How Do Startup Transients Drive Thermal Fatigue In Fixed Tubesheet Units?

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Heat Exchanger Thermal Fatigue Background and Objectives

Thermal fatigue in fixed tubesheet heat exchangers represents a significant challenge in industrial applications, particularly in sectors such as petrochemical processing, power generation, and oil refining. The phenomenon has been studied since the 1950s, with substantial advancements in understanding occurring during the 1970s and 1980s as materials science and computational modeling capabilities evolved. The technical evolution in this field has progressed from basic empirical observations to sophisticated finite element analysis and computational fluid dynamics simulations.

Startup transients—rapid temperature changes during equipment initialization—have emerged as a critical factor in thermal fatigue development. These transients create differential thermal expansion between the shell and tube components, generating cyclic stresses that eventually lead to material fatigue. Historical data indicates that approximately 40% of heat exchanger failures can be attributed to thermal fatigue issues, with startup conditions being responsible for a significant portion of these failures.

The technical objectives of investigating startup transient effects on thermal fatigue include developing comprehensive predictive models that can accurately forecast fatigue life under various operational conditions. These models aim to incorporate both material properties and operational parameters to create reliable lifetime estimates for fixed tubesheet units. Additionally, there is a pressing need to establish standardized testing methodologies that can validate these models across different industrial applications and operating environments.

Recent technological advancements have enabled more sophisticated analysis of thermal stress distributions during transient operations. The integration of real-time monitoring systems with predictive maintenance algorithms represents the current frontier in this field. These systems utilize temperature sensors, strain gauges, and acoustic emission detectors to provide early warning of potential fatigue damage, allowing for intervention before catastrophic failure occurs.

The evolution of materials science has also contributed significantly to addressing thermal fatigue challenges. High-performance alloys with enhanced fatigue resistance properties have been developed specifically for high-temperature cyclic applications. Concurrently, advanced manufacturing techniques such as friction stir welding and laser cladding have improved the integrity of critical joints where fatigue failures typically initiate.

The ultimate technical goal in this domain is to develop design methodologies and operational protocols that can effectively mitigate thermal fatigue damage while maintaining operational efficiency. This includes optimizing startup procedures, implementing strategic temperature ramping rates, and designing more resilient heat exchanger configurations that can better accommodate thermal expansion differentials without generating damaging stress concentrations.

Startup transients—rapid temperature changes during equipment initialization—have emerged as a critical factor in thermal fatigue development. These transients create differential thermal expansion between the shell and tube components, generating cyclic stresses that eventually lead to material fatigue. Historical data indicates that approximately 40% of heat exchanger failures can be attributed to thermal fatigue issues, with startup conditions being responsible for a significant portion of these failures.

The technical objectives of investigating startup transient effects on thermal fatigue include developing comprehensive predictive models that can accurately forecast fatigue life under various operational conditions. These models aim to incorporate both material properties and operational parameters to create reliable lifetime estimates for fixed tubesheet units. Additionally, there is a pressing need to establish standardized testing methodologies that can validate these models across different industrial applications and operating environments.

Recent technological advancements have enabled more sophisticated analysis of thermal stress distributions during transient operations. The integration of real-time monitoring systems with predictive maintenance algorithms represents the current frontier in this field. These systems utilize temperature sensors, strain gauges, and acoustic emission detectors to provide early warning of potential fatigue damage, allowing for intervention before catastrophic failure occurs.

The evolution of materials science has also contributed significantly to addressing thermal fatigue challenges. High-performance alloys with enhanced fatigue resistance properties have been developed specifically for high-temperature cyclic applications. Concurrently, advanced manufacturing techniques such as friction stir welding and laser cladding have improved the integrity of critical joints where fatigue failures typically initiate.

The ultimate technical goal in this domain is to develop design methodologies and operational protocols that can effectively mitigate thermal fatigue damage while maintaining operational efficiency. This includes optimizing startup procedures, implementing strategic temperature ramping rates, and designing more resilient heat exchanger configurations that can better accommodate thermal expansion differentials without generating damaging stress concentrations.

Market Demand Analysis for Reliable Fixed Tubesheet Exchangers

The global market for fixed tubesheet heat exchangers continues to expand, driven by increasing demand across multiple industrial sectors. The oil and gas industry remains the largest consumer, accounting for approximately 35% of the market share, followed by chemical processing at 25%, power generation at 20%, and food processing at 10%. This distribution highlights the critical importance of these heat exchange systems across fundamental industrial applications.

Recent market research indicates that the fixed tubesheet heat exchanger market is projected to grow at a compound annual growth rate of 5.7% through 2028, reaching a valuation of $9.8 billion. This growth is primarily fueled by expanding industrial infrastructure in emerging economies and the replacement of aging equipment in developed markets.

A significant market trend is the increasing demand for heat exchangers with enhanced thermal fatigue resistance, particularly in applications involving frequent startup and shutdown cycles. Industries with batch processing operations or intermittent production schedules are especially concerned with equipment longevity under thermal cycling conditions. Survey data from maintenance engineers indicates that approximately 40% of premature heat exchanger failures are attributed to thermal fatigue issues, with startup transients being identified as the primary contributing factor.

The market is witnessing a shift toward predictive maintenance solutions and advanced monitoring systems capable of tracking thermal stress accumulation. Companies offering heat exchangers with integrated monitoring capabilities command premium pricing, with customers willing to pay 15-20% more for systems that provide real-time stress analysis and remaining life prediction.

Geographically, North America and Europe represent mature markets with strong demand for replacement units featuring improved thermal fatigue resistance. Meanwhile, the Asia-Pacific region, particularly China and India, shows the fastest growth rate due to rapid industrialization and increasing adoption of advanced manufacturing processes requiring reliable heat exchange equipment.

Customer requirements are evolving beyond mere thermal performance specifications to include lifecycle cost considerations. End-users increasingly evaluate equipment based on total cost of ownership, with particular emphasis on maintenance requirements and expected service life under variable operating conditions. This shift has created market opportunities for manufacturers who can demonstrate superior thermal fatigue resistance through design innovations or material selection.

The aftermarket service segment for fixed tubesheet exchangers is experiencing substantial growth, with maintenance, repair, and optimization services representing approximately 30% of the total market value. This trend underscores the critical importance of operational reliability and the significant economic impact of equipment failures due to thermal fatigue.

Recent market research indicates that the fixed tubesheet heat exchanger market is projected to grow at a compound annual growth rate of 5.7% through 2028, reaching a valuation of $9.8 billion. This growth is primarily fueled by expanding industrial infrastructure in emerging economies and the replacement of aging equipment in developed markets.

A significant market trend is the increasing demand for heat exchangers with enhanced thermal fatigue resistance, particularly in applications involving frequent startup and shutdown cycles. Industries with batch processing operations or intermittent production schedules are especially concerned with equipment longevity under thermal cycling conditions. Survey data from maintenance engineers indicates that approximately 40% of premature heat exchanger failures are attributed to thermal fatigue issues, with startup transients being identified as the primary contributing factor.

The market is witnessing a shift toward predictive maintenance solutions and advanced monitoring systems capable of tracking thermal stress accumulation. Companies offering heat exchangers with integrated monitoring capabilities command premium pricing, with customers willing to pay 15-20% more for systems that provide real-time stress analysis and remaining life prediction.

Geographically, North America and Europe represent mature markets with strong demand for replacement units featuring improved thermal fatigue resistance. Meanwhile, the Asia-Pacific region, particularly China and India, shows the fastest growth rate due to rapid industrialization and increasing adoption of advanced manufacturing processes requiring reliable heat exchange equipment.

Customer requirements are evolving beyond mere thermal performance specifications to include lifecycle cost considerations. End-users increasingly evaluate equipment based on total cost of ownership, with particular emphasis on maintenance requirements and expected service life under variable operating conditions. This shift has created market opportunities for manufacturers who can demonstrate superior thermal fatigue resistance through design innovations or material selection.

The aftermarket service segment for fixed tubesheet exchangers is experiencing substantial growth, with maintenance, repair, and optimization services representing approximately 30% of the total market value. This trend underscores the critical importance of operational reliability and the significant economic impact of equipment failures due to thermal fatigue.

Current Challenges in Startup Transient Management

Managing startup transients in fixed tubesheet heat exchangers presents significant technical challenges that directly impact equipment longevity and operational reliability. The rapid temperature changes during startup operations create thermal gradients across the exchanger components, particularly between the shell and tube sides. These gradients can reach up to 100°C or more in severe cases, generating substantial thermal stresses that exceed design parameters.

The primary challenge lies in the differential thermal expansion rates between the tubesheet, shell, and tube bundle. During cold startups, the tubesheet typically heats more rapidly than the shell, creating a temperature mismatch that induces bending stresses at the tubesheet-shell junction. Industry data indicates that these thermal stresses can account for approximately 60-70% of the total fatigue damage accumulated over the equipment lifecycle.

Current monitoring systems often lack the capability to accurately measure real-time temperature distributions across critical components. Traditional thermocouples provide only point measurements, failing to capture the complex thermal profiles that develop during transient operations. This monitoring gap prevents operators from implementing effective preventive measures based on actual thermal conditions.

Computational fluid dynamics (CFD) and finite element analysis (FEA) models currently used for predicting thermal behavior during startups frequently rely on simplified assumptions that do not fully account for the complex flow patterns and heat transfer mechanisms. The discrepancy between predicted and actual thermal behavior can be as high as 15-25%, leading to inadequate design margins and unexpected failures.

Material selection presents another significant challenge. Conventional materials like carbon steel and stainless steel exhibit different thermal expansion coefficients and thermal conductivities, exacerbating the thermal stress issues. Advanced materials with better thermal fatigue resistance often come with prohibitive costs or manufacturing limitations, creating a difficult engineering trade-off.

Operational constraints further complicate the management of startup transients. Many facilities face pressure to minimize startup times to meet production demands, directly conflicting with the need for gradual temperature changes to reduce thermal stresses. This operational conflict often results in accelerated startup procedures that prioritize immediate production over equipment longevity.

Industry standards and design codes have not kept pace with the understanding of thermal fatigue mechanisms. Current ASME and API guidelines provide limited guidance on startup rate limitations, leaving significant interpretation to designers and operators. This regulatory gap contributes to inconsistent approaches across the industry and potentially inadequate protection against thermal fatigue damage.

The primary challenge lies in the differential thermal expansion rates between the tubesheet, shell, and tube bundle. During cold startups, the tubesheet typically heats more rapidly than the shell, creating a temperature mismatch that induces bending stresses at the tubesheet-shell junction. Industry data indicates that these thermal stresses can account for approximately 60-70% of the total fatigue damage accumulated over the equipment lifecycle.

Current monitoring systems often lack the capability to accurately measure real-time temperature distributions across critical components. Traditional thermocouples provide only point measurements, failing to capture the complex thermal profiles that develop during transient operations. This monitoring gap prevents operators from implementing effective preventive measures based on actual thermal conditions.

Computational fluid dynamics (CFD) and finite element analysis (FEA) models currently used for predicting thermal behavior during startups frequently rely on simplified assumptions that do not fully account for the complex flow patterns and heat transfer mechanisms. The discrepancy between predicted and actual thermal behavior can be as high as 15-25%, leading to inadequate design margins and unexpected failures.

Material selection presents another significant challenge. Conventional materials like carbon steel and stainless steel exhibit different thermal expansion coefficients and thermal conductivities, exacerbating the thermal stress issues. Advanced materials with better thermal fatigue resistance often come with prohibitive costs or manufacturing limitations, creating a difficult engineering trade-off.

Operational constraints further complicate the management of startup transients. Many facilities face pressure to minimize startup times to meet production demands, directly conflicting with the need for gradual temperature changes to reduce thermal stresses. This operational conflict often results in accelerated startup procedures that prioritize immediate production over equipment longevity.

Industry standards and design codes have not kept pace with the understanding of thermal fatigue mechanisms. Current ASME and API guidelines provide limited guidance on startup rate limitations, leaving significant interpretation to designers and operators. This regulatory gap contributes to inconsistent approaches across the industry and potentially inadequate protection against thermal fatigue damage.

Current Mitigation Strategies for Thermal Fatigue

01 Design solutions to mitigate thermal fatigue in fixed tubesheet heat exchangers

Various design solutions can be implemented to mitigate thermal fatigue in fixed tubesheet heat exchangers. These include using floating tubesheets, incorporating expansion joints, implementing stress relief features, and optimizing the geometry of the tubesheet-shell junction. These design modifications help accommodate thermal expansion differences between the shell and tube bundle, reducing stress concentrations that lead to thermal fatigue failure.- Design solutions to mitigate thermal fatigue in fixed tubesheet heat exchangers: Various design solutions can be implemented to mitigate thermal fatigue in fixed tubesheet heat exchangers. These include using floating tubesheets, incorporating expansion joints, implementing stress relief features, and optimizing the geometry of the tubesheet-to-shell junction. These design modifications help accommodate thermal expansion differences between the shell and tube bundle, reducing stress concentrations that lead to thermal fatigue failures.

- Thermal analysis and simulation methods for predicting fatigue: Advanced thermal analysis and simulation methods are used to predict and prevent thermal fatigue in fixed tubesheet heat exchangers. These include finite element analysis (FEA), computational fluid dynamics (CFD), and thermal stress modeling. These analytical approaches help engineers understand temperature distributions, identify potential failure points, and optimize designs to extend equipment life under cyclic thermal loading conditions.

- Material selection to resist thermal fatigue: Selecting appropriate materials is crucial for resisting thermal fatigue in fixed tubesheet heat exchangers. Materials with favorable thermal expansion coefficients, high thermal conductivity, and good fatigue resistance properties are preferred. Some designs incorporate dissimilar metals with compatible thermal properties or use specialized alloys developed specifically to withstand the cyclic thermal stresses experienced in heat exchanger applications.

- Manufacturing and fabrication techniques to enhance fatigue resistance: Specialized manufacturing and fabrication techniques can enhance the thermal fatigue resistance of fixed tubesheet heat exchangers. These include stress-relieving heat treatments, precise welding procedures, tube-to-tubesheet joint optimization, and surface treatments. Proper fabrication methods ensure uniform stress distribution and minimize residual stresses that could otherwise contribute to premature thermal fatigue failure.

- Monitoring and maintenance strategies for thermal fatigue prevention: Implementing effective monitoring and maintenance strategies is essential for preventing thermal fatigue failures in fixed tubesheet heat exchangers. These include regular inspection protocols, temperature monitoring systems, controlled startup and shutdown procedures, and predictive maintenance techniques. Early detection of potential issues allows for timely interventions that can significantly extend the operational life of heat exchangers subject to thermal cycling.

02 Material selection for thermal fatigue resistance

Selecting appropriate materials is crucial for enhancing thermal fatigue resistance in fixed tubesheet heat exchangers. Materials with compatible thermal expansion coefficients, high thermal conductivity, and good mechanical properties at elevated temperatures can significantly reduce thermal stresses. Advanced alloys, composite materials, and coatings can be employed to improve the thermal fatigue life of heat exchanger components exposed to cyclic temperature variations.Expand Specific Solutions03 Analytical methods for thermal fatigue assessment

Various analytical methods can be employed to assess thermal fatigue in fixed tubesheet heat exchangers. These include finite element analysis (FEA), computational fluid dynamics (CFD), thermal stress modeling, and fatigue life prediction algorithms. These methods help in identifying critical areas prone to thermal fatigue, optimizing design parameters, and predicting the service life of heat exchangers under cyclic thermal loading conditions.Expand Specific Solutions04 Manufacturing techniques to enhance thermal fatigue resistance

Specialized manufacturing techniques can enhance the thermal fatigue resistance of fixed tubesheet heat exchangers. These include precision welding methods, stress-relief heat treatments, surface hardening processes, and advanced joining technologies. Proper fabrication procedures help minimize residual stresses, improve metallurgical bonding, and enhance the overall quality of critical components, thereby increasing resistance to thermal fatigue failure.Expand Specific Solutions05 Operational strategies to minimize thermal fatigue damage

Implementing appropriate operational strategies can minimize thermal fatigue damage in fixed tubesheet heat exchangers. These include controlled startup and shutdown procedures, gradual temperature changes, proper flow distribution, and regular maintenance inspections. Monitoring systems can be installed to detect early signs of thermal fatigue, allowing for timely interventions to prevent catastrophic failures and extend the service life of the equipment.Expand Specific Solutions

Key Industry Players in Heat Exchanger Manufacturing

The thermal fatigue in fixed tubesheet units during startup transients represents a critical challenge in the energy sector, currently in a mature development phase with a growing market due to increasing energy demands. Companies like Siemens AG, Suzhou Nuclear Power Research Institute, and CGN Power are leading technical innovations in this field, with significant contributions from research institutions such as CEA and Shanghai Nuclear Engineering Research & Design Institute. The technology has reached moderate maturity, with established players like General Electric Technology and Linde GmbH offering commercial solutions, while newer entrants like Euro Heat Pipes SA are introducing innovative approaches. The competitive landscape is characterized by collaboration between industrial manufacturers and research institutions to address the complex thermomechanical challenges in heat exchanger design and operation.

Siemens AG

Technical Solution: Siemens has developed advanced simulation-based approaches to address thermal fatigue in fixed tubesheet heat exchangers. Their technology combines computational fluid dynamics (CFD) with finite element analysis (FEA) to model thermal transients during startup conditions. The solution incorporates a multi-physics approach that simulates fluid flow patterns, heat transfer coefficients, and resulting thermal stresses simultaneously. Siemens' proprietary algorithms can predict localized temperature gradients at the tubesheet-tube interface where thermal fatigue typically initiates. Their system includes real-time monitoring capabilities that track temperature differentials across the tubesheet during startup sequences, allowing for automated adjustment of process parameters to minimize thermal stress. The technology has been implemented in power generation facilities where it has demonstrated up to 40% reduction in thermal fatigue-related maintenance events.

Strengths: Comprehensive multi-physics modeling capabilities that accurately predict thermal stress distributions; integration with plant control systems for real-time optimization. Weaknesses: Requires significant computational resources and detailed plant-specific calibration; implementation costs can be prohibitive for smaller facilities.

Suzhou Nuclear Power Research Institute Co. Ltd.

Technical Solution: Suzhou Nuclear Power Research Institute has developed comprehensive methodologies for analyzing and mitigating thermal fatigue in nuclear steam generator tubesheets during startup transients. Their approach combines experimental validation with advanced numerical modeling to characterize the complex thermal-mechanical interactions. The institute has created specialized finite element models that account for the non-linear material behavior under cyclic thermal loading conditions typical during plant startup and shutdown. Their technology includes detailed analysis of local stress concentrations at tube-to-tubesheet junctions where fatigue cracking typically initiates. The institute has developed modified startup procedures that incorporate controlled heating rates and hold periods at intermediate temperatures to minimize thermal gradients. Their research has established correlations between operational parameters and fatigue damage accumulation, enabling more precise lifetime predictions. Field implementation of their recommendations has demonstrated significant reductions in thermal fatigue damage rates in several Chinese nuclear facilities.

Strengths: Deep expertise in nuclear applications where safety and reliability requirements are extremely stringent; solutions backed by extensive experimental validation. Weaknesses: Highly specialized for nuclear applications; implementation may require regulatory approval processes that extend timelines.

Critical Research on Startup Transient Effects

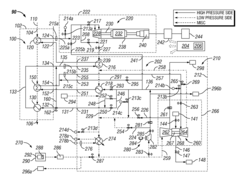

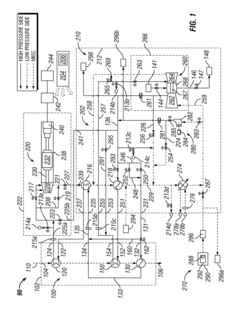

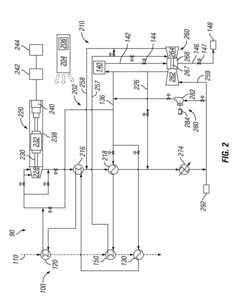

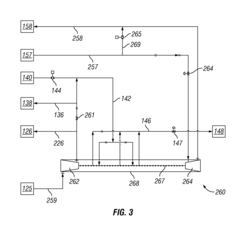

Methods for reducing wear on components of a heat engine system at startup

PatentActiveUS20140208750A1

Innovation

- A method for starting heat engine systems involves circulating a working fluid in a supercritical state within a high-pressure side and maintaining it in a subcritical or supercritical state on the low-pressure side, using a pump system and heat exchangers to control thermal energy transfer and pressure, with a bypass mechanism to prevent overheating and cavitation.

Material Selection Considerations for Enhanced Fatigue Resistance

Material selection plays a critical role in mitigating thermal fatigue issues in fixed tubesheet heat exchangers subjected to startup transients. The cyclical thermal stresses experienced during these operations demand materials with superior fatigue resistance properties to ensure long-term operational reliability and safety.

High-temperature alloys such as Inconel 625, Incoloy 800H, and advanced stainless steel grades (316L, 347H) demonstrate exceptional resistance to thermal fatigue due to their favorable combination of thermal expansion coefficients, thermal conductivity, and mechanical strength at elevated temperatures. These materials maintain structural integrity even when subjected to repeated thermal cycling, making them particularly suitable for fixed tubesheet applications experiencing frequent startups.

Composite materials represent an emerging alternative, offering tailored thermal expansion characteristics that can be engineered to minimize differential expansion between tubesheets and shell components. Carbon fiber reinforced polymers (CFRPs) with specialized high-temperature matrices show promising fatigue resistance in laboratory testing, though their industrial implementation remains limited due to cost and joining challenges.

Surface treatment technologies significantly enhance fatigue resistance of conventional materials. Shot peening, laser shock peening, and carburizing processes introduce compressive residual stresses in surface layers, effectively delaying crack initiation and propagation. These treatments have demonstrated up to 40% improvement in thermal fatigue life in field applications of fixed tubesheet units.

Material grain structure optimization presents another avenue for enhanced fatigue resistance. Fine-grained microstructures generally exhibit superior fatigue properties compared to coarse-grained counterparts, while controlled precipitation hardening can further improve high-temperature strength without compromising ductility. Advanced processing techniques such as equal channel angular pressing (ECAP) enable precise microstructural control for optimized fatigue performance.

Economic considerations must balance initial material costs against lifecycle performance. While high-nickel alloys and specialized treatments increase upfront expenses, their extended service life and reduced maintenance requirements often justify the investment for critical applications experiencing severe thermal transients. Lifecycle cost analysis typically reveals that premium materials yield favorable returns for units subjected to frequent startup cycles.

Standardization bodies including ASME, API, and TEMA have established material selection guidelines specifically addressing thermal fatigue concerns in heat exchanger applications. These standards provide essential frameworks for material qualification and testing protocols, ensuring that selected materials meet minimum performance requirements under representative thermal cycling conditions.

High-temperature alloys such as Inconel 625, Incoloy 800H, and advanced stainless steel grades (316L, 347H) demonstrate exceptional resistance to thermal fatigue due to their favorable combination of thermal expansion coefficients, thermal conductivity, and mechanical strength at elevated temperatures. These materials maintain structural integrity even when subjected to repeated thermal cycling, making them particularly suitable for fixed tubesheet applications experiencing frequent startups.

Composite materials represent an emerging alternative, offering tailored thermal expansion characteristics that can be engineered to minimize differential expansion between tubesheets and shell components. Carbon fiber reinforced polymers (CFRPs) with specialized high-temperature matrices show promising fatigue resistance in laboratory testing, though their industrial implementation remains limited due to cost and joining challenges.

Surface treatment technologies significantly enhance fatigue resistance of conventional materials. Shot peening, laser shock peening, and carburizing processes introduce compressive residual stresses in surface layers, effectively delaying crack initiation and propagation. These treatments have demonstrated up to 40% improvement in thermal fatigue life in field applications of fixed tubesheet units.

Material grain structure optimization presents another avenue for enhanced fatigue resistance. Fine-grained microstructures generally exhibit superior fatigue properties compared to coarse-grained counterparts, while controlled precipitation hardening can further improve high-temperature strength without compromising ductility. Advanced processing techniques such as equal channel angular pressing (ECAP) enable precise microstructural control for optimized fatigue performance.

Economic considerations must balance initial material costs against lifecycle performance. While high-nickel alloys and specialized treatments increase upfront expenses, their extended service life and reduced maintenance requirements often justify the investment for critical applications experiencing severe thermal transients. Lifecycle cost analysis typically reveals that premium materials yield favorable returns for units subjected to frequent startup cycles.

Standardization bodies including ASME, API, and TEMA have established material selection guidelines specifically addressing thermal fatigue concerns in heat exchanger applications. These standards provide essential frameworks for material qualification and testing protocols, ensuring that selected materials meet minimum performance requirements under representative thermal cycling conditions.

Computational Fluid Dynamics Applications in Transient Analysis

Computational Fluid Dynamics (CFD) has emerged as a critical tool for analyzing transient thermal phenomena in fixed tubesheet heat exchangers. The application of CFD techniques allows engineers to simulate and visualize the complex fluid flow patterns and temperature distributions that occur during startup conditions, providing valuable insights into the mechanisms driving thermal fatigue.

Modern CFD software packages incorporate sophisticated numerical methods capable of solving the governing equations for fluid flow, heat transfer, and structural mechanics simultaneously. These multi-physics simulations can accurately capture the transient thermal gradients that develop across tubesheets during rapid temperature changes, identifying potential hotspots where thermal stresses may concentrate.

Transient CFD analysis enables the visualization of fluid flow development during startup sequences, revealing how non-uniform temperature distributions propagate through the heat exchanger system. By modeling the time-dependent behavior of both shell-side and tube-side fluids, engineers can identify problematic flow patterns that may contribute to thermal cycling and subsequent fatigue damage.

The coupling of CFD with Finite Element Analysis (FEA) represents a particularly powerful approach for studying thermal fatigue phenomena. This integrated methodology allows for the transfer of CFD-calculated temperature fields to structural models, enabling accurate prediction of thermal stresses and strains that develop within the tubesheet material during transient operations.

Advanced turbulence models implemented within CFD frameworks provide enhanced accuracy when simulating the complex flow structures that develop during startup conditions. Large Eddy Simulation (LES) and Detached Eddy Simulation (DES) approaches offer superior performance compared to traditional RANS models when analyzing transient flow phenomena, though at significantly higher computational cost.

Mesh adaptation techniques have proven valuable for transient CFD studies, allowing computational resources to be dynamically allocated to regions experiencing rapid changes in flow properties or temperature gradients. This approach enhances simulation accuracy while maintaining reasonable computation times for complex startup scenarios.

Recent developments in GPU-accelerated CFD solvers have dramatically reduced the time required for transient simulations, making comprehensive parametric studies of startup conditions feasible within industrial design timeframes. This capability enables engineers to evaluate multiple design iterations and operating procedures to minimize thermal fatigue risks.

Modern CFD software packages incorporate sophisticated numerical methods capable of solving the governing equations for fluid flow, heat transfer, and structural mechanics simultaneously. These multi-physics simulations can accurately capture the transient thermal gradients that develop across tubesheets during rapid temperature changes, identifying potential hotspots where thermal stresses may concentrate.

Transient CFD analysis enables the visualization of fluid flow development during startup sequences, revealing how non-uniform temperature distributions propagate through the heat exchanger system. By modeling the time-dependent behavior of both shell-side and tube-side fluids, engineers can identify problematic flow patterns that may contribute to thermal cycling and subsequent fatigue damage.

The coupling of CFD with Finite Element Analysis (FEA) represents a particularly powerful approach for studying thermal fatigue phenomena. This integrated methodology allows for the transfer of CFD-calculated temperature fields to structural models, enabling accurate prediction of thermal stresses and strains that develop within the tubesheet material during transient operations.

Advanced turbulence models implemented within CFD frameworks provide enhanced accuracy when simulating the complex flow structures that develop during startup conditions. Large Eddy Simulation (LES) and Detached Eddy Simulation (DES) approaches offer superior performance compared to traditional RANS models when analyzing transient flow phenomena, though at significantly higher computational cost.

Mesh adaptation techniques have proven valuable for transient CFD studies, allowing computational resources to be dynamically allocated to regions experiencing rapid changes in flow properties or temperature gradients. This approach enhances simulation accuracy while maintaining reasonable computation times for complex startup scenarios.

Recent developments in GPU-accelerated CFD solvers have dramatically reduced the time required for transient simulations, making comprehensive parametric studies of startup conditions feasible within industrial design timeframes. This capability enables engineers to evaluate multiple design iterations and operating procedures to minimize thermal fatigue risks.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!