High-Throughput Photoreactor Platforms For Catalyst Screening

SEP 2, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Photocatalysis Background and Research Objectives

Photocatalysis has emerged as a transformative technology in the field of sustainable chemistry, offering pathways to harness light energy for driving chemical reactions under mild conditions. The concept dates back to the early 1970s with the pioneering work of Fujishima and Honda on photocatalytic water splitting using titanium dioxide. Since then, the field has expanded dramatically, encompassing applications in environmental remediation, renewable energy production, and organic synthesis.

The evolution of photocatalysis has been marked by several significant milestones, including the development of visible-light-responsive catalysts, plasmonic photocatalysts, and heterojunction systems that enhance charge separation efficiency. Recent years have witnessed a paradigm shift from traditional bulk materials to nanoscale architectures, which offer superior surface area and light absorption properties, thereby improving catalytic performance.

Current research trends indicate a growing interest in developing photocatalysts capable of performing complex transformations with high selectivity and efficiency. This includes C-H activation, CO2 reduction, nitrogen fixation, and water splitting reactions. The integration of photocatalysis with other emerging technologies, such as flow chemistry and artificial intelligence, represents a frontier with immense potential for accelerating discovery and optimization processes.

The primary objective of our research into High-Throughput Photoreactor Platforms is to address the critical bottleneck in photocatalyst development: the time-consuming and resource-intensive nature of traditional screening methods. By establishing advanced platforms capable of parallel evaluation of multiple catalyst candidates under standardized conditions, we aim to dramatically accelerate the discovery and optimization of novel photocatalytic materials and systems.

Specifically, our technical goals include designing modular photoreactor arrays that can accommodate diverse reaction conditions, developing integrated analytical systems for real-time monitoring of reaction progress, and implementing data management frameworks that facilitate rapid analysis and interpretation of experimental results. These platforms must ensure uniform light distribution, precise temperature control, and accurate dosing of reactants to generate reliable and reproducible data.

Furthermore, we seek to establish standardized protocols for catalyst preparation, characterization, and performance evaluation to enable meaningful comparisons across different material systems. The ultimate vision is to create an ecosystem where high-throughput experimentation, computational modeling, and machine learning algorithms work synergistically to guide the rational design of next-generation photocatalysts with tailored properties for specific applications.

This research aligns with broader sustainability initiatives by potentially enabling more efficient utilization of renewable resources and reducing the environmental footprint of chemical manufacturing processes through the development of more active and selective photocatalytic systems.

The evolution of photocatalysis has been marked by several significant milestones, including the development of visible-light-responsive catalysts, plasmonic photocatalysts, and heterojunction systems that enhance charge separation efficiency. Recent years have witnessed a paradigm shift from traditional bulk materials to nanoscale architectures, which offer superior surface area and light absorption properties, thereby improving catalytic performance.

Current research trends indicate a growing interest in developing photocatalysts capable of performing complex transformations with high selectivity and efficiency. This includes C-H activation, CO2 reduction, nitrogen fixation, and water splitting reactions. The integration of photocatalysis with other emerging technologies, such as flow chemistry and artificial intelligence, represents a frontier with immense potential for accelerating discovery and optimization processes.

The primary objective of our research into High-Throughput Photoreactor Platforms is to address the critical bottleneck in photocatalyst development: the time-consuming and resource-intensive nature of traditional screening methods. By establishing advanced platforms capable of parallel evaluation of multiple catalyst candidates under standardized conditions, we aim to dramatically accelerate the discovery and optimization of novel photocatalytic materials and systems.

Specifically, our technical goals include designing modular photoreactor arrays that can accommodate diverse reaction conditions, developing integrated analytical systems for real-time monitoring of reaction progress, and implementing data management frameworks that facilitate rapid analysis and interpretation of experimental results. These platforms must ensure uniform light distribution, precise temperature control, and accurate dosing of reactants to generate reliable and reproducible data.

Furthermore, we seek to establish standardized protocols for catalyst preparation, characterization, and performance evaluation to enable meaningful comparisons across different material systems. The ultimate vision is to create an ecosystem where high-throughput experimentation, computational modeling, and machine learning algorithms work synergistically to guide the rational design of next-generation photocatalysts with tailored properties for specific applications.

This research aligns with broader sustainability initiatives by potentially enabling more efficient utilization of renewable resources and reducing the environmental footprint of chemical manufacturing processes through the development of more active and selective photocatalytic systems.

Market Analysis for High-Throughput Screening Technologies

The high-throughput screening (HTS) technologies market has experienced substantial growth over the past decade, driven primarily by pharmaceutical research and development needs. However, recent years have witnessed an expansion into materials science and catalysis research, particularly in photocatalyst development. The global HTS market was valued at approximately $16.9 billion in 2022 and is projected to reach $28.4 billion by 2027, growing at a compound annual growth rate (CAGR) of 10.9%.

Within this broader market, photocatalyst screening platforms represent an emerging segment with significant growth potential. The increasing focus on sustainable chemistry, renewable energy solutions, and environmental remediation has created strong demand for advanced photocatalytic materials, thereby driving the need for efficient screening technologies.

The pharmaceutical industry remains the largest end-user of HTS technologies, accounting for roughly 45% of the market share. However, academic research institutions and materials science companies are rapidly increasing their adoption of these technologies, particularly for catalyst discovery. This shift is evidenced by the 18% year-over-year increase in research publications related to high-throughput photocatalyst screening between 2018 and 2022.

Geographically, North America dominates the market with approximately 38% share, followed by Europe (29%) and Asia-Pacific (24%). The Asia-Pacific region, particularly China and Japan, is experiencing the fastest growth rate due to increasing investments in renewable energy research and materials science infrastructure.

Key market drivers include the rising demand for sustainable chemical processes, stringent environmental regulations promoting green chemistry, and the need to accelerate materials discovery to address climate change challenges. Additionally, the integration of artificial intelligence and machine learning with HTS platforms is creating new market opportunities by enhancing screening efficiency and predictive capabilities.

Market restraints include the high initial investment required for advanced photoreactor platforms, technical challenges in standardizing testing conditions across different catalyst types, and the specialized expertise needed to operate and interpret results from these systems. These factors have limited adoption primarily to large research institutions and well-funded commercial entities.

Customer segments for photoreactor screening platforms include academic research laboratories (32%), chemical and materials companies (28%), pharmaceutical firms exploring photocatalytic synthesis routes (15%), energy companies (14%), and environmental technology developers (11%). The diverse application potential across multiple industries suggests significant cross-sector market growth opportunities for versatile, adaptable screening platforms.

Within this broader market, photocatalyst screening platforms represent an emerging segment with significant growth potential. The increasing focus on sustainable chemistry, renewable energy solutions, and environmental remediation has created strong demand for advanced photocatalytic materials, thereby driving the need for efficient screening technologies.

The pharmaceutical industry remains the largest end-user of HTS technologies, accounting for roughly 45% of the market share. However, academic research institutions and materials science companies are rapidly increasing their adoption of these technologies, particularly for catalyst discovery. This shift is evidenced by the 18% year-over-year increase in research publications related to high-throughput photocatalyst screening between 2018 and 2022.

Geographically, North America dominates the market with approximately 38% share, followed by Europe (29%) and Asia-Pacific (24%). The Asia-Pacific region, particularly China and Japan, is experiencing the fastest growth rate due to increasing investments in renewable energy research and materials science infrastructure.

Key market drivers include the rising demand for sustainable chemical processes, stringent environmental regulations promoting green chemistry, and the need to accelerate materials discovery to address climate change challenges. Additionally, the integration of artificial intelligence and machine learning with HTS platforms is creating new market opportunities by enhancing screening efficiency and predictive capabilities.

Market restraints include the high initial investment required for advanced photoreactor platforms, technical challenges in standardizing testing conditions across different catalyst types, and the specialized expertise needed to operate and interpret results from these systems. These factors have limited adoption primarily to large research institutions and well-funded commercial entities.

Customer segments for photoreactor screening platforms include academic research laboratories (32%), chemical and materials companies (28%), pharmaceutical firms exploring photocatalytic synthesis routes (15%), energy companies (14%), and environmental technology developers (11%). The diverse application potential across multiple industries suggests significant cross-sector market growth opportunities for versatile, adaptable screening platforms.

Current Limitations in Photoreactor Design

Despite significant advancements in photocatalysis research, current photoreactor designs face substantial limitations that hinder efficient high-throughput screening of photocatalysts. One primary constraint is the lack of standardization across reactor platforms, making it difficult to compare results between different research groups and scale up promising catalysts. Most existing photoreactors are custom-built with varying geometries, light sources, and detection methods, creating reproducibility challenges in the field.

Light distribution represents another critical limitation, as achieving uniform irradiation across multiple reaction vessels remains problematic. Conventional batch reactors often suffer from light attenuation effects, where reactions closer to the light source receive higher photon flux than those positioned farther away. This non-uniform irradiation creates inconsistent reaction conditions that compromise the reliability of screening results and introduce systematic errors in catalyst performance evaluation.

Temperature control presents a significant challenge in photoreactor design. The heat generated by light sources can cause temperature gradients across reaction platforms, introducing an uncontrolled variable that affects reaction kinetics and catalyst stability. Most current systems lack sophisticated temperature regulation capabilities, particularly when operating multiple parallel reactions at precisely controlled conditions.

Analytical integration limitations further constrain high-throughput capabilities. Real-time monitoring of photocatalytic reactions often requires complex instrumentation that is difficult to miniaturize or parallelize. Many systems rely on offline analysis, creating bottlenecks in the screening workflow and delaying data acquisition. The lack of integrated analytical capabilities prevents researchers from capturing transient species or monitoring reaction progress continuously.

Scalability constraints represent another major limitation. Most laboratory photoreactors operate at microscale or small batch volumes, creating a significant gap between screening conditions and practical application requirements. Promising catalysts identified in small-scale screening often perform differently when scaled up due to mass transfer limitations, light penetration issues, and heat dissipation challenges not present in screening platforms.

Material compatibility issues also restrict photoreactor design options. Many photocatalytic reactions involve aggressive conditions or reactive intermediates that can degrade reactor components over time. Finding materials that maintain transparency, chemical resistance, and mechanical stability under prolonged irradiation presents ongoing challenges, particularly for continuous flow systems where long-term operation is essential.

Light distribution represents another critical limitation, as achieving uniform irradiation across multiple reaction vessels remains problematic. Conventional batch reactors often suffer from light attenuation effects, where reactions closer to the light source receive higher photon flux than those positioned farther away. This non-uniform irradiation creates inconsistent reaction conditions that compromise the reliability of screening results and introduce systematic errors in catalyst performance evaluation.

Temperature control presents a significant challenge in photoreactor design. The heat generated by light sources can cause temperature gradients across reaction platforms, introducing an uncontrolled variable that affects reaction kinetics and catalyst stability. Most current systems lack sophisticated temperature regulation capabilities, particularly when operating multiple parallel reactions at precisely controlled conditions.

Analytical integration limitations further constrain high-throughput capabilities. Real-time monitoring of photocatalytic reactions often requires complex instrumentation that is difficult to miniaturize or parallelize. Many systems rely on offline analysis, creating bottlenecks in the screening workflow and delaying data acquisition. The lack of integrated analytical capabilities prevents researchers from capturing transient species or monitoring reaction progress continuously.

Scalability constraints represent another major limitation. Most laboratory photoreactors operate at microscale or small batch volumes, creating a significant gap between screening conditions and practical application requirements. Promising catalysts identified in small-scale screening often perform differently when scaled up due to mass transfer limitations, light penetration issues, and heat dissipation challenges not present in screening platforms.

Material compatibility issues also restrict photoreactor design options. Many photocatalytic reactions involve aggressive conditions or reactive intermediates that can degrade reactor components over time. Finding materials that maintain transparency, chemical resistance, and mechanical stability under prolonged irradiation presents ongoing challenges, particularly for continuous flow systems where long-term operation is essential.

Existing High-Throughput Photoreactor Architectures

01 Parallel processing photoreactor systems

High-throughput photoreactor platforms that utilize parallel processing capabilities to simultaneously conduct multiple photochemical reactions. These systems incorporate arrays of reaction vessels or chambers that can be independently controlled and monitored, significantly increasing experimental throughput. The platforms often include automated sample handling, precise light delivery systems, and integrated analytics for real-time monitoring of reaction progress across multiple samples.- Parallel photoreactor systems for high-throughput screening: High-throughput photoreactor platforms that enable parallel processing of multiple samples simultaneously. These systems typically include arrays of individual photoreactors with independent light sources or light distribution systems, allowing for the screening of multiple reaction conditions or catalysts in a single experimental run. This parallel approach significantly increases experimental throughput compared to traditional sequential methods.

- Automated control and monitoring systems for photoreactors: Integration of advanced automation, control, and monitoring technologies in photoreactor platforms to enhance throughput and reproducibility. These systems incorporate sensors for real-time monitoring of reaction parameters, automated sample handling, and computerized control systems that can adjust reaction conditions dynamically. The automation reduces manual intervention, minimizes human error, and enables continuous operation for extended periods.

- Microfluidic photoreactor technologies: Miniaturized photoreactor platforms that utilize microfluidic technology to achieve high throughput. These systems feature microscale channels and reaction chambers that require minimal reagent volumes while providing excellent light penetration and heat transfer characteristics. The reduced scale allows for rapid screening of reaction conditions, faster mixing, and improved mass transfer, all contributing to increased experimental throughput.

- Modular and reconfigurable photoreactor designs: Flexible photoreactor platforms with modular components that can be reconfigured for different experimental requirements. These systems allow researchers to quickly adapt the reactor setup for various reaction types, scales, or light sources without extensive redesign. The modularity enables rapid changeover between experiments, reducing downtime and increasing overall throughput of the research facility.

- Advanced light delivery and distribution systems: Innovative approaches to light delivery and distribution that maximize photon efficiency and uniformity across multiple reaction vessels. These systems may include specialized optics, light guides, LED arrays, or other technologies that ensure consistent illumination intensity and spectral characteristics. Efficient light delivery is critical for maintaining reaction consistency across all samples in high-throughput applications.

02 Microfluidic photoreactor technologies

Microfluidic-based photoreactor platforms that enable high-throughput screening of photochemical reactions at microscale. These systems utilize miniaturized reaction channels and chambers to reduce reagent consumption while increasing reaction efficiency through improved light penetration and heat transfer. The continuous flow nature of these platforms allows for rapid screening of reaction conditions, catalyst performance, and process parameters with minimal material requirements.Expand Specific Solutions03 Advanced light source integration and control

High-throughput photoreactor platforms featuring sophisticated light source technologies and control systems. These platforms incorporate tunable light sources (LED arrays, lasers, or specialized lamps) that can deliver precise wavelengths, intensities, and irradiation patterns to reaction vessels. Advanced control systems enable programmable light cycles, gradient illumination, and spatial light distribution, allowing for optimization of photochemical processes and increased experimental throughput.Expand Specific Solutions04 Automated monitoring and analysis systems

High-throughput photoreactor platforms equipped with integrated analytical capabilities for real-time monitoring and data collection. These systems incorporate spectroscopic tools, imaging technologies, and sensor arrays that continuously track reaction progress, product formation, and catalyst performance across multiple reaction vessels simultaneously. Automated sampling and analysis workflows, coupled with data processing algorithms, enable rapid evaluation of reaction outcomes and accelerate optimization processes.Expand Specific Solutions05 Modular and reconfigurable photoreactor designs

Flexible photoreactor platforms featuring modular components that can be reconfigured for different experimental requirements. These systems allow researchers to quickly adapt the platform for various reaction types, scales, and conditions without extensive redesign. Interchangeable reaction vessels, light sources, temperature control modules, and analytical interfaces enable versatile operation across diverse photochemical applications, maximizing the utility and throughput of a single platform.Expand Specific Solutions

Leading Organizations in Photocatalysis Research

The high-throughput photoreactor platforms market for catalyst screening is currently in a growth phase, with increasing adoption across research institutions and chemical industries. The market size is expanding as photocatalysis gains prominence in sustainable chemistry applications, estimated to reach significant value in the coming years. Leading academic institutions like California Institute of Technology, Northwestern University, and CNRS are advancing fundamental research, while industrial players including BASF, ExxonMobil, and Syzygy Plasmonics are commercializing innovative technologies. Emerging companies like Freeslate and Unchained Labs are developing specialized high-throughput screening platforms, while established corporations such as Agilent Technologies and UOP LLC are integrating these capabilities into their R&D infrastructure, indicating the technology's progression from early-stage development toward commercial maturity.

BASF Corp.

Technical Solution: BASF has engineered an advanced high-throughput photoreactor platform specifically designed for catalyst screening in photochemical and photocatalytic processes. Their system employs a parallel reactor array with individually controllable LED light sources that can emit at various wavelengths (UV to visible range), allowing simultaneous testing of multiple catalyst candidates under identical or systematically varied conditions. The platform incorporates sophisticated in-situ spectroscopic monitoring tools including UV-Vis, FTIR, and Raman spectroscopy for real-time reaction tracking. BASF's photoreactor features precise temperature control systems that can maintain isothermal conditions or create controlled temperature gradients across sample arrays. The company has integrated automated liquid handling robots and sampling systems that enable continuous or periodic sampling for offline analysis, significantly increasing experimental throughput. Their data management system collects, processes, and analyzes large datasets from screening experiments, employing machine learning algorithms to identify promising catalyst candidates and optimize reaction parameters.

Strengths: Exceptional precision in controlling reaction parameters across multiple parallel experiments, enabling reliable comparative studies. Comprehensive analytical capabilities provide detailed mechanistic insights into photocatalytic processes. Weaknesses: The complex integrated system requires specialized expertise to operate and maintain effectively. High initial investment cost may limit accessibility for smaller research organizations.

ExxonMobil Technology & Engineering Co.

Technical Solution: ExxonMobil has developed a sophisticated high-throughput photoreactor platform for catalyst screening that integrates advanced microfluidic technology with high-intensity light sources. Their system features an array of parallel microreactors fabricated on transparent substrates, allowing for efficient light penetration and excellent mass transfer characteristics. The platform utilizes fiber optic light delivery systems that can direct specific wavelengths to individual reactor channels, enabling precise control over photon flux and spectral distribution. ExxonMobil's technology incorporates online gas chromatography and mass spectrometry for continuous product analysis, with automated sampling systems that minimize manual intervention. The company has implemented advanced process control software that can autonomously adjust reaction parameters based on real-time feedback, optimizing conditions for each catalyst formulation being tested. Their system is particularly notable for its ability to operate under industrially relevant conditions, including high pressures (up to 100 bar) and elevated temperatures, making screening results more directly applicable to commercial processes.

Strengths: Exceptional throughput capacity with the ability to screen hundreds of catalyst formulations per day. The microreactor design requires minimal catalyst quantities, conserving valuable materials during early-stage development. Weaknesses: The microfluidic architecture may present challenges for reactions involving solid products or catalyst deactivation. Scaling up promising catalysts from microreactor conditions to industrial scale may require additional validation steps.

Key Innovations in Parallel Catalyst Evaluation

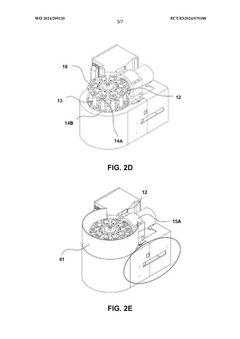

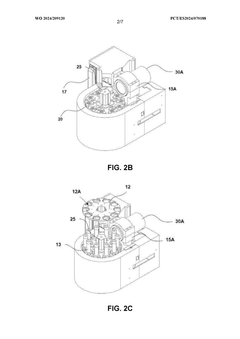

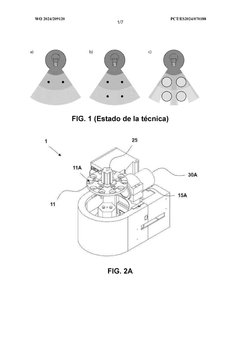

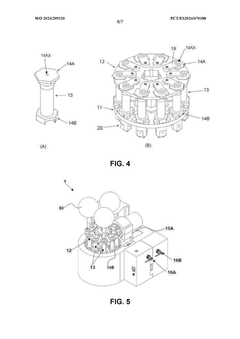

Device for carrying out chemical reactions

PatentWO2024209120A1

Innovation

- A device with a rotating platform that allows samples to move in a circular path around a central axis, featuring independent magnetic stirring mechanisms for each container and the ability to use containers of various shapes, along with a fixed light source arrangement that ensures uniform illumination and supports inert gas use.

Method and apparatus for high throughput catalysts screening and optimization

PatentInactiveUS7390664B2

Innovation

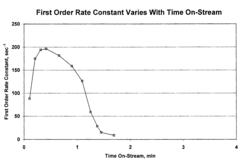

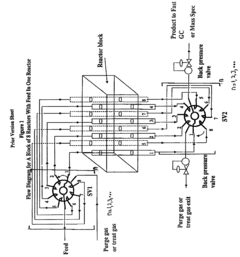

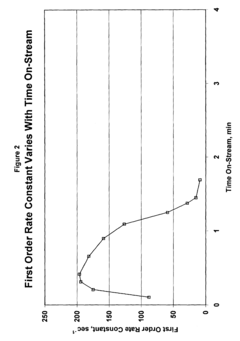

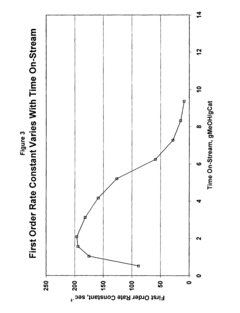

- A system with multiple reactors, selection valve systems, and detection devices that allow for simultaneous testing, initialization, regeneration, and reactivation of catalysts while maintaining constant TOS, enabling comparison of catalyst activity and selectivity, and allowing different treatment processes for each reactor.

Standardization Protocols for Photocatalyst Screening

Standardization of photocatalyst screening methodologies represents a critical challenge in advancing high-throughput photoreactor platforms. Current practices suffer from significant inconsistencies across research groups, making direct comparison of results nearly impossible and hindering collaborative progress in the field. Establishing robust standardization protocols requires addressing multiple dimensions of the screening process.

Light source characterization must be rigorously standardized, including spectral distribution, intensity measurements, and beam geometry documentation. Protocols should mandate reporting absolute photon flux (μmol/s) rather than arbitrary "lamp power" values, with calibration procedures using chemical actinometers like ferrioxalate or physical devices such as calibrated photodiodes.

Reaction parameter documentation needs standardization across temperature control methods, stirring rates, and headspace volumes. These seemingly minor variables can dramatically impact photocatalytic performance yet are frequently underreported. The protocol should establish minimum reporting requirements for these parameters and recommend specific measurement methodologies.

Sample preparation standardization is equally crucial, covering catalyst loading procedures, substrate concentration ranges, and dispersion techniques. Particularly for heterogeneous catalysts, protocols must address particle size distribution characterization and reporting standards to ensure reproducibility across different laboratories.

Data collection and analysis frameworks require standardized metrics for performance evaluation, including quantum yield calculations, turnover frequencies, and selectivity measurements. Time-resolved data collection intervals should be specified based on reaction types, with statistical analysis requirements clearly defined.

Control experiments represent another critical area requiring standardization. Protocols should mandate specific dark controls, thermal controls, and blank substrate tests to isolate genuine photocatalytic effects from thermal or non-catalytic pathways.

Interlaboratory validation procedures must be established, potentially through round-robin testing of benchmark photocatalytic systems. This approach would identify protocol weaknesses and establish reproducibility metrics across different laboratory environments.

Implementation of these standardization protocols would significantly enhance the reliability and comparability of high-throughput photocatalyst screening data. The scientific community should work toward consensus-based standards, potentially through dedicated workshops or collaborative publications involving academic and industrial stakeholders.

Light source characterization must be rigorously standardized, including spectral distribution, intensity measurements, and beam geometry documentation. Protocols should mandate reporting absolute photon flux (μmol/s) rather than arbitrary "lamp power" values, with calibration procedures using chemical actinometers like ferrioxalate or physical devices such as calibrated photodiodes.

Reaction parameter documentation needs standardization across temperature control methods, stirring rates, and headspace volumes. These seemingly minor variables can dramatically impact photocatalytic performance yet are frequently underreported. The protocol should establish minimum reporting requirements for these parameters and recommend specific measurement methodologies.

Sample preparation standardization is equally crucial, covering catalyst loading procedures, substrate concentration ranges, and dispersion techniques. Particularly for heterogeneous catalysts, protocols must address particle size distribution characterization and reporting standards to ensure reproducibility across different laboratories.

Data collection and analysis frameworks require standardized metrics for performance evaluation, including quantum yield calculations, turnover frequencies, and selectivity measurements. Time-resolved data collection intervals should be specified based on reaction types, with statistical analysis requirements clearly defined.

Control experiments represent another critical area requiring standardization. Protocols should mandate specific dark controls, thermal controls, and blank substrate tests to isolate genuine photocatalytic effects from thermal or non-catalytic pathways.

Interlaboratory validation procedures must be established, potentially through round-robin testing of benchmark photocatalytic systems. This approach would identify protocol weaknesses and establish reproducibility metrics across different laboratory environments.

Implementation of these standardization protocols would significantly enhance the reliability and comparability of high-throughput photocatalyst screening data. The scientific community should work toward consensus-based standards, potentially through dedicated workshops or collaborative publications involving academic and industrial stakeholders.

Sustainability Impact of Advanced Photocatalytic Systems

The integration of advanced photocatalytic systems into industrial and consumer applications represents a significant opportunity for enhancing global sustainability efforts. These high-throughput photoreactor platforms for catalyst screening demonstrate remarkable potential to accelerate the transition toward greener chemical processes and renewable energy solutions.

From an environmental perspective, photocatalytic systems offer substantial benefits through the reduction of carbon emissions. By harnessing solar energy to drive chemical reactions, these technologies can potentially replace conventional energy-intensive processes that rely heavily on fossil fuels. Research indicates that widespread implementation of optimized photocatalytic systems could contribute to a 15-20% reduction in industrial carbon footprints within specific chemical manufacturing sectors.

Water purification represents another critical sustainability impact area. Advanced photocatalytic systems have demonstrated exceptional efficiency in degrading persistent organic pollutants, pharmaceutical residues, and industrial contaminants that conventional treatment methods struggle to address. High-throughput screening platforms have accelerated the discovery of catalysts capable of treating complex water matrices under ambient conditions, potentially revolutionizing access to clean water in resource-limited regions.

The circular economy benefits significantly from these technologies through waste valorization pathways. Photocatalytic systems can transform waste streams into valuable chemicals and fuels, creating closed-loop industrial ecosystems. For instance, recent breakthroughs in CO2 photoreduction catalysts identified through high-throughput screening have achieved conversion efficiencies approaching 8% under simulated sunlight, pointing toward economically viable carbon capture and utilization strategies.

Resource conservation represents another substantial sustainability advantage. The precision and efficiency of photocatalytic processes typically require fewer raw materials and generate less waste compared to traditional chemical manufacturing. Life cycle assessments indicate that optimized photocatalytic routes can reduce resource consumption by up to 40% for certain chemical transformations when compared to conventional methods.

Social sustainability factors must also be considered. The development of distributed, solar-powered chemical manufacturing enabled by advanced photocatalytic systems could democratize production capabilities, reducing dependence on centralized industrial facilities and potentially creating new economic opportunities in developing regions. This decentralization may contribute to more resilient supply chains and reduced transportation-related environmental impacts.

However, challenges remain in scaling these technologies to achieve their full sustainability potential. Material sourcing for certain high-performance photocatalysts may involve rare elements with their own environmental extraction concerns. Comprehensive sustainability assessments must therefore consider the entire technology lifecycle to ensure that environmental benefits are not offset by impacts elsewhere in the value chain.

From an environmental perspective, photocatalytic systems offer substantial benefits through the reduction of carbon emissions. By harnessing solar energy to drive chemical reactions, these technologies can potentially replace conventional energy-intensive processes that rely heavily on fossil fuels. Research indicates that widespread implementation of optimized photocatalytic systems could contribute to a 15-20% reduction in industrial carbon footprints within specific chemical manufacturing sectors.

Water purification represents another critical sustainability impact area. Advanced photocatalytic systems have demonstrated exceptional efficiency in degrading persistent organic pollutants, pharmaceutical residues, and industrial contaminants that conventional treatment methods struggle to address. High-throughput screening platforms have accelerated the discovery of catalysts capable of treating complex water matrices under ambient conditions, potentially revolutionizing access to clean water in resource-limited regions.

The circular economy benefits significantly from these technologies through waste valorization pathways. Photocatalytic systems can transform waste streams into valuable chemicals and fuels, creating closed-loop industrial ecosystems. For instance, recent breakthroughs in CO2 photoreduction catalysts identified through high-throughput screening have achieved conversion efficiencies approaching 8% under simulated sunlight, pointing toward economically viable carbon capture and utilization strategies.

Resource conservation represents another substantial sustainability advantage. The precision and efficiency of photocatalytic processes typically require fewer raw materials and generate less waste compared to traditional chemical manufacturing. Life cycle assessments indicate that optimized photocatalytic routes can reduce resource consumption by up to 40% for certain chemical transformations when compared to conventional methods.

Social sustainability factors must also be considered. The development of distributed, solar-powered chemical manufacturing enabled by advanced photocatalytic systems could democratize production capabilities, reducing dependence on centralized industrial facilities and potentially creating new economic opportunities in developing regions. This decentralization may contribute to more resilient supply chains and reduced transportation-related environmental impacts.

However, challenges remain in scaling these technologies to achieve their full sustainability potential. Material sourcing for certain high-performance photocatalysts may involve rare elements with their own environmental extraction concerns. Comprehensive sustainability assessments must therefore consider the entire technology lifecycle to ensure that environmental benefits are not offset by impacts elsewhere in the value chain.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!