Product Separation And Concentration From Dilute Streams

SEP 2, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Separation Technology Background and Objectives

Separation technology has evolved significantly over the past century, transforming from rudimentary physical methods to sophisticated chemical and biological approaches. The field has seen accelerated development since the 1970s with the introduction of membrane technologies, which revolutionized industrial separation processes. Recent advancements in materials science and nanotechnology have further expanded the capabilities and applications of separation technologies across various industries.

Product separation and concentration from dilute streams represents a critical challenge in numerous sectors including pharmaceuticals, food processing, mining, and wastewater treatment. The fundamental difficulty lies in efficiently extracting valuable components from solutions where they exist at low concentrations, often below 1% by weight. Traditional separation methods typically become economically unfeasible or technically inefficient when dealing with such dilute systems.

The evolution trajectory of separation technologies shows a clear trend toward more energy-efficient, environmentally sustainable, and economically viable solutions. Early techniques relied heavily on thermal processes such as distillation and evaporation, which are energy-intensive. Modern approaches increasingly leverage selective membrane technologies, advanced adsorbents, and hybrid systems that combine multiple separation principles to achieve higher efficiency at lower energy costs.

Current technological objectives in this field focus on developing separation methods that can operate effectively at ambient conditions, minimize energy consumption, reduce waste generation, and maximize product recovery rates. There is particular emphasis on creating solutions that can handle complex feed streams with multiple contaminants or competing products while maintaining high selectivity for target compounds.

Emerging research directions include the development of stimuli-responsive materials that can dynamically alter their separation properties, biomimetic approaches that emulate natural separation mechanisms, and integrated systems that combine separation with other process steps. Additionally, there is growing interest in modular and scalable technologies that can be deployed across different scales of operation, from laboratory to industrial settings.

The ultimate goal of current research efforts is to establish separation technologies that can economically recover valuable products from extremely dilute streams (concentrations below 0.1%) while minimizing environmental impact. This would unlock significant value in previously untapped resources such as mining tailings, industrial wastewater, and agricultural runoff, contributing to circular economy principles and resource conservation objectives.

Product separation and concentration from dilute streams represents a critical challenge in numerous sectors including pharmaceuticals, food processing, mining, and wastewater treatment. The fundamental difficulty lies in efficiently extracting valuable components from solutions where they exist at low concentrations, often below 1% by weight. Traditional separation methods typically become economically unfeasible or technically inefficient when dealing with such dilute systems.

The evolution trajectory of separation technologies shows a clear trend toward more energy-efficient, environmentally sustainable, and economically viable solutions. Early techniques relied heavily on thermal processes such as distillation and evaporation, which are energy-intensive. Modern approaches increasingly leverage selective membrane technologies, advanced adsorbents, and hybrid systems that combine multiple separation principles to achieve higher efficiency at lower energy costs.

Current technological objectives in this field focus on developing separation methods that can operate effectively at ambient conditions, minimize energy consumption, reduce waste generation, and maximize product recovery rates. There is particular emphasis on creating solutions that can handle complex feed streams with multiple contaminants or competing products while maintaining high selectivity for target compounds.

Emerging research directions include the development of stimuli-responsive materials that can dynamically alter their separation properties, biomimetic approaches that emulate natural separation mechanisms, and integrated systems that combine separation with other process steps. Additionally, there is growing interest in modular and scalable technologies that can be deployed across different scales of operation, from laboratory to industrial settings.

The ultimate goal of current research efforts is to establish separation technologies that can economically recover valuable products from extremely dilute streams (concentrations below 0.1%) while minimizing environmental impact. This would unlock significant value in previously untapped resources such as mining tailings, industrial wastewater, and agricultural runoff, contributing to circular economy principles and resource conservation objectives.

Market Analysis for Dilute Stream Processing

The global market for dilute stream processing technologies is experiencing significant growth, driven by increasing industrial waste management regulations and the rising demand for resource recovery solutions. Currently valued at approximately $8.2 billion, this market is projected to reach $12.5 billion by 2027, representing a compound annual growth rate of 8.7%. This growth trajectory is particularly pronounced in regions with stringent environmental regulations, including Western Europe, North America, and increasingly, parts of Asia-Pacific.

Water-intensive industries constitute the primary demand drivers, with mining operations, chemical manufacturing, and food processing collectively accounting for over 65% of the market share. The mining sector alone represents 28% of the current market, as operations increasingly seek to recover valuable metals and minerals from low-concentration waste streams while meeting tightening discharge regulations.

Pharmaceutical manufacturing has emerged as the fastest-growing segment, with a 12.3% annual growth rate, driven by the need to recover high-value active pharmaceutical ingredients from process waters. This trend is reinforced by the industry's dual focus on sustainability goals and cost reduction initiatives.

Geographically, North America currently leads the market with a 34% share, followed closely by Europe at 31%. However, the Asia-Pacific region is demonstrating the most rapid expansion, with China and India collectively projected to increase their market share from 18% to 27% by 2027, primarily due to strengthening environmental regulations and industrial expansion.

Customer demand patterns reveal a significant shift toward integrated solutions that combine separation, concentration, and recovery processes. End-users increasingly prioritize technologies offering lower energy consumption, reduced chemical usage, and smaller physical footprints. Market research indicates that 73% of potential customers rank operational cost reduction as their primary consideration, followed by regulatory compliance (68%) and sustainability metrics (54%).

The competitive landscape features both established players offering conventional technologies and emerging companies introducing innovative approaches. The market currently exhibits moderate fragmentation, with the top five companies controlling approximately 42% of the global market share. Strategic partnerships between technology providers and end-users are becoming increasingly common, particularly for developing customized solutions for specific industrial applications.

Water-intensive industries constitute the primary demand drivers, with mining operations, chemical manufacturing, and food processing collectively accounting for over 65% of the market share. The mining sector alone represents 28% of the current market, as operations increasingly seek to recover valuable metals and minerals from low-concentration waste streams while meeting tightening discharge regulations.

Pharmaceutical manufacturing has emerged as the fastest-growing segment, with a 12.3% annual growth rate, driven by the need to recover high-value active pharmaceutical ingredients from process waters. This trend is reinforced by the industry's dual focus on sustainability goals and cost reduction initiatives.

Geographically, North America currently leads the market with a 34% share, followed closely by Europe at 31%. However, the Asia-Pacific region is demonstrating the most rapid expansion, with China and India collectively projected to increase their market share from 18% to 27% by 2027, primarily due to strengthening environmental regulations and industrial expansion.

Customer demand patterns reveal a significant shift toward integrated solutions that combine separation, concentration, and recovery processes. End-users increasingly prioritize technologies offering lower energy consumption, reduced chemical usage, and smaller physical footprints. Market research indicates that 73% of potential customers rank operational cost reduction as their primary consideration, followed by regulatory compliance (68%) and sustainability metrics (54%).

The competitive landscape features both established players offering conventional technologies and emerging companies introducing innovative approaches. The market currently exhibits moderate fragmentation, with the top five companies controlling approximately 42% of the global market share. Strategic partnerships between technology providers and end-users are becoming increasingly common, particularly for developing customized solutions for specific industrial applications.

Current Separation Challenges and Limitations

The separation and concentration of valuable products from dilute streams presents significant technical challenges across multiple industries. Current separation technologies often struggle with efficiency when dealing with low concentration solutions, typically below 1% by weight. This fundamental limitation stems from thermodynamic constraints, where the energy required for separation increases exponentially as concentration decreases, following principles established in Sherwood's Rule.

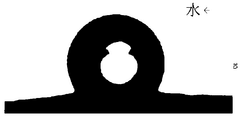

Membrane-based separation technologies, while promising for their selectivity, face persistent issues with fouling and concentration polarization when processing complex dilute streams. These phenomena reduce membrane performance over time, necessitating frequent cleaning or replacement and increasing operational costs. Additionally, achieving high selectivity while maintaining adequate flux remains a difficult balance to strike in membrane design.

Conventional thermal separation methods such as distillation and evaporation become prohibitively energy-intensive for dilute solutions. The energy requirement to vaporize large volumes of solvent to recover small amounts of product creates unfavorable economics and significant carbon footprints. This is particularly problematic in pharmaceutical and fine chemical industries where product recovery from highly dilute process streams is common.

Adsorption-based separation techniques face limitations in capacity and selectivity when dealing with complex mixtures. Competitive adsorption between target molecules and impurities often reduces recovery efficiency. Furthermore, the regeneration of adsorbents typically requires additional energy and chemical inputs, creating secondary waste streams that require further processing.

Extraction processes using conventional solvents encounter challenges with phase separation when dealing with dilute aqueous streams. The formation of stable emulsions and the need for multiple extraction stages increase process complexity and reduce overall efficiency. Additionally, solvent loss during processing creates both economic and environmental concerns.

Emerging technologies like forward osmosis and capacitive deionization show promise but remain limited in scale and application range. Forward osmosis struggles with draw solution recovery, while capacitive deionization faces challenges with organic contaminants and scaling issues in complex streams.

The economic viability of separation processes for dilute streams is further complicated by high capital costs for specialized equipment and the operational expenses associated with energy consumption and consumable materials. These economic barriers have slowed innovation and commercial implementation of novel separation technologies, particularly in cost-sensitive industries.

Membrane-based separation technologies, while promising for their selectivity, face persistent issues with fouling and concentration polarization when processing complex dilute streams. These phenomena reduce membrane performance over time, necessitating frequent cleaning or replacement and increasing operational costs. Additionally, achieving high selectivity while maintaining adequate flux remains a difficult balance to strike in membrane design.

Conventional thermal separation methods such as distillation and evaporation become prohibitively energy-intensive for dilute solutions. The energy requirement to vaporize large volumes of solvent to recover small amounts of product creates unfavorable economics and significant carbon footprints. This is particularly problematic in pharmaceutical and fine chemical industries where product recovery from highly dilute process streams is common.

Adsorption-based separation techniques face limitations in capacity and selectivity when dealing with complex mixtures. Competitive adsorption between target molecules and impurities often reduces recovery efficiency. Furthermore, the regeneration of adsorbents typically requires additional energy and chemical inputs, creating secondary waste streams that require further processing.

Extraction processes using conventional solvents encounter challenges with phase separation when dealing with dilute aqueous streams. The formation of stable emulsions and the need for multiple extraction stages increase process complexity and reduce overall efficiency. Additionally, solvent loss during processing creates both economic and environmental concerns.

Emerging technologies like forward osmosis and capacitive deionization show promise but remain limited in scale and application range. Forward osmosis struggles with draw solution recovery, while capacitive deionization faces challenges with organic contaminants and scaling issues in complex streams.

The economic viability of separation processes for dilute streams is further complicated by high capital costs for specialized equipment and the operational expenses associated with energy consumption and consumable materials. These economic barriers have slowed innovation and commercial implementation of novel separation technologies, particularly in cost-sensitive industries.

Current Separation and Concentration Methods

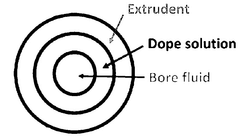

01 Membrane-based separation technologies

Membrane-based separation technologies utilize selective barriers to separate and concentrate target substances based on molecular size, charge, or other properties. These systems can achieve high separation efficiency through optimized membrane materials, pore sizes, and operating conditions. Advanced membrane configurations such as hollow fiber, spiral wound, and flat sheet designs enhance concentration levels while minimizing energy consumption. These technologies are particularly effective for liquid-liquid and gas-liquid separations in various industrial applications.- Membrane-based separation technologies: Membrane-based separation technologies utilize selective barriers to separate components based on size, charge, or affinity. These systems can achieve high separation efficiency through optimized membrane materials and configurations. Advanced membrane designs incorporate specific pore sizes and surface modifications to enhance selectivity and throughput. The concentration level can be controlled by adjusting operating parameters such as pressure, flow rate, and membrane characteristics, making these technologies suitable for various industrial applications.

- Chromatographic separation methods: Chromatographic separation methods leverage differential migration of compounds through a stationary phase to achieve high-resolution separation. These techniques can be optimized for improved efficiency through selection of appropriate column materials, mobile phase composition, and operating conditions. The concentration level of target compounds can be enhanced through gradient elution, peak focusing, or multi-dimensional chromatography approaches. These methods are particularly valuable for separating complex mixtures with similar components.

- Centrifugal and density-based separation: Centrifugal and density-based separation technologies utilize differences in density or specific gravity to separate components. These systems can achieve high separation efficiency through optimized rotor design, rotation speed control, and residence time management. The concentration level can be enhanced through multi-stage processing or continuous flow designs. Advanced centrifugal systems incorporate automated controls to maintain optimal separation parameters and improve consistency in separation outcomes.

- Adsorption and ion exchange technologies: Adsorption and ion exchange technologies utilize selective binding materials to capture specific components from mixtures. These methods achieve high separation efficiency through tailored adsorbent materials with specific surface properties and binding sites. The concentration level of target compounds can be controlled through optimized adsorption-desorption cycles and regeneration protocols. Advanced systems incorporate multi-bed configurations and pressure/temperature swing operations to enhance separation performance and concentration factors.

- Integrated hybrid separation systems: Integrated hybrid separation systems combine multiple separation technologies to overcome limitations of individual methods. These systems achieve enhanced separation efficiency through synergistic effects of combined processes, such as membrane filtration followed by chromatographic purification. The concentration level can be significantly improved through strategic sequencing of separation steps, with each stage optimized for specific components. These hybrid approaches enable processing of complex feedstocks and achievement of higher purity levels than possible with single technologies.

02 Chromatographic separation methods

Chromatographic separation methods leverage differential migration of compounds through stationary phases to achieve high-efficiency separation and concentration. These techniques utilize various interaction mechanisms including adsorption, partition, ion exchange, and size exclusion to separate complex mixtures. Advanced chromatographic systems incorporate continuous operation modes, simulated moving beds, and multi-column configurations to enhance separation efficiency and concentration levels. Process parameters such as mobile phase composition, flow rate, and temperature are optimized to achieve desired purity and recovery.Expand Specific Solutions03 Centrifugal and density-based separation

Centrifugal and density-based separation technologies utilize gravitational or centrifugal forces to separate components based on density differences. These systems include advanced centrifuges, hydrocyclones, and density gradient techniques that can achieve high separation efficiency through optimized rotation speeds, residence times, and equipment geometry. Multi-stage configurations and continuous operation modes enhance concentration levels of target substances. These methods are particularly effective for solid-liquid separations and are widely used in industrial, environmental, and biological applications.Expand Specific Solutions04 Adsorption and ion exchange technologies

Adsorption and ion exchange technologies utilize specialized materials with high surface area and selective binding properties to separate and concentrate target substances from mixtures. These systems employ various adsorbents including activated carbon, zeolites, silica gels, and ion exchange resins to achieve high separation efficiency. Process innovations such as pressure swing adsorption, temperature swing adsorption, and simulated moving bed techniques enhance concentration levels while reducing energy consumption. Regeneration methods and cycle optimization are critical for maintaining long-term performance.Expand Specific Solutions05 Extraction and distillation processes

Extraction and distillation processes separate components based on differences in solubility or volatility. Advanced extraction techniques include liquid-liquid extraction, supercritical fluid extraction, and reactive extraction, while distillation innovations encompass reactive distillation, extractive distillation, and dividing wall columns. These technologies achieve high separation efficiency through optimized solvent selection, operating conditions, and equipment design. Multi-stage configurations, heat integration, and hybrid processes significantly enhance concentration levels while reducing energy requirements. Process intensification approaches combine reaction and separation to improve overall efficiency.Expand Specific Solutions

Key Industry Players in Separation Technology

The product separation and concentration from dilute streams technology landscape is currently in a growth phase, with an estimated market size of $5-7 billion annually and expanding at 8-10% CAGR. The competitive field features established industrial players like ExxonMobil Technology & Engineering and BASF Corp. focusing on large-scale industrial applications, while specialized firms such as SmartFlow Technologies, InnovaPrep, and Gradiant Corp. are developing innovative filtration and separation solutions. Academic institutions (MIT, Arizona State University) and research organizations (Advanced Industrial Science & Technology) are driving fundamental breakthroughs. The technology is approaching maturity in conventional applications but remains in development for emerging sustainable solutions, with Saltworks Technologies and TotalEnergies leading advancements in energy-efficient separation processes for challenging dilute streams.

ExxonMobil Technology & Engineering Co.

Technical Solution: ExxonMobil has developed advanced membrane separation technologies for product separation from dilute streams, particularly focusing on hydrocarbon recovery. Their proprietary selective separation membranes utilize polymer-based materials with tailored pore structures that enable efficient separation of valuable components from dilute process streams. The company has implemented a hybrid approach combining membrane technology with conventional distillation processes, reducing energy consumption by up to 40% compared to traditional separation methods. ExxonMobil's technology incorporates specialized surface modifications to their membranes that enhance selectivity while minimizing fouling issues common in industrial applications. Their systems are particularly effective for recovering dilute organic compounds from wastewater streams, achieving recovery rates exceeding 95% for certain hydrocarbons while maintaining product purity.

Strengths: Superior energy efficiency compared to conventional separation methods; excellent selectivity for hydrocarbon compounds; robust design suitable for harsh industrial environments. Weaknesses: Higher initial capital investment compared to conventional technologies; potential membrane fouling in certain applications requiring regular maintenance cycles.

BASF Corp.

Technical Solution: BASF has developed advanced adsorption-based separation technologies for recovering valuable products from dilute streams. Their proprietary adsorbent materials feature tailored pore structures and surface chemistries that enable highly selective capture of target compounds even at low concentrations. The company's Sorbead® adsorbent technology utilizes specialized silica gel materials that can achieve separation factors exceeding 100 for certain applications. BASF has also pioneered hybrid separation systems that combine adsorption with membrane technology, creating synergistic effects that enhance overall separation efficiency. Their process designs incorporate innovative regeneration methods that minimize energy consumption while maximizing adsorbent lifespan. BASF's separation technologies are particularly effective for recovering high-value specialty chemicals and pharmaceuticals from dilute process streams, achieving recovery rates above 99% while maintaining product purity specifications.

Strengths: Exceptional selectivity for specific target compounds; ability to handle complex feed mixtures; relatively low energy requirements compared to distillation. Weaknesses: Potential for adsorbent degradation over time requiring periodic replacement; batch processing nature can limit throughput for high-volume applications.

Critical Patents in Dilute Stream Processing

Return flow system for ion concentration polarization (ICP) desalination

PatentWO2019147802A9

Innovation

- A return flow ICP desalination system is developed, featuring a primary channel with opposing ion exchange membranes and a porous membrane that allows ion passage while suppressing chaotic electroconvection and preventing enriched salt propagation, by creating a flow barrier that directs the feed stream to flow back towards the inlet, increasing the channel's effective length and dwell time.

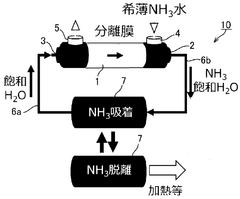

Method for producing separation/concentration product of volatile substance, and system for producing separation/concentration product of volatile substance

PatentWO2025135145A1

Innovation

- A method combining a gas sweep membrane distillation process with an adsorbent that selectively adsorbs and desorbs volatile substances, using a Prussian blue derivative as the adsorbent, to concentrate and separate volatile substances efficiently.

Energy Efficiency Considerations

Energy efficiency represents a critical dimension in the evaluation and implementation of product separation and concentration technologies for dilute streams. The energy intensity of separation processes often constitutes the primary economic and environmental constraint, particularly when dealing with highly dilute solutions where the target compound may represent less than 1% of the total stream volume. Traditional separation methods such as distillation, evaporation, and thermal drying typically require substantial energy inputs proportional to the dilution factor, making them increasingly inefficient as concentration decreases.

Recent advancements in energy-efficient separation technologies have focused on membrane-based processes that operate at ambient temperatures, significantly reducing thermal energy requirements. Forward osmosis, for instance, utilizes concentration gradients rather than hydraulic pressure or thermal energy to drive separation, potentially reducing energy consumption by 30-60% compared to reverse osmosis for certain applications. Similarly, pervaporation techniques combine membrane permeation with evaporation at reduced pressures, offering energy savings of up to 70% versus conventional distillation for azeotropic mixtures.

Electrodialysis and capacitive deionization have emerged as promising electrochemical separation methods with favorable energy profiles for ionic species recovery. These technologies demonstrate particular efficiency when target compounds carry electrical charges, enabling selective separation with energy requirements that scale more favorably with concentration than thermal alternatives.

Heat integration strategies represent another crucial approach to improving energy efficiency in separation processes. Pinch analysis and process integration techniques can identify opportunities to recover and reuse thermal energy within separation systems, potentially reducing external energy requirements by 20-40%. Multi-effect evaporation and vapor recompression systems exemplify this approach by reusing latent heat multiple times throughout the concentration process.

Hybrid separation systems that strategically combine multiple technologies based on concentration ranges show particular promise. For example, a membrane pre-concentration step followed by more energy-intensive methods for final purification can optimize overall energy consumption by applying each technology within its most efficient operating range. Such hybrid approaches have demonstrated energy reductions of 40-65% in industrial applications for pharmaceutical and food processing streams.

The development of novel materials with enhanced selectivity and permeability continues to drive improvements in separation energy efficiency. Advanced materials such as mixed matrix membranes, metal-organic frameworks, and stimuli-responsive polymers offer pathways to reduce the fundamental energy requirements of separation processes by enabling more precise molecular discrimination with lower driving forces.

Recent advancements in energy-efficient separation technologies have focused on membrane-based processes that operate at ambient temperatures, significantly reducing thermal energy requirements. Forward osmosis, for instance, utilizes concentration gradients rather than hydraulic pressure or thermal energy to drive separation, potentially reducing energy consumption by 30-60% compared to reverse osmosis for certain applications. Similarly, pervaporation techniques combine membrane permeation with evaporation at reduced pressures, offering energy savings of up to 70% versus conventional distillation for azeotropic mixtures.

Electrodialysis and capacitive deionization have emerged as promising electrochemical separation methods with favorable energy profiles for ionic species recovery. These technologies demonstrate particular efficiency when target compounds carry electrical charges, enabling selective separation with energy requirements that scale more favorably with concentration than thermal alternatives.

Heat integration strategies represent another crucial approach to improving energy efficiency in separation processes. Pinch analysis and process integration techniques can identify opportunities to recover and reuse thermal energy within separation systems, potentially reducing external energy requirements by 20-40%. Multi-effect evaporation and vapor recompression systems exemplify this approach by reusing latent heat multiple times throughout the concentration process.

Hybrid separation systems that strategically combine multiple technologies based on concentration ranges show particular promise. For example, a membrane pre-concentration step followed by more energy-intensive methods for final purification can optimize overall energy consumption by applying each technology within its most efficient operating range. Such hybrid approaches have demonstrated energy reductions of 40-65% in industrial applications for pharmaceutical and food processing streams.

The development of novel materials with enhanced selectivity and permeability continues to drive improvements in separation energy efficiency. Advanced materials such as mixed matrix membranes, metal-organic frameworks, and stimuli-responsive polymers offer pathways to reduce the fundamental energy requirements of separation processes by enabling more precise molecular discrimination with lower driving forces.

Sustainability and Environmental Impact

The environmental impact of separation and concentration processes from dilute streams has become a critical consideration in modern industrial operations. Traditional separation methods often involve high energy consumption, chemical usage, and waste generation, contributing significantly to industrial carbon footprints. Recent life cycle assessments reveal that separation processes can account for 40-70% of total energy consumption in chemical and pharmaceutical manufacturing, highlighting the urgent need for more sustainable approaches.

Water usage represents another significant environmental concern, particularly in membrane-based separation technologies. Conventional processes may require substantial water volumes for cleaning and maintenance, exacerbating water scarcity issues in regions already facing hydrological stress. Advanced technologies like forward osmosis and capacitive deionization are demonstrating potential to reduce water footprints by 30-45% compared to traditional methods.

Chemical usage in separation processes presents additional environmental challenges. Solvents, flocculants, and other process chemicals often create secondary waste streams requiring treatment before discharge. The transition toward green chemistry principles has spurred development of biodegradable separation agents and bio-based alternatives that reduce environmental persistence and toxicity while maintaining separation efficiency.

Waste minimization strategies have evolved significantly, with closed-loop systems gaining prominence in dilute stream processing. These approaches recover and reuse process materials, reducing both input requirements and output waste. Industries implementing such circular economy principles have reported waste reduction of 25-60% while simultaneously lowering operational costs.

Energy efficiency improvements represent perhaps the most impactful sustainability advancement in separation technologies. Emerging techniques like low-temperature separation, pressure-retarded osmosis, and selective adsorption processes demonstrate energy requirement reductions of 30-80% compared to conventional distillation or evaporation methods. These innovations directly translate to reduced greenhouse gas emissions and improved carbon footprints.

Regulatory frameworks increasingly influence technology adoption, with stringent environmental standards driving innovation in separation processes. Companies proactively implementing sustainable separation technologies often gain competitive advantages through regulatory compliance, reduced operational costs, and enhanced corporate sustainability profiles. The economic benefits of sustainable separation technologies frequently materialize through reduced energy costs, decreased waste management expenses, and potential access to green financing mechanisms.

Looking forward, the integration of renewable energy sources with separation processes presents a promising frontier for further sustainability improvements. Solar-powered membrane distillation, wind-powered electrochemical separation, and geothermal energy utilization for thermal separation processes demonstrate the potential for near-zero carbon separation technologies in appropriate geographical contexts.

Water usage represents another significant environmental concern, particularly in membrane-based separation technologies. Conventional processes may require substantial water volumes for cleaning and maintenance, exacerbating water scarcity issues in regions already facing hydrological stress. Advanced technologies like forward osmosis and capacitive deionization are demonstrating potential to reduce water footprints by 30-45% compared to traditional methods.

Chemical usage in separation processes presents additional environmental challenges. Solvents, flocculants, and other process chemicals often create secondary waste streams requiring treatment before discharge. The transition toward green chemistry principles has spurred development of biodegradable separation agents and bio-based alternatives that reduce environmental persistence and toxicity while maintaining separation efficiency.

Waste minimization strategies have evolved significantly, with closed-loop systems gaining prominence in dilute stream processing. These approaches recover and reuse process materials, reducing both input requirements and output waste. Industries implementing such circular economy principles have reported waste reduction of 25-60% while simultaneously lowering operational costs.

Energy efficiency improvements represent perhaps the most impactful sustainability advancement in separation technologies. Emerging techniques like low-temperature separation, pressure-retarded osmosis, and selective adsorption processes demonstrate energy requirement reductions of 30-80% compared to conventional distillation or evaporation methods. These innovations directly translate to reduced greenhouse gas emissions and improved carbon footprints.

Regulatory frameworks increasingly influence technology adoption, with stringent environmental standards driving innovation in separation processes. Companies proactively implementing sustainable separation technologies often gain competitive advantages through regulatory compliance, reduced operational costs, and enhanced corporate sustainability profiles. The economic benefits of sustainable separation technologies frequently materialize through reduced energy costs, decreased waste management expenses, and potential access to green financing mechanisms.

Looking forward, the integration of renewable energy sources with separation processes presents a promising frontier for further sustainability improvements. Solar-powered membrane distillation, wind-powered electrochemical separation, and geothermal energy utilization for thermal separation processes demonstrate the potential for near-zero carbon separation technologies in appropriate geographical contexts.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!