Scale-Up Catalytic Architecture: Panel, Tubular, And Packed Beds

SEP 2, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Catalytic Architecture Evolution and Objectives

Catalytic processes have evolved significantly over the past century, transforming from rudimentary reaction vessels to sophisticated engineered systems. The journey began in the early 20th century with simple batch reactors, progressing through continuous flow systems in the mid-century, to today's highly optimized architectures designed for specific reaction environments. This evolution has been driven by industrial demands for greater efficiency, selectivity, and sustainability in chemical processing operations.

Panel, tubular, and packed bed architectures represent the three fundamental design paradigms that have emerged as dominant solutions for large-scale catalytic processes. Each configuration offers distinct advantages in terms of heat transfer, pressure drop characteristics, catalyst loading capacity, and flow dynamics. The historical development of these architectures reflects the industry's growing understanding of reaction kinetics and transport phenomena at different scales.

The panel architecture, characterized by flat catalyst-coated surfaces arranged in parallel, emerged from efforts to maximize surface area while maintaining laminar flow conditions. This design has proven particularly valuable in applications requiring precise control of residence time and minimal pressure drop, such as in environmental catalysis for air purification systems and certain petrochemical processes.

Tubular reactors evolved from heat exchanger technology, offering excellent temperature control through their high surface-to-volume ratio. Their development accelerated during the mid-20th century with advances in materials science that enabled the creation of catalyst-coated tubes capable of withstanding extreme conditions. Today, tubular designs dominate in steam reforming, partial oxidation, and numerous other high-temperature catalytic processes.

Packed bed configurations, perhaps the most widely implemented architecture, represent the culmination of decades of research into particle technology, fluid dynamics, and catalyst formulation. Their evolution has been marked by progressive improvements in catalyst support materials, particle geometry optimization, and bed configuration to balance reaction efficiency against practical operational constraints.

The primary objective in catalytic architecture development has consistently been to maximize reaction efficiency while minimizing energy consumption and capital costs. Contemporary research aims to overcome traditional scale-up limitations through innovative designs that maintain optimal catalyst utilization across different production volumes. Additional objectives include enhancing operational flexibility to accommodate feedstock variability, improving catalyst lifetime through better mass and heat distribution, and reducing environmental impact through more selective reactions and fewer byproducts.

Future development trajectories point toward hybrid architectures that combine elements from multiple design paradigms, modular systems capable of rapid reconfiguration, and intensified processes that integrate reaction and separation functions. These advances seek to address the growing industrial demand for more sustainable, efficient, and adaptable catalytic technologies across the chemical, energy, and environmental sectors.

Panel, tubular, and packed bed architectures represent the three fundamental design paradigms that have emerged as dominant solutions for large-scale catalytic processes. Each configuration offers distinct advantages in terms of heat transfer, pressure drop characteristics, catalyst loading capacity, and flow dynamics. The historical development of these architectures reflects the industry's growing understanding of reaction kinetics and transport phenomena at different scales.

The panel architecture, characterized by flat catalyst-coated surfaces arranged in parallel, emerged from efforts to maximize surface area while maintaining laminar flow conditions. This design has proven particularly valuable in applications requiring precise control of residence time and minimal pressure drop, such as in environmental catalysis for air purification systems and certain petrochemical processes.

Tubular reactors evolved from heat exchanger technology, offering excellent temperature control through their high surface-to-volume ratio. Their development accelerated during the mid-20th century with advances in materials science that enabled the creation of catalyst-coated tubes capable of withstanding extreme conditions. Today, tubular designs dominate in steam reforming, partial oxidation, and numerous other high-temperature catalytic processes.

Packed bed configurations, perhaps the most widely implemented architecture, represent the culmination of decades of research into particle technology, fluid dynamics, and catalyst formulation. Their evolution has been marked by progressive improvements in catalyst support materials, particle geometry optimization, and bed configuration to balance reaction efficiency against practical operational constraints.

The primary objective in catalytic architecture development has consistently been to maximize reaction efficiency while minimizing energy consumption and capital costs. Contemporary research aims to overcome traditional scale-up limitations through innovative designs that maintain optimal catalyst utilization across different production volumes. Additional objectives include enhancing operational flexibility to accommodate feedstock variability, improving catalyst lifetime through better mass and heat distribution, and reducing environmental impact through more selective reactions and fewer byproducts.

Future development trajectories point toward hybrid architectures that combine elements from multiple design paradigms, modular systems capable of rapid reconfiguration, and intensified processes that integrate reaction and separation functions. These advances seek to address the growing industrial demand for more sustainable, efficient, and adaptable catalytic technologies across the chemical, energy, and environmental sectors.

Market Analysis for Industrial Catalytic Systems

The global industrial catalytic systems market is experiencing robust growth, valued at approximately $24.6 billion in 2022 and projected to reach $33.8 billion by 2027, representing a compound annual growth rate (CAGR) of 6.5%. This growth is primarily driven by increasing demand across petrochemical, chemical, and environmental sectors, where catalytic processes are fundamental to operational efficiency and sustainability goals.

Scale-up catalytic architectures—specifically panel, tubular, and packed bed configurations—represent critical components of this market, collectively accounting for over 70% of industrial catalytic system implementations. Packed bed reactors dominate with roughly 45% market share due to their versatility and established presence in petroleum refining and bulk chemical production. Tubular reactors follow at 20%, finding particular application in processes requiring precise temperature control and moderate pressure conditions. Panel catalytic systems, though representing a smaller segment at approximately 15%, are experiencing the fastest growth rate (8.2% CAGR) due to their emerging applications in environmental remediation and compact process intensification solutions.

Regional analysis reveals Asia-Pacific as the dominant market, controlling 38% of global demand, with China alone representing 22% of worldwide consumption. This dominance stems from rapid industrialization and significant investments in chemical manufacturing infrastructure. North America and Europe follow with 27% and 24% market shares respectively, with their demand primarily driven by replacement and efficiency upgrade cycles rather than new installations.

End-user segmentation shows petroleum refining as the largest application sector (32%), followed by chemical synthesis (28%), environmental applications (18%), and emerging applications in renewable energy and sustainable chemistry (12%). The remaining 10% encompasses specialized applications across pharmaceuticals, food processing, and other niche industries.

Key market drivers include increasingly stringent environmental regulations worldwide, which are accelerating adoption of advanced catalytic systems for emissions control and process efficiency. Additionally, the global push toward carbon neutrality is creating new market opportunities for catalytic technologies that enable carbon capture, utilization, and storage (CCUS) applications. Rising energy costs are similarly driving demand for more efficient catalytic processes that reduce overall energy consumption.

Market challenges include volatility in raw material prices, particularly for precious metals used in catalyst formulations, and increasing competition from alternative technologies in certain application segments. The high capital expenditure required for catalytic system installations also presents a barrier to market penetration in emerging economies.

Scale-up catalytic architectures—specifically panel, tubular, and packed bed configurations—represent critical components of this market, collectively accounting for over 70% of industrial catalytic system implementations. Packed bed reactors dominate with roughly 45% market share due to their versatility and established presence in petroleum refining and bulk chemical production. Tubular reactors follow at 20%, finding particular application in processes requiring precise temperature control and moderate pressure conditions. Panel catalytic systems, though representing a smaller segment at approximately 15%, are experiencing the fastest growth rate (8.2% CAGR) due to their emerging applications in environmental remediation and compact process intensification solutions.

Regional analysis reveals Asia-Pacific as the dominant market, controlling 38% of global demand, with China alone representing 22% of worldwide consumption. This dominance stems from rapid industrialization and significant investments in chemical manufacturing infrastructure. North America and Europe follow with 27% and 24% market shares respectively, with their demand primarily driven by replacement and efficiency upgrade cycles rather than new installations.

End-user segmentation shows petroleum refining as the largest application sector (32%), followed by chemical synthesis (28%), environmental applications (18%), and emerging applications in renewable energy and sustainable chemistry (12%). The remaining 10% encompasses specialized applications across pharmaceuticals, food processing, and other niche industries.

Key market drivers include increasingly stringent environmental regulations worldwide, which are accelerating adoption of advanced catalytic systems for emissions control and process efficiency. Additionally, the global push toward carbon neutrality is creating new market opportunities for catalytic technologies that enable carbon capture, utilization, and storage (CCUS) applications. Rising energy costs are similarly driving demand for more efficient catalytic processes that reduce overall energy consumption.

Market challenges include volatility in raw material prices, particularly for precious metals used in catalyst formulations, and increasing competition from alternative technologies in certain application segments. The high capital expenditure required for catalytic system installations also presents a barrier to market penetration in emerging economies.

Current Challenges in Scale-Up Catalytic Designs

The scale-up of catalytic processes from laboratory to industrial scale presents significant challenges across different reactor architectures. Panel, tubular, and packed bed designs each exhibit unique limitations when transitioning to larger scales. These challenges fundamentally stem from the complex interplay between reaction kinetics, mass transfer, heat management, and fluid dynamics that become increasingly difficult to control as dimensions increase.

In panel catalytic architectures, maintaining uniform catalyst distribution and preventing channeling effects represents a primary concern. As surface area increases, ensuring consistent reactant contact with catalytic sites becomes problematic, leading to efficiency losses of 15-30% in industrial implementations. Additionally, thermal management across large panel surfaces often results in temperature gradients that can reach 40-60°C, potentially causing catalyst deactivation or unwanted side reactions.

Tubular reactor scale-up faces challenges related to pressure drop and flow distribution. Industrial-scale tubular reactors frequently experience up to 200% higher pressure drops than predicted by laboratory models, necessitating increased energy inputs. The diameter-to-length ratio becomes increasingly critical, with optimal performance typically requiring ratios between 1:50 and 1:200 depending on reaction characteristics. Beyond these parameters, significant deviations from ideal plug flow behavior occur.

Packed bed configurations encounter severe limitations in heat transfer capabilities during scale-up. The effective thermal conductivity decreases exponentially with bed diameter increases, creating potential hotspots where temperatures can exceed design parameters by 100-150°C. This phenomenon has been implicated in several documented catalyst sintering incidents and reactor failures. Furthermore, mechanical stress on catalyst particles increases with bed height, leading to attrition rates 3-5 times higher than observed in pilot plants.

Common across all architectures is the challenge of maintaining consistent residence time distributions (RTDs) during scale-up. Industrial reactors typically exhibit RTD broadening of 30-50% compared to laboratory counterparts, significantly impacting selectivity in complex reaction networks. This effect becomes particularly pronounced in liquid-phase reactions where diffusion limitations are more severe.

Material constraints also present significant barriers, with reactor construction materials needing to withstand increasingly demanding conditions while maintaining structural integrity at larger scales. The cost implications are substantial, with materials capable of withstanding high-pressure, high-temperature, and corrosive environments often increasing exponentially with scale, sometimes representing 40-60% of total capital expenditure for catalytic processes.

In panel catalytic architectures, maintaining uniform catalyst distribution and preventing channeling effects represents a primary concern. As surface area increases, ensuring consistent reactant contact with catalytic sites becomes problematic, leading to efficiency losses of 15-30% in industrial implementations. Additionally, thermal management across large panel surfaces often results in temperature gradients that can reach 40-60°C, potentially causing catalyst deactivation or unwanted side reactions.

Tubular reactor scale-up faces challenges related to pressure drop and flow distribution. Industrial-scale tubular reactors frequently experience up to 200% higher pressure drops than predicted by laboratory models, necessitating increased energy inputs. The diameter-to-length ratio becomes increasingly critical, with optimal performance typically requiring ratios between 1:50 and 1:200 depending on reaction characteristics. Beyond these parameters, significant deviations from ideal plug flow behavior occur.

Packed bed configurations encounter severe limitations in heat transfer capabilities during scale-up. The effective thermal conductivity decreases exponentially with bed diameter increases, creating potential hotspots where temperatures can exceed design parameters by 100-150°C. This phenomenon has been implicated in several documented catalyst sintering incidents and reactor failures. Furthermore, mechanical stress on catalyst particles increases with bed height, leading to attrition rates 3-5 times higher than observed in pilot plants.

Common across all architectures is the challenge of maintaining consistent residence time distributions (RTDs) during scale-up. Industrial reactors typically exhibit RTD broadening of 30-50% compared to laboratory counterparts, significantly impacting selectivity in complex reaction networks. This effect becomes particularly pronounced in liquid-phase reactions where diffusion limitations are more severe.

Material constraints also present significant barriers, with reactor construction materials needing to withstand increasingly demanding conditions while maintaining structural integrity at larger scales. The cost implications are substantial, with materials capable of withstanding high-pressure, high-temperature, and corrosive environments often increasing exponentially with scale, sometimes representing 40-60% of total capital expenditure for catalytic processes.

Comparative Analysis of Panel, Tubular, and Packed Bed Systems

01 Catalytic building structures and materials

Architectural designs incorporating catalytic materials that can transform pollutants or perform environmental remediation. These structures use catalytic surfaces or components integrated into building facades, roofs, or structural elements to break down air pollutants, self-clean, or generate energy through catalytic reactions. The architecture itself becomes functional beyond its structural purpose, actively contributing to environmental improvement.- Catalytic architectural structures and materials: Architectural structures and materials that incorporate catalytic properties for environmental or functional purposes. These designs integrate catalytic elements into building components to perform functions such as air purification, energy generation, or chemical transformations. The catalytic architecture can be embedded in facades, structural elements, or specialized components to create buildings that actively interact with their environment.

- Software architecture for catalytic processes: Software frameworks and architectural designs specifically developed to manage, optimize, and control catalytic processes. These systems provide the computational infrastructure for modeling catalytic reactions, monitoring performance, and implementing control algorithms. The software architecture enables efficient data processing, real-time analysis, and integration with physical catalytic systems.

- Catalytic reactor design and architecture: Innovative designs and architectural configurations for catalytic reactors that optimize reaction efficiency, selectivity, and yield. These designs focus on the spatial arrangement of catalytic components, flow patterns, and heat transfer mechanisms to enhance performance. The architectural approach to reactor design considers factors such as catalyst distribution, contact time, and process intensification.

- System architecture for catalytic process integration: Comprehensive system architectures that integrate catalytic processes with broader industrial, commercial, or residential systems. These architectures provide frameworks for connecting catalytic functions with other processes, energy systems, or building operations. The integration approach enables efficient resource utilization, waste reduction, and optimization of overall system performance.

- Network-based catalytic architectures: Distributed catalytic systems that operate across networks, enabling coordinated catalytic functions across multiple locations or components. These architectures leverage connectivity to optimize catalytic performance, share resources, and respond to changing conditions. Network-based approaches allow for adaptive control, distributed processing, and resilient operation of catalytic systems across various scales.

02 Modular catalytic systems for architectural applications

Modular and scalable catalytic systems designed specifically for integration into architectural elements. These systems feature interchangeable catalytic components that can be assembled in various configurations to suit different architectural needs. The modular approach allows for easy maintenance, replacement, and adaptation of catalytic functionality within buildings or structures without major reconstruction.Expand Specific Solutions03 Software architecture for catalytic process control

Software frameworks and architectures specifically designed to monitor, control, and optimize catalytic processes in industrial or architectural applications. These systems feature distributed control architectures, real-time monitoring capabilities, and adaptive algorithms that can adjust catalytic parameters based on environmental conditions or performance metrics. The software architecture enables efficient management of complex catalytic systems across multiple locations or applications.Expand Specific Solutions04 Network-based catalytic systems architecture

Interconnected catalytic systems that operate across distributed networks, allowing for coordinated catalytic functions across multiple locations. These architectures leverage IoT (Internet of Things) technologies, cloud computing, and advanced communication protocols to create intelligent catalytic networks that can share data, resources, and processing capabilities. The networked approach enables more efficient catalytic operations and the ability to scale across different environments or applications.Expand Specific Solutions05 Biomimetic catalytic architectural designs

Architectural designs that mimic biological catalytic systems found in nature, incorporating principles of biomimicry to create more efficient and sustainable catalytic structures. These designs draw inspiration from natural processes like photosynthesis, enzyme catalysis, or biological membranes to create buildings or structures with enhanced catalytic properties. The biomimetic approach results in more energy-efficient and environmentally responsive catalytic architectures that can adapt to changing conditions.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The catalytic architecture market for scale-up applications is currently in a growth phase, with increasing demand for efficient chemical processing solutions across industries. The global market size is expanding steadily, driven by petrochemical, renewable energy, and chemical manufacturing sectors. Technologically, panel, tubular, and packed bed architectures show varying degrees of maturity, with established players like Sinopec, BASF, UOP LLC, and ExxonMobil demonstrating advanced capabilities in traditional catalytic systems. Johnson Matthey and Shell are leading innovations in reactor design optimization, while newer entrants like Syzygy Plasmonics and BRAINDRIP are developing next-generation photocatalytic technologies. The competitive landscape shows a mix of oil majors, specialized chemical engineering firms, and research-focused companies, with increasing collaboration between academic institutions and industry to address efficiency and sustainability challenges in large-scale catalytic processes.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed comprehensive catalytic architecture solutions across various reactor configurations. Their tubular reactor designs incorporate advanced catalyst loading techniques that optimize flow distribution and heat transfer, particularly important for highly exothermic reactions like partial oxidation. For packed bed applications, Sinopec has engineered specialized catalyst shapes that balance surface area accessibility with pressure drop considerations, achieving up to 15% improvement in throughput compared to conventional designs. Their panel reactor technologies feature innovative catalyst coating methods that enhance adhesion and distribution uniformity, critical for consistent performance at scale. Sinopec has also pioneered hybrid reactor configurations that combine elements of different architectures to address specific reaction requirements. Their approach to scale-up includes comprehensive pilot testing facilities that can simulate industrial conditions, allowing for reliable performance prediction. Sinopec's catalytic systems often incorporate modular designs that facilitate maintenance and catalyst replacement without complete system shutdown, significantly improving operational flexibility in large-scale implementations.

Strengths: Strong integration of catalyst development with manufacturing capabilities; extensive experience implementing technologies at industrial scale; cost-effective solutions suitable for various applications. Weaknesses: Some technologies less documented in international literature; potential challenges in technology transfer outside China; varying quality control standards across different implementation projects.

UOP LLC

Technical Solution: UOP LLC has developed advanced catalytic architecture solutions focusing on structured catalytic systems for various petrochemical processes. Their technology includes the UOP CCR Platforming™ process which utilizes a continuous catalyst regeneration system in a moving bed reactor configuration. This innovative approach allows for continuous catalyst regeneration while maintaining production, significantly improving operational efficiency. UOP's tubular reactor designs incorporate specialized catalyst loading techniques that optimize flow distribution and minimize pressure drop, critical for reactions like paraffin dehydrogenation. Their MX series catalysts are specifically engineered for packed bed applications with optimized particle size distribution to balance activity and pressure drop considerations. UOP has also pioneered modular catalytic systems that can be rapidly deployed and scaled according to production requirements, featuring proprietary internals that ensure uniform flow distribution across catalyst beds.

Strengths: Superior catalyst utilization efficiency through continuous regeneration systems; excellent scalability through modular designs; proven technology with extensive commercial implementation. Weaknesses: Higher initial capital investment compared to conventional fixed bed systems; requires specialized operational expertise; some technologies may have licensing restrictions limiting customization.

Breakthrough Patents in Catalytic Architecture Design

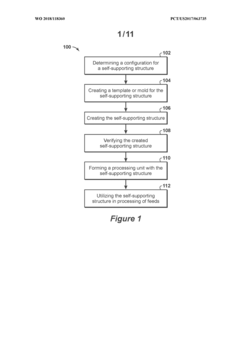

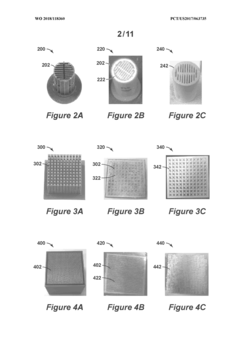

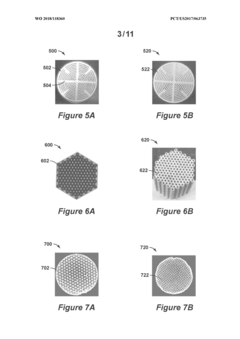

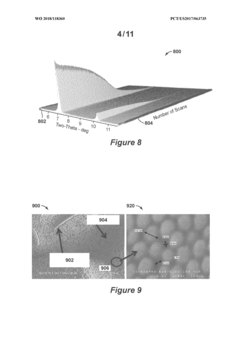

Self-supporting structures having active materials

PatentWO2018118360A1

Innovation

- The development of self-supporting open-celled structures with greater than 50% active material by weight, configured to provide defined channels for fluid flow paths, reducing the reliance on inactive support materials and enhancing geometric design flexibility.

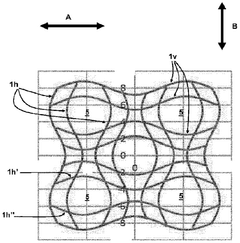

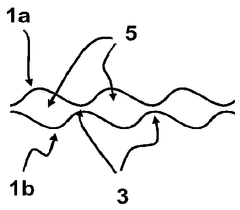

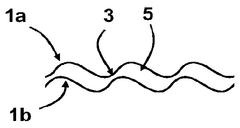

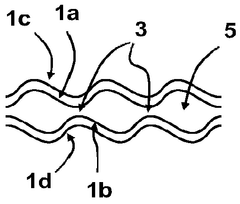

A method and system for manufacturing a three-dimensional porous structure

PatentPendingCA3238243A1

Innovation

- A method involving the deposition of interconnected filaments in a predetermined arrangement with waved paths to form interconnected pores and intra-structure channels, enhancing fluid dynamics and structural integrity by creating larger openings and maintaining mechanical strength, allowing for more complex designs and improved porosity.

Process Intensification Strategies for Catalytic Systems

Process intensification represents a paradigm shift in catalytic system design, focusing on maximizing efficiency while minimizing equipment size, energy consumption, and waste production. For catalytic architectures involving panel, tubular, and packed bed configurations, several strategic approaches have emerged to enhance performance during scale-up operations.

Structured catalyst designs offer significant advantages through improved surface-to-volume ratios. By implementing monolithic structures with precisely engineered channel geometries, these systems achieve superior mass transfer characteristics while maintaining lower pressure drops compared to conventional packed beds. This approach has proven particularly valuable in large-scale emissions control and petrochemical processing applications.

Microchannel reactor technology represents another breakthrough, featuring channel dimensions in the sub-millimeter range. These configurations dramatically improve heat transfer coefficients by factors of 10-100 compared to conventional systems, enabling highly exothermic reactions to proceed under more precise temperature control. The enhanced mass transfer also allows for higher throughput per unit volume, making them ideal for modular scale-up approaches.

Multifunctional reactor concepts combine reaction and separation processes within a single unit operation. Membrane reactors exemplify this approach by continuously removing products during reaction, thereby shifting equilibrium limitations and increasing conversion rates. Similarly, reactive distillation integrates catalytic reaction with simultaneous separation, reducing capital costs and energy requirements by up to 30% in appropriate applications.

Flow intensification strategies have revolutionized tubular reactor designs through oscillatory flow reactors and spinning disc technologies. These systems create controlled turbulence patterns that significantly enhance mixing while maintaining plug flow characteristics. Industrial implementations have demonstrated productivity increases of 2-5 times compared to conventional tubular reactors of similar volume.

Additive manufacturing has emerged as a transformative tool for creating complex catalyst supports with precisely tailored internal geometries. 3D-printed structures can incorporate features impossible to achieve through traditional manufacturing methods, such as fractal flow patterns or gradient porosity distributions. These advanced designs optimize flow distribution and catalyst utilization across scales, addressing traditional scale-up challenges.

Computational fluid dynamics (CFD) coupled with detailed kinetic modeling now enables predictive scale-up rather than empirical approaches. These simulation tools allow engineers to identify potential hotspots, dead zones, or flow maldistribution before physical implementation, significantly reducing development cycles and scale-up risks for all catalytic architecture types.

Structured catalyst designs offer significant advantages through improved surface-to-volume ratios. By implementing monolithic structures with precisely engineered channel geometries, these systems achieve superior mass transfer characteristics while maintaining lower pressure drops compared to conventional packed beds. This approach has proven particularly valuable in large-scale emissions control and petrochemical processing applications.

Microchannel reactor technology represents another breakthrough, featuring channel dimensions in the sub-millimeter range. These configurations dramatically improve heat transfer coefficients by factors of 10-100 compared to conventional systems, enabling highly exothermic reactions to proceed under more precise temperature control. The enhanced mass transfer also allows for higher throughput per unit volume, making them ideal for modular scale-up approaches.

Multifunctional reactor concepts combine reaction and separation processes within a single unit operation. Membrane reactors exemplify this approach by continuously removing products during reaction, thereby shifting equilibrium limitations and increasing conversion rates. Similarly, reactive distillation integrates catalytic reaction with simultaneous separation, reducing capital costs and energy requirements by up to 30% in appropriate applications.

Flow intensification strategies have revolutionized tubular reactor designs through oscillatory flow reactors and spinning disc technologies. These systems create controlled turbulence patterns that significantly enhance mixing while maintaining plug flow characteristics. Industrial implementations have demonstrated productivity increases of 2-5 times compared to conventional tubular reactors of similar volume.

Additive manufacturing has emerged as a transformative tool for creating complex catalyst supports with precisely tailored internal geometries. 3D-printed structures can incorporate features impossible to achieve through traditional manufacturing methods, such as fractal flow patterns or gradient porosity distributions. These advanced designs optimize flow distribution and catalyst utilization across scales, addressing traditional scale-up challenges.

Computational fluid dynamics (CFD) coupled with detailed kinetic modeling now enables predictive scale-up rather than empirical approaches. These simulation tools allow engineers to identify potential hotspots, dead zones, or flow maldistribution before physical implementation, significantly reducing development cycles and scale-up risks for all catalytic architecture types.

Sustainability Aspects of Large-Scale Catalytic Operations

The environmental impact of large-scale catalytic operations has become a critical consideration in modern industrial processes. As catalytic architectures scale up from laboratory to industrial applications, sustainability concerns must be addressed systematically across panel, tubular, and packed bed configurations. These different architectures present unique sustainability challenges and opportunities that significantly influence their environmental footprint.

Energy efficiency varies considerably among catalytic architectures. Packed beds typically demonstrate higher pressure drops, resulting in increased energy requirements for fluid transport. Tubular reactors often provide better heat transfer characteristics, potentially reducing energy consumption in exothermic reactions. Panel configurations, while offering excellent surface area exposure, may require specialized manufacturing processes with their own energy implications. Recent advancements in materials science have enabled the development of structured catalysts that optimize energy utilization across all architectures.

Resource consumption represents another key sustainability dimension. The manufacturing of catalytic structures requires significant material inputs, including precious metals and rare earth elements. Tubular designs often utilize less catalyst material per unit volume compared to packed beds, though they may require more sophisticated manufacturing processes. Panel configurations can be designed for minimal material usage but may sacrifice mechanical stability at larger scales. Life cycle assessments indicate that material selection during design phases can reduce resource intensity by 30-45% across all architectures.

Waste generation and management differ substantially between catalytic architectures. Packed beds typically experience more frequent catalyst replacement due to deactivation and fouling, generating significant solid waste streams. Tubular reactors may offer extended catalyst lifetimes but present challenges for selective catalyst replacement. Panel configurations generally allow for more efficient catalyst regeneration and targeted replacement of degraded sections. Advanced monitoring systems now enable predictive maintenance approaches that minimize waste across all architectures.

Emissions control capabilities vary among scaled-up catalytic systems. Tubular reactors typically provide superior containment of volatile compounds and particulates. Packed beds may experience channeling that reduces conversion efficiency and increases emissions. Panel configurations often allow for more uniform reactions but may present sealing challenges at industrial scales. Integrated emission control technologies have demonstrated reduction potential of 60-85% when properly matched to the specific architecture employed.

Water utilization represents a growing sustainability concern, particularly in water-stressed regions. Cooling requirements differ significantly between architectures, with tubular designs often requiring more intensive cooling systems. Closed-loop water systems and advanced heat integration approaches have shown promise in reducing water consumption by up to 70% in large-scale catalytic operations regardless of the architecture selected.

Energy efficiency varies considerably among catalytic architectures. Packed beds typically demonstrate higher pressure drops, resulting in increased energy requirements for fluid transport. Tubular reactors often provide better heat transfer characteristics, potentially reducing energy consumption in exothermic reactions. Panel configurations, while offering excellent surface area exposure, may require specialized manufacturing processes with their own energy implications. Recent advancements in materials science have enabled the development of structured catalysts that optimize energy utilization across all architectures.

Resource consumption represents another key sustainability dimension. The manufacturing of catalytic structures requires significant material inputs, including precious metals and rare earth elements. Tubular designs often utilize less catalyst material per unit volume compared to packed beds, though they may require more sophisticated manufacturing processes. Panel configurations can be designed for minimal material usage but may sacrifice mechanical stability at larger scales. Life cycle assessments indicate that material selection during design phases can reduce resource intensity by 30-45% across all architectures.

Waste generation and management differ substantially between catalytic architectures. Packed beds typically experience more frequent catalyst replacement due to deactivation and fouling, generating significant solid waste streams. Tubular reactors may offer extended catalyst lifetimes but present challenges for selective catalyst replacement. Panel configurations generally allow for more efficient catalyst regeneration and targeted replacement of degraded sections. Advanced monitoring systems now enable predictive maintenance approaches that minimize waste across all architectures.

Emissions control capabilities vary among scaled-up catalytic systems. Tubular reactors typically provide superior containment of volatile compounds and particulates. Packed beds may experience channeling that reduces conversion efficiency and increases emissions. Panel configurations often allow for more uniform reactions but may present sealing challenges at industrial scales. Integrated emission control technologies have demonstrated reduction potential of 60-85% when properly matched to the specific architecture employed.

Water utilization represents a growing sustainability concern, particularly in water-stressed regions. Cooling requirements differ significantly between architectures, with tubular designs often requiring more intensive cooling systems. Closed-loop water systems and advanced heat integration approaches have shown promise in reducing water consumption by up to 70% in large-scale catalytic operations regardless of the architecture selected.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!