Scale-Up Challenges: From Microreactors To Flow Panels

SEP 2, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Microreactor Scale-Up Background and Objectives

Microreactors represent a paradigm shift in chemical processing technology, offering unprecedented control over reaction parameters through miniaturized channels typically ranging from 10 to 500 micrometers in diameter. The evolution of this technology began in the early 1990s with pioneering work in microfluidics, gradually expanding into chemical synthesis applications by the early 2000s. The trajectory has been marked by continuous refinement in materials, fabrication techniques, and integration capabilities, leading to today's sophisticated microreactor systems.

The fundamental advantage of microreactors lies in their exceptional surface-to-volume ratio, enabling superior heat and mass transfer characteristics compared to conventional batch reactors. This translates to enhanced reaction control, improved safety profiles for hazardous chemistries, and often higher yields and selectivities. Recent technological advances have further expanded capabilities through integration with real-time analytics, automated control systems, and modular designs.

Current industry trends indicate a growing adoption across pharmaceutical, fine chemical, and specialty materials sectors, with annual market growth rates exceeding 15%. This expansion is driven by increasing pressure for process intensification, sustainability improvements, and the need for flexible manufacturing platforms capable of rapid adaptation to changing market demands.

Despite these advantages, the transition from laboratory-scale microreactors to industrially relevant production volumes remains a significant challenge. The core technical objective of scale-up efforts is to maintain the inherent advantages of microreactor technology while achieving commercially viable throughput. This requires innovative approaches that preserve the critical process parameters across multiple orders of magnitude in production capacity.

Flow panels represent one promising approach to this scale-up challenge, offering a middle ground between microreactors and conventional equipment. These systems typically employ parallel arrangements of microchannels or structured reactor elements to increase throughput while maintaining the essential characteristics of microscale processing.

The primary technical goals for successful scale-up include: developing robust numbering-up strategies that maintain uniform flow distribution across parallel channels; creating materials and fabrication methods suitable for larger-scale implementation; designing effective heat management systems for exothermic processes at increased throughput; and integrating appropriate sensing and control technologies to ensure consistent product quality across scaled systems.

This technical investigation aims to comprehensively assess the current state of microreactor scale-up technologies, identify key technical barriers, and evaluate emerging solutions that could enable broader industrial implementation of continuous flow processing across multiple scales of operation.

The fundamental advantage of microreactors lies in their exceptional surface-to-volume ratio, enabling superior heat and mass transfer characteristics compared to conventional batch reactors. This translates to enhanced reaction control, improved safety profiles for hazardous chemistries, and often higher yields and selectivities. Recent technological advances have further expanded capabilities through integration with real-time analytics, automated control systems, and modular designs.

Current industry trends indicate a growing adoption across pharmaceutical, fine chemical, and specialty materials sectors, with annual market growth rates exceeding 15%. This expansion is driven by increasing pressure for process intensification, sustainability improvements, and the need for flexible manufacturing platforms capable of rapid adaptation to changing market demands.

Despite these advantages, the transition from laboratory-scale microreactors to industrially relevant production volumes remains a significant challenge. The core technical objective of scale-up efforts is to maintain the inherent advantages of microreactor technology while achieving commercially viable throughput. This requires innovative approaches that preserve the critical process parameters across multiple orders of magnitude in production capacity.

Flow panels represent one promising approach to this scale-up challenge, offering a middle ground between microreactors and conventional equipment. These systems typically employ parallel arrangements of microchannels or structured reactor elements to increase throughput while maintaining the essential characteristics of microscale processing.

The primary technical goals for successful scale-up include: developing robust numbering-up strategies that maintain uniform flow distribution across parallel channels; creating materials and fabrication methods suitable for larger-scale implementation; designing effective heat management systems for exothermic processes at increased throughput; and integrating appropriate sensing and control technologies to ensure consistent product quality across scaled systems.

This technical investigation aims to comprehensively assess the current state of microreactor scale-up technologies, identify key technical barriers, and evaluate emerging solutions that could enable broader industrial implementation of continuous flow processing across multiple scales of operation.

Market Demand Analysis for Flow Chemistry Solutions

The global flow chemistry market has witnessed substantial growth in recent years, driven by increasing demand for more efficient, sustainable, and cost-effective chemical manufacturing processes. Current market valuations place the flow chemistry equipment sector at approximately 1.4 billion USD in 2023, with projections indicating a compound annual growth rate of 9.8% through 2030. This growth trajectory reflects the expanding adoption of continuous flow technologies across multiple industries.

Pharmaceutical companies represent the largest market segment, accounting for nearly 45% of the total demand for flow chemistry solutions. This dominance stems from the industry's need for precise reaction control, enhanced safety protocols, and improved product quality. The ability of flow chemistry to facilitate challenging reactions under controlled conditions makes it particularly valuable for developing complex active pharmaceutical ingredients.

Chemical manufacturing constitutes the second-largest market segment, with approximately 30% market share. In this sector, the demand is primarily driven by the need for process intensification, reduced environmental footprint, and improved energy efficiency. Flow chemistry enables significant reductions in solvent usage and waste generation, aligning with increasingly stringent environmental regulations worldwide.

Academic and research institutions form a smaller but rapidly growing segment, representing about 15% of the market. Their demand focuses primarily on versatile, modular systems that can accommodate diverse research applications and educational purposes. This segment plays a crucial role in advancing flow chemistry technologies and expanding their application scope.

Regionally, North America and Europe currently dominate the market with combined market share exceeding 65%. However, the Asia-Pacific region is experiencing the fastest growth rate, driven by expanding pharmaceutical manufacturing capabilities in China and India, coupled with increasing government investments in advanced manufacturing technologies.

The scale-up challenge represents a significant market opportunity, as evidenced by recent industry surveys indicating that over 70% of potential adopters cite scalability concerns as a primary barrier to implementation. The transition from laboratory-scale microreactors to production-scale flow panels requires substantial technical expertise and specialized equipment, creating demand for integrated solutions that address this specific pain point.

Market analysis reveals growing interest in modular, scalable systems that can evolve with production needs. Approximately 85% of potential customers express preference for solutions offering seamless scalability pathways rather than requiring complete system replacements when moving from development to production scales.

Pharmaceutical companies represent the largest market segment, accounting for nearly 45% of the total demand for flow chemistry solutions. This dominance stems from the industry's need for precise reaction control, enhanced safety protocols, and improved product quality. The ability of flow chemistry to facilitate challenging reactions under controlled conditions makes it particularly valuable for developing complex active pharmaceutical ingredients.

Chemical manufacturing constitutes the second-largest market segment, with approximately 30% market share. In this sector, the demand is primarily driven by the need for process intensification, reduced environmental footprint, and improved energy efficiency. Flow chemistry enables significant reductions in solvent usage and waste generation, aligning with increasingly stringent environmental regulations worldwide.

Academic and research institutions form a smaller but rapidly growing segment, representing about 15% of the market. Their demand focuses primarily on versatile, modular systems that can accommodate diverse research applications and educational purposes. This segment plays a crucial role in advancing flow chemistry technologies and expanding their application scope.

Regionally, North America and Europe currently dominate the market with combined market share exceeding 65%. However, the Asia-Pacific region is experiencing the fastest growth rate, driven by expanding pharmaceutical manufacturing capabilities in China and India, coupled with increasing government investments in advanced manufacturing technologies.

The scale-up challenge represents a significant market opportunity, as evidenced by recent industry surveys indicating that over 70% of potential adopters cite scalability concerns as a primary barrier to implementation. The transition from laboratory-scale microreactors to production-scale flow panels requires substantial technical expertise and specialized equipment, creating demand for integrated solutions that address this specific pain point.

Market analysis reveals growing interest in modular, scalable systems that can evolve with production needs. Approximately 85% of potential customers express preference for solutions offering seamless scalability pathways rather than requiring complete system replacements when moving from development to production scales.

Current Technological Barriers in Microreactor Scale-Up

The scaling up of microreactors to flow panels represents a significant technological challenge in chemical engineering and process intensification. Despite the promising advantages of microreactor technology, several critical barriers impede the successful transition from laboratory-scale microreactors to industrial-scale flow panels.

Heat management presents one of the most formidable challenges. While microreactors excel at heat transfer due to their high surface-to-volume ratio, this advantage diminishes during scale-up. As reactor dimensions increase, the surface-to-volume ratio decreases exponentially, resulting in less efficient heat transfer. This can lead to temperature gradients, hotspots, and potential runaway reactions in larger systems, compromising both safety and product quality.

Fluid dynamics complexities emerge prominently during scale-up. Microreactors typically operate in laminar flow regimes with predictable mixing patterns. However, as channel dimensions increase, maintaining uniform flow distribution becomes increasingly difficult. Flow maldistribution across parallel channels can result in varying residence times, leading to inconsistent reaction outcomes and reduced product quality. The transition from laminar to turbulent flow regimes further complicates the predictability of reaction kinetics.

Materials and manufacturing constraints also pose significant barriers. The precision engineering required for microreactors becomes exponentially more challenging and costly at larger scales. Current manufacturing techniques struggle to maintain the same level of precision across larger surface areas, leading to inconsistencies in channel geometry and surface properties. Additionally, materials that perform well at small scales may exhibit different mechanical, thermal, or chemical properties when implemented in larger systems.

Pressure drop considerations become increasingly critical during scale-up. The pressure requirements to maintain desired flow rates increase substantially with channel length, necessitating more robust pumping systems and potentially limiting the types of reactions that can be performed. This challenge is particularly acute for viscous fluids or multiphase reactions.

Control and monitoring systems face significant limitations at larger scales. The precise control achievable in microreactors becomes more difficult to maintain across larger flow panels. Real-time monitoring of reaction parameters throughout the entire system presents both technological and economic challenges, potentially compromising the ability to ensure consistent product quality.

Clogging and fouling issues are amplified during scale-up. Larger systems typically operate for extended periods, increasing the likelihood of channel blockages. The consequences of such blockages are more severe in scaled-up systems, potentially affecting larger production volumes and creating safety hazards due to pressure buildup.

Heat management presents one of the most formidable challenges. While microreactors excel at heat transfer due to their high surface-to-volume ratio, this advantage diminishes during scale-up. As reactor dimensions increase, the surface-to-volume ratio decreases exponentially, resulting in less efficient heat transfer. This can lead to temperature gradients, hotspots, and potential runaway reactions in larger systems, compromising both safety and product quality.

Fluid dynamics complexities emerge prominently during scale-up. Microreactors typically operate in laminar flow regimes with predictable mixing patterns. However, as channel dimensions increase, maintaining uniform flow distribution becomes increasingly difficult. Flow maldistribution across parallel channels can result in varying residence times, leading to inconsistent reaction outcomes and reduced product quality. The transition from laminar to turbulent flow regimes further complicates the predictability of reaction kinetics.

Materials and manufacturing constraints also pose significant barriers. The precision engineering required for microreactors becomes exponentially more challenging and costly at larger scales. Current manufacturing techniques struggle to maintain the same level of precision across larger surface areas, leading to inconsistencies in channel geometry and surface properties. Additionally, materials that perform well at small scales may exhibit different mechanical, thermal, or chemical properties when implemented in larger systems.

Pressure drop considerations become increasingly critical during scale-up. The pressure requirements to maintain desired flow rates increase substantially with channel length, necessitating more robust pumping systems and potentially limiting the types of reactions that can be performed. This challenge is particularly acute for viscous fluids or multiphase reactions.

Control and monitoring systems face significant limitations at larger scales. The precise control achievable in microreactors becomes more difficult to maintain across larger flow panels. Real-time monitoring of reaction parameters throughout the entire system presents both technological and economic challenges, potentially compromising the ability to ensure consistent product quality.

Clogging and fouling issues are amplified during scale-up. Larger systems typically operate for extended periods, increasing the likelihood of channel blockages. The consequences of such blockages are more severe in scaled-up systems, potentially affecting larger production volumes and creating safety hazards due to pressure buildup.

Current Scale-Up Methodologies and Engineering Approaches

01 Microreactor design and fabrication techniques

Microreactors are designed with specific channel geometries and fabrication methods to optimize flow characteristics and reaction efficiency. These designs incorporate features such as specialized mixing zones, heat exchange surfaces, and catalyst integration. Advanced fabrication techniques including micromachining, etching, and additive manufacturing enable precise control over microreactor architecture, which is essential for successful scale-up operations. These design considerations directly impact flow dynamics, residence time distribution, and overall process performance.- Design and optimization of microreactor systems: Microreactors are designed with specific features to enhance chemical reactions and processes at small scales. These designs include optimized flow channels, mixing zones, and heat exchange surfaces that improve reaction efficiency. The optimization focuses on parameters such as residence time, mixing efficiency, and temperature control, which are crucial for successful scale-up operations. Advanced designs incorporate features that maintain consistent performance when transitioning from laboratory to industrial scale.

- Flow panel integration and modular scaling approaches: Flow panels can be integrated in modular configurations to achieve scale-up without compromising performance. This approach involves connecting multiple microreactor units in parallel or series arrangements to increase throughput while maintaining the advantages of microreactor technology. Modular designs allow for flexible capacity adjustment and easier maintenance. The integration of flow panels includes considerations for uniform flow distribution, pressure balancing, and consistent heat transfer across all modules.

- Heat management and thermal control systems: Effective heat management is critical in microreactor scale-up to maintain reaction conditions and prevent hotspots. Thermal control systems incorporate specialized materials and designs that enable rapid heat transfer and precise temperature regulation. These systems may include microchannel heat exchangers, cooling jackets, or integrated heating elements. Advanced thermal management solutions address challenges related to exothermic reactions and ensure uniform temperature distribution across scaled-up microreactor arrays.

- Process monitoring and control technologies: Sophisticated monitoring and control technologies are essential for successful microreactor scale-up. These include integrated sensors for real-time measurement of parameters such as temperature, pressure, flow rate, and concentration. Advanced control systems use this data to make automatic adjustments, ensuring process stability and product quality. Monitoring technologies may incorporate spectroscopic methods, flow visualization techniques, or electrical measurements to provide comprehensive process information during scale-up operations.

- Materials and manufacturing techniques for scaled microreactors: The selection of appropriate materials and manufacturing techniques is crucial for microreactor scale-up. Materials must offer chemical compatibility, thermal stability, and mechanical strength suitable for industrial conditions. Advanced manufacturing methods include precision micromachining, 3D printing, etching techniques, and bonding processes that maintain critical microfeatures at larger scales. These techniques enable the production of complex internal geometries that preserve the advantages of microreactors when scaling up to industrial production volumes.

02 Flow control and monitoring systems

Effective scale-up of microreactor technology requires sophisticated flow control and monitoring systems. These systems incorporate sensors, actuators, and control algorithms to maintain precise flow rates, pressure, and temperature distributions across multiple parallel channels. Real-time monitoring capabilities allow for detection of flow irregularities, channel blockages, or performance deviations. Advanced control systems can automatically adjust operating parameters to maintain optimal conditions during scale-up, ensuring consistent product quality and process efficiency.Expand Specific Solutions03 Numbering-up strategies for industrial scale production

Rather than traditional scale-up approaches that increase reactor dimensions, microreactor technology often employs a 'numbering-up' strategy where multiple identical microreactor units operate in parallel. This approach preserves the advantageous characteristics of microreactors while increasing production capacity. Key considerations include uniform flow distribution among parallel units, modular design for easy maintenance, and integrated control systems that coordinate the operation of multiple units. This strategy maintains the heat and mass transfer advantages of microreactors while achieving industrial production volumes.Expand Specific Solutions04 Heat management in scaled-up microreactor systems

Efficient heat management is critical in scaled-up microreactor systems, particularly for exothermic or endothermic reactions. Advanced heat exchange designs incorporate dedicated cooling or heating channels, specialized materials with high thermal conductivity, and precise temperature control systems. These features enable isothermal operation even at increased production scales, preventing hot spots or cold zones that could affect reaction selectivity or yield. Effective heat management systems are essential for maintaining the process intensification benefits of microreactors during scale-up.Expand Specific Solutions05 Integration of microreactors with downstream processing

Successful scale-up of microreactor technology often requires seamless integration with downstream processing units. This integration involves designing interfaces between microreactor outputs and subsequent separation, purification, or formulation steps. Continuous flow approaches that connect microreactors directly to downstream operations can eliminate intermediate storage and handling steps, improving efficiency and product quality. Integrated systems may incorporate inline analysis, feedback control loops, and automated process adjustments to maintain optimal performance throughout the entire production chain.Expand Specific Solutions

Leading Companies and Research Institutions in Flow Chemistry

The microreactor to flow panel scale-up landscape is currently in a growth phase, with an estimated market size of $2-3 billion and projected annual growth of 15-20%. The technology is approaching maturity but faces significant challenges in maintaining performance during scale-up. Leading players demonstrate varying technological readiness: Corning has established commercial-scale flow panel systems, while Life Technologies and Global Life Sciences Solutions offer integrated solutions with advanced control systems. Emerging innovators include Finesse Solutions with novel sensor technologies and D-CRBN with specialized CO2 conversion applications. Academic institutions like Technical University of Denmark and Texas A&M University contribute fundamental research, while Asian players such as Tianjin University and Nanjing Tech University are rapidly advancing capabilities, particularly in pharmaceutical applications.

Corning, Inc.

Technical Solution: Corning has developed Advanced-Flow™ Reactors (AFR) technology specifically addressing scale-up challenges in continuous flow chemistry. Their modular approach uses glass microstructured reactors that can be scaled from lab to production without redesigning the process. The system employs a "numbering-up" strategy rather than traditional scale-up, where multiple identical reactor units operate in parallel to increase throughput while maintaining the same reaction conditions and performance. Corning's G1 (lab), G3 (pilot), and G4 (production) reactors maintain consistent heat and mass transfer characteristics across scales, with production capacities reaching several tons per year. The glass construction offers superior chemical resistance, transparency for process monitoring, and excellent heat transfer properties. Their fluidic modules incorporate advanced mixing technologies that ensure uniform residence time distribution and mixing efficiency regardless of scale[1][3].

Strengths: Superior chemical compatibility with corrosion-resistant glass construction; excellent heat transfer capabilities; visual process monitoring through transparent reactors; proven scalability from lab to commercial production. Weaknesses: Higher initial capital investment compared to conventional batch systems; requires specialized expertise for implementation; potential limitations with highly viscous materials or solid-forming reactions.

Uhde

Technical Solution: Uhde has pioneered the STAR process® (Stream Transmission And Reaction) technology for scaling up microreactor systems to industrial production levels. Their approach combines microstructured reactor technology with innovative flow panel designs that maintain the advantages of microreactors while enabling significantly higher throughput. The system features specially designed distribution headers that ensure uniform flow across multiple parallel channels, addressing one of the key challenges in scale-up: maintaining consistent residence time distribution. Uhde's technology incorporates sophisticated process control systems that monitor and adjust parameters in real-time across the entire reactor network. For highly exothermic reactions, they've developed specialized heat exchange modules integrated directly into the flow panels, capable of removing up to 20 kW/L of heat, far exceeding conventional reactor capabilities. The modular design allows for capacity expansion by adding identical process units without compromising reaction performance[2][5].

Strengths: Exceptional heat removal capabilities for handling highly exothermic reactions; modular design enables flexible capacity adjustment; advanced process control systems ensure consistent product quality across scale. Weaknesses: Complex flow distribution systems require precise engineering; higher maintenance requirements for multiple parallel channels; potential for channel blockage in solid-forming reactions requiring specialized monitoring systems.

Key Technical Innovations in Flow Panel Design

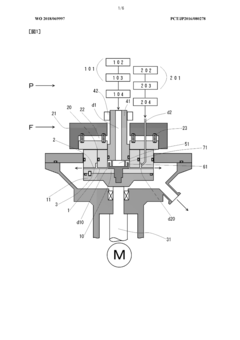

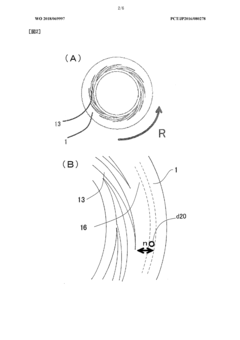

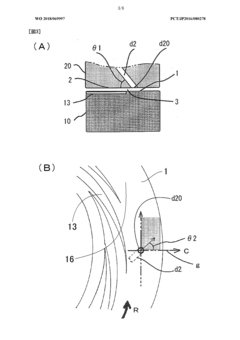

Immediately-before-stirring-type fluid processing device and processing method

PatentWO2018069997A1

Innovation

- A microreactor device with an annular flow path between rotating processing surfaces, equipped with a cylindrical stirring space and adjustable screen, applies stirring energy and shearing force to fluids before introduction, ensuring laminar flow conditions and independent control of shear force, allowing for precise handling of fluids and uniform reactions.

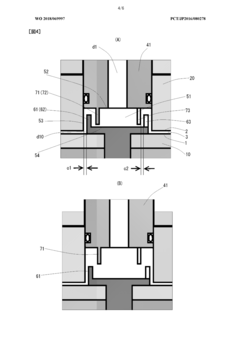

Micro-reactor and micro-channel heat exchanger

PatentInactiveEP1506054A1

Innovation

- A microreactor design featuring a channel layer composed of multiple individual layers with microstructures that form microchannels, where these layers are thermally well-coupled and connected via a common inlet and outlet channel, allowing for scalable performance without significant pressure losses by varying the number of microchannel levels and using a matrix arrangement to minimize pressure losses.

Economic Feasibility and ROI Analysis

The economic viability of scaling up from microreactors to flow panels represents a critical consideration for organizations contemplating this technological transition. Initial capital expenditure for flow panel systems typically exceeds that of conventional batch processing equipment by 30-45%, primarily due to specialized materials, precision engineering requirements, and integrated control systems. However, this higher upfront investment must be evaluated against substantial operational cost reductions over the system lifecycle.

Operational expenditure analysis reveals that flow panel systems can reduce production costs by 15-25% compared to traditional batch processes. These savings derive from multiple sources: reduced solvent usage (typically 40-60% less), decreased energy consumption (25-35% improvement in energy efficiency), minimized waste generation (50-70% reduction), and significantly lower labor costs due to automation capabilities. Additionally, the continuous nature of flow processing enables just-in-time production models that can reduce inventory carrying costs by up to 30%.

Return on investment calculations indicate that the break-even point for flow panel implementations typically occurs within 2-3 years for pharmaceutical applications, 1.5-2 years for specialty chemicals, and 3-4 years for more complex fine chemical processes. These timelines are heavily influenced by production volume, with higher throughput operations achieving faster returns. Sensitivity analysis suggests that ROI is most affected by production scale, product value, and regulatory compliance requirements.

Risk assessment models demonstrate that while initial technical risks during scale-up are moderate to high, financial risks decrease significantly after successful implementation. The economic resilience of flow panel systems becomes particularly evident during market fluctuations, as their modular nature allows for incremental capacity adjustments with proportional capital investment—unlike batch systems requiring large, discrete expansion steps.

Long-term economic analysis projects that organizations implementing flow panel technology can expect a 20-30% improvement in overall manufacturing cost structure, with the most substantial gains realized in high-value, complex chemical processes. Furthermore, the enhanced quality consistency achieved through continuous processing can reduce costly quality deviations by 40-60%, providing additional financial benefits not immediately apparent in basic ROI calculations.

Market competitiveness factors suggest that early adopters of scaled-up flow technology gain significant economic advantages through faster time-to-market capabilities (30-50% reduction in development-to-production timelines) and enhanced manufacturing flexibility, allowing more responsive adaptation to changing market demands with minimal additional investment.

Operational expenditure analysis reveals that flow panel systems can reduce production costs by 15-25% compared to traditional batch processes. These savings derive from multiple sources: reduced solvent usage (typically 40-60% less), decreased energy consumption (25-35% improvement in energy efficiency), minimized waste generation (50-70% reduction), and significantly lower labor costs due to automation capabilities. Additionally, the continuous nature of flow processing enables just-in-time production models that can reduce inventory carrying costs by up to 30%.

Return on investment calculations indicate that the break-even point for flow panel implementations typically occurs within 2-3 years for pharmaceutical applications, 1.5-2 years for specialty chemicals, and 3-4 years for more complex fine chemical processes. These timelines are heavily influenced by production volume, with higher throughput operations achieving faster returns. Sensitivity analysis suggests that ROI is most affected by production scale, product value, and regulatory compliance requirements.

Risk assessment models demonstrate that while initial technical risks during scale-up are moderate to high, financial risks decrease significantly after successful implementation. The economic resilience of flow panel systems becomes particularly evident during market fluctuations, as their modular nature allows for incremental capacity adjustments with proportional capital investment—unlike batch systems requiring large, discrete expansion steps.

Long-term economic analysis projects that organizations implementing flow panel technology can expect a 20-30% improvement in overall manufacturing cost structure, with the most substantial gains realized in high-value, complex chemical processes. Furthermore, the enhanced quality consistency achieved through continuous processing can reduce costly quality deviations by 40-60%, providing additional financial benefits not immediately apparent in basic ROI calculations.

Market competitiveness factors suggest that early adopters of scaled-up flow technology gain significant economic advantages through faster time-to-market capabilities (30-50% reduction in development-to-production timelines) and enhanced manufacturing flexibility, allowing more responsive adaptation to changing market demands with minimal additional investment.

Regulatory Compliance and Safety Considerations

The regulatory landscape for scaling up microreactors to flow panels presents significant challenges that require careful navigation. Chemical manufacturing processes are subject to stringent regulations from agencies such as the FDA, EPA, and OSHA in the United States, and equivalent bodies internationally. When transitioning from laboratory-scale microreactors to industrial-scale flow panels, compliance requirements become more complex and demanding. Companies must demonstrate that scaled-up processes maintain the same safety profiles and product quality as their smaller counterparts, requiring extensive validation protocols and documentation.

Safety considerations in flow chemistry scale-up are paramount, as the increased volumes of potentially hazardous materials present elevated risks. The containment strategies that work effectively at microscale must be redesigned for larger systems, incorporating robust engineering controls such as pressure relief systems, redundant sensors, and automated shutdown mechanisms. Risk assessment methodologies must evolve to address the unique challenges of continuous flow processes at scale, including the potential for runaway reactions, material incompatibilities, and thermal management issues.

Process safety management (PSM) protocols become increasingly critical during scale-up operations. Organizations must implement comprehensive hazard and operability studies (HAZOP) and failure mode and effects analyses (FMEA) to identify potential failure points and establish appropriate mitigation strategies. The dynamic nature of flow chemistry introduces unique safety challenges compared to batch processes, requiring specialized training for operators and engineers to recognize and respond to deviations in real-time.

Environmental compliance represents another significant consideration in the scale-up journey. Larger flow panel systems generate increased waste streams and emissions that must be managed within regulatory limits. Companies must design integrated waste treatment solutions and implement continuous monitoring systems to ensure environmental standards are consistently met. The adoption of green chemistry principles becomes increasingly important at scale to minimize environmental impact and reduce compliance burdens.

Worker safety regulations impose additional requirements as processes scale up. Enhanced personal protective equipment, specialized training programs, and robust emergency response procedures must be implemented to protect personnel working with larger volumes of chemicals and more complex equipment. Ergonomic considerations also become more significant as operators interact with larger flow panel systems, requiring thoughtful design of control interfaces and maintenance access points.

International regulatory harmonization presents challenges for organizations operating globally. Variations in safety standards, documentation requirements, and approval processes across different jurisdictions necessitate careful planning and region-specific compliance strategies. Companies must develop scalable quality management systems that can accommodate these regional differences while maintaining consistent safety and quality standards throughout their operations.

Safety considerations in flow chemistry scale-up are paramount, as the increased volumes of potentially hazardous materials present elevated risks. The containment strategies that work effectively at microscale must be redesigned for larger systems, incorporating robust engineering controls such as pressure relief systems, redundant sensors, and automated shutdown mechanisms. Risk assessment methodologies must evolve to address the unique challenges of continuous flow processes at scale, including the potential for runaway reactions, material incompatibilities, and thermal management issues.

Process safety management (PSM) protocols become increasingly critical during scale-up operations. Organizations must implement comprehensive hazard and operability studies (HAZOP) and failure mode and effects analyses (FMEA) to identify potential failure points and establish appropriate mitigation strategies. The dynamic nature of flow chemistry introduces unique safety challenges compared to batch processes, requiring specialized training for operators and engineers to recognize and respond to deviations in real-time.

Environmental compliance represents another significant consideration in the scale-up journey. Larger flow panel systems generate increased waste streams and emissions that must be managed within regulatory limits. Companies must design integrated waste treatment solutions and implement continuous monitoring systems to ensure environmental standards are consistently met. The adoption of green chemistry principles becomes increasingly important at scale to minimize environmental impact and reduce compliance burdens.

Worker safety regulations impose additional requirements as processes scale up. Enhanced personal protective equipment, specialized training programs, and robust emergency response procedures must be implemented to protect personnel working with larger volumes of chemicals and more complex equipment. Ergonomic considerations also become more significant as operators interact with larger flow panel systems, requiring thoughtful design of control interfaces and maintenance access points.

International regulatory harmonization presents challenges for organizations operating globally. Variations in safety standards, documentation requirements, and approval processes across different jurisdictions necessitate careful planning and region-specific compliance strategies. Companies must develop scalable quality management systems that can accommodate these regional differences while maintaining consistent safety and quality standards throughout their operations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!