How Does Tube Expansion Versus Seal Welding Affect Joint Integrity Over Life?

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Tube Joint Technology Background and Objectives

Tube joining technology has evolved significantly over the past century, with applications spanning across critical industries including power generation, oil and gas, aerospace, and chemical processing. The integrity of tube joints directly impacts system reliability, safety, and operational efficiency. Historically, tube joining methods have progressed from basic mechanical connections to sophisticated welding and expansion techniques, each representing significant technological milestones in industrial manufacturing.

The two predominant methods for creating tube joints—tube expansion and seal welding—emerged as solutions to different industrial challenges. Tube expansion, dating back to the early 20th century, gained prominence in heat exchanger manufacturing where thousands of tube-to-tubesheet joints require reliable, cost-effective connections. Seal welding technology developed alongside advancements in metallurgy and welding processes, offering enhanced leak-tight integrity for high-pressure and high-temperature applications.

Recent technological trends indicate a growing interest in hybrid joining methods that combine the mechanical advantages of expansion with the hermetic sealing capabilities of welding. This convergence aims to address the increasing demands for joint reliability in extreme operating conditions, particularly in next-generation nuclear facilities, supercritical power plants, and advanced chemical processing units.

The fundamental objective of this technical research is to comprehensively evaluate how tube expansion and seal welding methodologies differently affect joint integrity throughout the operational lifecycle. This includes analyzing initial joint strength, resistance to thermal cycling, vibration tolerance, corrosion behavior at the joint interface, and long-term creep performance under sustained loading conditions.

Secondary objectives include identifying the specific failure mechanisms associated with each joining method, determining optimal process parameters for maximizing joint longevity, and establishing predictive models for joint performance under various service conditions. These insights will inform design guidelines for critical applications where joint failure carries significant safety, environmental, or economic consequences.

The technological landscape continues to evolve with innovations in materials science, computational modeling, and non-destructive evaluation techniques. Advanced high-temperature alloys, composite materials, and dissimilar metal combinations present new challenges and opportunities for tube joining technology. Simultaneously, developments in finite element analysis and machine learning enable more accurate prediction of joint behavior under complex loading scenarios.

This research aims to bridge the gap between theoretical understanding and practical application, providing engineers with actionable insights for selecting and optimizing tube joining methods based on specific application requirements and lifecycle considerations.

The two predominant methods for creating tube joints—tube expansion and seal welding—emerged as solutions to different industrial challenges. Tube expansion, dating back to the early 20th century, gained prominence in heat exchanger manufacturing where thousands of tube-to-tubesheet joints require reliable, cost-effective connections. Seal welding technology developed alongside advancements in metallurgy and welding processes, offering enhanced leak-tight integrity for high-pressure and high-temperature applications.

Recent technological trends indicate a growing interest in hybrid joining methods that combine the mechanical advantages of expansion with the hermetic sealing capabilities of welding. This convergence aims to address the increasing demands for joint reliability in extreme operating conditions, particularly in next-generation nuclear facilities, supercritical power plants, and advanced chemical processing units.

The fundamental objective of this technical research is to comprehensively evaluate how tube expansion and seal welding methodologies differently affect joint integrity throughout the operational lifecycle. This includes analyzing initial joint strength, resistance to thermal cycling, vibration tolerance, corrosion behavior at the joint interface, and long-term creep performance under sustained loading conditions.

Secondary objectives include identifying the specific failure mechanisms associated with each joining method, determining optimal process parameters for maximizing joint longevity, and establishing predictive models for joint performance under various service conditions. These insights will inform design guidelines for critical applications where joint failure carries significant safety, environmental, or economic consequences.

The technological landscape continues to evolve with innovations in materials science, computational modeling, and non-destructive evaluation techniques. Advanced high-temperature alloys, composite materials, and dissimilar metal combinations present new challenges and opportunities for tube joining technology. Simultaneously, developments in finite element analysis and machine learning enable more accurate prediction of joint behavior under complex loading scenarios.

This research aims to bridge the gap between theoretical understanding and practical application, providing engineers with actionable insights for selecting and optimizing tube joining methods based on specific application requirements and lifecycle considerations.

Market Demand Analysis for Tube Connection Methods

The global tube connection market is experiencing significant growth, driven by increasing demand across multiple industries including power generation, oil and gas, chemical processing, and HVAC systems. Current market valuations indicate the tube connection technologies sector is expanding at a compound annual growth rate of approximately 5.7%, with particular acceleration in regions undergoing rapid industrialization such as Southeast Asia and parts of Africa.

Market research reveals a distinct shift in customer preferences regarding tube connection methods. While traditional seal welding has dominated critical applications for decades, tube expansion technologies are gaining substantial market share due to their cost-effectiveness and reduced installation time. This trend is particularly evident in maintenance-intensive industries where system downtime translates directly to revenue loss.

Industry surveys indicate that engineering firms and end-users are increasingly prioritizing long-term joint integrity over initial installation costs. This paradigm shift stems from growing awareness of lifecycle costs associated with connection failures, including emergency repairs, production losses, and potential safety incidents. Consequently, manufacturers are experiencing heightened demand for connection solutions that offer verifiable performance data across extended operational lifespans.

Regional market analysis shows divergent demands based on local regulatory environments and industry concentrations. North American and European markets demonstrate stronger preference for connection methods with comprehensive certification and testing documentation, often favoring technologies with established performance histories. Conversely, emerging markets show greater price sensitivity while still requiring adequate performance guarantees.

The maintenance and repair segment represents a particularly lucrative market opportunity, valued at over $3.2 billion annually. This segment shows increasing preference for connection technologies that facilitate rapid replacement and minimize system downtime. Tube expansion methods have gained significant traction in this segment due to their non-destructive nature and potential for reusability.

Environmental regulations are also reshaping market demands, with stricter emissions controls driving interest in connection technologies that minimize leakage potential. This regulatory pressure has intensified competition between welding and expansion technologies, with both approaches evolving to address heightened performance expectations regarding fugitive emissions and joint integrity under thermal cycling conditions.

Customer feedback indicates growing interest in hybrid solutions that combine the mechanical stability of expansion techniques with the hermetic sealing properties of welding. This emerging market segment represents a potential high-growth opportunity for manufacturers capable of developing innovative connection technologies that address the limitations of both traditional approaches.

Market research reveals a distinct shift in customer preferences regarding tube connection methods. While traditional seal welding has dominated critical applications for decades, tube expansion technologies are gaining substantial market share due to their cost-effectiveness and reduced installation time. This trend is particularly evident in maintenance-intensive industries where system downtime translates directly to revenue loss.

Industry surveys indicate that engineering firms and end-users are increasingly prioritizing long-term joint integrity over initial installation costs. This paradigm shift stems from growing awareness of lifecycle costs associated with connection failures, including emergency repairs, production losses, and potential safety incidents. Consequently, manufacturers are experiencing heightened demand for connection solutions that offer verifiable performance data across extended operational lifespans.

Regional market analysis shows divergent demands based on local regulatory environments and industry concentrations. North American and European markets demonstrate stronger preference for connection methods with comprehensive certification and testing documentation, often favoring technologies with established performance histories. Conversely, emerging markets show greater price sensitivity while still requiring adequate performance guarantees.

The maintenance and repair segment represents a particularly lucrative market opportunity, valued at over $3.2 billion annually. This segment shows increasing preference for connection technologies that facilitate rapid replacement and minimize system downtime. Tube expansion methods have gained significant traction in this segment due to their non-destructive nature and potential for reusability.

Environmental regulations are also reshaping market demands, with stricter emissions controls driving interest in connection technologies that minimize leakage potential. This regulatory pressure has intensified competition between welding and expansion technologies, with both approaches evolving to address heightened performance expectations regarding fugitive emissions and joint integrity under thermal cycling conditions.

Customer feedback indicates growing interest in hybrid solutions that combine the mechanical stability of expansion techniques with the hermetic sealing properties of welding. This emerging market segment represents a potential high-growth opportunity for manufacturers capable of developing innovative connection technologies that address the limitations of both traditional approaches.

Current Challenges in Tube Joining Technologies

The tube joining industry faces significant technical hurdles that impact performance, reliability, and cost-effectiveness across various applications. One of the most persistent challenges is achieving consistent joint integrity between tube expansion and seal welding methods. While tube expansion offers simplicity and cost advantages, it struggles with long-term sealing performance under thermal cycling and vibration conditions, particularly in high-pressure systems where even minor leakage can lead to catastrophic failures.

Seal welding, though providing superior hermetic sealing, introduces its own set of complications including heat-affected zone weakening, residual stress formation, and material property alterations that can compromise the overall structural integrity. The industry lacks standardized testing protocols that accurately predict joint performance over extended operational lifetimes, making reliability predictions difficult and often leading to over-engineering or premature failures.

Material compatibility issues present another significant obstacle, especially in corrosive environments or high-temperature applications. The galvanic corrosion potential between dissimilar metals in joined tubes accelerates degradation, while specialized alloys often exhibit unpredictable behavior during joining processes. This creates a complex matrix of material selection criteria that must be carefully navigated for each specific application.

Quality control and inspection methodologies remain inadequate for detecting subtle defects in tube joints. Non-destructive testing techniques frequently fail to identify micro-cracks, incomplete fusion zones, or areas of excessive strain that may develop into failure points over time. The industry struggles with balancing thorough inspection requirements against production efficiency demands.

Automation challenges persist despite technological advances, with tube joining processes still requiring significant manual intervention for optimal results. The geometric complexity of tube assemblies, particularly in confined spaces or with variable tube diameters, limits the effectiveness of robotic solutions. This dependency on skilled labor introduces variability in joint quality and increases production costs.

Regulatory compliance adds another layer of complexity, with standards varying significantly across industries and geographical regions. Meeting these diverse requirements while maintaining cost-effectiveness requires sophisticated engineering approaches and often leads to compromises in design optimization. The lack of harmonized global standards further complicates international manufacturing and distribution.

Environmental and sustainability concerns are increasingly influencing tube joining technology development, with traditional methods facing scrutiny for energy consumption, waste generation, and use of hazardous materials. The industry is under pressure to develop greener joining technologies while maintaining or improving performance metrics.

Seal welding, though providing superior hermetic sealing, introduces its own set of complications including heat-affected zone weakening, residual stress formation, and material property alterations that can compromise the overall structural integrity. The industry lacks standardized testing protocols that accurately predict joint performance over extended operational lifetimes, making reliability predictions difficult and often leading to over-engineering or premature failures.

Material compatibility issues present another significant obstacle, especially in corrosive environments or high-temperature applications. The galvanic corrosion potential between dissimilar metals in joined tubes accelerates degradation, while specialized alloys often exhibit unpredictable behavior during joining processes. This creates a complex matrix of material selection criteria that must be carefully navigated for each specific application.

Quality control and inspection methodologies remain inadequate for detecting subtle defects in tube joints. Non-destructive testing techniques frequently fail to identify micro-cracks, incomplete fusion zones, or areas of excessive strain that may develop into failure points over time. The industry struggles with balancing thorough inspection requirements against production efficiency demands.

Automation challenges persist despite technological advances, with tube joining processes still requiring significant manual intervention for optimal results. The geometric complexity of tube assemblies, particularly in confined spaces or with variable tube diameters, limits the effectiveness of robotic solutions. This dependency on skilled labor introduces variability in joint quality and increases production costs.

Regulatory compliance adds another layer of complexity, with standards varying significantly across industries and geographical regions. Meeting these diverse requirements while maintaining cost-effectiveness requires sophisticated engineering approaches and often leads to compromises in design optimization. The lack of harmonized global standards further complicates international manufacturing and distribution.

Environmental and sustainability concerns are increasingly influencing tube joining technology development, with traditional methods facing scrutiny for energy consumption, waste generation, and use of hazardous materials. The industry is under pressure to develop greener joining technologies while maintaining or improving performance metrics.

Comparative Analysis of Expansion vs Welding Methods

01 Tube expansion techniques for joint integrity

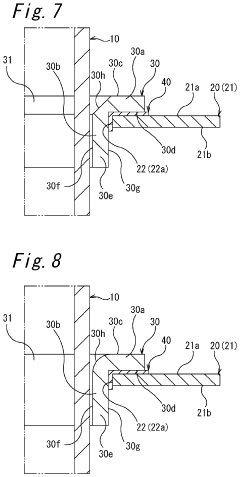

Various tube expansion techniques are employed to ensure joint integrity in tubular connections. These methods involve mechanically expanding the tube into a tube sheet or fitting to create a tight seal. The expansion can be achieved through hydraulic, mechanical, or explosive means, creating a strong interference fit between the tube and the surrounding structure. Proper expansion techniques help prevent leakage and ensure structural stability of the joint.- Tube expansion techniques for joint integrity: Various tube expansion techniques are employed to ensure joint integrity in tubular connections. These methods involve mechanically expanding the tube into a tube sheet or fitting to create a tight seal. The expansion can be achieved through rolling, hydraulic pressure, or mechanical means. Proper expansion ensures that the joint can withstand pressure, temperature variations, and mechanical stress while maintaining a leak-proof connection.

- Seal welding methods for tube joints: Seal welding provides an additional layer of protection for tube joints by creating a fusion bond between the tube and the connecting component. Various welding techniques, including TIG welding, laser welding, and orbital welding, can be used depending on the application requirements. Seal welding is particularly important in high-pressure and high-temperature applications where mechanical joints alone might not provide sufficient integrity.

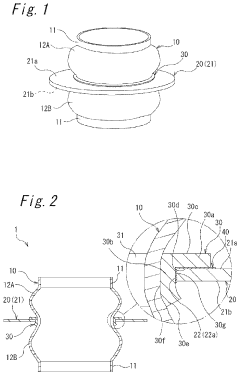

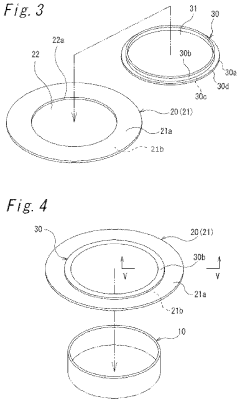

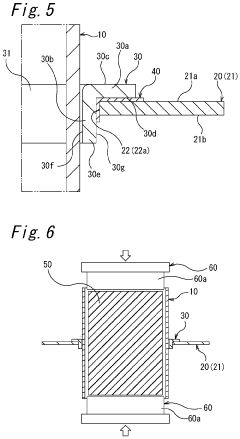

- Combined expansion and welding techniques: Combining tube expansion with seal welding creates highly reliable joints with superior integrity. In this approach, the tube is first expanded to create a mechanical connection, followed by seal welding to provide additional sealing and structural strength. This dual approach is particularly effective in critical applications where joint failure could have severe consequences, such as in nuclear power plants, oil and gas facilities, and chemical processing equipment.

- Testing and verification of joint integrity: Various methods are used to test and verify the integrity of tube joints after expansion and/or welding. These include pressure testing, helium leak testing, ultrasonic testing, radiographic examination, and visual inspection. Regular inspection and maintenance protocols are essential to ensure the continued integrity of tube joints throughout their service life, especially in safety-critical applications.

- Specialized joint designs for enhanced integrity: Innovative joint designs have been developed to enhance the integrity of tube connections. These include specially designed tube sheets, ferrules, sleeves, and fittings that improve the mechanical strength and sealing capability of the joint. Some designs incorporate multiple sealing surfaces, tapered connections, or special geometries that distribute stress more evenly. These specialized designs are particularly valuable in applications with extreme operating conditions or stringent safety requirements.

02 Seal welding methods for tube joints

Seal welding provides an additional layer of protection for tube joints by creating a hermetic seal that prevents leakage. Various welding techniques, including TIG welding, laser welding, and orbital welding, can be applied to create high-integrity tube joints. The welding process typically follows the tube expansion step to reinforce the mechanical connection. Proper welding parameters and procedures are essential to avoid thermal distortion and ensure joint reliability.Expand Specific Solutions03 Hybrid joining systems combining expansion and welding

Hybrid joining systems integrate both tube expansion and seal welding techniques to maximize joint integrity. These systems first establish a mechanical connection through expansion and then enhance the seal through strategic welding. This dual approach provides redundant sealing mechanisms, improving reliability in high-pressure or high-temperature applications. The combination helps distribute stress more evenly across the joint and provides superior resistance to thermal cycling and vibration.Expand Specific Solutions04 Joint integrity testing and verification methods

Various testing and verification methods are employed to ensure tube joint integrity after expansion and welding. These include pressure testing, helium leak detection, ultrasonic testing, and radiographic examination. Non-destructive testing techniques help identify potential defects such as incomplete expansion, weld porosity, or cracks that could compromise joint integrity. Regular inspection protocols and quality control measures are essential for maintaining long-term reliability of tube joints.Expand Specific Solutions05 Specialized fittings and connectors for enhanced joint integrity

Specialized fittings and connectors are designed to enhance tube joint integrity in various applications. These include ferrule systems, compression fittings, and proprietary connector designs that facilitate proper tube expansion and sealing. Advanced materials and coatings are incorporated to improve corrosion resistance and thermal stability. Some designs feature self-aligning components or integrated sealing elements to simplify installation while maintaining high-integrity connections.Expand Specific Solutions

Key Industry Players in Tube Joining Solutions

The tube expansion versus seal welding joint integrity competition landscape is currently in a mature development phase, with a global market size estimated at several billion dollars across oil and gas, power generation, and automotive industries. Technologically, the field shows varying maturity levels, with companies like Vallourec, Baker Hughes, and Weatherford leading innovation in oil and gas applications through advanced testing methodologies and material science. NIPPON STEEL and Sumitomo have established strong positions in heat exchanger applications, while automotive sector players like MANN+HUMMEL and Zhejiang Sanhua focus on specialized sealing solutions. Academic institutions such as Tianjin University and Southwest Petroleum University contribute significant research to improve joint reliability under extreme conditions, creating a competitive ecosystem where industry-academia collaboration drives technological advancement.

Baker Hughes Co.

Technical Solution: Baker Hughes has pioneered the MS-2 Seal Technology for tubular connections that combines controlled plastic deformation through tube expansion with specialized metal-to-metal sealing surfaces. Their approach utilizes precision-controlled hydraulic expansion tools that apply uniform radial force to create consistent interference fits. The company's research has shown that their expanded connections maintain integrity under thermal cycling from -40°F to 350°F, with test data demonstrating leak resistance at pressures exceeding 15,000 psi. Baker Hughes has also developed hybrid solutions that incorporate both expansion techniques and supplementary welding for critical applications. Their proprietary AutoTrak™ system includes sensors that monitor expansion parameters in real-time, ensuring optimal joint formation and documenting quality metrics for each connection.

Strengths: Excellent performance under thermal cycling, documented quality control, versatility across various operating environments. Weaknesses: Complex installation procedures, higher equipment costs, potential for over-expansion if not properly monitored.

NIPPON STEEL CORP.

Technical Solution: Nippon Steel has developed the NS-TJ (Nippon Steel Tube Joining) system that optimizes the balance between mechanical expansion and supplementary welding for critical tubular connections. Their approach utilizes controlled hydraulic expansion with proprietary mandrel designs that create uniform contact pressure while minimizing residual stress concentrations. Research by Nippon Steel has demonstrated that their optimized expansion process creates a residual compressive stress state that enhances fatigue resistance by up to 40% compared to conventional welded joints. Their technology incorporates specialized surface treatments that enhance the tube-tubesheet interface metallurgical properties. For high-temperature applications, Nippon Steel has developed a hybrid joining method that combines precise mechanical expansion with automated micro-welding that minimizes heat-affected zones while providing secondary sealing. Long-term testing has shown their joints maintain integrity through over 10,000 thermal cycles.

Strengths: Superior fatigue resistance, excellent performance in high-temperature applications, minimal heat-affected zone in hybrid joints. Weaknesses: Requires specialized equipment, higher initial costs, more complex quality control requirements.

Technical Innovations in Joint Integrity Research

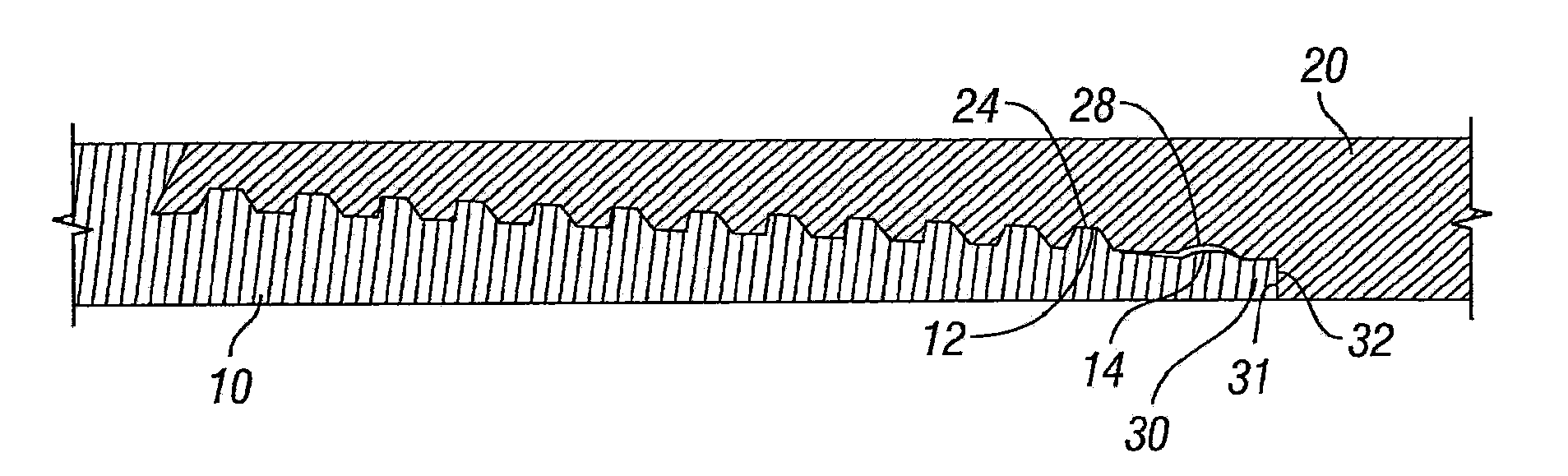

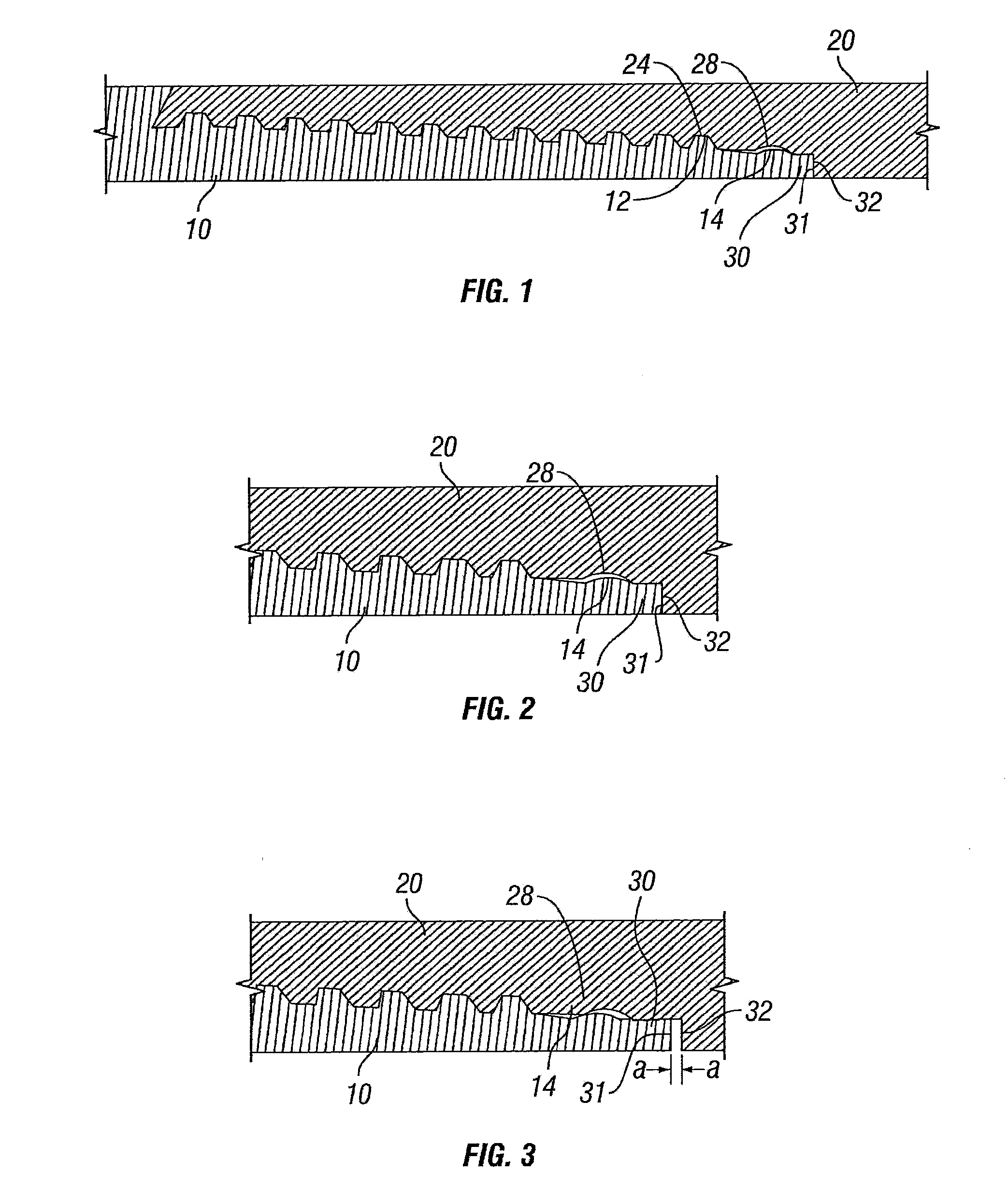

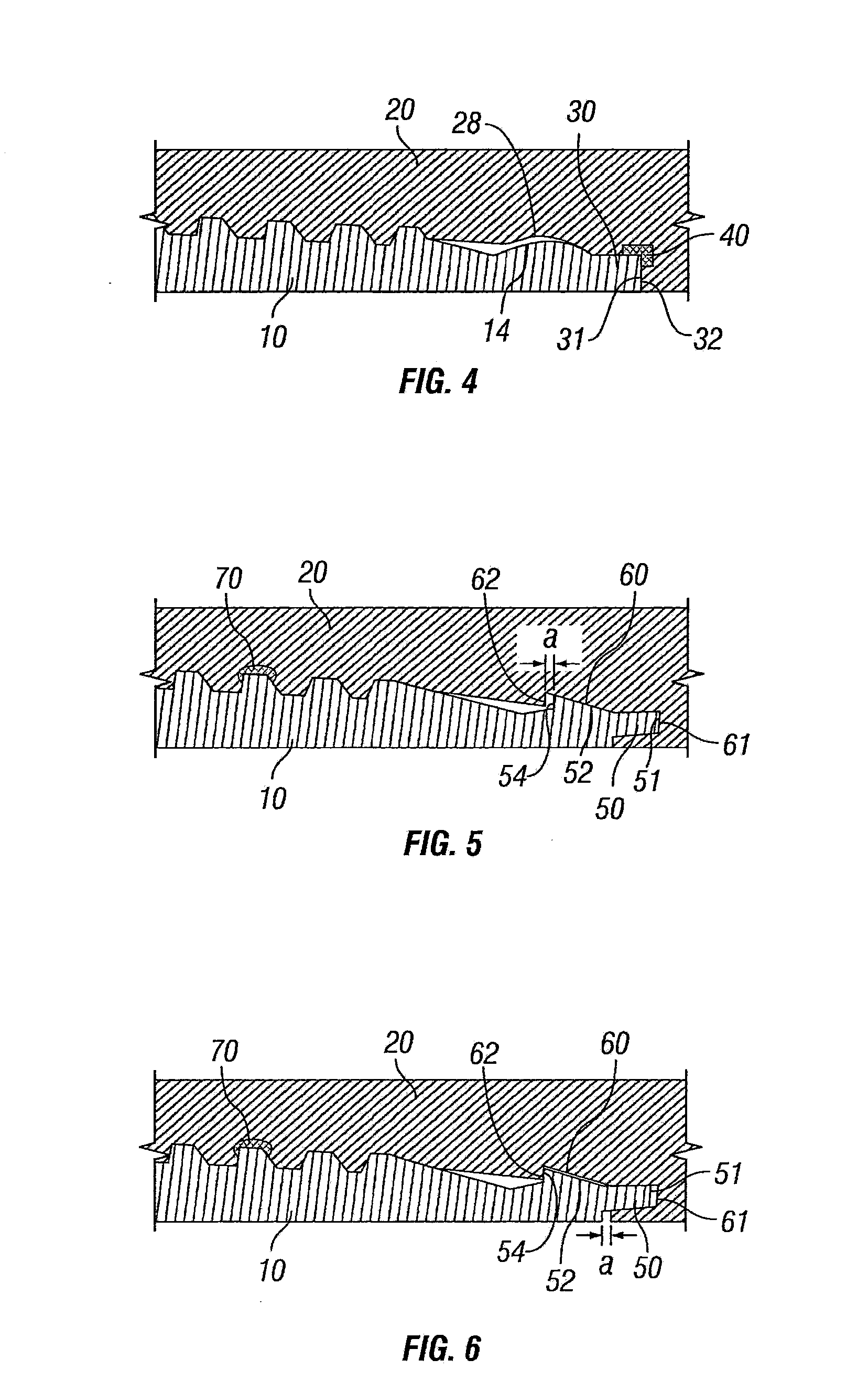

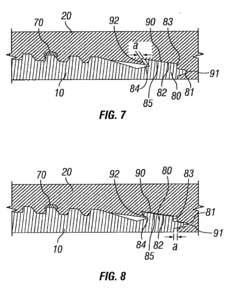

Reverse sliding seal for expandable tubular connections

PatentInactiveUS20100320754A1

Innovation

- The design incorporates a groove on the box member and a corresponding rib on the pin nose, where radial expansion creates a high-bearing pressure metal-to-metal seal by the contact between the rib and groove, and optionally includes an elastomeric sealing ring to form a secondary resilient seal, enhancing pressure integrity without weakening the coupling strength.

Joined body and method for producing same

PatentActiveUS11946580B2

Innovation

- A joined body configuration that includes a tubular first member and a plate-shaped second member with a collar member interposed between them, where the collar member has a tubular portion extending through the hole, increasing the joint area and using an adhesive layer to prevent electrolytic corrosion, thereby enhancing joint strength and durability.

Lifecycle Performance Testing Methodologies

To effectively evaluate the long-term performance differences between tube expansion and seal welding techniques, comprehensive lifecycle testing methodologies must be implemented. These methodologies should simulate real-world conditions while accelerating aging processes to predict joint integrity over extended operational periods.

Accelerated life testing (ALT) represents a cornerstone approach, subjecting tube joints to intensified thermal cycling, pressure fluctuations, and mechanical vibrations at frequencies and amplitudes exceeding normal operating conditions. This methodology can compress decades of operational wear into manageable testing timeframes, typically ranging from 3-6 months depending on the application requirements.

Finite Element Analysis (FEA) modeling complements physical testing by simulating stress distribution patterns and identifying potential failure points before they manifest in actual components. For tube expansion joints, FEA can predict relaxation behaviors and contact pressure degradation over time, while for welded joints, it can forecast residual stress evolution and potential crack propagation pathways.

Environmental exposure chambers provide critical insights by subjecting test specimens to controlled corrosive environments, including salt spray, humidity cycling, and chemical exposure relevant to the intended application. These tests are particularly valuable for comparing the corrosion resistance of mechanical expansion joints versus the metallurgically bonded interfaces of welded connections.

Non-destructive evaluation (NDE) techniques form an essential component of lifecycle testing protocols. Periodic ultrasonic testing, radiographic inspection, and eddy current analysis allow for monitoring joint integrity without compromising the test specimens. Advanced techniques such as acoustic emission monitoring can detect microscopic changes in joint characteristics during cyclic loading tests.

Destructive testing at predetermined intervals provides definitive data points on joint strength degradation over time. Pull-out force measurements for expanded joints and fracture mechanics testing for welded connections establish quantitative benchmarks for performance comparison. Statistical analysis of these results enables reliable extrapolation to predict end-of-life performance.

Real-time monitoring systems incorporating pressure sensors, strain gauges, and leak detection equipment provide continuous data streams during long-duration testing. These systems can detect subtle changes in joint performance that might otherwise go unnoticed in periodic inspection regimes, offering early indicators of potential failure modes specific to each joining technique.

Accelerated life testing (ALT) represents a cornerstone approach, subjecting tube joints to intensified thermal cycling, pressure fluctuations, and mechanical vibrations at frequencies and amplitudes exceeding normal operating conditions. This methodology can compress decades of operational wear into manageable testing timeframes, typically ranging from 3-6 months depending on the application requirements.

Finite Element Analysis (FEA) modeling complements physical testing by simulating stress distribution patterns and identifying potential failure points before they manifest in actual components. For tube expansion joints, FEA can predict relaxation behaviors and contact pressure degradation over time, while for welded joints, it can forecast residual stress evolution and potential crack propagation pathways.

Environmental exposure chambers provide critical insights by subjecting test specimens to controlled corrosive environments, including salt spray, humidity cycling, and chemical exposure relevant to the intended application. These tests are particularly valuable for comparing the corrosion resistance of mechanical expansion joints versus the metallurgically bonded interfaces of welded connections.

Non-destructive evaluation (NDE) techniques form an essential component of lifecycle testing protocols. Periodic ultrasonic testing, radiographic inspection, and eddy current analysis allow for monitoring joint integrity without compromising the test specimens. Advanced techniques such as acoustic emission monitoring can detect microscopic changes in joint characteristics during cyclic loading tests.

Destructive testing at predetermined intervals provides definitive data points on joint strength degradation over time. Pull-out force measurements for expanded joints and fracture mechanics testing for welded connections establish quantitative benchmarks for performance comparison. Statistical analysis of these results enables reliable extrapolation to predict end-of-life performance.

Real-time monitoring systems incorporating pressure sensors, strain gauges, and leak detection equipment provide continuous data streams during long-duration testing. These systems can detect subtle changes in joint performance that might otherwise go unnoticed in periodic inspection regimes, offering early indicators of potential failure modes specific to each joining technique.

Environmental Factors Affecting Joint Longevity

The environmental conditions in which tube joints operate significantly influence their long-term integrity, with different joining methods exhibiting varying resilience under challenging conditions. Temperature fluctuations represent a primary concern, as thermal cycling can induce expansion and contraction stresses that may compromise joint stability over time. Tube expansion joints typically demonstrate superior performance under thermal cycling conditions due to their inherent flexibility, whereas seal welded joints may develop microcracks from repeated thermal stress, particularly at the heat-affected zones.

Corrosive environments pose another critical challenge to joint longevity. In chemical processing facilities, power plants, and marine applications, exposure to corrosive media can accelerate degradation at the joint interface. Seal welded joints generally offer better protection against corrosion infiltration due to their hermetic nature, provided the weld quality is high. Expanded joints, however, may be more susceptible to crevice corrosion if proper material selection and surface treatments are not implemented.

Mechanical vibration and cyclic loading constitute significant environmental factors affecting joint performance. Industrial equipment, transportation systems, and pressure vessels frequently subject tube joints to continuous vibration and pressure fluctuations. Expanded joints may exhibit superior fatigue resistance in these conditions due to their ability to absorb and distribute mechanical energy, whereas welded joints can develop fatigue cracks at stress concentration points if not properly designed with stress relief features.

Radiation exposure in nuclear applications presents unique challenges for joint integrity. Both joining methods can experience radiation-induced embrittlement, but seal welded joints typically provide better containment properties in high-radiation environments. However, the heat-affected zones in welds may be more susceptible to radiation damage compared to the more uniform structure of expanded joints.

Humidity and moisture exposure can lead to various degradation mechanisms including galvanic corrosion at dissimilar metal interfaces. Seal welded joints generally provide better protection against moisture ingress, while expanded joints may require additional sealing measures in high-humidity environments to prevent moisture-related deterioration.

Atmospheric contaminants such as sulfur compounds, chlorides, and industrial pollutants can accelerate corrosion processes at joint interfaces. The presence of these contaminants may necessitate specialized material selection or protective coatings, particularly for expanded joints where crevices might trap corrosive species. Seal welded joints typically offer better resistance to atmospheric contaminants but may still require corrosion-resistant filler materials in severe environments.

Understanding these environmental factors is essential for proper joint selection and design, as the optimal joining method ultimately depends on the specific operating conditions and expected service life of the system.

Corrosive environments pose another critical challenge to joint longevity. In chemical processing facilities, power plants, and marine applications, exposure to corrosive media can accelerate degradation at the joint interface. Seal welded joints generally offer better protection against corrosion infiltration due to their hermetic nature, provided the weld quality is high. Expanded joints, however, may be more susceptible to crevice corrosion if proper material selection and surface treatments are not implemented.

Mechanical vibration and cyclic loading constitute significant environmental factors affecting joint performance. Industrial equipment, transportation systems, and pressure vessels frequently subject tube joints to continuous vibration and pressure fluctuations. Expanded joints may exhibit superior fatigue resistance in these conditions due to their ability to absorb and distribute mechanical energy, whereas welded joints can develop fatigue cracks at stress concentration points if not properly designed with stress relief features.

Radiation exposure in nuclear applications presents unique challenges for joint integrity. Both joining methods can experience radiation-induced embrittlement, but seal welded joints typically provide better containment properties in high-radiation environments. However, the heat-affected zones in welds may be more susceptible to radiation damage compared to the more uniform structure of expanded joints.

Humidity and moisture exposure can lead to various degradation mechanisms including galvanic corrosion at dissimilar metal interfaces. Seal welded joints generally provide better protection against moisture ingress, while expanded joints may require additional sealing measures in high-humidity environments to prevent moisture-related deterioration.

Atmospheric contaminants such as sulfur compounds, chlorides, and industrial pollutants can accelerate corrosion processes at joint interfaces. The presence of these contaminants may necessitate specialized material selection or protective coatings, particularly for expanded joints where crevices might trap corrosive species. Seal welded joints typically offer better resistance to atmospheric contaminants but may still require corrosion-resistant filler materials in severe environments.

Understanding these environmental factors is essential for proper joint selection and design, as the optimal joining method ultimately depends on the specific operating conditions and expected service life of the system.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!