Butane's Role in Modifying Structural Foam Density

JUL 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Butane Foam Evolution

The evolution of butane foam technology has been a significant journey in the field of structural foam engineering. Initially, butane was primarily used as a blowing agent in the production of polyurethane foams, offering advantages such as low cost and ease of handling. However, its role in modifying structural foam density has become increasingly sophisticated over time.

In the early stages of development, butane was employed as a simple expansion agent, creating basic cellular structures within the foam. The process involved introducing liquid butane into the polymer mixture, which would vaporize during the curing process, creating bubbles and reducing the overall density of the material. This method, while effective, offered limited control over the final foam structure and density distribution.

As research progressed, scientists and engineers began to explore more nuanced approaches to utilizing butane in foam production. The focus shifted towards achieving precise control over foam density and cell structure. This led to the development of advanced injection techniques, where butane could be introduced at specific stages of the foam formation process, allowing for greater manipulation of the final product's properties.

A significant breakthrough came with the introduction of variable pressure systems in the foam production process. By carefully controlling the pressure during butane injection and foam expansion, manufacturers gained the ability to create foams with gradient densities. This innovation opened up new possibilities for tailoring foam properties to specific applications, such as creating impact-absorbing materials with varying densities throughout their structure.

The integration of computer-controlled systems marked another milestone in butane foam evolution. These systems enabled real-time adjustments to butane injection rates and pressures, resulting in unprecedented precision in foam density control. This level of automation not only improved product consistency but also allowed for the creation of complex foam structures with predefined density patterns.

Recent advancements have focused on combining butane with other blowing agents and additives to further enhance foam properties. For instance, the use of butane in conjunction with CO2 has shown promise in creating foams with improved environmental profiles and enhanced thermal insulation properties. Additionally, researchers have explored the potential of nano-additives to modify the interaction between butane and the polymer matrix, leading to foams with superior mechanical and thermal characteristics.

The latest frontier in butane foam evolution involves the application of artificial intelligence and machine learning algorithms to optimize foam formulations and production processes. These technologies are being used to predict and fine-tune foam properties based on complex interactions between butane, polymer chemistry, and processing conditions, pushing the boundaries of what is possible in structural foam engineering.

In the early stages of development, butane was employed as a simple expansion agent, creating basic cellular structures within the foam. The process involved introducing liquid butane into the polymer mixture, which would vaporize during the curing process, creating bubbles and reducing the overall density of the material. This method, while effective, offered limited control over the final foam structure and density distribution.

As research progressed, scientists and engineers began to explore more nuanced approaches to utilizing butane in foam production. The focus shifted towards achieving precise control over foam density and cell structure. This led to the development of advanced injection techniques, where butane could be introduced at specific stages of the foam formation process, allowing for greater manipulation of the final product's properties.

A significant breakthrough came with the introduction of variable pressure systems in the foam production process. By carefully controlling the pressure during butane injection and foam expansion, manufacturers gained the ability to create foams with gradient densities. This innovation opened up new possibilities for tailoring foam properties to specific applications, such as creating impact-absorbing materials with varying densities throughout their structure.

The integration of computer-controlled systems marked another milestone in butane foam evolution. These systems enabled real-time adjustments to butane injection rates and pressures, resulting in unprecedented precision in foam density control. This level of automation not only improved product consistency but also allowed for the creation of complex foam structures with predefined density patterns.

Recent advancements have focused on combining butane with other blowing agents and additives to further enhance foam properties. For instance, the use of butane in conjunction with CO2 has shown promise in creating foams with improved environmental profiles and enhanced thermal insulation properties. Additionally, researchers have explored the potential of nano-additives to modify the interaction between butane and the polymer matrix, leading to foams with superior mechanical and thermal characteristics.

The latest frontier in butane foam evolution involves the application of artificial intelligence and machine learning algorithms to optimize foam formulations and production processes. These technologies are being used to predict and fine-tune foam properties based on complex interactions between butane, polymer chemistry, and processing conditions, pushing the boundaries of what is possible in structural foam engineering.

Market Demand Analysis

The market demand for structural foam with modified density using butane has been steadily increasing across various industries. This growth is primarily driven by the automotive, aerospace, and construction sectors, where lightweight yet strong materials are crucial for improving performance and energy efficiency.

In the automotive industry, there is a growing need for lightweight components to enhance fuel efficiency and reduce emissions. Structural foam modified with butane offers an excellent solution, as it provides high strength-to-weight ratios while maintaining structural integrity. This has led to increased adoption in vehicle interiors, body panels, and impact-absorbing structures.

The aerospace sector also shows significant demand for advanced structural foams. With the push for more fuel-efficient aircraft, manufacturers are seeking materials that can reduce overall weight without compromising safety. Butane-modified structural foams are being explored for use in cabin interiors, cargo compartments, and non-critical structural components.

In the construction industry, there is a rising interest in energy-efficient building materials. Structural foams with tailored densities offer excellent insulation properties and can contribute to improved thermal performance in buildings. This has led to increased use in insulation panels, prefabricated wall systems, and composite building materials.

The packaging industry is another significant market for butane-modified structural foams. With the growth of e-commerce and the need for protective packaging solutions, there is a demand for lightweight yet durable materials that can withstand shipping and handling stresses. Structural foams offer an ideal balance of cushioning and strength for this application.

Market trends indicate a shift towards sustainable and recyclable materials. This presents both a challenge and an opportunity for butane-modified structural foams. Manufacturers are investing in research to develop more environmentally friendly formulations and recycling processes to meet this growing demand.

The global market for structural foams is expected to continue its growth trajectory. Factors such as urbanization, infrastructure development, and the ongoing focus on energy efficiency in transportation are likely to sustain this demand. Additionally, emerging applications in renewable energy systems, such as wind turbine blades and solar panel substrates, are opening new avenues for market expansion.

As industries continue to seek innovative solutions for weight reduction and improved performance, the role of butane in modifying structural foam density is likely to become increasingly important. This presents opportunities for material scientists and manufacturers to develop advanced formulations that can meet the evolving needs of various sectors.

In the automotive industry, there is a growing need for lightweight components to enhance fuel efficiency and reduce emissions. Structural foam modified with butane offers an excellent solution, as it provides high strength-to-weight ratios while maintaining structural integrity. This has led to increased adoption in vehicle interiors, body panels, and impact-absorbing structures.

The aerospace sector also shows significant demand for advanced structural foams. With the push for more fuel-efficient aircraft, manufacturers are seeking materials that can reduce overall weight without compromising safety. Butane-modified structural foams are being explored for use in cabin interiors, cargo compartments, and non-critical structural components.

In the construction industry, there is a rising interest in energy-efficient building materials. Structural foams with tailored densities offer excellent insulation properties and can contribute to improved thermal performance in buildings. This has led to increased use in insulation panels, prefabricated wall systems, and composite building materials.

The packaging industry is another significant market for butane-modified structural foams. With the growth of e-commerce and the need for protective packaging solutions, there is a demand for lightweight yet durable materials that can withstand shipping and handling stresses. Structural foams offer an ideal balance of cushioning and strength for this application.

Market trends indicate a shift towards sustainable and recyclable materials. This presents both a challenge and an opportunity for butane-modified structural foams. Manufacturers are investing in research to develop more environmentally friendly formulations and recycling processes to meet this growing demand.

The global market for structural foams is expected to continue its growth trajectory. Factors such as urbanization, infrastructure development, and the ongoing focus on energy efficiency in transportation are likely to sustain this demand. Additionally, emerging applications in renewable energy systems, such as wind turbine blades and solar panel substrates, are opening new avenues for market expansion.

As industries continue to seek innovative solutions for weight reduction and improved performance, the role of butane in modifying structural foam density is likely to become increasingly important. This presents opportunities for material scientists and manufacturers to develop advanced formulations that can meet the evolving needs of various sectors.

Technical Challenges

The development of structural foam with modified density using butane faces several technical challenges that require innovative solutions. One of the primary obstacles is achieving precise control over the foam's density distribution. The introduction of butane as a blowing agent introduces variability in the foaming process, making it difficult to maintain consistent density throughout the material.

Another significant challenge lies in optimizing the interaction between butane and the polymer matrix. The compatibility of butane with different polymer types varies, affecting the foam's cellular structure and overall performance. Researchers must develop formulations that ensure proper dispersion of butane within the polymer melt and control its release during the foaming process.

The stability of butane-modified structural foam poses additional technical hurdles. As butane is a volatile compound, there is a risk of gas loss over time, potentially leading to dimensional instability and changes in the foam's properties. Engineers must devise strategies to encapsulate or retain the butane within the foam structure effectively, ensuring long-term performance and dimensional stability.

Temperature sensitivity presents another challenge in the production and application of butane-modified structural foams. The low boiling point of butane (approximately -0.5°C) necessitates careful control of processing temperatures to prevent premature expansion or collapse of the foam structure. This requirement complicates manufacturing processes and limits the range of potential applications.

Environmental and safety concerns also contribute to the technical challenges faced by researchers and manufacturers. Butane is a flammable gas, which raises safety issues during production, storage, and transportation of the modified structural foam. Additionally, the potential environmental impact of butane emissions must be addressed to comply with increasingly stringent regulations.

The development of suitable analytical techniques for characterizing butane-modified structural foams presents another technical challenge. Existing methods may not adequately capture the unique properties and behavior of these materials, necessitating the development of new testing protocols and equipment.

Scalability and cost-effectiveness of production processes represent significant hurdles in the commercialization of butane-modified structural foams. Researchers must develop efficient manufacturing techniques that can maintain precise control over foam properties while being economically viable for large-scale production.

Lastly, the integration of butane-modified structural foams into existing product designs and manufacturing processes poses technical challenges. Engineers must address issues related to bonding, finishing, and compatibility with other materials to ensure seamless incorporation of these foams into various applications.

Another significant challenge lies in optimizing the interaction between butane and the polymer matrix. The compatibility of butane with different polymer types varies, affecting the foam's cellular structure and overall performance. Researchers must develop formulations that ensure proper dispersion of butane within the polymer melt and control its release during the foaming process.

The stability of butane-modified structural foam poses additional technical hurdles. As butane is a volatile compound, there is a risk of gas loss over time, potentially leading to dimensional instability and changes in the foam's properties. Engineers must devise strategies to encapsulate or retain the butane within the foam structure effectively, ensuring long-term performance and dimensional stability.

Temperature sensitivity presents another challenge in the production and application of butane-modified structural foams. The low boiling point of butane (approximately -0.5°C) necessitates careful control of processing temperatures to prevent premature expansion or collapse of the foam structure. This requirement complicates manufacturing processes and limits the range of potential applications.

Environmental and safety concerns also contribute to the technical challenges faced by researchers and manufacturers. Butane is a flammable gas, which raises safety issues during production, storage, and transportation of the modified structural foam. Additionally, the potential environmental impact of butane emissions must be addressed to comply with increasingly stringent regulations.

The development of suitable analytical techniques for characterizing butane-modified structural foams presents another technical challenge. Existing methods may not adequately capture the unique properties and behavior of these materials, necessitating the development of new testing protocols and equipment.

Scalability and cost-effectiveness of production processes represent significant hurdles in the commercialization of butane-modified structural foams. Researchers must develop efficient manufacturing techniques that can maintain precise control over foam properties while being economically viable for large-scale production.

Lastly, the integration of butane-modified structural foams into existing product designs and manufacturing processes poses technical challenges. Engineers must address issues related to bonding, finishing, and compatibility with other materials to ensure seamless incorporation of these foams into various applications.

Current Butane Methods

01 Density range and control methods

Structural foam density typically ranges from 0.3 to 0.8 g/cm³. Density can be controlled by adjusting the amount of blowing agent, processing parameters, and material composition. Lower densities offer weight reduction benefits, while higher densities provide improved mechanical properties.- Density range of structural foam: Structural foam typically has a density range from 0.3 to 0.9 g/cm³, depending on the specific application and manufacturing process. This low density provides a high strength-to-weight ratio, making it suitable for various industries including automotive, construction, and aerospace.

- Factors affecting structural foam density: The density of structural foam can be influenced by several factors, including the type of blowing agent used, the ratio of gas to polymer, processing temperature, and pressure. Adjusting these parameters allows manufacturers to achieve desired foam densities for specific applications.

- Relationship between density and mechanical properties: The density of structural foam directly impacts its mechanical properties. Generally, lower density foams offer better insulation and weight reduction, while higher density foams provide increased strength and stiffness. Balancing these properties is crucial for optimal performance in various applications.

- Density gradient in structural foam: Some structural foams exhibit a density gradient, with a higher density skin and a lower density core. This gradient structure can enhance the overall performance of the foam, providing a good balance between surface hardness and overall weight reduction.

- Controlling density in structural foam manufacturing: Various techniques are employed to control the density of structural foam during manufacturing. These include adjusting the amount of blowing agent, modifying processing parameters, and using specialized equipment. Advanced process control systems can help maintain consistent foam density throughout production.

02 Material selection for structural foam

Various thermoplastic and thermoset materials can be used for structural foam, including polypropylene, polyethylene, polystyrene, and polyurethane. The choice of material affects the final density and properties of the foam. Additives and fillers can be incorporated to modify density and enhance specific characteristics.Expand Specific Solutions03 Manufacturing processes for structural foam

Structural foam can be produced through various processes, including injection molding, extrusion, and reaction injection molding. Each method offers different control over foam density and structure. The choice of process depends on the desired product characteristics and production volume.Expand Specific Solutions04 Relationship between density and mechanical properties

The density of structural foam directly influences its mechanical properties. Lower density foams generally offer improved insulation and weight reduction, while higher density foams provide better strength and stiffness. Balancing density with desired mechanical properties is crucial for optimal performance in specific applications.Expand Specific Solutions05 Applications of structural foam with varying densities

Structural foams with different densities find applications in various industries. Low-density foams are used in automotive parts for weight reduction, while higher density foams are employed in load-bearing structures. The versatility of structural foam density allows for customization in packaging, construction, and consumer products.Expand Specific Solutions

Key Industry Players

The market for butane's role in modifying structural foam density is in a growth phase, driven by increasing demand for lightweight materials in various industries. The global market size is estimated to be in the billions, with steady expansion projected. Technologically, the field is moderately mature, with ongoing innovations. Key players like Evonik Operations GmbH, BASF Corp., and Bayer AG are at the forefront, leveraging their extensive R&D capabilities to develop advanced formulations. Companies such as Sunstar Suisse SA and Sekisui Plastics Industrial Materials are also making significant contributions, particularly in specialized applications. The competitive landscape is characterized by a mix of established chemical giants and niche players, with a focus on product differentiation and sustainability.

BASF Corp.

Technical Solution: BASF has developed a novel approach to modifying structural foam density using butane as a blowing agent. Their process involves incorporating butane into their Styropor® expandable polystyrene (EPS) beads. During the pre-expansion phase, the butane vaporizes, creating a cellular structure within the beads. The amount of butane used can be precisely controlled to achieve desired foam densities ranging from 10 to 300 kg/m³ [1]. BASF's technology allows for fine-tuning of the foam's properties, including thermal insulation, compressive strength, and dimensional stability. The company has also introduced Neopor®, an advanced version of EPS containing graphite particles, which further enhances insulation properties while maintaining the butane-based density modification technique [2].

Strengths: Precise control over foam density, wide density range achievable, improved thermal insulation properties. Weaknesses: Potential environmental concerns due to butane emissions, requires specialized equipment for safe handling of flammable blowing agents.

Bayer AG

Technical Solution: Bayer AG has developed a proprietary technology for modifying structural foam density using butane in conjunction with their polyurethane systems. Their approach involves a two-component system where butane is incorporated into the polyol component. During the mixing and reaction process, the butane acts as a physical blowing agent, expanding to create a cellular structure. Bayer's technology allows for real-time adjustment of butane content, enabling on-the-fly density modifications. This is particularly useful in applications requiring gradient density foams, such as automotive parts or insulation panels [3]. The company has also implemented a closed-loop butane recovery system to minimize emissions and improve process efficiency. Bayer's foams produced using this method exhibit excellent dimensional stability and consistent cell structure across a wide range of densities [4].

Strengths: Real-time density adjustment capability, suitable for gradient density applications, environmentally responsible butane recovery system. Weaknesses: Complex two-component system may require specialized training and equipment, potential safety concerns due to flammable nature of butane.

Core Butane Patents

Foams containing butene and ethylene

PatentWO2013190069A1

Innovation

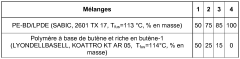

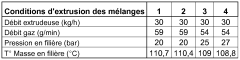

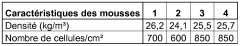

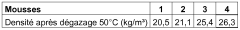

- Incorporating a polymer rich in butene-1 with a melting temperature less than 135 °C, either as a homopolymer or copolymer, into a mixture with a polymer rich in ethylene, to enhance flexibility and mechanical properties while maintaining excellent thermal insulation.

Environmental Impact

The use of butane in modifying structural foam density has significant environmental implications that warrant careful consideration. Butane, a hydrocarbon gas, is commonly employed as a blowing agent in the production of structural foams. While it offers advantages in terms of foam density control, its environmental impact is multifaceted and extends throughout the product lifecycle.

During the manufacturing process, the release of butane into the atmosphere contributes to the formation of ground-level ozone and smog. These air pollutants can have detrimental effects on human health and ecosystems. Additionally, butane is a volatile organic compound (VOC) that can contribute to indoor air pollution when released from finished foam products over time.

From a climate change perspective, butane is a greenhouse gas, albeit with a relatively short atmospheric lifetime compared to carbon dioxide. However, its global warming potential is still significant in the short term. The production and use of butane in foam manufacturing contribute to the overall carbon footprint of the industry, raising concerns about its long-term sustainability.

The disposal of structural foam products containing butane presents another environmental challenge. When these materials are incinerated or decompose in landfills, they release greenhouse gases and potentially harmful chemicals into the environment. This underscores the importance of developing effective recycling and waste management strategies for foam products.

On the positive side, the use of butane in structural foam production can lead to improved energy efficiency in buildings and vehicles where these materials are used for insulation. This indirect environmental benefit should be weighed against the direct impacts of butane use.

Regulatory bodies worldwide are increasingly scrutinizing the use of hydrocarbon blowing agents like butane. This has led to a push for alternative, more environmentally friendly options such as water-based blowing agents or natural substances. The industry is responding with research into bio-based and recyclable foam materials that could potentially mitigate some of the environmental concerns associated with butane use.

As environmental awareness grows, manufacturers are exploring ways to reduce butane emissions during production and improve the overall lifecycle assessment of structural foam products. This includes developing closed-loop manufacturing systems, enhancing material recovery processes, and investing in technologies that minimize the release of blowing agents into the atmosphere.

During the manufacturing process, the release of butane into the atmosphere contributes to the formation of ground-level ozone and smog. These air pollutants can have detrimental effects on human health and ecosystems. Additionally, butane is a volatile organic compound (VOC) that can contribute to indoor air pollution when released from finished foam products over time.

From a climate change perspective, butane is a greenhouse gas, albeit with a relatively short atmospheric lifetime compared to carbon dioxide. However, its global warming potential is still significant in the short term. The production and use of butane in foam manufacturing contribute to the overall carbon footprint of the industry, raising concerns about its long-term sustainability.

The disposal of structural foam products containing butane presents another environmental challenge. When these materials are incinerated or decompose in landfills, they release greenhouse gases and potentially harmful chemicals into the environment. This underscores the importance of developing effective recycling and waste management strategies for foam products.

On the positive side, the use of butane in structural foam production can lead to improved energy efficiency in buildings and vehicles where these materials are used for insulation. This indirect environmental benefit should be weighed against the direct impacts of butane use.

Regulatory bodies worldwide are increasingly scrutinizing the use of hydrocarbon blowing agents like butane. This has led to a push for alternative, more environmentally friendly options such as water-based blowing agents or natural substances. The industry is responding with research into bio-based and recyclable foam materials that could potentially mitigate some of the environmental concerns associated with butane use.

As environmental awareness grows, manufacturers are exploring ways to reduce butane emissions during production and improve the overall lifecycle assessment of structural foam products. This includes developing closed-loop manufacturing systems, enhancing material recovery processes, and investing in technologies that minimize the release of blowing agents into the atmosphere.

Safety Regulations

The use of butane in modifying structural foam density necessitates careful consideration of safety regulations to ensure the protection of workers, consumers, and the environment. Regulatory bodies such as the Occupational Safety and Health Administration (OSHA) and the Environmental Protection Agency (EPA) in the United States, as well as similar organizations in other countries, have established guidelines and standards for the handling, storage, and use of butane in industrial processes.

One of the primary safety concerns when working with butane is its high flammability. OSHA mandates specific requirements for the storage and handling of flammable gases, including proper ventilation, fire suppression systems, and the use of explosion-proof electrical equipment in areas where butane is present. Additionally, workers must be provided with appropriate personal protective equipment (PPE) and undergo regular safety training to mitigate risks associated with butane exposure.

The EPA regulates the emissions of volatile organic compounds (VOCs) from industrial processes, including those involving butane. Manufacturers using butane in structural foam production must comply with emission limits and implement control technologies to minimize the release of VOCs into the atmosphere. This may include the use of closed-loop systems, vapor recovery units, or other emission reduction techniques.

In the context of product safety, regulatory bodies such as the Consumer Product Safety Commission (CPSC) in the United States and the European Chemicals Agency (ECHA) in the European Union have established guidelines for the use of chemical substances in consumer products. These regulations often require manufacturers to assess and disclose the potential risks associated with the use of butane in structural foam products, particularly in applications where the foam may come into direct contact with consumers.

Transportation of butane and butane-containing products is subject to strict regulations governed by agencies such as the Department of Transportation (DOT) in the United States and the International Maritime Dangerous Goods (IMDG) Code for international shipments. These regulations specify requirements for packaging, labeling, and documentation to ensure safe transport and handling throughout the supply chain.

Compliance with these safety regulations is not only a legal requirement but also a crucial aspect of responsible manufacturing practices. Companies involved in the production of structural foam using butane must implement comprehensive safety management systems, conduct regular risk assessments, and maintain detailed documentation of their compliance efforts. This includes maintaining safety data sheets (SDS) for butane and any butane-containing products, as well as implementing emergency response plans in case of accidents or spills.

As the industry continues to evolve, regulatory bodies are likely to update and refine safety regulations related to butane use in structural foam production. Manufacturers must stay informed about these changes and adapt their processes accordingly to maintain compliance and ensure the safety of their operations, products, and stakeholders.

One of the primary safety concerns when working with butane is its high flammability. OSHA mandates specific requirements for the storage and handling of flammable gases, including proper ventilation, fire suppression systems, and the use of explosion-proof electrical equipment in areas where butane is present. Additionally, workers must be provided with appropriate personal protective equipment (PPE) and undergo regular safety training to mitigate risks associated with butane exposure.

The EPA regulates the emissions of volatile organic compounds (VOCs) from industrial processes, including those involving butane. Manufacturers using butane in structural foam production must comply with emission limits and implement control technologies to minimize the release of VOCs into the atmosphere. This may include the use of closed-loop systems, vapor recovery units, or other emission reduction techniques.

In the context of product safety, regulatory bodies such as the Consumer Product Safety Commission (CPSC) in the United States and the European Chemicals Agency (ECHA) in the European Union have established guidelines for the use of chemical substances in consumer products. These regulations often require manufacturers to assess and disclose the potential risks associated with the use of butane in structural foam products, particularly in applications where the foam may come into direct contact with consumers.

Transportation of butane and butane-containing products is subject to strict regulations governed by agencies such as the Department of Transportation (DOT) in the United States and the International Maritime Dangerous Goods (IMDG) Code for international shipments. These regulations specify requirements for packaging, labeling, and documentation to ensure safe transport and handling throughout the supply chain.

Compliance with these safety regulations is not only a legal requirement but also a crucial aspect of responsible manufacturing practices. Companies involved in the production of structural foam using butane must implement comprehensive safety management systems, conduct regular risk assessments, and maintain detailed documentation of their compliance efforts. This includes maintaining safety data sheets (SDS) for butane and any butane-containing products, as well as implementing emergency response plans in case of accidents or spills.

As the industry continues to evolve, regulatory bodies are likely to update and refine safety regulations related to butane use in structural foam production. Manufacturers must stay informed about these changes and adapt their processes accordingly to maintain compliance and ensure the safety of their operations, products, and stakeholders.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!