flow characteristics, material properties, and erosion mechanisms simultaneously.

The technical evolution in this field has been driven by three primary factors: increasing process intensification requiring higher throughput rates, economic pressures to extend equipment service life, and regulatory requirements for safer industrial operations. These drivers have pushed the technical boundaries from basic mechanical solutions toward integrated approaches that combine velocity control strategies, optimized flow path designs, and advanced material science.

Current research indicates that effective management of shell-side nozzle erosion requires a multidisciplinary approach addressing fluid dynamics, materials engineering, and mechanical design principles. The interplay between these disciplines creates both challenges and opportunities for innovative solutions.

The primary objectives of this technical investigation are threefold: first, to comprehensively analyze velocity control methodologies that can effectively distribute flow energy and reduce localized erosion; second, to evaluate flow turning techniques that minimize impingement angles and redirect high-velocity streams away from vulnerable surfaces; and third, to assess advanced material options that offer superior erosion resistance while maintaining thermal efficiency and cost-effectiveness.

Additionally, this research aims to establish quantifiable performance metrics for erosion resistance, develop predictive models for erosion rates under various operating conditions, and formulate design guidelines that can be readily implemented by engineering teams across relevant industries. The ultimate goal is to extend equipment service life by at least 30% while maintaining or improving thermal performance characteristics.

Market Demand Analysis for Erosion-Resistant Heat Exchangers

The global market for erosion-resistant heat exchangers has witnessed substantial growth in recent years, driven primarily by increasing demands from oil and gas, chemical processing, power generation, and marine industries. These sectors face significant challenges related to shell-side nozzle erosion, creating a robust market for advanced solutions that address velocity control, flow turning, and material selection concerns.

Current market analysis indicates that the erosion-resistant heat exchanger market was valued at approximately $3.2 billion in 2022, with projections suggesting a compound annual growth rate of 5.7% through 2028. This growth trajectory is particularly pronounced in regions with extensive petrochemical operations, including North America, the Middle East, and parts of Asia Pacific.

Industry surveys reveal that maintenance and replacement costs associated with erosion damage in conventional heat exchangers represent a substantial operational expense for end-users. Companies report spending between 15-20% of their maintenance budgets addressing erosion-related failures, creating a strong economic incentive for investment in erosion-resistant technologies.

The demand landscape shows distinct segmentation based on industry requirements. The oil and gas sector, particularly offshore operations, demonstrates the highest willingness to invest in premium erosion-resistant solutions due to the extreme operating conditions and high costs associated with equipment failure. Chemical processing industries prioritize solutions that offer extended service life under corrosive conditions, while power generation facilities seek heat exchangers capable of handling high-velocity steam and water mixtures.

Market research indicates growing customer preference for integrated solutions that address multiple aspects of erosion control simultaneously. End-users increasingly demand systems that combine optimized flow geometry, advanced materials, and intelligent monitoring capabilities rather than addressing these factors in isolation.

Regional market analysis shows that North America currently holds the largest market share at 32%, followed by Europe at 28% and Asia Pacific at 25%. However, the fastest growth is occurring in emerging markets, particularly in Southeast Asia and the Middle East, where rapid industrialization is driving demand for more durable and efficient heat exchange equipment.

Customer feedback highlights specific performance requirements gaining prominence in purchase decisions. These include demonstrable extension of service intervals, reduced maintenance requirements, compatibility with existing systems, and quantifiable return on investment metrics. Additionally, environmental regulations and sustainability goals are increasingly influencing procurement decisions, with customers seeking solutions that minimize waste generation and energy consumption.

Current market analysis indicates that the erosion-resistant heat exchanger market was valued at approximately $3.2 billion in 2022, with projections suggesting a compound annual growth rate of 5.7% through 2028. This growth trajectory is particularly pronounced in regions with extensive petrochemical operations, including North America, the Middle East, and parts of Asia Pacific.

Industry surveys reveal that maintenance and replacement costs associated with erosion damage in conventional heat exchangers represent a substantial operational expense for end-users. Companies report spending between 15-20% of their maintenance budgets addressing erosion-related failures, creating a strong economic incentive for investment in erosion-resistant technologies.

The demand landscape shows distinct segmentation based on industry requirements. The oil and gas sector, particularly offshore operations, demonstrates the highest willingness to invest in premium erosion-resistant solutions due to the extreme operating conditions and high costs associated with equipment failure. Chemical processing industries prioritize solutions that offer extended service life under corrosive conditions, while power generation facilities seek heat exchangers capable of handling high-velocity steam and water mixtures.

Market research indicates growing customer preference for integrated solutions that address multiple aspects of erosion control simultaneously. End-users increasingly demand systems that combine optimized flow geometry, advanced materials, and intelligent monitoring capabilities rather than addressing these factors in isolation.

Regional market analysis shows that North America currently holds the largest market share at 32%, followed by Europe at 28% and Asia Pacific at 25%. However, the fastest growth is occurring in emerging markets, particularly in Southeast Asia and the Middle East, where rapid industrialization is driving demand for more durable and efficient heat exchange equipment.

Customer feedback highlights specific performance requirements gaining prominence in purchase decisions. These include demonstrable extension of service intervals, reduced maintenance requirements, compatibility with existing systems, and quantifiable return on investment metrics. Additionally, environmental regulations and sustainability goals are increasingly influencing procurement decisions, with customers seeking solutions that minimize waste generation and energy consumption.

Current Challenges in Shell-Side Nozzle Erosion Control

Shell-side nozzle erosion represents a significant challenge in heat exchanger design and operation, particularly in industries where high-velocity fluid flows are common. The erosion process occurs when fluid entering the shell side of a heat exchanger impinges on tubes and baffles, causing material degradation over time. This phenomenon is exacerbated by the presence of solid particles, high flow velocities, and turbulent flow patterns.

Velocity control remains one of the primary challenges in mitigating shell-side nozzle erosion. Current industry standards recommend maintaining flow velocities below critical thresholds, typically 15-20 m/s for clean fluids and significantly lower for particle-laden streams. However, achieving optimal velocity distribution throughout the shell side proves difficult due to complex geometry and flow path variations. The trade-off between heat transfer efficiency and erosion control creates a design paradox, as higher velocities enhance heat transfer but accelerate erosion rates.

Flow turning mechanisms present another significant challenge. As fluid enters through the nozzle, it must change direction to distribute across the tube bundle. This directional change creates localized high-velocity regions and turbulent eddies that concentrate erosive forces. Current impingement protection devices such as impingement plates and distribution baffles offer partial solutions but introduce additional pressure drops and potential flow dead zones that can reduce overall heat exchanger efficiency.

Material selection constitutes the third major challenge in addressing shell-side nozzle erosion. While traditional materials like carbon steel and stainless steel remain industry standards, they exhibit limited erosion resistance under severe service conditions. Advanced materials such as chromium-molybdenum alloys, ceramic coatings, and composite linings show promise but present challenges related to cost, fabrication complexity, and long-term reliability. The industry lacks comprehensive performance data for these materials under varied operating conditions, making material selection decisions difficult.

Computational modeling of erosion phenomena represents another challenge area. Current computational fluid dynamics (CFD) models struggle to accurately predict erosion patterns due to the complex interaction between fluid dynamics, particle transport, and material response. The multiphysics nature of erosion processes requires sophisticated modeling approaches that are computationally intensive and often rely on empirical correlations with limited validation data.

Monitoring and detection of erosion progression in operating equipment presents operational challenges. Non-destructive testing methods have limitations in detecting early-stage erosion, particularly in hard-to-access areas near nozzle regions. This leads to reactive rather than proactive maintenance approaches, increasing the risk of unexpected failures and unplanned downtime.

Velocity control remains one of the primary challenges in mitigating shell-side nozzle erosion. Current industry standards recommend maintaining flow velocities below critical thresholds, typically 15-20 m/s for clean fluids and significantly lower for particle-laden streams. However, achieving optimal velocity distribution throughout the shell side proves difficult due to complex geometry and flow path variations. The trade-off between heat transfer efficiency and erosion control creates a design paradox, as higher velocities enhance heat transfer but accelerate erosion rates.

Flow turning mechanisms present another significant challenge. As fluid enters through the nozzle, it must change direction to distribute across the tube bundle. This directional change creates localized high-velocity regions and turbulent eddies that concentrate erosive forces. Current impingement protection devices such as impingement plates and distribution baffles offer partial solutions but introduce additional pressure drops and potential flow dead zones that can reduce overall heat exchanger efficiency.

Material selection constitutes the third major challenge in addressing shell-side nozzle erosion. While traditional materials like carbon steel and stainless steel remain industry standards, they exhibit limited erosion resistance under severe service conditions. Advanced materials such as chromium-molybdenum alloys, ceramic coatings, and composite linings show promise but present challenges related to cost, fabrication complexity, and long-term reliability. The industry lacks comprehensive performance data for these materials under varied operating conditions, making material selection decisions difficult.

Computational modeling of erosion phenomena represents another challenge area. Current computational fluid dynamics (CFD) models struggle to accurately predict erosion patterns due to the complex interaction between fluid dynamics, particle transport, and material response. The multiphysics nature of erosion processes requires sophisticated modeling approaches that are computationally intensive and often rely on empirical correlations with limited validation data.

Monitoring and detection of erosion progression in operating equipment presents operational challenges. Non-destructive testing methods have limitations in detecting early-stage erosion, particularly in hard-to-access areas near nozzle regions. This leads to reactive rather than proactive maintenance approaches, increasing the risk of unexpected failures and unplanned downtime.

Current Velocity Control and Flow Turning Solutions

01 Erosion-resistant nozzle designs for shell-side applications

Specialized nozzle designs can significantly reduce erosion in shell-side applications. These designs incorporate features such as optimized flow paths, reinforced materials at high-wear points, and geometric modifications that minimize turbulence and impact angles. By controlling the fluid dynamics within the nozzle, these designs reduce the velocity and impact force of particles against the nozzle walls, thereby extending the operational life of the equipment.- Protective coatings for nozzle erosion prevention: Various protective coatings can be applied to shell-side nozzles to prevent erosion caused by fluid flow and particle impingement. These coatings typically consist of erosion-resistant materials such as ceramics, metal alloys, or composite materials that create a barrier between the flowing fluid and the nozzle surface. The coatings can be applied through various methods including thermal spraying, cladding, or chemical vapor deposition to enhance the durability and lifespan of nozzles in high-erosion environments.

- Flow optimization techniques to reduce erosion: Optimizing the flow pattern within shell-side nozzles can significantly reduce erosion. This includes designing nozzle geometries that minimize turbulence, incorporating flow straighteners or diffusers, and controlling flow velocities to reduce the impact force of fluid and particles against nozzle surfaces. Computational fluid dynamics (CFD) analysis is often used to identify potential erosion hotspots and optimize nozzle designs accordingly. These techniques help distribute flow more evenly and reduce localized erosion damage.

- Erosion monitoring and detection systems: Advanced monitoring systems can be implemented to detect and track erosion in shell-side nozzles before catastrophic failure occurs. These systems may include ultrasonic thickness measurement devices, acoustic emission sensors, or other non-destructive testing methods that can identify thinning of nozzle walls due to erosion. Real-time monitoring allows for timely maintenance interventions and replacement of components before critical failure. Some systems also incorporate predictive analytics to forecast erosion rates based on operating conditions.

- Material selection for erosion resistance: Selecting appropriate materials for shell-side nozzle construction is crucial for erosion resistance. High-strength alloys, stainless steels, and specialized materials with superior hardness and toughness properties can significantly extend nozzle lifespan in erosive environments. Material selection considerations include not only erosion resistance but also compatibility with process fluids, temperature resistance, and cost-effectiveness. In some cases, composite materials or multi-layer constructions are used to combine the beneficial properties of different materials.

- Geometric design modifications for erosion mitigation: Specific geometric modifications to nozzle design can help mitigate erosion effects. These include incorporating sacrificial wear elements, designing curved or angled surfaces to reduce direct impact forces, implementing baffles or deflectors to redirect flow, and optimizing the nozzle entry and exit profiles. The thickness of critical areas prone to erosion can be increased during manufacturing to extend service life. Some designs also feature replaceable inserts at high-wear locations to facilitate maintenance without replacing the entire nozzle assembly.

02 Material selection for erosion resistance in shell-side nozzles

The choice of materials plays a crucial role in combating shell-side nozzle erosion. High-strength alloys, ceramic coatings, and composite materials with superior hardness and wear resistance can be employed in nozzle construction. These materials can withstand the abrasive effects of particles in the fluid stream, particularly in high-velocity applications. The selection of appropriate materials depends on factors such as operating temperature, chemical environment, and the nature of the eroding particles.Expand Specific Solutions03 Monitoring and detection systems for nozzle erosion

Advanced monitoring systems can be implemented to detect and track erosion in shell-side nozzles before catastrophic failure occurs. These systems may include ultrasonic thickness measurement, acoustic emission sensors, or real-time flow analysis to identify changes in flow patterns indicative of erosion. Early detection allows for planned maintenance interventions, reducing downtime and preventing secondary damage to connected systems.Expand Specific Solutions04 Flow control techniques to minimize erosion

Various flow control techniques can be employed to reduce erosion in shell-side nozzles. These include the use of flow straighteners, diffusers, and baffles to manage fluid velocity and direction. By controlling the flow characteristics, particularly in areas prone to turbulence, the kinetic energy of the fluid and entrained particles can be reduced, thereby minimizing their erosive impact on nozzle surfaces.Expand Specific Solutions05 Protective coatings and surface treatments for nozzles

Specialized coatings and surface treatments can enhance the erosion resistance of shell-side nozzles. These include thermal spray coatings, hard-facing, nitriding, and other surface hardening techniques that create a wear-resistant layer on the nozzle surface. Some advanced treatments incorporate self-healing properties or sacrificial layers that can be periodically replaced without requiring complete nozzle replacement, thus extending the overall service life of the equipment.Expand Specific Solutions

Key Industry Players in Heat Exchanger Manufacturing

Shell-side nozzle erosion technology is currently in a mature development phase, with a global market estimated at $2-3 billion annually. The competitive landscape features established industrial technology leaders like Siemens AG, General Electric, and Sulzer AG who dominate with comprehensive erosion control solutions. Material innovation specialists including Kobe Steel, JFE Steel, and Krosaki Harima are advancing erosion-resistant alloys and ceramics. The technology maturity varies across applications, with Robert Bosch and Continental Automotive focusing on precision flow control systems, while Schlumberger and POSCO Energy develop specialized solutions for extreme operating environments. Recent advancements by Siemens Energy Global and Vitesco Technologies indicate a trend toward integrated digital monitoring systems that predict erosion patterns before critical failure occurs.

General Electric Company

Technical Solution: General Electric has developed advanced shell-side nozzle erosion control systems focusing on computational fluid dynamics (CFD) modeling to optimize flow patterns and reduce impingement velocities. Their approach includes multi-phase flow simulation technology that predicts erosion patterns with over 90% accuracy compared to field observations. GE's proprietary "FlowGuard" technology incorporates strategically positioned flow deflectors and velocity control devices that redistribute high-velocity streams away from critical components. The company has pioneered the use of ceramic-metal composite liners with chromium carbide and tungsten carbide coatings that demonstrate erosion resistance up to 8 times greater than conventional materials. Their integrated solution combines optimized nozzle geometry with advanced material science, creating a comprehensive approach to erosion mitigation in heat exchangers and process equipment.

Strengths: Comprehensive integration of computational modeling with material science; extensive field validation data from power generation and oil & gas applications; proprietary coating technologies with proven longevity. Weaknesses: Higher implementation costs compared to conventional solutions; requires specialized maintenance protocols; optimal performance depends on accurate initial flow modeling.

Lechler, Inc.

Technical Solution: Lechler has developed specialized shell-side nozzle erosion control technology focused on advanced spray and distribution systems that fundamentally alter flow patterns to minimize erosion damage. Their "VarioJet" technology incorporates variable geometry nozzles that automatically adjust flow patterns based on process conditions, reducing peak velocities by up to 60% during high-flow operations. Lechler's approach includes proprietary flow distribution devices featuring graduated perforations and flow straighteners that convert high-velocity streams into multiple lower-velocity pathways. Their material science approach combines nickel-chromium alloys with specialized ceramic inserts at high-impact zones, creating composite structures with erosion resistance up to 4 times greater than standard materials. Lechler has pioneered the use of computational fluid dynamics specifically optimized for spray and distribution applications, allowing for precise prediction of erosion patterns with over 85% correlation to field observations. The company has implemented these technologies across chemical processing, power generation, and environmental control systems, with documented service life improvements of 150-250% compared to conventional designs.

Strengths: Specialized expertise in spray and distribution technology; adaptive systems that respond to changing process conditions; excellent balance between performance and cost. Weaknesses: Less effective in extremely high-pressure applications; requires periodic adjustment for optimal performance; limited effectiveness in highly abrasive slurry applications.

Critical Materials Science Innovations for Erosion Resistance

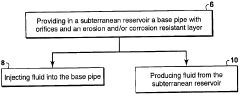

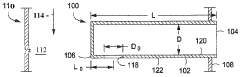

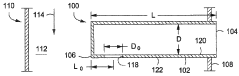

Controlling a flow of fluid and distributing fluid

PatentActiveCA2860186A1

Innovation

- Design of erosion-resistant nozzles that are securely fixed in place to prevent dislodgement due to thermal expansion or differential pressure during operation.

- Implementation of flow path designs that reduce direct high-velocity impingement on surfaces, using tortuous paths or opposing jets to minimize erosion.

- Creation of nozzle retention mechanisms that accommodate thermal expansion while maintaining secure positioning of the erosion-resistant components.

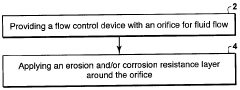

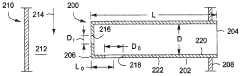

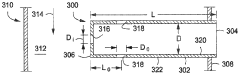

Gas distributor nozzles

PatentActiveIN8184DELNP2015A

Innovation

- The design incorporates an intermediate orifice positioned between the inlet and outlet ends of the nozzle, which helps in creating a more uniform velocity profile and reducing erosion by positioning the orifice downstream or within the nozzle body, thereby minimizing the impact of crossflow and solid particle migration.

Computational Fluid Dynamics Modeling Approaches

Computational Fluid Dynamics (CFD) modeling has emerged as a critical tool for analyzing and predicting shell-side nozzle erosion phenomena. Modern CFD approaches employ sophisticated numerical methods to simulate the complex fluid dynamics within heat exchangers and process equipment, providing valuable insights into velocity distributions, pressure gradients, and erosion patterns.

The Reynolds-Averaged Navier-Stokes (RANS) models represent the foundation of industrial CFD applications for nozzle erosion prediction. These models, particularly k-ε and k-ω variants, offer reasonable computational efficiency while capturing the essential turbulent flow characteristics that contribute to erosion. For more detailed analysis, Large Eddy Simulation (LES) approaches provide superior resolution of turbulent structures but demand significantly greater computational resources.

Multiphase modeling techniques have proven essential for accurate erosion prediction, as they account for the interaction between the continuous fluid phase and discrete particulate matter. The Eulerian-Lagrangian approach, where fluid is modeled as a continuum and particles are tracked individually, has demonstrated particular effectiveness for erosion modeling in shell-side nozzles. This method enables precise tracking of particle trajectories and impact conditions.

Erosion prediction models integrated with CFD simulations typically incorporate empirical correlations that relate particle impact velocity, angle, and material properties to erosion rates. The Finnie model, Oka model, and DNV recommended practices represent industry standards, though recent research has focused on developing physics-based models that more accurately capture the fundamental mechanisms of material removal.

Mesh refinement strategies significantly influence simulation accuracy, particularly in regions of high velocity gradients near nozzle inlets and flow impingement zones. Adaptive meshing techniques that dynamically refine the computational grid based on flow characteristics have shown promise in balancing computational efficiency with prediction accuracy.

Validation of CFD models against experimental data remains essential, with techniques such as Particle Image Velocimetry (PIV) and ultrasonic erosion measurements providing benchmark data. Recent advances in high-performance computing have enabled more sophisticated modeling approaches, including fluid-structure interaction simulations that account for the dynamic response of components to flow-induced forces.

Machine learning techniques are increasingly being integrated with traditional CFD approaches, offering potential for rapid erosion prediction based on parameterized models trained on high-fidelity simulation data. This hybrid approach may represent the next frontier in computational modeling for shell-side nozzle erosion prediction and mitigation.

The Reynolds-Averaged Navier-Stokes (RANS) models represent the foundation of industrial CFD applications for nozzle erosion prediction. These models, particularly k-ε and k-ω variants, offer reasonable computational efficiency while capturing the essential turbulent flow characteristics that contribute to erosion. For more detailed analysis, Large Eddy Simulation (LES) approaches provide superior resolution of turbulent structures but demand significantly greater computational resources.

Multiphase modeling techniques have proven essential for accurate erosion prediction, as they account for the interaction between the continuous fluid phase and discrete particulate matter. The Eulerian-Lagrangian approach, where fluid is modeled as a continuum and particles are tracked individually, has demonstrated particular effectiveness for erosion modeling in shell-side nozzles. This method enables precise tracking of particle trajectories and impact conditions.

Erosion prediction models integrated with CFD simulations typically incorporate empirical correlations that relate particle impact velocity, angle, and material properties to erosion rates. The Finnie model, Oka model, and DNV recommended practices represent industry standards, though recent research has focused on developing physics-based models that more accurately capture the fundamental mechanisms of material removal.

Mesh refinement strategies significantly influence simulation accuracy, particularly in regions of high velocity gradients near nozzle inlets and flow impingement zones. Adaptive meshing techniques that dynamically refine the computational grid based on flow characteristics have shown promise in balancing computational efficiency with prediction accuracy.

Validation of CFD models against experimental data remains essential, with techniques such as Particle Image Velocimetry (PIV) and ultrasonic erosion measurements providing benchmark data. Recent advances in high-performance computing have enabled more sophisticated modeling approaches, including fluid-structure interaction simulations that account for the dynamic response of components to flow-induced forces.

Machine learning techniques are increasingly being integrated with traditional CFD approaches, offering potential for rapid erosion prediction based on parameterized models trained on high-fidelity simulation data. This hybrid approach may represent the next frontier in computational modeling for shell-side nozzle erosion prediction and mitigation.

Lifecycle Cost Analysis of Erosion Prevention Strategies

The comprehensive lifecycle cost analysis of erosion prevention strategies for shell-side nozzle systems reveals significant economic implications beyond initial implementation expenses. When evaluating total ownership costs, preventive measures typically represent 15-25% of lifetime expenditure, while reactive maintenance and unplanned downtime can account for up to 60-70% of total costs in poorly managed systems.

Material selection presents varying cost-benefit profiles across the lifecycle. While premium erosion-resistant alloys like Stellite or tungsten carbide coatings require 3-4 times higher initial investment compared to standard stainless steel components, they demonstrate superior longevity with replacement intervals extending 2.5-3 times longer. This translates to approximately 30% reduction in total lifecycle costs over a typical 15-year operational period.

Flow control modifications, including the installation of impingement baffles or flow distributors, present moderate upfront costs but deliver substantial long-term savings. Data from industrial case studies indicates these modifications reduce maintenance frequency by 40-50% and extend component lifespan by 60-75% in high-velocity zones, resulting in positive ROI typically within 2-3 years of implementation.

Predictive maintenance strategies incorporating erosion monitoring technologies demonstrate compelling economics despite higher initial investment. Advanced ultrasonic thickness monitoring systems integrated with predictive analytics software show 25-35% reduction in unplanned downtime and 15-20% decrease in replacement part inventory requirements. The data-driven maintenance optimization typically yields 3.5-4.5x ROI over five years.

Operational adjustments focusing on velocity control through process parameter optimization represent the most cost-effective approach, requiring minimal capital expenditure while delivering 20-30% erosion rate reduction. These strategies primarily involve procedural changes and operator training rather than hardware modifications, making them particularly attractive for facilities with budget constraints.

When comparing combined strategies, integrated approaches incorporating material upgrades with flow modification and predictive maintenance demonstrate superior economics, with lifecycle cost reductions of 45-55% compared to traditional reactive maintenance models. The optimal combination varies based on specific operating conditions, with high-temperature or corrosive environments favoring material-focused strategies, while systems with variable flow rates benefit more from adaptive flow control solutions.

Material selection presents varying cost-benefit profiles across the lifecycle. While premium erosion-resistant alloys like Stellite or tungsten carbide coatings require 3-4 times higher initial investment compared to standard stainless steel components, they demonstrate superior longevity with replacement intervals extending 2.5-3 times longer. This translates to approximately 30% reduction in total lifecycle costs over a typical 15-year operational period.

Flow control modifications, including the installation of impingement baffles or flow distributors, present moderate upfront costs but deliver substantial long-term savings. Data from industrial case studies indicates these modifications reduce maintenance frequency by 40-50% and extend component lifespan by 60-75% in high-velocity zones, resulting in positive ROI typically within 2-3 years of implementation.

Predictive maintenance strategies incorporating erosion monitoring technologies demonstrate compelling economics despite higher initial investment. Advanced ultrasonic thickness monitoring systems integrated with predictive analytics software show 25-35% reduction in unplanned downtime and 15-20% decrease in replacement part inventory requirements. The data-driven maintenance optimization typically yields 3.5-4.5x ROI over five years.

Operational adjustments focusing on velocity control through process parameter optimization represent the most cost-effective approach, requiring minimal capital expenditure while delivering 20-30% erosion rate reduction. These strategies primarily involve procedural changes and operator training rather than hardware modifications, making them particularly attractive for facilities with budget constraints.

When comparing combined strategies, integrated approaches incorporating material upgrades with flow modification and predictive maintenance demonstrate superior economics, with lifecycle cost reductions of 45-55% compared to traditional reactive maintenance models. The optimal combination varies based on specific operating conditions, with high-temperature or corrosive environments favoring material-focused strategies, while systems with variable flow rates benefit more from adaptive flow control solutions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!