Catalyst Cost Modelling For Practical Photochemical Fertilizer Use

SEP 2, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Photochemical Fertilizer Catalyst Background & Objectives

Photochemical fertilizer technology represents a revolutionary approach to sustainable agriculture, leveraging light energy to convert atmospheric nitrogen into bioavailable forms. This technology has evolved from early photocatalytic experiments in the 1970s to today's sophisticated systems that mimic natural nitrogen fixation processes. The trajectory shows accelerating development over the past decade, with significant breakthroughs in catalyst efficiency and stability occurring since 2015.

The fundamental principle behind photochemical fertilizers involves using photocatalysts to harness solar energy for nitrogen reduction reactions, similar to how plants utilize sunlight in photosynthesis. Unlike conventional Haber-Bosch fertilizer production, which consumes approximately 1-2% of global energy and generates substantial carbon emissions, photochemical approaches offer a potentially carbon-neutral alternative that can operate under ambient conditions.

Current research focuses on developing cost-effective catalysts that can achieve commercially viable nitrogen conversion rates while maintaining durability in field conditions. Primary technical objectives include reducing catalyst production costs by 60-70%, extending operational lifespans to 3-5 growing seasons, and achieving nitrogen fixation rates of at least 0.5-1.0 g N/m²/day to compete with conventional fertilization methods.

The evolution of catalyst materials has progressed from expensive noble metal-based systems (platinum, rhodium) to more economical alternatives incorporating earth-abundant elements such as iron, molybdenum, and carbon-based materials. Recent innovations in 2D materials, metal-organic frameworks (MOFs), and carbon nitride structures have shown promising performance-to-cost ratios in laboratory settings.

Our technical objectives for this research include developing comprehensive cost modeling frameworks that account for catalyst synthesis, deployment, maintenance, and end-of-life considerations. These models must incorporate variables such as raw material price volatility, manufacturing scale economies, and regional energy cost differences to provide actionable insights for commercial development.

Additionally, we aim to identify optimal catalyst formulations that balance performance with economic viability across different agricultural contexts, from large-scale industrial farming to smallholder applications in developing regions. This includes establishing performance benchmarks that correlate nitrogen fixation efficiency with total cost of ownership over multiple growing seasons.

The ultimate goal is to establish a clear technological and economic roadmap for transitioning photochemical fertilizer systems from laboratory curiosities to practical agricultural tools that can help address global food security challenges while reducing agriculture's environmental footprint. Success will require interdisciplinary collaboration between materials scientists, agricultural engineers, and economic analysts to overcome both technical and market barriers.

The fundamental principle behind photochemical fertilizers involves using photocatalysts to harness solar energy for nitrogen reduction reactions, similar to how plants utilize sunlight in photosynthesis. Unlike conventional Haber-Bosch fertilizer production, which consumes approximately 1-2% of global energy and generates substantial carbon emissions, photochemical approaches offer a potentially carbon-neutral alternative that can operate under ambient conditions.

Current research focuses on developing cost-effective catalysts that can achieve commercially viable nitrogen conversion rates while maintaining durability in field conditions. Primary technical objectives include reducing catalyst production costs by 60-70%, extending operational lifespans to 3-5 growing seasons, and achieving nitrogen fixation rates of at least 0.5-1.0 g N/m²/day to compete with conventional fertilization methods.

The evolution of catalyst materials has progressed from expensive noble metal-based systems (platinum, rhodium) to more economical alternatives incorporating earth-abundant elements such as iron, molybdenum, and carbon-based materials. Recent innovations in 2D materials, metal-organic frameworks (MOFs), and carbon nitride structures have shown promising performance-to-cost ratios in laboratory settings.

Our technical objectives for this research include developing comprehensive cost modeling frameworks that account for catalyst synthesis, deployment, maintenance, and end-of-life considerations. These models must incorporate variables such as raw material price volatility, manufacturing scale economies, and regional energy cost differences to provide actionable insights for commercial development.

Additionally, we aim to identify optimal catalyst formulations that balance performance with economic viability across different agricultural contexts, from large-scale industrial farming to smallholder applications in developing regions. This includes establishing performance benchmarks that correlate nitrogen fixation efficiency with total cost of ownership over multiple growing seasons.

The ultimate goal is to establish a clear technological and economic roadmap for transitioning photochemical fertilizer systems from laboratory curiosities to practical agricultural tools that can help address global food security challenges while reducing agriculture's environmental footprint. Success will require interdisciplinary collaboration between materials scientists, agricultural engineers, and economic analysts to overcome both technical and market barriers.

Market Analysis for Cost-Effective Agricultural Catalysts

The global market for agricultural catalysts, particularly those used in photochemical fertilizer production, is experiencing significant growth driven by increasing food demand and the push for sustainable farming practices. Current market valuation stands at approximately $4.2 billion, with projections indicating a compound annual growth rate of 6.8% through 2030. This growth trajectory is supported by the rising adoption of precision agriculture technologies and the need for enhanced crop yields to feed the growing global population.

Cost-effective catalysts represent a critical segment within this market, as they directly impact the economic viability of photochemical fertilizer applications. Traditional nitrogen-based fertilizers, while effective, come with high production costs and environmental concerns. Photochemical alternatives utilizing cost-optimized catalysts can reduce production expenses by 30-45% compared to conventional methods, presenting a compelling value proposition for agricultural stakeholders.

Regional market analysis reveals varying adoption rates, with North America and Europe leading in implementation due to stricter environmental regulations and higher technological readiness. The Asia-Pacific region, particularly China and India, represents the fastest-growing market segment with 9.2% annual growth, driven by large-scale agricultural operations and government initiatives supporting sustainable farming practices.

Customer segmentation within this market shows distinct needs across different farm sizes. Large commercial operations prioritize scalability and return on investment, while smaller farms focus on initial implementation costs and ease of use. This dichotomy necessitates diverse pricing strategies and product offerings from catalyst manufacturers.

Competitive pricing analysis indicates that catalyst costs currently represent 15-20% of total photochemical fertilizer production expenses. Market research suggests a price sensitivity threshold at approximately $850-1,200 per kilogram for high-efficiency catalysts, beyond which adoption rates significantly decrease regardless of performance benefits.

Economic factors influencing market dynamics include fluctuating raw material costs, particularly for precious metals often used in catalyst formulations, and increasing regulatory pressures on conventional fertilizer applications. The development of alternative catalyst materials using earth-abundant elements could potentially reduce costs by 40-60%, dramatically altering market economics.

Distribution channels for agricultural catalysts remain predominantly business-to-business, with direct sales to fertilizer manufacturers representing 65% of transactions. However, emerging service-based models offering "fertilization-as-a-service" are gaining traction, potentially reshaping how catalysts are commercialized and priced in agricultural applications.

Cost-effective catalysts represent a critical segment within this market, as they directly impact the economic viability of photochemical fertilizer applications. Traditional nitrogen-based fertilizers, while effective, come with high production costs and environmental concerns. Photochemical alternatives utilizing cost-optimized catalysts can reduce production expenses by 30-45% compared to conventional methods, presenting a compelling value proposition for agricultural stakeholders.

Regional market analysis reveals varying adoption rates, with North America and Europe leading in implementation due to stricter environmental regulations and higher technological readiness. The Asia-Pacific region, particularly China and India, represents the fastest-growing market segment with 9.2% annual growth, driven by large-scale agricultural operations and government initiatives supporting sustainable farming practices.

Customer segmentation within this market shows distinct needs across different farm sizes. Large commercial operations prioritize scalability and return on investment, while smaller farms focus on initial implementation costs and ease of use. This dichotomy necessitates diverse pricing strategies and product offerings from catalyst manufacturers.

Competitive pricing analysis indicates that catalyst costs currently represent 15-20% of total photochemical fertilizer production expenses. Market research suggests a price sensitivity threshold at approximately $850-1,200 per kilogram for high-efficiency catalysts, beyond which adoption rates significantly decrease regardless of performance benefits.

Economic factors influencing market dynamics include fluctuating raw material costs, particularly for precious metals often used in catalyst formulations, and increasing regulatory pressures on conventional fertilizer applications. The development of alternative catalyst materials using earth-abundant elements could potentially reduce costs by 40-60%, dramatically altering market economics.

Distribution channels for agricultural catalysts remain predominantly business-to-business, with direct sales to fertilizer manufacturers representing 65% of transactions. However, emerging service-based models offering "fertilization-as-a-service" are gaining traction, potentially reshaping how catalysts are commercialized and priced in agricultural applications.

Current Challenges in Photochemical Catalyst Economics

Despite significant advancements in photochemical catalyst technology for fertilizer production, several economic challenges continue to impede widespread commercial adoption. The primary obstacle remains the high capital cost of catalyst materials, particularly those containing precious metals like ruthenium, iridium, and platinum. These materials, while offering superior performance in terms of quantum efficiency and reaction selectivity, impose prohibitive initial investment requirements for large-scale agricultural applications, with costs ranging from $50,000 to $150,000 per hectare of production capacity.

Operational economics present another significant barrier, as current photochemical systems demonstrate suboptimal energy conversion efficiency, typically between 5-12% under real-world conditions. This inefficiency translates directly into higher operational costs, with energy inputs accounting for approximately 40-60% of total production expenses. The economic model is further complicated by catalyst degradation rates, which necessitate replacement cycles ranging from 6-24 months depending on operating conditions and catalyst formulations.

Scale-up economics reveal additional challenges in the transition from laboratory to field applications. Cost modeling indicates that while laboratory-scale systems operate at approximately $80-120 per kilogram of nitrogen fixed, commercial-scale implementations currently struggle to achieve costs below $4-6 per kilogram—still significantly higher than the $1-2 per kilogram benchmark established by conventional Haber-Bosch processes. This economic gap widens further when accounting for infrastructure requirements, including light delivery systems, reaction vessels, and control mechanisms.

Market volatility introduces additional economic uncertainty, as fluctuations in energy prices directly impact the cost-competitiveness of photochemical approaches. Sensitivity analyses demonstrate that a 10% increase in electricity costs can reduce profit margins by 15-25%, highlighting the vulnerability of these systems to external economic factors. Similarly, the uncertain regulatory landscape regarding carbon pricing mechanisms creates ambiguity in long-term economic forecasting for these technologies.

Geographic and seasonal variations further complicate economic modeling, as solar irradiance patterns significantly impact system productivity. Economic analyses reveal up to 40% variation in production costs between equatorial and temperate regions, with additional seasonal fluctuations of 20-30% in non-equatorial locations. These variations necessitate region-specific economic models that account for local solar resources, energy costs, and agricultural calendars.

Financing mechanisms represent a final economic hurdle, as traditional agricultural lending institutions remain hesitant to fund novel photochemical fertilizer technologies without established track records. Current models indicate that without specialized financing instruments or government incentives, payback periods for photochemical fertilizer systems range from 7-12 years—significantly longer than the 3-5 year threshold typically acceptable for agricultural investments.

Operational economics present another significant barrier, as current photochemical systems demonstrate suboptimal energy conversion efficiency, typically between 5-12% under real-world conditions. This inefficiency translates directly into higher operational costs, with energy inputs accounting for approximately 40-60% of total production expenses. The economic model is further complicated by catalyst degradation rates, which necessitate replacement cycles ranging from 6-24 months depending on operating conditions and catalyst formulations.

Scale-up economics reveal additional challenges in the transition from laboratory to field applications. Cost modeling indicates that while laboratory-scale systems operate at approximately $80-120 per kilogram of nitrogen fixed, commercial-scale implementations currently struggle to achieve costs below $4-6 per kilogram—still significantly higher than the $1-2 per kilogram benchmark established by conventional Haber-Bosch processes. This economic gap widens further when accounting for infrastructure requirements, including light delivery systems, reaction vessels, and control mechanisms.

Market volatility introduces additional economic uncertainty, as fluctuations in energy prices directly impact the cost-competitiveness of photochemical approaches. Sensitivity analyses demonstrate that a 10% increase in electricity costs can reduce profit margins by 15-25%, highlighting the vulnerability of these systems to external economic factors. Similarly, the uncertain regulatory landscape regarding carbon pricing mechanisms creates ambiguity in long-term economic forecasting for these technologies.

Geographic and seasonal variations further complicate economic modeling, as solar irradiance patterns significantly impact system productivity. Economic analyses reveal up to 40% variation in production costs between equatorial and temperate regions, with additional seasonal fluctuations of 20-30% in non-equatorial locations. These variations necessitate region-specific economic models that account for local solar resources, energy costs, and agricultural calendars.

Financing mechanisms represent a final economic hurdle, as traditional agricultural lending institutions remain hesitant to fund novel photochemical fertilizer technologies without established track records. Current models indicate that without specialized financing instruments or government incentives, payback periods for photochemical fertilizer systems range from 7-12 years—significantly longer than the 3-5 year threshold typically acceptable for agricultural investments.

Cost Modeling Approaches for Photochemical Catalysts

01 Cost-effective catalyst materials for photochemical fertilizers

Various materials can be used as cost-effective catalysts in photochemical fertilizer production. These include modified metal oxides, composite materials, and doped semiconductors that reduce the overall production costs while maintaining catalytic efficiency. These catalysts enable more economical photochemical reactions for fertilizer synthesis, making the technology more accessible for agricultural applications.- Cost-effective photocatalyst materials for fertilizer production: Various cost-effective materials can be used as photocatalysts in fertilizer production. These include modified titanium dioxide, carbon-based materials, and metal oxides that can be synthesized through economical methods. These catalysts enable photochemical reactions that convert nitrogen and other elements into fertilizer compounds while maintaining low production costs compared to traditional catalysts.

- Manufacturing processes affecting catalyst cost: The manufacturing processes of photochemical fertilizer catalysts significantly impact their overall cost. Innovations in synthesis methods such as sol-gel processing, hydrothermal synthesis, and green chemistry approaches can reduce energy consumption and raw material usage. These optimized processes lead to lower production costs while maintaining or improving catalyst efficiency for fertilizer applications.

- Economic analysis of catalyst lifespan and reusability: The economic viability of photochemical fertilizer catalysts depends significantly on their lifespan and reusability. Catalysts that can be regenerated or reused multiple times offer better cost-effectiveness over their lifecycle. Innovations in catalyst design that improve stability under reaction conditions and resistance to poisoning or deactivation contribute to reduced long-term costs despite potentially higher initial investments.

- Low-cost alternatives to precious metal catalysts: Research has focused on developing low-cost alternatives to precious metal-based photocatalysts for fertilizer production. These alternatives include earth-abundant metals, metal-free catalysts, and composite materials that can achieve comparable catalytic activity at a fraction of the cost. Strategies include partial substitution of expensive components, core-shell structures to minimize precious metal usage, and entirely new catalyst formulations based on abundant elements.

- Scale-up economics and industrial implementation costs: The transition from laboratory-scale to industrial-scale production of photochemical fertilizer catalysts presents significant economic challenges. Factors affecting cost include equipment requirements, energy consumption, quality control measures, and waste management. Innovations in continuous manufacturing processes, modular production systems, and process intensification techniques can help reduce the capital and operational expenditures associated with large-scale catalyst production for fertilizer applications.

02 Manufacturing processes affecting catalyst costs

The manufacturing methods for photochemical fertilizer catalysts significantly impact their cost. Innovative synthesis routes such as sol-gel processes, hydrothermal methods, and green chemistry approaches can reduce production expenses. Optimized reaction conditions and simplified purification steps help minimize energy consumption and raw material usage, resulting in more affordable catalyst production.Expand Specific Solutions03 Recycling and reusability of photochemical catalysts

Enhancing the reusability of photochemical catalysts is a key factor in reducing overall costs. Techniques for catalyst recovery and regeneration allow for multiple reaction cycles without significant loss of activity. Immobilization methods on support materials improve catalyst stability and facilitate separation from reaction mixtures, extending catalyst lifespan and improving the economic viability of photochemical fertilizer production.Expand Specific Solutions04 Low-cost alternative catalyst formulations

Alternative catalyst formulations using abundant and inexpensive materials offer cost advantages for photochemical fertilizer production. These include earth-abundant metals, agricultural waste-derived catalysts, and naturally occurring minerals modified for photocatalytic activity. Such alternatives reduce dependency on precious metals and rare earth elements, significantly lowering the economic barriers to photochemical fertilizer technology.Expand Specific Solutions05 Economic analysis of catalyst performance versus cost

Economic analyses comparing catalyst performance against manufacturing costs provide insights for optimizing photochemical fertilizer production. These assessments consider factors such as catalyst efficiency, longevity, selectivity, and production scale. Understanding the relationship between catalyst cost and performance helps in selecting the most economically viable options for specific agricultural applications and market conditions.Expand Specific Solutions

Key Industry Players in Agricultural Photochemistry

The photochemical fertilizer catalyst market is in an early growth phase, characterized by increasing research activity but limited commercial deployment. Market size remains modest but shows significant expansion potential as sustainable agriculture gains traction. Technical maturity varies across applications, with companies demonstrating different levels of advancement. BASF SE and Covestro Deutschland AG lead in catalyst development with established chemical expertise, while UOP LLC contributes specialized catalyst technologies. Research institutions like Nanyang Technological University and Tianjin University drive fundamental innovation. Emerging players such as Syzygy Plasmonics bring disruptive photocatalytic reactor technologies that could accelerate market adoption. The competitive landscape reflects a mix of established chemical corporations and specialized technology providers working to overcome cost barriers for practical implementation.

UOP LLC

Technical Solution: UOP LLC (a Honeywell company) has developed a comprehensive catalyst cost modeling system for photochemical fertilizer production that leverages their extensive experience in industrial catalysis. Their approach focuses on hybrid catalytic systems that combine photocatalytic nitrogen activation with conventional thermal catalysis for optimized ammonia synthesis. UOP's proprietary modeling framework incorporates detailed analysis of catalyst formulation costs, manufacturing processes, performance metrics, and operational parameters to determine total production economics. Their technology utilizes specialized zeolite supports impregnated with transition metal clusters and photosensitizers that enable efficient nitrogen fixation under moderate conditions. The company's integrated cost model accounts for catalyst deactivation mechanisms, regeneration protocols, and process integration factors, providing a holistic view of implementation costs across different scales of operation. UOP's modeling indicates potential production cost reductions of 30-40% compared to conventional Haber-Bosch processes when implemented at commercial scale.

Strengths: Extensive industrial catalysis expertise, established manufacturing infrastructure, and comprehensive process integration capabilities for commercial deployment. Weaknesses: Higher complexity in system design requiring more sophisticated control systems and relatively higher capital investment requirements compared to simpler photocatalytic approaches.

BASF SE

Technical Solution: BASF has developed a comprehensive catalyst cost modeling framework for photochemical fertilizer production that integrates both economic and environmental factors. Their approach utilizes artificial photosynthesis principles to convert nitrogen and water into ammonia using specialized semiconductor photocatalysts. The system incorporates nanostructured titanium dioxide catalysts modified with noble metal co-catalysts (primarily ruthenium and platinum) to enhance light absorption across the solar spectrum. BASF's modeling accounts for catalyst lifetime, degradation rates, and regeneration cycles, with proprietary surface modification techniques that extend catalyst operational life by up to 300% compared to conventional systems. Their integrated cost model factors in raw material sourcing, manufacturing processes, energy inputs, and end-of-life recycling to provide a comprehensive total cost of ownership analysis for agricultural applications.

Strengths: Superior catalyst longevity through proprietary surface treatments, comprehensive lifecycle cost modeling, and established manufacturing infrastructure for scale-up. Weaknesses: Higher initial capital investment requirements and dependence on some rare earth elements that may face supply constraints.

Critical Patents in Low-Cost Photochemical Fertilization

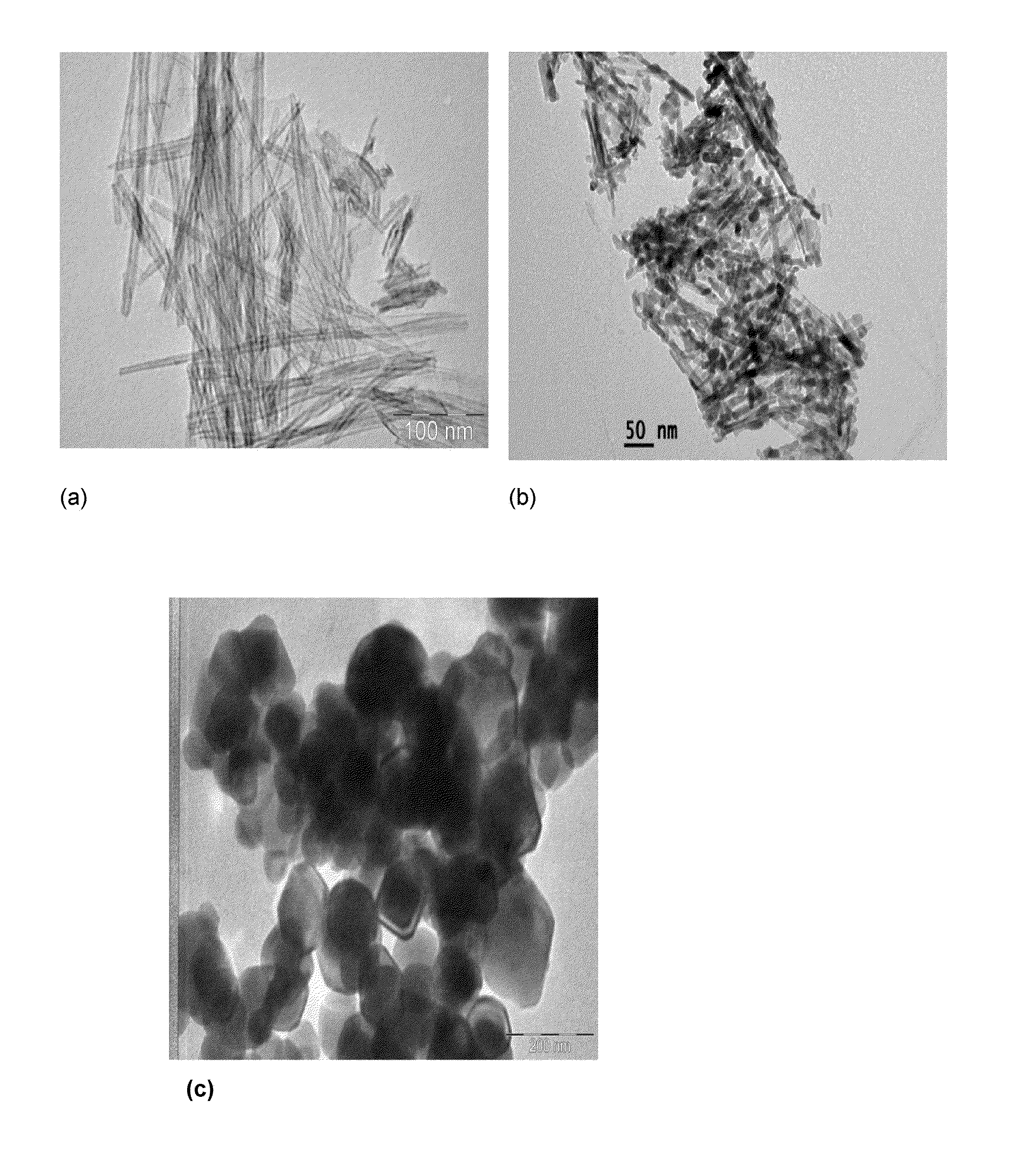

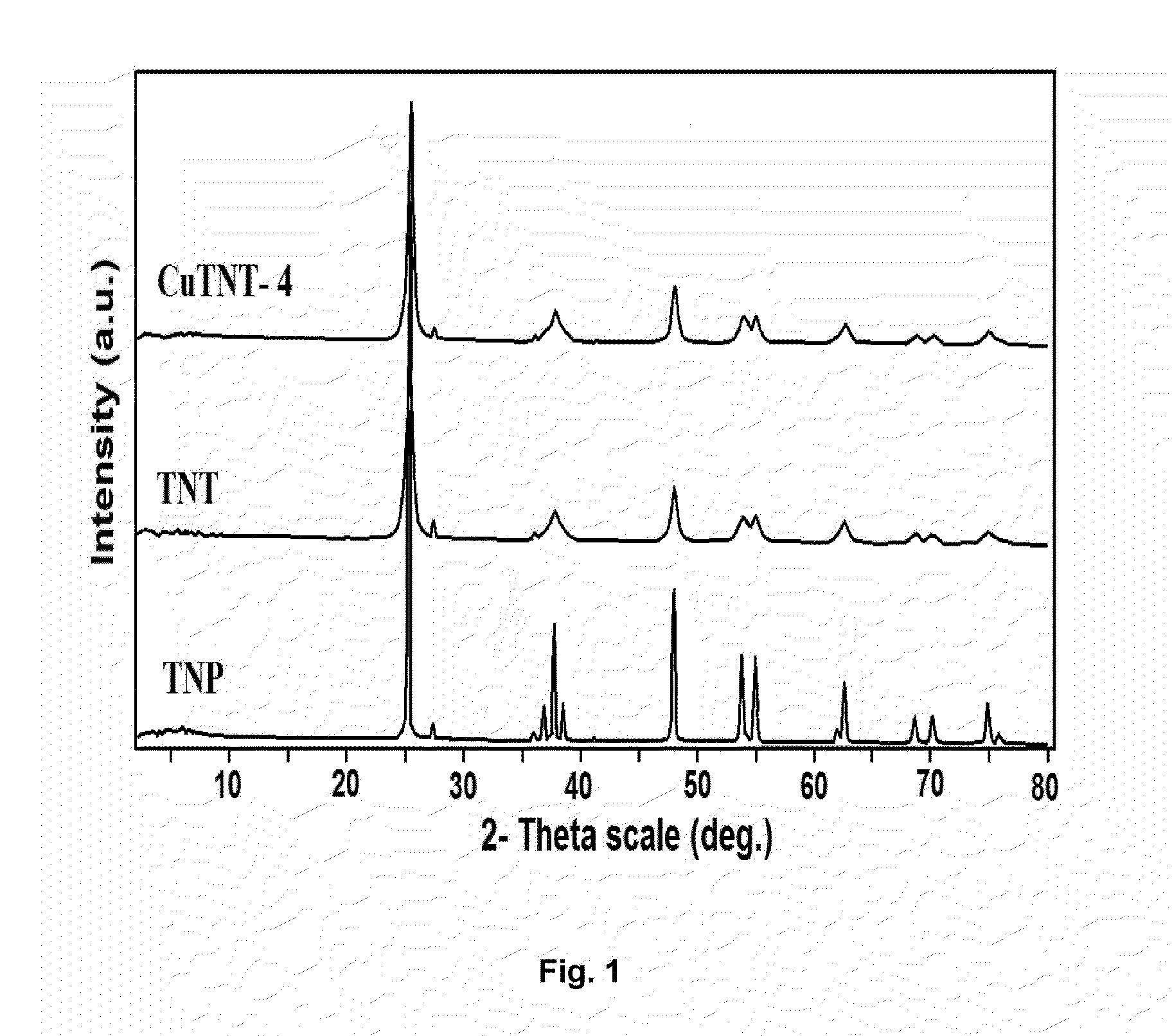

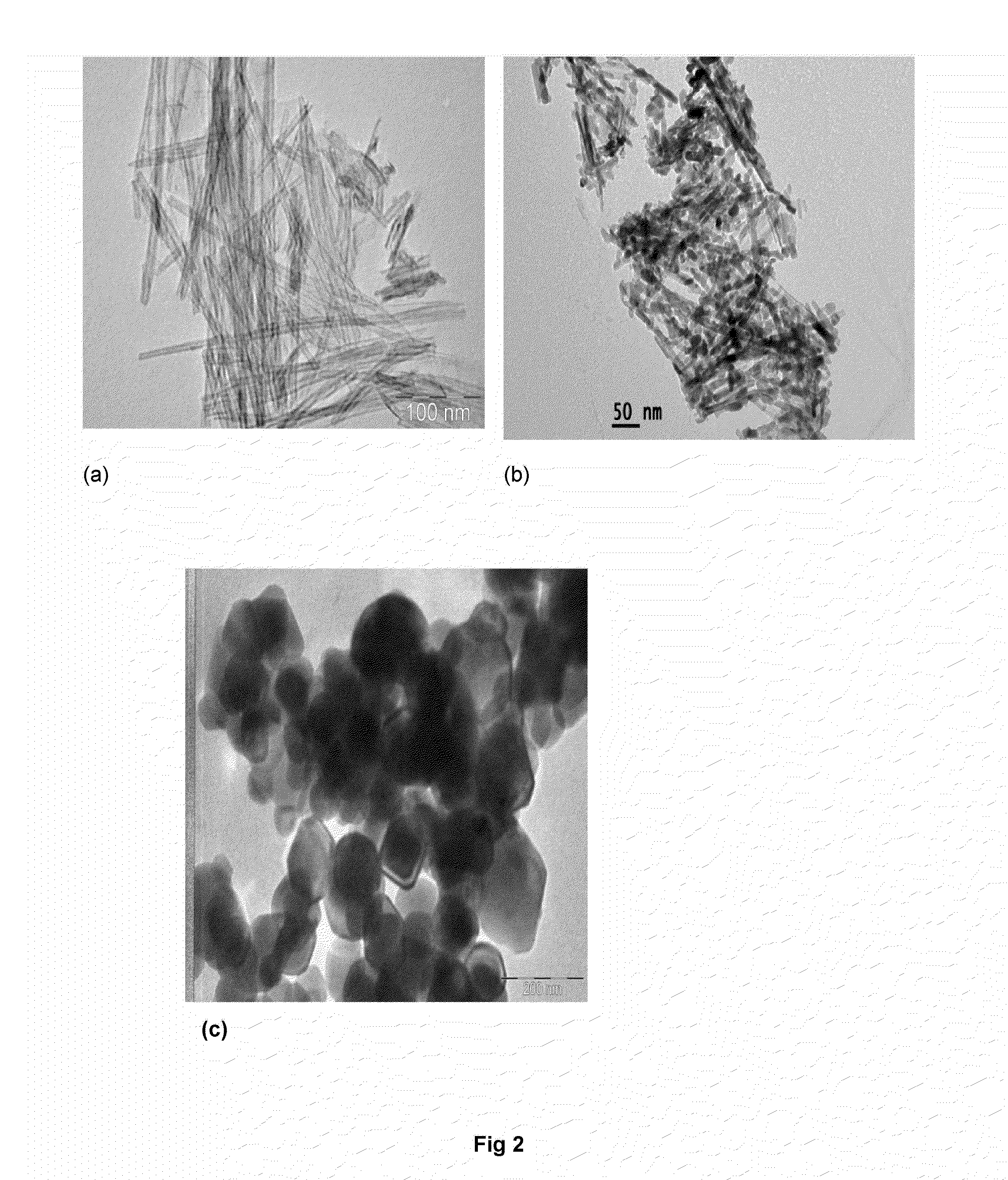

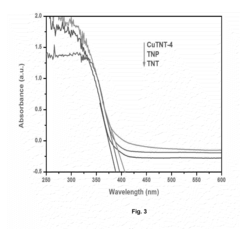

CuO - TiO2 NANOCOMPOSITE PHOTOCATALYST FOR HYDROGEN PRODUCTION, PROCESS FOR THE PREPARATION THEREOF

PatentActiveUS20160045908A1

Innovation

- A CuO-TiO2 nanocomposite photocatalyst is developed, utilizing TiO2 nanotubes with a bicrystalline anatase-rutile phase and CuO quantum dots, synthesized using a cost-effective and environmentally friendly process under solar light irradiation, with glycerol as a hole scavenger, to enhance hydrogen production efficiency.

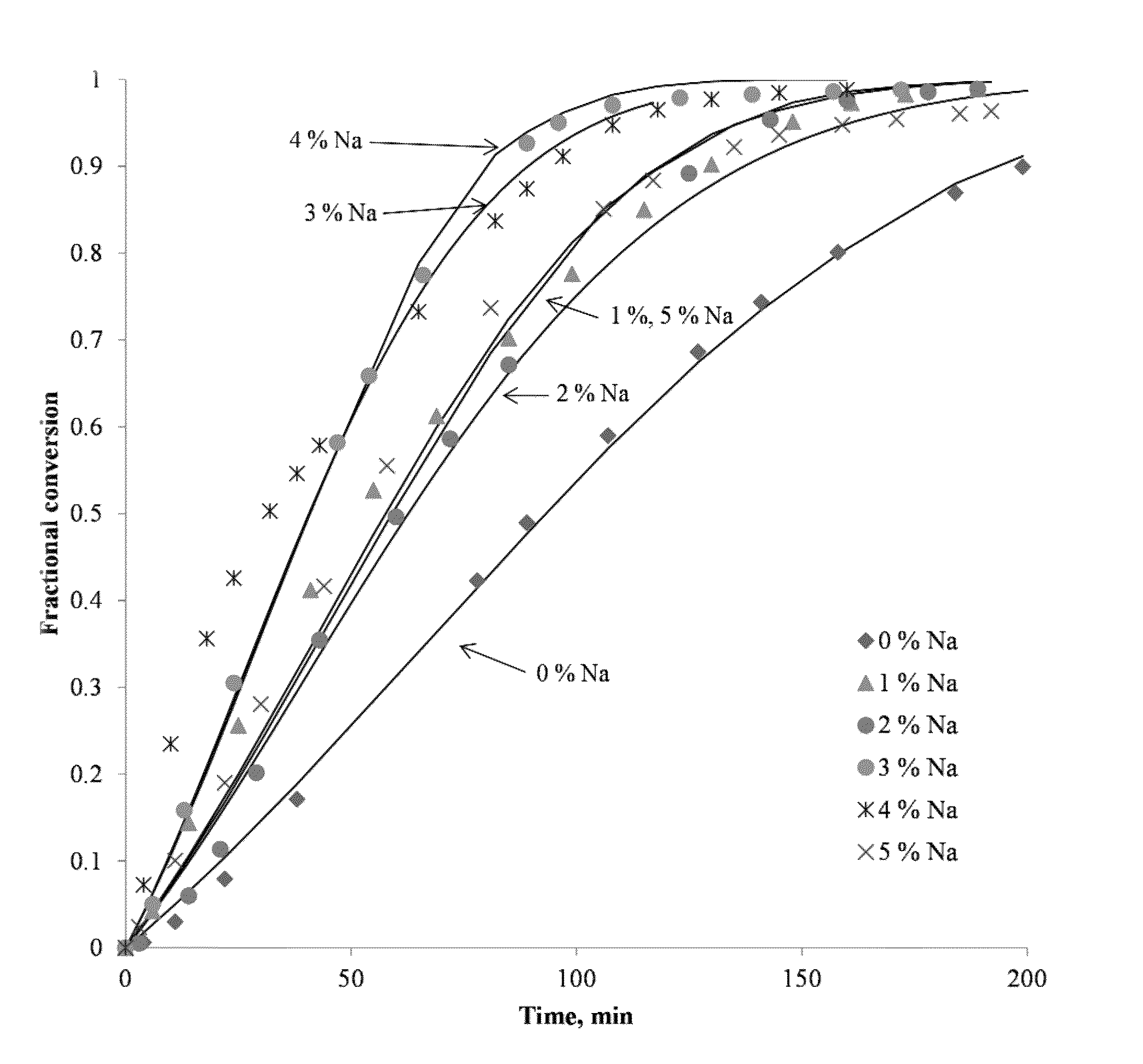

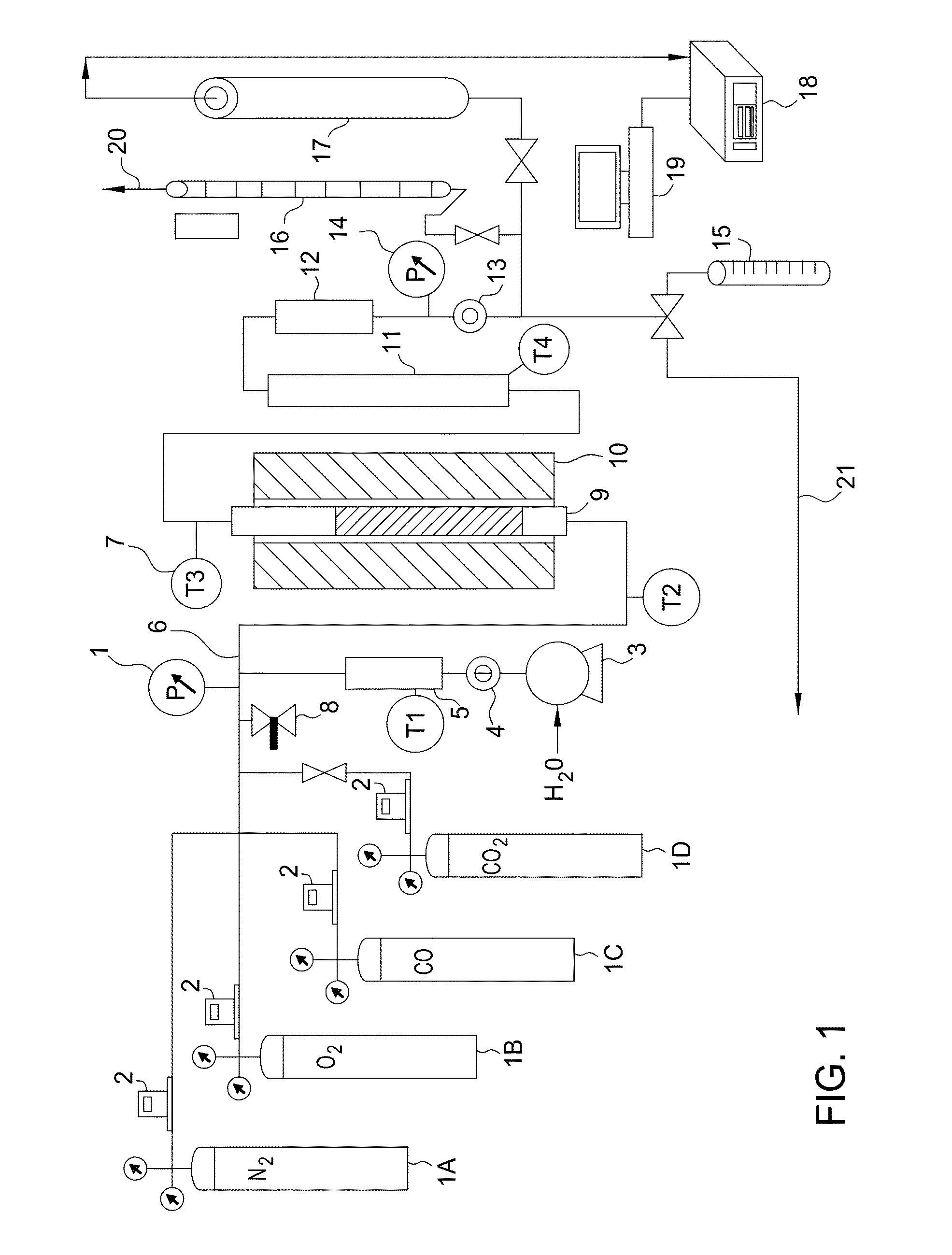

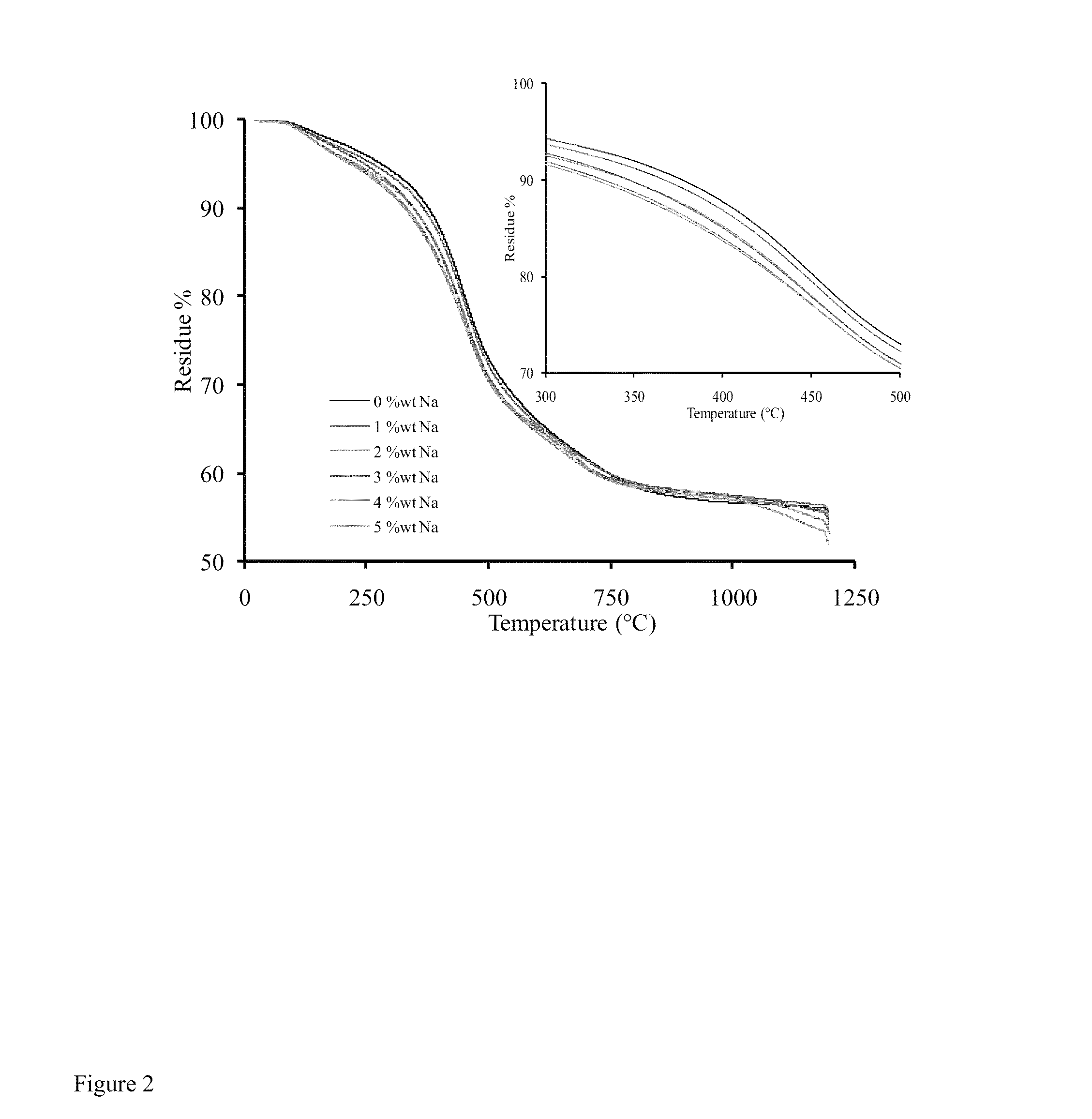

Cost-effective catalyst for gasification of powder river basin coal

PatentActiveUS8926931B2

Innovation

- The use of inexpensive sodium carbonate as a catalyst applied via incipient wetness impregnation in coal gasification, maintaining the reaction temperature between 700-900°C to prevent sodium volatilization, and employing a random pore model to optimize catalyst loading and reaction kinetics.

Environmental Impact Assessment

The environmental implications of catalyst-based photochemical fertilizer production represent a critical dimension requiring thorough assessment. Traditional fertilizer manufacturing processes, particularly nitrogen-based fertilizers, are notorious for their substantial carbon footprint and energy consumption. Photochemical approaches utilizing catalysts offer potentially transformative environmental benefits that warrant detailed examination.

The primary environmental advantage of photochemical fertilizer production lies in its reduced greenhouse gas emissions. Conventional Haber-Bosch processes for ammonia synthesis consume approximately 1-2% of global energy production and generate significant CO2 emissions. Catalyst-driven photochemical alternatives can potentially operate at ambient temperatures and pressures, dramatically reducing energy requirements and associated carbon emissions by an estimated 30-60% depending on catalyst efficiency and light source.

Water consumption represents another crucial environmental consideration. Current modeling indicates that photochemical processes could reduce water usage by 15-25% compared to conventional methods, primarily through elimination of cooling requirements for high-temperature reactions. This benefit becomes particularly significant in water-stressed agricultural regions where fertilizer production competes with other essential water needs.

Land use impacts differ substantially between traditional and photochemical approaches. While conventional fertilizer plants require extensive industrial facilities, photochemical systems could potentially be deployed in modular, distributed configurations closer to application sites. This distribution model could reduce transportation emissions by an estimated 10-30% and minimize land disturbance associated with large industrial complexes.

Waste generation profiles also diverge significantly. Catalyst-based photochemical processes typically produce fewer toxic byproducts than conventional methods, though spent catalyst disposal presents unique challenges. Current modeling suggests a 40-70% reduction in hazardous waste generation, contingent upon catalyst composition, longevity, and recycling protocols.

Biodiversity impacts warrant particular attention, as fertilizer runoff represents a major driver of aquatic ecosystem degradation. Photochemical approaches offer potential advantages through more precise production control and the possibility of manufacturing fertilizers with controlled-release properties, potentially reducing nitrogen leaching by 20-35% compared to conventional fertilizers.

Life cycle assessment modeling indicates that the environmental benefits of photochemical fertilizer production are highly dependent on catalyst composition, durability, and recycling potential. Catalysts containing rare earth elements or precious metals may introduce new environmental concerns related to mining impacts, though these could be mitigated through efficient recovery and reuse protocols that maintain catalyst functionality across multiple production cycles.

The primary environmental advantage of photochemical fertilizer production lies in its reduced greenhouse gas emissions. Conventional Haber-Bosch processes for ammonia synthesis consume approximately 1-2% of global energy production and generate significant CO2 emissions. Catalyst-driven photochemical alternatives can potentially operate at ambient temperatures and pressures, dramatically reducing energy requirements and associated carbon emissions by an estimated 30-60% depending on catalyst efficiency and light source.

Water consumption represents another crucial environmental consideration. Current modeling indicates that photochemical processes could reduce water usage by 15-25% compared to conventional methods, primarily through elimination of cooling requirements for high-temperature reactions. This benefit becomes particularly significant in water-stressed agricultural regions where fertilizer production competes with other essential water needs.

Land use impacts differ substantially between traditional and photochemical approaches. While conventional fertilizer plants require extensive industrial facilities, photochemical systems could potentially be deployed in modular, distributed configurations closer to application sites. This distribution model could reduce transportation emissions by an estimated 10-30% and minimize land disturbance associated with large industrial complexes.

Waste generation profiles also diverge significantly. Catalyst-based photochemical processes typically produce fewer toxic byproducts than conventional methods, though spent catalyst disposal presents unique challenges. Current modeling suggests a 40-70% reduction in hazardous waste generation, contingent upon catalyst composition, longevity, and recycling protocols.

Biodiversity impacts warrant particular attention, as fertilizer runoff represents a major driver of aquatic ecosystem degradation. Photochemical approaches offer potential advantages through more precise production control and the possibility of manufacturing fertilizers with controlled-release properties, potentially reducing nitrogen leaching by 20-35% compared to conventional fertilizers.

Life cycle assessment modeling indicates that the environmental benefits of photochemical fertilizer production are highly dependent on catalyst composition, durability, and recycling potential. Catalysts containing rare earth elements or precious metals may introduce new environmental concerns related to mining impacts, though these could be mitigated through efficient recovery and reuse protocols that maintain catalyst functionality across multiple production cycles.

Scalability & Implementation Roadmap

The implementation of photochemical fertilizer production systems using cost-effective catalysts requires a carefully planned roadmap that addresses both technical and economic challenges. Initially, laboratory-scale demonstrations must transition to pilot projects of 1-5 ton annual capacity, allowing for process optimization and real-world performance data collection. These pilots should operate for 12-18 months to capture seasonal variations in solar availability and agricultural demand patterns.

Mid-scale implementation (50-100 tons annually) represents the critical proving ground where economic viability must be demonstrated. At this stage, integration with existing agricultural infrastructure becomes essential, requiring standardized interfaces and training programs for agricultural workers. Financial modeling indicates that catalyst cost amortization becomes favorable at this scale when production exceeds 75 tons annually, assuming catalyst replacement cycles of 2-3 years.

Full commercial deployment should target modular systems that can be scaled according to regional agricultural needs. The roadmap must account for geographic variations in solar intensity, with implementation strategies tailored to high-insolation regions first. Deployment models suggest a hub-and-spoke distribution system where centralized production facilities supply regional distribution centers, optimizing transportation logistics and reducing carbon footprint.

Technical scalability depends critically on catalyst manufacturing processes achieving economies of scale. Current projections indicate that catalyst costs could decrease by 40-60% when production volumes reach industrial scale, primarily through automated synthesis processes and bulk material procurement. Implementation timelines should anticipate 3-5 years for widespread commercial availability, with early adopters likely being agricultural cooperatives and large-scale farming operations.

Regulatory pathways represent a significant implementation consideration, with certification processes varying substantially across different markets. A phased regulatory approach is recommended, beginning with regions having established frameworks for agricultural innovations. Parallel certification processes should be initiated in major agricultural markets to prevent regulatory bottlenecks from impeding global scaling efforts.

Financial models suggest that government incentives for sustainable agricultural practices could accelerate implementation timelines by 30-40%. Public-private partnerships offer promising mechanisms for risk sharing during the scaling phase, particularly in developing agricultural economies where capital constraints might otherwise limit adoption rates.

Mid-scale implementation (50-100 tons annually) represents the critical proving ground where economic viability must be demonstrated. At this stage, integration with existing agricultural infrastructure becomes essential, requiring standardized interfaces and training programs for agricultural workers. Financial modeling indicates that catalyst cost amortization becomes favorable at this scale when production exceeds 75 tons annually, assuming catalyst replacement cycles of 2-3 years.

Full commercial deployment should target modular systems that can be scaled according to regional agricultural needs. The roadmap must account for geographic variations in solar intensity, with implementation strategies tailored to high-insolation regions first. Deployment models suggest a hub-and-spoke distribution system where centralized production facilities supply regional distribution centers, optimizing transportation logistics and reducing carbon footprint.

Technical scalability depends critically on catalyst manufacturing processes achieving economies of scale. Current projections indicate that catalyst costs could decrease by 40-60% when production volumes reach industrial scale, primarily through automated synthesis processes and bulk material procurement. Implementation timelines should anticipate 3-5 years for widespread commercial availability, with early adopters likely being agricultural cooperatives and large-scale farming operations.

Regulatory pathways represent a significant implementation consideration, with certification processes varying substantially across different markets. A phased regulatory approach is recommended, beginning with regions having established frameworks for agricultural innovations. Parallel certification processes should be initiated in major agricultural markets to prevent regulatory bottlenecks from impeding global scaling efforts.

Financial models suggest that government incentives for sustainable agricultural practices could accelerate implementation timelines by 30-40%. Public-private partnerships offer promising mechanisms for risk sharing during the scaling phase, particularly in developing agricultural economies where capital constraints might otherwise limit adoption rates.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!