Elastomer Seal Aging: Temperature, Chemicals And Tightness Degradation

SEP 12, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Elastomer Seal Technology Background and Objectives

Elastomer seals have been integral components in industrial applications since the early 20th century, evolving from simple rubber gaskets to sophisticated engineered materials designed for specific operational environments. The technology has progressed significantly from natural rubber compounds to advanced synthetic elastomers capable of withstanding extreme conditions. This evolution has been driven by increasing demands in industries such as aerospace, automotive, oil and gas, and chemical processing, where seal failure can lead to catastrophic consequences.

The aging process of elastomer seals represents a critical area of concern across these industries. Seals naturally degrade over time due to various environmental factors, with temperature fluctuations, chemical exposure, and mechanical stress being primary contributors. Historical data indicates that approximately 70% of fluid system failures can be attributed to seal degradation, highlighting the economic and safety implications of this technological challenge.

Temperature effects on elastomers manifest through multiple mechanisms including oxidation, which accelerates at elevated temperatures, and embrittlement at low temperatures. Each 10°C increase in operating temperature can potentially reduce seal life by 50%, following the Arrhenius relationship. This thermal degradation alters the elastomer's molecular structure, compromising its essential properties such as elasticity and recovery.

Chemical compatibility presents another significant challenge, as elastomers interact with process fluids through mechanisms including swelling, extraction of plasticizers, and chemical breakdown of polymer chains. Modern industrial environments often expose seals to complex chemical cocktails rather than single substances, creating multifaceted degradation pathways that are difficult to predict using traditional models.

The progressive loss of sealing force, known as compression set, represents the cumulative effect of these aging factors. As elastomers lose their ability to maintain contact pressure against mating surfaces, leak paths develop, compromising system integrity. This tightness degradation follows non-linear patterns that vary significantly based on material composition and environmental conditions.

The primary objective of current research in elastomer seal technology is to develop predictive models that accurately forecast seal performance throughout its operational lifetime. This includes creating accelerated aging protocols that reliably simulate years of service in weeks of laboratory testing, identifying early indicators of impending seal failure before leakage occurs, and formulating new elastomer compounds with enhanced resistance to multiple degradation mechanisms simultaneously.

Additionally, there is growing interest in developing smart seal technologies incorporating sensors that monitor real-time condition, allowing for predictive maintenance rather than scheduled replacement. These innovations aim to extend service intervals while maintaining system reliability, ultimately reducing both operational costs and environmental impact through reduced waste generation.

The aging process of elastomer seals represents a critical area of concern across these industries. Seals naturally degrade over time due to various environmental factors, with temperature fluctuations, chemical exposure, and mechanical stress being primary contributors. Historical data indicates that approximately 70% of fluid system failures can be attributed to seal degradation, highlighting the economic and safety implications of this technological challenge.

Temperature effects on elastomers manifest through multiple mechanisms including oxidation, which accelerates at elevated temperatures, and embrittlement at low temperatures. Each 10°C increase in operating temperature can potentially reduce seal life by 50%, following the Arrhenius relationship. This thermal degradation alters the elastomer's molecular structure, compromising its essential properties such as elasticity and recovery.

Chemical compatibility presents another significant challenge, as elastomers interact with process fluids through mechanisms including swelling, extraction of plasticizers, and chemical breakdown of polymer chains. Modern industrial environments often expose seals to complex chemical cocktails rather than single substances, creating multifaceted degradation pathways that are difficult to predict using traditional models.

The progressive loss of sealing force, known as compression set, represents the cumulative effect of these aging factors. As elastomers lose their ability to maintain contact pressure against mating surfaces, leak paths develop, compromising system integrity. This tightness degradation follows non-linear patterns that vary significantly based on material composition and environmental conditions.

The primary objective of current research in elastomer seal technology is to develop predictive models that accurately forecast seal performance throughout its operational lifetime. This includes creating accelerated aging protocols that reliably simulate years of service in weeks of laboratory testing, identifying early indicators of impending seal failure before leakage occurs, and formulating new elastomer compounds with enhanced resistance to multiple degradation mechanisms simultaneously.

Additionally, there is growing interest in developing smart seal technologies incorporating sensors that monitor real-time condition, allowing for predictive maintenance rather than scheduled replacement. These innovations aim to extend service intervals while maintaining system reliability, ultimately reducing both operational costs and environmental impact through reduced waste generation.

Market Demand Analysis for High-Performance Seals

The global market for high-performance elastomer seals continues to expand significantly, driven by increasing demands across multiple industries where seal reliability under extreme conditions is critical. The oil and gas sector remains the largest consumer of advanced sealing solutions, accounting for approximately 35% of the total market share, with requirements for seals that can withstand high temperatures, aggressive chemicals, and maintain tightness under fluctuating pressure conditions.

Aerospace and automotive industries follow closely behind, collectively representing about 30% of market demand. In these sectors, the push toward more efficient engines operating at higher temperatures has intensified the need for seals with enhanced thermal stability and chemical resistance. The automotive industry specifically has seen a 12% annual increase in demand for high-performance seals due to stricter emission regulations and the growth of electric vehicles requiring specialized thermal management systems.

Chemical processing and pharmaceutical manufacturing constitute another significant market segment, where the focus lies on seals resistant to a wide spectrum of aggressive chemicals while maintaining compliance with stringent regulatory standards. This sector has experienced steady growth at 8% annually over the past five years, with particular emphasis on materials that resist degradation while preventing contamination.

Market research indicates that end-users are increasingly prioritizing total cost of ownership over initial purchase price, recognizing that premature seal failure leads to substantial operational downtime and maintenance costs. A recent industry survey revealed that 78% of maintenance engineers identified seal failure as a primary cause of equipment downtime, with aging-related degradation being the predominant failure mechanism.

Regional analysis shows North America and Europe currently dominating the high-performance seal market with approximately 60% combined share, though Asia-Pacific represents the fastest-growing region with a projected compound annual growth rate of 9.5% through 2028. This growth is primarily driven by rapid industrialization in China and India, alongside increasing adoption of advanced manufacturing technologies requiring superior sealing solutions.

The market is also witnessing a significant shift toward customized sealing solutions designed for specific operating environments rather than general-purpose products. This trend reflects growing awareness among end-users about the critical relationship between seal material selection and application-specific degradation factors such as temperature cycling, chemical exposure patterns, and mechanical stress profiles.

Sustainability concerns are emerging as another market driver, with increasing demand for environmentally friendly elastomer materials that maintain high performance while reducing environmental impact throughout their lifecycle. This includes growing interest in bio-based elastomers and recyclable compound formulations that do not compromise on temperature resistance or chemical compatibility.

Aerospace and automotive industries follow closely behind, collectively representing about 30% of market demand. In these sectors, the push toward more efficient engines operating at higher temperatures has intensified the need for seals with enhanced thermal stability and chemical resistance. The automotive industry specifically has seen a 12% annual increase in demand for high-performance seals due to stricter emission regulations and the growth of electric vehicles requiring specialized thermal management systems.

Chemical processing and pharmaceutical manufacturing constitute another significant market segment, where the focus lies on seals resistant to a wide spectrum of aggressive chemicals while maintaining compliance with stringent regulatory standards. This sector has experienced steady growth at 8% annually over the past five years, with particular emphasis on materials that resist degradation while preventing contamination.

Market research indicates that end-users are increasingly prioritizing total cost of ownership over initial purchase price, recognizing that premature seal failure leads to substantial operational downtime and maintenance costs. A recent industry survey revealed that 78% of maintenance engineers identified seal failure as a primary cause of equipment downtime, with aging-related degradation being the predominant failure mechanism.

Regional analysis shows North America and Europe currently dominating the high-performance seal market with approximately 60% combined share, though Asia-Pacific represents the fastest-growing region with a projected compound annual growth rate of 9.5% through 2028. This growth is primarily driven by rapid industrialization in China and India, alongside increasing adoption of advanced manufacturing technologies requiring superior sealing solutions.

The market is also witnessing a significant shift toward customized sealing solutions designed for specific operating environments rather than general-purpose products. This trend reflects growing awareness among end-users about the critical relationship between seal material selection and application-specific degradation factors such as temperature cycling, chemical exposure patterns, and mechanical stress profiles.

Sustainability concerns are emerging as another market driver, with increasing demand for environmentally friendly elastomer materials that maintain high performance while reducing environmental impact throughout their lifecycle. This includes growing interest in bio-based elastomers and recyclable compound formulations that do not compromise on temperature resistance or chemical compatibility.

Current Challenges in Elastomer Seal Degradation

Elastomer seals face significant degradation challenges across various industrial applications, with three primary factors contributing to their deterioration: temperature extremes, chemical exposure, and mechanical stress. Temperature-induced aging accelerates cross-linking in elastomers, leading to increased hardness, reduced elasticity, and eventual cracking. High-temperature environments particularly affect nitrile (NBR) and ethylene propylene diene monomer (EPDM) seals, with degradation rates approximately doubling with every 10°C increase above their rated temperature thresholds.

Chemical compatibility presents another critical challenge, as elastomers exhibit varying resistance to different chemical environments. Fluoroelastomers (FKM) demonstrate excellent resistance to hydrocarbons but degrade rapidly when exposed to ketones or esters. Silicone seals, while thermally stable, show poor resistance to many solvents and oils. The chemical degradation mechanisms include swelling, extraction of plasticizers, and chemical attack on the polymer backbone, all of which compromise seal integrity.

Compression set represents a significant mechanical challenge, occurring when elastomer seals fail to recover their original dimensions after prolonged compression. This phenomenon is particularly problematic in static applications where seals remain under constant stress. Industry data indicates that compression set increases exponentially with time and temperature, with most elastomers showing significant performance degradation after reaching 70-80% compression set.

The synergistic effects of these degradation factors create complex failure modes that are difficult to predict. For instance, chemical exposure often accelerates temperature-induced aging, while mechanical stress can create microcracks that provide pathways for chemical attack. Current predictive models struggle to account for these interactions, leading to significant discrepancies between laboratory testing and real-world performance.

Monitoring seal degradation in situ presents additional challenges, as most detection methods are reactive rather than preventive. Traditional inspection techniques often identify seal failure only after leakage has occurred, resulting in costly downtime and potential safety hazards. Non-destructive testing methods such as ultrasonic inspection and infrared thermography show promise but remain limited in their ability to detect early-stage degradation.

The economic impact of premature seal failure is substantial across industries. In oil and gas applications alone, seal failures account for approximately 25% of equipment downtime, with associated costs estimated at billions annually. Similar patterns emerge in chemical processing, automotive, and aerospace sectors, highlighting the critical need for improved understanding of elastomer degradation mechanisms and development of more resilient sealing solutions.

Chemical compatibility presents another critical challenge, as elastomers exhibit varying resistance to different chemical environments. Fluoroelastomers (FKM) demonstrate excellent resistance to hydrocarbons but degrade rapidly when exposed to ketones or esters. Silicone seals, while thermally stable, show poor resistance to many solvents and oils. The chemical degradation mechanisms include swelling, extraction of plasticizers, and chemical attack on the polymer backbone, all of which compromise seal integrity.

Compression set represents a significant mechanical challenge, occurring when elastomer seals fail to recover their original dimensions after prolonged compression. This phenomenon is particularly problematic in static applications where seals remain under constant stress. Industry data indicates that compression set increases exponentially with time and temperature, with most elastomers showing significant performance degradation after reaching 70-80% compression set.

The synergistic effects of these degradation factors create complex failure modes that are difficult to predict. For instance, chemical exposure often accelerates temperature-induced aging, while mechanical stress can create microcracks that provide pathways for chemical attack. Current predictive models struggle to account for these interactions, leading to significant discrepancies between laboratory testing and real-world performance.

Monitoring seal degradation in situ presents additional challenges, as most detection methods are reactive rather than preventive. Traditional inspection techniques often identify seal failure only after leakage has occurred, resulting in costly downtime and potential safety hazards. Non-destructive testing methods such as ultrasonic inspection and infrared thermography show promise but remain limited in their ability to detect early-stage degradation.

The economic impact of premature seal failure is substantial across industries. In oil and gas applications alone, seal failures account for approximately 25% of equipment downtime, with associated costs estimated at billions annually. Similar patterns emerge in chemical processing, automotive, and aerospace sectors, highlighting the critical need for improved understanding of elastomer degradation mechanisms and development of more resilient sealing solutions.

Current Solutions for Seal Aging Mitigation

01 Aging mechanisms and degradation factors of elastomer seals

Elastomer seals degrade over time due to various environmental factors including temperature fluctuations, chemical exposure, UV radiation, and mechanical stress. These factors cause molecular changes in the elastomer material, leading to hardening, cracking, and loss of elasticity. The degradation process typically involves oxidation, cross-linking, and chain scission of the polymer structure, which ultimately compromises the seal's ability to maintain tightness and prevent leakage in industrial applications.- Aging mechanisms and degradation factors of elastomer seals: Elastomer seals degrade over time due to various environmental factors including temperature fluctuations, chemical exposure, UV radiation, and mechanical stress. The aging process involves chemical changes in the elastomer structure, such as cross-linking or chain scission, which leads to hardening, cracking, and loss of elasticity. These changes directly impact the sealing performance and tightness, reducing the effectiveness of the seal in maintaining pressure or preventing leakage.

- Testing and monitoring methods for seal integrity: Various testing and monitoring methods have been developed to assess the integrity and remaining service life of elastomer seals. These include non-destructive testing techniques such as ultrasonic inspection, pressure decay testing, and electrical resistance measurements. Advanced monitoring systems employ sensors to continuously track seal performance parameters, allowing for early detection of degradation before catastrophic failure occurs. These methods help in predicting seal failure and optimizing maintenance schedules.

- Material innovations to improve seal longevity: Innovative elastomer formulations have been developed to enhance seal durability and resistance to aging factors. These include the incorporation of antioxidants, UV stabilizers, and specialized fillers that improve resistance to chemical attack and thermal degradation. Advanced composite elastomers combine different materials to achieve superior performance characteristics, such as improved temperature resistance, reduced compression set, and enhanced chemical compatibility, resulting in extended service life and maintained tightness over longer periods.

- Design improvements for enhanced seal performance: Seal design innovations focus on optimizing geometry and installation configurations to minimize stress concentration and improve sealing effectiveness. These include specialized groove designs, multi-lip configurations, and engineered contact surfaces that maintain sealing pressure even as the elastomer ages. Some designs incorporate backup rings or secondary sealing elements that compensate for primary seal degradation. Advanced computational modeling techniques are used to predict seal behavior under various operating conditions and optimize designs for specific applications.

- Predictive maintenance and lifecycle management: Predictive maintenance strategies for elastomer seals utilize data analytics and artificial intelligence to forecast seal degradation and optimize replacement intervals. These approaches incorporate operational data, environmental conditions, and material characteristics to create models that predict remaining useful life. Digital twin technology enables virtual simulation of seal performance under actual operating conditions, allowing for proactive maintenance decisions. Implementation of condition-based maintenance programs helps prevent unexpected failures while maximizing the service life of elastomer seals.

02 Testing and monitoring methods for seal integrity

Various testing and monitoring methods have been developed to assess the integrity and remaining service life of elastomer seals. These include non-destructive testing techniques such as ultrasonic inspection, pressure decay testing, and electrical resistance measurements. Advanced monitoring systems employ sensors to continuously track seal performance parameters including compression set, stress relaxation, and leak rates. These methods enable early detection of seal degradation before catastrophic failure occurs, allowing for timely maintenance interventions.Expand Specific Solutions03 Material innovations for improved seal longevity

Recent innovations in elastomer materials have focused on enhancing seal longevity and performance under harsh conditions. These include the development of fluoroelastomers with improved chemical resistance, silicone compounds with enhanced thermal stability, and hybrid materials that combine the beneficial properties of multiple elastomer types. Additionally, nanomaterial additives and specialized fillers are being incorporated to improve mechanical properties, reduce compression set, and increase resistance to environmental degradation factors, thereby extending the functional lifespan of seals.Expand Specific Solutions04 Predictive maintenance and failure analysis techniques

Predictive maintenance strategies for elastomer seals involve sophisticated failure analysis techniques and computational models to forecast seal degradation. These approaches utilize machine learning algorithms, finite element analysis, and historical performance data to predict when seals will reach critical degradation thresholds. By analyzing factors such as compression set, stress relaxation rates, and environmental exposure history, these techniques can accurately estimate remaining seal life and optimize maintenance schedules, reducing unexpected failures and associated downtime.Expand Specific Solutions05 Design optimizations for enhanced seal performance

Innovative seal design approaches focus on optimizing geometry, compression ratios, and installation methods to enhance long-term performance and mitigate degradation effects. These include specialized groove designs that maintain proper compression throughout the seal's life, multi-component seal systems that distribute stress more effectively, and self-compensating designs that adjust to wear and compression set. Additionally, surface treatments and coatings are being applied to seal contact surfaces to reduce friction, minimize wear, and improve chemical resistance, thereby extending functional seal life.Expand Specific Solutions

Key Industry Players in Elastomer Seal Manufacturing

The elastomer seal aging market is currently in a growth phase, driven by increasing demand for reliable sealing solutions across industries. The market size is expanding due to growing applications in oil and gas, automotive, and industrial sectors. Technologically, the field is moderately mature but continues to evolve with innovations in material science. Leading players include Baker Hughes and Vetco Gray in the oil and gas sector, while DuPont, 3M, and Freudenberg dominate materials development. Academic institutions like Tsinghua University contribute significant research. Automotive manufacturers Toyota and Mercedes-Benz are advancing seal technology for extreme conditions, while specialized companies like James Walker and Kalsi Engineering focus on high-performance sealing solutions for challenging chemical and temperature environments.

DAIKIN INDUSTRIES Ltd.

Technical Solution: DAIKIN has developed advanced elastomer seal aging solutions through their DAI-EL® fluoroelastomer technology. Their approach to temperature degradation involves specialized polymer architectures with optimized monomer ratios and cross-linking systems that maintain elasticity and sealing force at temperatures ranging from -40°C to +250°C, while incorporating proprietary heat stabilizers that prevent chain scission during prolonged high-temperature exposure[1]. For chemical resistance, DAIKIN has engineered their fluoroelastomers with varying fluorine content (65-71%) and specialized cure systems to resist specific chemical families including aggressive acids, bases, and hydrocarbon fuels[2]. Their compression set resistance technology employs optimized vulcanization processes and specialized peroxide-cure systems that create more stable cross-links compared to conventional bisphenol-cured systems. DAIKIN's Accelerated Aging Protocol combines high-temperature immersion testing with specialized analytical techniques including Fourier Transform Infrared Spectroscopy (FTIR) and Thermogravimetric Analysis (TGA) to identify degradation mechanisms and predict long-term performance in specific chemical and temperature environments, enabling precise material selection for challenging applications[3].

Strengths: Superior chemical resistance particularly against automotive fluids and aggressive industrial chemicals; excellent compression set resistance at elevated temperatures; comprehensive material development capabilities with application-specific formulations. Weaknesses: Higher cost compared to general-purpose elastomers; requires specialized processing expertise for optimal vulcanization; some grades have limited low-temperature flexibility when optimized for high-temperature performance.

James Walker & Co. Ltd.

Technical Solution: James Walker has developed advanced elastomer seal aging solutions through their RotaBolt® technology and specialized materials engineering. Their approach focuses on combating temperature-induced degradation through high-temperature resistant compounds that maintain integrity up to 325°C while incorporating antioxidants and thermal stabilizers to prevent chain scission and cross-linking[1]. For chemical resistance, they've engineered their Elast-O-Lion® materials with fluoroelastomer and perfluoroelastomer bases that resist aggressive chemicals, acids, and hydrocarbons[2]. Their compression set resistance technology employs optimized cross-linking density and specialized fillers to maintain sealing force over extended periods. James Walker's predictive aging models utilize accelerated aging tests and Arrhenius relationship calculations to accurately predict seal lifespans in various operating conditions, allowing for preventive maintenance scheduling before critical failure occurs[3].

Strengths: Industry-leading expertise in high-temperature applications with materials engineered specifically for extreme environments; comprehensive testing capabilities including NORSOK standards compliance; advanced predictive modeling for maintenance optimization. Weaknesses: Higher cost compared to standard elastomer solutions; some specialized materials require careful handling and installation procedures; performance in combined extreme conditions (high temperature with specific chemicals) may require custom formulations.

Critical Patents in Elastomer Seal Longevity

Variable TG article, method of making, and use of same

PatentWO2013176792A1

Innovation

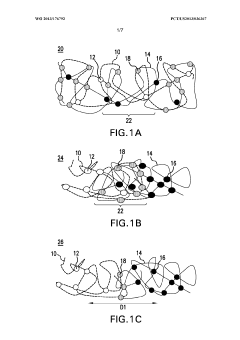

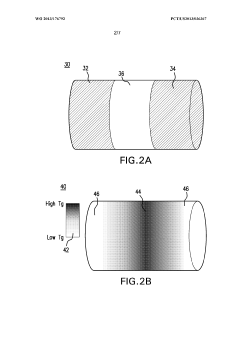

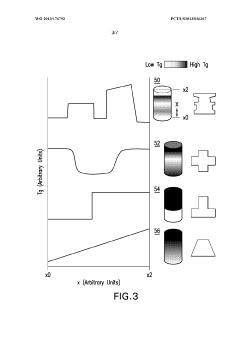

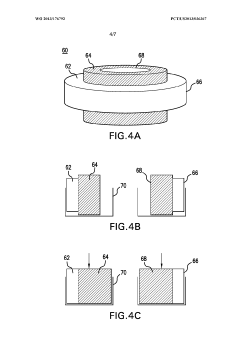

- A crosslinked polymer composition with a gradient in glass transition temperature is developed, combining different crosslinked polymers to provide a broad and tunable temperature range, allowing portions of the material to remain elastic and resistant to extrusion even at high temperatures and pressures, with a self-backup property that maintains sealing effectiveness.

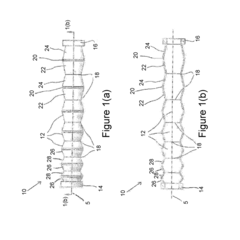

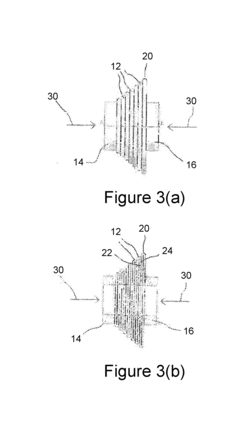

Apparatus for use in a fluid conduit

PatentActiveUS20180202256A1

Innovation

- An apparatus comprising a plurality of segments arranged along a longitudinal axis, where each segment is configured for sequential lateral extension to provide sealing, anchoring, or flow restriction functions, with segments having different maximum extended dimensions and adjacent support surfaces for mutual support, allowing for higher extension ratios without compromising integrity.

Material Science Advancements for Elastomer Seals

Recent advancements in material science have significantly transformed the landscape of elastomer seal technology. Traditional elastomeric materials such as natural rubber, nitrile rubber (NBR), and ethylene propylene diene monomer (EPDM) have been enhanced through innovative compounding techniques and molecular engineering. These improvements have directly addressed the critical challenges of temperature resistance, chemical compatibility, and long-term tightness retention that plague conventional sealing systems.

Nanomaterial integration represents one of the most promising frontiers in elastomer seal development. Carbon nanotubes and graphene, when properly dispersed within elastomer matrices, create composite materials with substantially improved mechanical properties and thermal stability. These nanocomposites demonstrate up to 40% greater temperature resistance compared to conventional elastomers, extending operational lifespans in high-temperature environments from months to years.

Self-healing elastomers constitute another revolutionary advancement, incorporating microcapsules containing healing agents or utilizing reversible chemical bonds that reconnect when damaged. When microcracks form due to aging or chemical attack, these materials can autonomously restore their sealing properties, potentially extending service life by 30-50% in challenging industrial applications.

Computational material design has accelerated development cycles through predictive modeling of elastomer aging mechanisms. Advanced simulation techniques now accurately forecast how specific elastomer formulations will respond to various temperature profiles and chemical exposures over time. This capability has reduced traditional trial-and-error development cycles from years to months, enabling rapid optimization of material compositions for specific operational environments.

Surface modification technologies have enhanced elastomer-substrate interactions, improving initial sealing performance and long-term adhesion. Techniques such as plasma treatment, chemical grafting, and the application of specialized coupling agents create stronger molecular bonds between elastomers and mating surfaces, reducing leak paths that typically develop during thermal cycling and chemical exposure.

Hybrid elastomer systems combining different polymer types have demonstrated superior resistance to multiple degradation mechanisms simultaneously. These strategically engineered materials incorporate components that provide complementary protection against temperature extremes, oxidative aging, and chemical attack, addressing the multifaceted nature of seal failure in complex industrial environments.

Bio-inspired designs have introduced novel structural approaches to sealing technology, mimicking natural systems that maintain integrity under extreme conditions. Biomimetic elastomers with hierarchical structures similar to those found in resilient natural materials like spider silk show promising resistance to crack propagation and fatigue, potentially revolutionizing seal longevity in dynamic applications.

Nanomaterial integration represents one of the most promising frontiers in elastomer seal development. Carbon nanotubes and graphene, when properly dispersed within elastomer matrices, create composite materials with substantially improved mechanical properties and thermal stability. These nanocomposites demonstrate up to 40% greater temperature resistance compared to conventional elastomers, extending operational lifespans in high-temperature environments from months to years.

Self-healing elastomers constitute another revolutionary advancement, incorporating microcapsules containing healing agents or utilizing reversible chemical bonds that reconnect when damaged. When microcracks form due to aging or chemical attack, these materials can autonomously restore their sealing properties, potentially extending service life by 30-50% in challenging industrial applications.

Computational material design has accelerated development cycles through predictive modeling of elastomer aging mechanisms. Advanced simulation techniques now accurately forecast how specific elastomer formulations will respond to various temperature profiles and chemical exposures over time. This capability has reduced traditional trial-and-error development cycles from years to months, enabling rapid optimization of material compositions for specific operational environments.

Surface modification technologies have enhanced elastomer-substrate interactions, improving initial sealing performance and long-term adhesion. Techniques such as plasma treatment, chemical grafting, and the application of specialized coupling agents create stronger molecular bonds between elastomers and mating surfaces, reducing leak paths that typically develop during thermal cycling and chemical exposure.

Hybrid elastomer systems combining different polymer types have demonstrated superior resistance to multiple degradation mechanisms simultaneously. These strategically engineered materials incorporate components that provide complementary protection against temperature extremes, oxidative aging, and chemical attack, addressing the multifaceted nature of seal failure in complex industrial environments.

Bio-inspired designs have introduced novel structural approaches to sealing technology, mimicking natural systems that maintain integrity under extreme conditions. Biomimetic elastomers with hierarchical structures similar to those found in resilient natural materials like spider silk show promising resistance to crack propagation and fatigue, potentially revolutionizing seal longevity in dynamic applications.

Environmental Impact of Seal Failure and Leakage

Seal failures and subsequent leakage events pose significant environmental risks that extend far beyond immediate operational concerns. When elastomer seals deteriorate due to temperature fluctuations, chemical exposure, or mechanical stress, the resulting leakage can release harmful substances into soil, water systems, and the atmosphere. These contaminants may include industrial chemicals, petroleum products, or process fluids that can persist in ecosystems for extended periods.

The environmental footprint of seal failures varies dramatically based on the application context. In industrial settings, even minor leakages accumulating over time can lead to substantial soil contamination, potentially reaching groundwater reserves and affecting drinking water quality. Studies indicate that hydrocarbon leakages from deteriorated seals in oil and gas operations can contaminate soil up to 3-5 meters deep, with remediation costs averaging $200-500 per cubic meter of affected soil.

Aquatic ecosystems demonstrate particular vulnerability to seal failures in marine applications or facilities near water bodies. Chemical leakages can disrupt aquatic habitats, affecting biodiversity and potentially entering the food chain. Research has documented cases where persistent leakage from industrial facilities has contributed to up to 30% reduction in local aquatic species diversity within affected zones.

Atmospheric emissions resulting from volatile compound leakage represent another significant environmental concern. In chemical processing facilities, deteriorated seals can release volatile organic compounds (VOCs) that contribute to air quality degradation and potentially affect regional climate patterns through greenhouse gas emissions. EPA estimates suggest that fugitive emissions from deteriorated seals account for approximately 5-10% of total industrial VOC emissions in certain sectors.

The economic dimension of environmental damage from seal failures extends to remediation costs, regulatory penalties, and reputational damage. Companies face increasingly stringent environmental regulations, with fines for contamination incidents reaching millions of dollars in severe cases. The European Environmental Agency reports that the average cost of major industrial leakage incidents exceeds €2 million when accounting for cleanup, legal penalties, and operational disruptions.

Preventive approaches to mitigating environmental impacts include implementing comprehensive seal monitoring programs, selecting appropriate elastomer materials for specific environmental conditions, and establishing rapid response protocols for leakage events. Advanced monitoring technologies such as infrared imaging and ultrasonic detection systems can identify potential seal failures before significant environmental damage occurs, reducing both ecological impact and remediation costs by up to 70% compared to reactive approaches.

The environmental footprint of seal failures varies dramatically based on the application context. In industrial settings, even minor leakages accumulating over time can lead to substantial soil contamination, potentially reaching groundwater reserves and affecting drinking water quality. Studies indicate that hydrocarbon leakages from deteriorated seals in oil and gas operations can contaminate soil up to 3-5 meters deep, with remediation costs averaging $200-500 per cubic meter of affected soil.

Aquatic ecosystems demonstrate particular vulnerability to seal failures in marine applications or facilities near water bodies. Chemical leakages can disrupt aquatic habitats, affecting biodiversity and potentially entering the food chain. Research has documented cases where persistent leakage from industrial facilities has contributed to up to 30% reduction in local aquatic species diversity within affected zones.

Atmospheric emissions resulting from volatile compound leakage represent another significant environmental concern. In chemical processing facilities, deteriorated seals can release volatile organic compounds (VOCs) that contribute to air quality degradation and potentially affect regional climate patterns through greenhouse gas emissions. EPA estimates suggest that fugitive emissions from deteriorated seals account for approximately 5-10% of total industrial VOC emissions in certain sectors.

The economic dimension of environmental damage from seal failures extends to remediation costs, regulatory penalties, and reputational damage. Companies face increasingly stringent environmental regulations, with fines for contamination incidents reaching millions of dollars in severe cases. The European Environmental Agency reports that the average cost of major industrial leakage incidents exceeds €2 million when accounting for cleanup, legal penalties, and operational disruptions.

Preventive approaches to mitigating environmental impacts include implementing comprehensive seal monitoring programs, selecting appropriate elastomer materials for specific environmental conditions, and establishing rapid response protocols for leakage events. Advanced monitoring technologies such as infrared imaging and ultrasonic detection systems can identify potential seal failures before significant environmental damage occurs, reducing both ecological impact and remediation costs by up to 70% compared to reactive approaches.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!